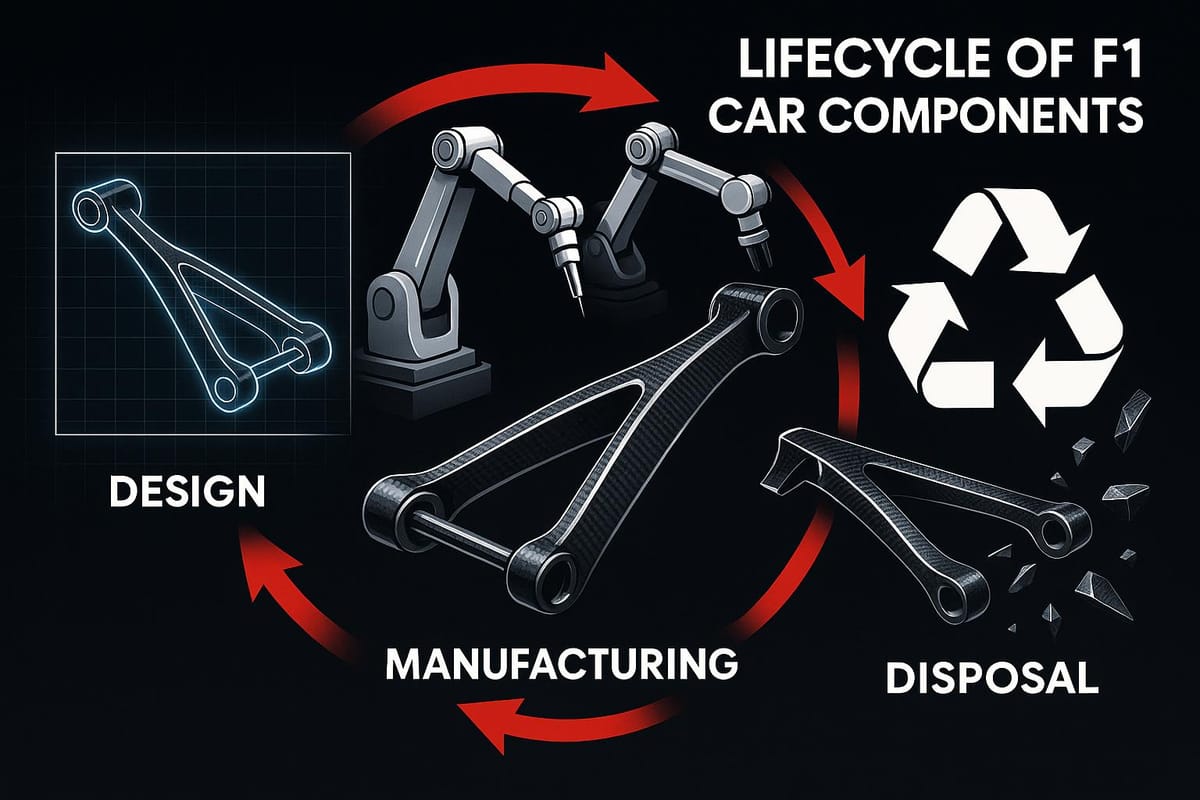

Lifecycle of F1 Car Components: From Design to Disposal

Explore the lifecycle of F1 car components, from cutting-edge design to sustainable disposal, and how innovation shapes racing's future.

Ever wonder what happens to F1 car parts before and after they hit the track? Here's a quick breakdown of their lifecycle:

- Design & Modeling: Teams use advanced simulations and digital twins to create efficient, high-performance designs.

- Material Selection & Manufacturing: Lightweight materials like carbon fiber and titanium are used, with a growing shift toward recycled and sustainable options.

- Track Use & Maintenance: Components endure extreme stress, monitored by sensors generating terabytes of data. Post-race, parts are inspected, repaired, or replaced.

- Disposal & Recycling: Teams recycle carbon fiber, tires, and other materials to reduce waste, aiming for "circular" cars by 2030.

