The Evolution of F1 Transmission: From Manual to Cutting-Edge Engineering

Explore the remarkable evolution of Formula 1 transmissions from manual gearboxes to advanced systems that redefine performance and strategy.

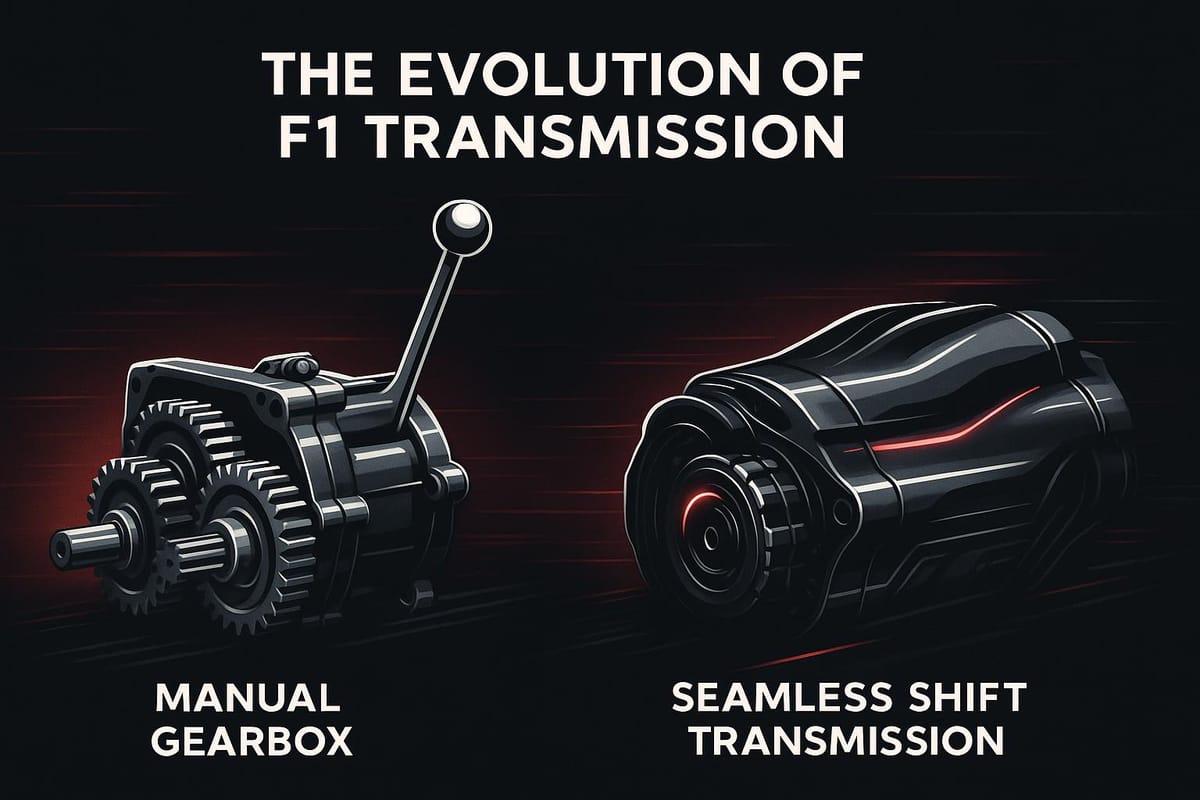

Formula 1 transmissions have evolved from manual H-pattern gearboxes to modern sequential systems that shift in milliseconds. This transformation has reshaped racing, improving speed, precision, and reliability. Early drivers manually operated gear levers, requiring skill and physical effort. Today, paddle shifters, lightweight materials, and advanced engineering dominate the sport. Key highlights include:

- Manual Gearboxes (1950s–1980s): H-pattern systems required drivers to take one hand off the wheel, with gear shifts taking 200–250 milliseconds.

- Semi-Automatic Systems (1989–2000s): Ferrari introduced paddle shifters, reducing shift times to 30–50 milliseconds and allowing both hands to remain on the wheel.

- Modern Sequential Gearboxes (2000s–Present): Current systems achieve shifts in 2–3 milliseconds, integrate seamlessly with hybrid power units, and influence race strategies through data-driven optimizations.

Engineering advancements have reduced driver workload, increased durability, and improved car handling. Modern transmissions are lightweight, costing up to $325,000 each, and must last four race weekends. As F1 moves toward a 50-50 hybrid energy split by 2026, transmissions will play an even greater role in managing power delivery and race performance.

FASTER THAN YOU CAN BLINK! A History of Formula One Gearbox Construction

Manual Gearboxes in Early F1

In the early days of Formula 1, drivers relied on manual transmissions that demanded extraordinary skill and precision. Unlike today’s lightning-fast paddle shifters, those early racers used traditional H-pattern gearboxes, which required a delicate balance of coordination and timing. Interestingly, the era of manual gearboxes lasted longer than many might think. For instance, Team Forti continued using a stick shift and floor clutch as late as the 1995 season. This period laid the foundation for the complex mechanics that shaped gear changes in motorsport history.

How Manual Gearboxes Worked

The manual gearboxes in early F1 cars operated on a three-pedal system - clutch, brake, and accelerator (arranged left to right) - much like a standard road car. However, these were used under the extreme conditions of racing. Drivers had to shift gears using an H-pattern gear stick, which required them to momentarily take one hand off the steering wheel during each gear change. The process was far from simple: it involved pressing the clutch pedal to disengage the engine, moving the gear lever to the desired gear, and then releasing the clutch to re-engage the power.

These cars used dog clutches to engage the gears, which allowed for quicker shifts compared to the synchromesh systems found in regular vehicles. However, this method made the engagement more abrupt. A basic gear lever connected directly to the selector mechanism via a rod, making the system mechanically straightforward but physically demanding.

Michael Burke described the challenge:

"Before the sequential gearbox they had to use normal gears and a gear stick like you'd find in any normal car. It would have required a high level of skill to do the gears effectively and every car probably had its own quirks that the driver had to work around."

One particularly tricky aspect was downshifting. Without synchromesh, drivers had to master rev matching to align the engine speed with the lower gear. This led to the development of the heel-and-toe technique, which involved operating the clutch, brake, and throttle simultaneously. It was a skill that separated the best from the rest, especially with the Hewland 5-speed gearboxes that were common at the time. These transmissions weren’t built to last, often surviving only a quarter of a season. The intricacies of these systems not only tested drivers but also paved the way for the advanced gearboxes we see today.

Famous Manual Gearboxes in F1 History

The challenges of manual transmissions drove innovations in gearbox design, leading to safer and more efficient systems in later years. During the early days, Hewland was a dominant name in F1, with its gearboxes positioned behind the engine in many competitive cars. Among the most celebrated examples of manual technology in F1 was the McLaren MP4/6, driven by Ayrton Senna.

In 1991, Senna captured the Formula One World Championship in the MP4/6, which featured a Weismann/McLaren transverse 6-speed manual gearbox. That year, the car achieved 8 race wins, 10 pole positions, and amassed 148 points. Notably, the MP4/6 was the last F1 car with a manual transmission to win a championship and the only one powered by a V12 engine to do so. Senna’s victories in the United States, Brazil, San Marino, and Monaco set the stage for his championship triumph in Japan. The car’s Honda RA121E V12 engine, which initially produced 725 bhp and was later upgraded to 780 bhp, demanded incredible precision to harness its power effectively.

However, manual systems came with risks. The dangers became evident in incidents like Jacques Laffitte’s crash at Brands Hatch in 1986, where the gear linkage contributed to his injuries. Similarly, Bryan Herta suffered a similar fate during a CART race in Toronto in 1994. Beyond safety concerns, manual gear changes were prone to errors - missed shifts could open the door for overtaking - and the physical strain on drivers during long races was immense. Navigating braking zones while constantly shifting gears added another layer of complexity to an already grueling sport.