F1 is not just about speed - it’s also a testing ground for sustainable innovation. Keep reading to see how cutting-edge engineering and eco-friendly practices are reshaping the sport.

The Life of a Bolt

Phase 1: Design and Computer Modeling

The design phase is where Formula 1 teams turn initial ideas into detailed digital blueprints. This process leans heavily on advanced computational modeling and simulations, which allow teams to test thousands of design variations before producing a single physical part. These simulations not only ensure performance goals are met but also simplify the production process that follows.

Modern F1 teams handle an enormous amount of data during this phase. For example, Mercedes F1 collects 45 terabytes of data per race from 300 sensors, while McLaren processes 11.8 billion data points annually to fine-tune their cars’ performance. With physical testing becoming more restricted, this data-centric approach has become indispensable.

"Data is in the team's lifeblood. Every element of performance – how we run a race, how we develop a car, how we select and analyze drivers – it's all driven by data."

– Christian Horner, CEO of Oracle Red Bull Racing

Aerodynamic Design and Computer Analysis

Aerodynamics play a massive role in F1 car performance, accounting for about 50% of the overall results. Computational fluid dynamics (CFD) is the backbone of aerodynamic design, helping teams simulate how air moves around the car - from the front wing to the rear diffuser.

Oracle Red Bull Racing is a prime example of this approach. Since teaming up with Ansys in 2008, they’ve expanded their use of simulations to include not just aerodynamics but also cooling, materials, and crash safety. When Formula 1 brought back ground effects regulations in 2022, Red Bull used Ansys Fluent software to redesign their car’s floor, boosting downforce for better stability, speed, and grip.

Red Bull’s reliance on Oracle Cloud enables them to run billions of simulations during each race. Since 2021, they’ve managed to speed up simulations by 25% and are on track for a further 10% improvement by 2025, thanks to upgraded cloud hardware.

"Ansys simulation software helped Oracle Red Bull Racing quickly adapt to the new F1 design guidelines last year and positioned us to maintain our technical leadership in a dramatically altered engineering landscape."

– Craig Skinner, chief designer, Oracle Red Bull Racing

AI-powered simulations take this even further by eliminating the need for costly track tests. Engineers can simulate billions of race scenarios to find the best setups for various conditions.

FIA Rules and Material Selection

Once aerodynamic modeling is complete, the focus shifts to ensuring compliance with FIA regulations and selecting the right materials. FIA rules play a major role in shaping design decisions, and the organization has modernized its compliance checks using advanced electronic scanning systems to compare components with digital specifications.

"The aerodynamic regulations have become quite a lot more complex... Because of that we needed to change the game on checks, so we have gone for a fully electronic state-of-the-art scanning system."

– Nikolas Tombazis, FIA Single Seater Technical Director

This digital system has significantly streamlined the approval process, with FIA officials now manually reviewing only 5% of cases that require closer inspection. Teams also use laser scanning to ensure their physical cars match the digital models, maintaining compliance throughout the design phase.

Material selection is equally critical, balancing the need for performance, safety, and sustainability. About 75% of an F1 car is made from composite materials, with carbon fiber being a favorite for its exceptional strength-to-weight ratio - it’s as strong as steel but five times lighter. Teams are also exploring sustainable options, such as spread tow reinforcements, which reduce weight by 20–30% compared to traditional composites. McLaren, for instance, tested recycled carbon fiber during the USA Grand Prix in October 2023.

Digital Twin Technology for Component Testing

Digital twin technology creates virtual replicas of cars and manufacturing processes, enabling teams to test and refine designs before building physical components. Each F1 car streams 100,000 data points per second, generating over 100 GB of data per race. This real-world data feeds into digital twins, making simulations even more accurate.

"F1 has been exploring the use of digital twins for a long time and the level of simulation and correlation with reality has proven impressive."

– Maurizio Sperati, vice president for automotive global account management for Stellantis, Ferrari and Italy automotive operations, Altair

Alpine has demonstrated the potential of digital twins with their Azure-hosted data science platform. By uniting data from their Enstone chassis and Viry engine plants, they accelerated design iterations and climbed to 4th place in the constructors' championship in 2022.

Digital twins also allow teams to prepare for race-day surprises. Ferrari’s engine team, for example, processes four times the data of their previous manual systems, cutting analysis time in half. Red Bull has reduced part design cycles by 300% using advanced CAD/PLM systems, enabling rapid design iteration and virtual testing of multiple components before committing to expensive manufacturing.

"We're going with prototype cars that are changing nearly race-on-race … different tracks, different tires … the right way of doing that is to use modeling tools that will run millions of race scenarios."

– James Vowels, Williams boss

These digital tools also help identify potential durability issues, ensuring that every element of the car is ready for the rigors of racing. This phase sets the stage for precise material selection and seamless production in the next steps.

Phase 2: Material Choice and Production

After finalizing the digital design, Formula 1 teams move into the critical phase of selecting materials and manufacturing components that can withstand the intense demands of racing. This step turns virtual designs into real-world parts, relying on precision manufacturing to push the boundaries of material science and production accuracy.

Back in the 1980s, F1 cars faced a mechanical failure rate of nearly 48%. By 2019, that number had dropped to just 4%, thanks to advancements in manufacturing techniques and material quality. This remarkable progress underscores the sport's dedication to precision and reliability.

Advanced Materials Used in F1 Cars

F1 cars are built using a sophisticated mix of materials, each chosen to optimize performance. At the forefront is carbon fiber composite, which makes up 80% of a modern F1 car. This material is prized for its ability to deliver the same strength as steel but at just one-fifth the weight.

The shift to carbon fiber began in 1980 when McLaren Racing introduced it to F1 car construction. Its combination of durability, reduced weight, and improved structural integrity revolutionized the sport. Today, carbon fiber is used extensively for chassis, bodywork, and other key components.

Other advanced materials also play crucial roles:

- Titanium alloys: Found in engine and suspension parts, these alloys balance strength, heat resistance, and lightweight properties, making them ideal for high-stress areas.

- Inconel: A nickel-chromium superalloy, Inconel is essential for exhaust systems and turbochargers, which must endure temperatures up to 4,700°F (2,600°C).

- Magnesium alloys: Used in gearbox casings and wheel rims, these alloys offer a 35% weight reduction compared to aluminum but require careful handling due to their flammability.

- High-strength steel alloys: With strengths up to 174,000 psi (1,200 MPa), these steels are critical for roll cages and suspension systems, ensuring maximum impact resistance.

Additionally, advanced ceramic coatings are applied to engine parts to reduce friction and heat, while aramid fibers like Kevlar and Zylon enhance driver safety in suits, helmets, and cockpit protection systems.

"The lighter, the faster: the choice of materials in the F1 car combines maximum weight reduction and maximum safety." - Surplex GmbH

Every material is selected not only for its performance benefits but also to meet evolving goals for sustainability.

High-Precision Manufacturing Methods

Building an F1 car involves assembling over 14,500 individual components. The complexity of this task demands manufacturing methods that deliver flawless results every time.

The Mercedes AMG Petronas F1 Team exemplifies this commitment with a "zero defects" quality management system. This process ensures full traceability from raw materials to finished parts, enhancing both safety and performance on the track.

Key manufacturing techniques include:

- 5-axis CNC machining: This method enables precise shaping of components.

- Carbon fiber mold-making: Ensures the structural integrity of composite parts.

- 3D scanning and CAD software: Used for design accuracy and comprehensive analysis.

Components undergo rigorous testing - stress simulations, impact analysis, and thermal evaluations - to guarantee they can handle the extreme conditions of racing. The pressure to deliver perfect parts quickly is immense, as Gene Haas, founder of the Haas F1 Team, explains:

"Haas F1 Team gives new meaning to the term rapid development, especially when you consider the fact that the effort is truly global... Parts need to be made in days, not weeks, and they need to be right the first time. At the end of the day, each race is really a metaphor for the development process to get there - speed, precision, quality, and no room for error."