Major Advances in F1 Transmission Technology

The shift from manual gearboxes to advanced electronic systems not only sped up gear changes but also reshaped race strategies and car design. Over the years, a series of breakthroughs have transformed F1 transmissions into the ultra-precise, lightning-fast systems we see today. These advancements built on the challenges of manual systems, pushing innovation to new heights.

Semi-Automatic Transmissions Arrive

The game changed in 1989 when Ferrari unveiled the 640 - the first F1 car to feature a true paddle-shift gearbox. This groundbreaking system, introduced under the leadership of John Barnard, Ferrari's technical director in 1986, became essential for cars with naturally aspirated engines that required more frequent shifting.

The Ferrari 640 made its debut at the 1989 Brazilian Grand Prix, where Nigel Mansell clinched victory, proving the effectiveness of the new technology. The paddle-shift system used a traditional clutch only at race starts and during pit stops, allowing drivers to keep both hands on the wheel. Early reliability issues, such as battery malfunctions, were quickly addressed by Magneti Marelli.

Patrick Head, Williams F1's Director of Engineering, highlighted the benefits of the semi-automatic gearbox:

"There are several advantages to the semi-automatic gearbox. First, the driver gets to keep both hands on the wheel, so it's easier for him to get the maximum from the car – particularly through fast corners, when the steering gets very heavy. Second, you can change gear in 30-50 milliseconds as opposed to 200-250 milliseconds, so it's significantly faster."

Williams began working on their own semi-automatic gearbox in 1986, though it didn’t make its race debut until 1991. Beyond speed, this new system eliminated engine over-revving caused by incorrect downshifts, reducing both mechanical failures and costs. From this foundation, sequential gear systems emerged, bringing even greater advancements.

Sequential Gear Systems

Sequential gear systems took the innovations of semi-automatic transmissions a step further. These systems use a ratcheting mechanism to shift gears in order - either up or down - ensuring smooth, error-free transitions. With a rotating drum mechanism at their core, sequential systems slashed shift times to just 30–50 milliseconds, a dramatic improvement over the 200–250 milliseconds typical of manual systems .

But it wasn’t just about speed. Sequential systems allowed drivers to keep both hands on the wheel, even during high-speed cornering, enhancing control and precision. By the mid-1990s, every F1 car used a sequential semi-automatic gearbox. The technology became so integral that the FIA eventually introduced regulations, such as limiting teams to 30 pairs of gear ratios per season starting in 2011 . As these systems evolved, engineers focused on integrating them seamlessly with the car's overall design, emphasizing weight reduction and aerodynamic efficiency.

Weight and Aerodynamic Improvements

Faster gear shifts were only part of the story. To fully exploit the potential of advanced transmissions, engineers turned their attention to reducing weight and improving aerodynamics. Colin Chapman famously said:

"Adding power makes you faster on the straights; subtracting weight makes you faster everywhere."

Modern F1 gearboxes embody this philosophy. Despite handling over 1,000 horsepower and enduring more than 4,000 gear shifts in a single Grand Prix, these transmissions weigh just 40 kilograms (88 pounds). They consist of over 500 intricately designed components, built to last around 3,000 miles of racing, with teams restricted to five driveline assemblies per season.

Aerodynamics also played a pivotal role. Removing shift linkages optimized chassis design, enabling narrower cockpits and improved airflow around the driver . The gearbox’s placement became critical for maintaining structural integrity and aerodynamic efficiency. The introduction of hybrid power units - with a minimum weight of 151 kg (333 pounds) - further pushed engineers to find weight savings elsewhere in the drivetrain.

These advancements turned the gearbox into more than just a mechanical component. It became a key factor in overall performance, influencing everything from chassis stiffness to aerodynamic efficiency and race strategy.

Current F1 Transmission Systems

Formula 1 cars today represent the pinnacle of engineering, blending decades of advancements to deliver astonishing performance. These systems have come a long way from the manual gearboxes of the past, integrating advanced materials and technologies that push the limits of what’s possible on the track.

Features of Today's F1 Transmissions

Modern F1 transmissions are feats of precision engineering, designed to endure the extreme demands of racing. Every car on the grid uses a semi-automatic sequential gearbox with eight forward gears and one reverse gear, controlled by paddle shifters located behind the steering wheel. This setup allows drivers to keep their hands on the wheel at all times, even during the sharpest turns.