Automation plays a growing role in reducing human error, particularly in the handling of composites, which account for 80% of an F1 car's volume. As manufacturing becomes more precise, teams are also prioritizing sustainable sourcing.

Environmentally Conscious Material Sourcing

F1 teams are increasingly exploring materials that match the performance of traditional options like carbon fiber and titanium but with a reduced environmental footprint. This marks a shift in how teams approach material selection and production.

McLaren Racing has been a leader in this space. In October 2023, they tested recycled carbon fiber during the USA Grand Prix, part of their goal to create a "fully circular" car by 2030. This effort aligns with their broader sustainability strategy.

In 2025, McLaren Racing, Deloitte UK, and the Fédération Internationale de l'Automobile (FIA) introduced the first-ever Circularity Handbook for Formula 1. This guide provides a standardized framework for measuring and improving the circularity of manufacturing processes. It focuses on reducing waste, optimizing resources, and extending the lifecycle of materials. AI-powered tools are also being integrated to help teams adopt these practices seamlessly.

Kim Wilson, Director of Sustainability at McLaren Racing, highlighted the importance of this initiative:

"By embracing circular economy practices, teams can minimise their environmental impact and drive innovation in Formula 1."

David Rakowski, partner and circularity lead at Deloitte UK, echoed this sentiment:

"Formula 1 is a phenomenal platform for showcasing what is possible in sustainability. The implementation of circular practices without compromising performance will be transformative for the entire industry."

Efforts to recycle and reuse carbon fiber parts are gaining traction, and teams are also promoting sustainable clothing and equipment for both teams and fans, incorporating materials like organic cotton and recycled polyester.

Phase 3: Track Use and Component Maintenance

In Formula 1, the components of a car endure incredible stress during races. The extreme conditions push every part to its limits, demanding advanced monitoring systems and rigorous maintenance routines to ensure both top-notch performance and safety.

Performance Testing Under Racing Conditions

Modern F1 cars are outfitted with more than 250 sensors that continuously track performance throughout a race weekend. These sensors generate an astounding 1 terabyte of data per car over the course of a weekend, with live data streaming at rates of about 30 megabytes per lap. During European races, teams receive this data at their factories in just 10 milliseconds. For flyaway races, satellite transmission introduces a slight delay, averaging around 300 milliseconds. Depending on the type of sensor, sampling rates can range from 1 Hz to an impressive 200 kHz.

To handle this data flood, teams use software like ATLAS to analyze it in real time. Engineers keep a close eye on critical parameters like engine temperatures, tire pressures, suspension loads, and aerodynamic efficiency. This allows them to evaluate component health and address potential issues before they escalate. As Rupesh N. Bhambwani from Formula One Forever put it:

"Without good reliable data, an F1 driver cannot give his best in the modern era of Formula 1".

The FIA also plays a role in monitoring car performance, using both sensor data and physical tests to ensure compliance with regulations.

To put the scale of data into perspective, Mercedes generated approximately 11 terabytes of data during the 2022 Mexico GP weekend, transferring it seamlessly between the track and their factories. Once the data is collected, teams swiftly move into post-race maintenance to maintain their competitive edge.

Between-Race Maintenance and Repairs

After each race, teams dive into meticulous post-race inspections and maintenance. Hundreds of components are removed from the cars and sent back to team facilities for detailed testing. Non-destructive testing (NDT) techniques - like magnetic particle inspection (MPI), eddy current testing, dye penetrant analysis, digital X-rays, CT scans, and ultrasonic testing - are used to examine parts for damage and track defect progression over time. For example, scanning a single wishbone with ultrasonic methods can take up to an hour.

Strict FIA regulations limit how many components teams can use and impose rules on sealed power-unit parts, guiding repair and replacement decisions.

Managing Crash Damage and Component Replacement

When crashes happen, teams must quickly assess the damage and decide on repairs or replacements. The choice depends on the extent of the damage and the availability of spare parts. Since an F1 car costs around $5 million, repairing parts is often the more practical option. However, fabricating new components can take anywhere from 4 to 8 weeks.

Joel Osborne, formerly with Team Peugeot Total, explains the repair process:

"We state, as in the mechanics, we can fix this part. We have a plan, and it takes 6.5 hours to complete. Or the engineers say, this part is beyond economic repair and, we replace the part. Or it could be a hybrid of let's fix a part of the 'car' and let's replace a part of the same part. So, there are many decisions to play out."

Certain parts, like the front wing and suspension, are often repairable. However, components such as sidepods, which are designed to crumple during impacts to absorb force, are typically replaced entirely if damaged. As Aleksi Kurtti, a Front Suspension R&D Engineer at Red Bull Racing, explains:

"If the car is damaged beyond repair (like the sidepods, which are made to crumble heavily in an impact to absorb force) we will replace the part entirely."

Mechanics frequently perform these repairs in a matter of minutes or hours, ensuring the car is ready for the next session. Teams also bring enough spare parts to rebuild an entire car if necessary, though regulations no longer allow for a fully assembled spare car to be on standby. The monocoque, the car's central structure and one of its most expensive components, is rarely replaced unless absolutely necessary.

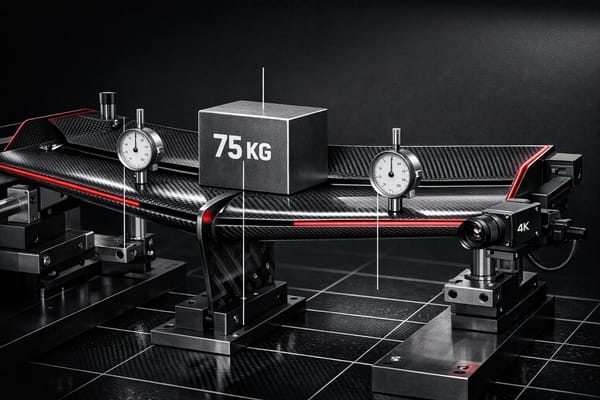

Safety is a top priority when assessing crash damage. The FIA requires medical checks for crashes involving forces of 15 Gs or higher. Additionally, starting in 2025, the combined weight of the car and driver must meet a minimum of 800 kg. Teams may also perform temporary repairs on power units to avoid penalties, and under parc fermé conditions, they can replace power units with newer parts between qualifying and the race.

Nikolas Tombazis, FIA Single Seater Director, highlights the importance of stringent testing:

"When championship battles become intense, teams tend to focus on each other's cars a lot, and naturally they raise concerns and over the latter half of the season we came to the conclusion that we needed to toughen a bit more the tests for 2025."

Phase 4: Component Disposal and Recycling

When the racing life of F1 components comes to an end, disposing of them responsibly becomes essential to reduce environmental impact. Formula 1 is moving away from the old "take-make-dispose" model and embracing recycling and resource recovery strategies. This final step builds on the precision engineering and sustainability efforts established earlier in the lifecycle.

Carbon Fiber Recycling Methods

Carbon fiber composites account for about 75% of a modern Formula 1 car's structural components. Given their prevalence, recycling these materials is a critical step toward reducing their environmental impact. Teams are leading efforts to develop advanced recycling techniques that minimize waste and emissions.

For example, McLaren Racing tested recycled carbon fiber on its MCL60 during the US Grand Prix, contributing to its goal of creating a fully circular car by 2030. Similarly, Mercedes-AMG Petronas F1 plans to integrate sustainable composites into its cars starting in the 2025 season. Using recycled carbon fiber can slash lifecycle emissions by 90%, saving 27 tons of carbon for every ton of material recycled. With global demand for carbon fiber expected to reach 262,000 tons next year, recycling just 1% of this material could prevent 70,848 tons of carbon emissions.

These efforts align with upcoming FIA regulations, which will require teams to increase the use of recycled materials in car construction starting in 2025.

"Developing a fully circular F1 car is our moonshot. We know that innovating in this space has the potential to make a large contribution to achieving our ambitious sustainability goals."

- Kim Wilson, Director of Sustainability at McLaren Racing

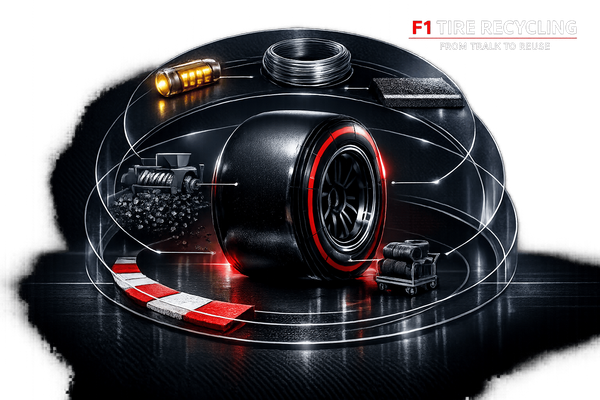

Used Tire Processing and Reuse

Each year, Pirelli processes around 40,000 F1-specific tires, including the approximately 1,500 tires used during a typical race weekend. Instead of discarding these tires, the company transforms them into secondary materials, extending their usefulness.

Mario Isola, Pirelli's Director of Motorsport, shared the company’s evolving approach:

"We recently changed our approach to recycling tyres... But since last year, we are also generating secondary raw materials from the tyres. And these new materials can be used in different applications, such as flooring. But this is not an end point for our journey because we have ideas for the future, to use the materials coming from used tyres even better than now."

The recycling process involves multiple methods. Tires are shredded and used as a coal replacement in cement factories, while pyrolysis recovers materials like carbon black and oil. All used tires are sent to Pirelli's technical center in the UK, where they are processed into materials for uses such as plastic flooring and tarmac. Since 2011, Ecopneus has managed over 2.2 million tons of used tires, reflecting the scale of these efforts.

Moving Toward Zero-Waste F1 Operations

Beyond recycling individual components, Formula 1 is rethinking its entire waste management strategy. The sport has set an ambitious target of achieving net zero emissions by 2030. Teams like McLaren Racing are tackling emissions from air travel and electricity while experimenting with natural fiber composites that have a 75% lower CO₂ footprint.

Zak Brown, CEO of McLaren Racing, emphasized the importance of a focused approach:

"By identifying our greatest emissions sources, such as air travel and purchased electricity, we are developing a roadmap to reduce our footprint across our operations."

Meanwhile, the Mercedes-AMG Petronas F1 Team has implemented practical solutions. During the 2023 European race season, the team used HVO100 biofuel in its freight trucks, cutting emissions by 67% and saving 339 tons of CO₂. DHL’s biofuel-powered trucks further reduced logistics-related emissions by an average of 83%.

F1 leadership underscores the collective responsibility for these changes. Stefano Domenicali, F1 President and CEO, remarked:

"Everyone understands the need for change. Everyone is onboard. Some of them have already started this huge plan of investment. When leaders start to do these things, everyone will follow."

Teams are also exploring additional solutions, including biodegradable composites, advanced carbon fiber recycling, and alternative energy sources like hydrogen, electricity, and synthetic fuels. These efforts are reshaping the way Formula 1 approaches sustainability.

As one industry analysis notes:

"Recycling is also playing an increasingly important role, with teams looking for ways to reuse used components such as carbon fiber and tires, significantly reducing the amount of waste generated during the season."

Conclusion: F1's Environmental Future

Formula 1 has come a long way in rethinking the lifecycle of its car components, shifting from a singular focus on performance to a balance of cutting-edge technology and environmental accountability. This evolution reflects F1's ambitious goal of achieving net zero carbon emissions by 2030.

Between 2019 and 2022, F1 managed to lower its emissions from 256,551 tonnes CO₂e to 223,031 tonnes CO₂e. A key milestone came in 2024, with investments in Sustainable Aviation Fuel (SAF) through partnerships with DHL and Qatar Airways, reducing emissions by over 8,000 tCO₂e - an approximate 19% drop in air freight-related emissions.

Looking to 2025, sustainability will take center stage during the European leg of the F1 season. DHL will deploy 37 biofuel-powered trucks for freight delivery, while pit and paddock operations will rely on a centralized renewable energy system. These measures aim to slash related carbon emissions by 90%. This builds on the success of 2023, when DHL's biofuel trucks cut logistics emissions by 83% compared to conventional fuels.

Fuel innovation is another key focus. In 2025, F2 and F3 cars will transition to 100% sustainable fuels, setting the stage for Formula 1 to follow in 2026. These advanced fuels have the potential to reduce carbon emissions by up to 96%, making them a cornerstone of F1's environmental strategy.

Ellen Jones, Head of ESG at Formula 1, highlights the sport's unique position to lead global change through its technological and global influence:

"Innovation and community drove Formula 1's work in 2024. We are thrilled to outline our progress and continued work in this space. Formula 1 as a sport is uniquely positioned to take action through our global reach and technological leadership."

In addition to fuel advancements, material innovation is on the horizon. Starting in 2025, the Mercedes-AMG Petronas Formula One Team will incorporate sustainable carbon fiber composites into its cars, aligning with its goal of net zero emissions by 2040. This shift could ripple across the automotive and aerospace industries, paving the way for broader adoption of greener materials.

F1 is also exploring cutting-edge solutions like digital twin testing and advanced recycling techniques, which could reduce carbon fiber emissions by up to 90%. These efforts demonstrate that high-performance engineering and environmental care can go hand in hand.

Stefano Domenicali, President and CEO of Formula 1, emphasizes the importance of these changes:

"The change will make the future flow of our calendar not only more sustainable, but logistically more sensible for our teams and personnel. Our net zero by 2030 commitment continues to be a priority for us as a sport and it is thanks to changes like this that we are on track to hitting our goal."

FAQs

How does digital twin technology enhance the design and testing of F1 car components?

Digital twin technology has transformed the way Formula 1 teams approach car design and testing. By creating precise virtual models of physical components, teams can simulate performance under different conditions without the need for expensive and time-intensive physical prototypes.

Thanks to real-time data collected from sensors on the car, these digital models are constantly updated and refined - even during races. This allows teams to fine-tune crucial aspects like aerodynamics, suspension, and engine performance on the fly. The result? Faster development cycles and lower costs, a game-changer in the high-stakes, fast-moving world of Formula 1.

What are the environmental advantages of using recycled carbon fiber in F1 cars?

Using recycled carbon fiber (rCF) in F1 cars brings massive environmental advantages. For starters, it slashes lifecycle emissions by up to 90% compared to traditional carbon fiber, which translates to saving about 27 metric tons of carbon emissions for every ton of rCF utilized.

To put it into perspective, if just 1% of the global carbon fiber produced in 2022 had been replaced with rCF, the world could have avoided around 32,535 metric tons of emissions. That’s nearly half of McLaren Racing's total emissions for the same year. This move not only shrinks the carbon footprint of F1 car production but also paves the way for more sustainable practices in the sport.

What happens to an F1 car after a crash during a race?

When an F1 car crashes during a race, the driver's safety is always the team's top concern. Once it's confirmed that the driver is unharmed, the focus shifts to assessing the car's condition. Any visibly broken parts are swapped out with spares brought to the track, while components that look fine but might be compromised are put through rigorous testing.

For more severe impacts, the car may be completely stripped down to inspect critical areas like the chassis. Teams rely heavily on telemetry data to understand the forces involved in the crash and identify potential weak points. Repair crews often work through the night, determined to have the car ready for the next session. But if the damage is beyond repair, the car may be retired for the rest of the event. In these cases, the team shifts its attention to salvaging usable parts and gearing up for the next race.