Built with carbon-reinforced titanium, these gearboxes are both incredibly strong and lightweight. This design philosophy echoes Colin Chapman's famous belief that reducing weight improves performance in every aspect of a car.

One of the standout features of modern transmissions is seamless shift technology, which enables gear changes in just 2–3 milliseconds. To put this into perspective, during a single Grand Prix, these systems handle over 4,000 shifts - each faster than the blink of an eye.

But the gearbox does more than just change gears. Its casing also supports the rear suspension, making it a vital structural component that influences both handling and aerodynamics. Additionally, efficient oil flow systems ensure the gearbox can withstand engine speeds of up to 15,000 rpm and speeds exceeding 149 mph. A built-in differential system allows the rear wheels to rotate at different speeds, which is crucial for smooth cornering. Drivers can even adjust the differential settings mid-race to adapt to changing track conditions.

The evolution of F1 transmissions can be best understood by comparing their performance over the years:

| System Type | Shift Time | Driver Control | Key Advantages | Era |

|---|---|---|---|---|

| Manual H-Pattern | 200–250 milliseconds | Hands off the wheel | Simple, reliable; skill-intensive | 1950s–1980s |

| Semi-Automatic | 30–50 milliseconds | Hands on the wheel | Faster shifts, fewer errors | 1989–2000s |

| Modern Sequential | 2–3 milliseconds | Full steering control | Seamless power delivery, peak efficiency | 2000s–Present |

These modern systems shift up to 100 times faster than manual gearboxes, turning gear changes into smooth, uninterrupted transitions.

Unlike road cars, which often rely on automatic or dual-clutch transmissions, F1 vehicles use sequential manual systems. This choice allows for faster gear engagement, better feedback, and simpler mechanics. Sequential gearboxes also prevent mistakes like skipping gears or selecting the wrong one, making them far more reliable than the traditional H-pattern designs.

Reliability has also improved dramatically. Modern systems prevent engine over-revving during downshifts, reducing mechanical failures and saving teams from costly breakdowns. However, this cutting-edge technology comes with a hefty price tag - developing and maintaining an F1 gearbox costs over $6 million annually.

FIA Rules and Transmission Development

While technology drives F1 forward, the FIA’s regulations play a key role in shaping transmission development. These rules aim to balance innovation with fairness, ensuring no team gains an overwhelming advantage.

Since 2014, all F1 cars must use transmissions with eight forward gears and one reverse gear. To control costs, teams are required to stick with fixed gear ratios for the entire season, preventing constant re-optimization for each race.

The FIA has also banned certain technologies to maintain competitive balance. For example, continuously variable transmissions (CVTs) were prohibited in 1994 after Williams tested a system in 1993 that could have shaved several seconds off lap times. The ban was partly due to the challenges of designing durable belts for F1 use and concerns about creating an unfair advantage.

"High-performance bearings are integral to Formula 1 engineering, enabling cars to achieve remarkable speeds and be reliable even in extreme conditions."

- John Smith, Editor at Total-Motorsport.com

In recent years, regulations have continued to push innovation within set boundaries. For instance, in 2024, some manufacturers introduced updates like lower-friction bearings and improved cooling for power electronics. These changes enhance energy regeneration and deployment, helping F1 engines achieve thermal efficiency above 50%.

The rules also govern driver assistance and data systems. While teams face limits on the information they can provide to drivers during races, they retain significant freedom in programming and setting up transmissions. This flexibility allows for ongoing development within the regulatory framework.

This dynamic interplay between strict rules and creative engineering often leads to breakthroughs that influence everyday car technology. The push-and-pull between regulation and innovation ensures that F1 transmission systems remain at the forefront of automotive engineering.

How Transmissions Affect F1 Race Strategy

Modern F1 transmissions are more than just a technical marvel - they’re a cornerstone of race strategy. These advanced systems have redefined how teams approach races, allowing for seamless, automated gear shifts that free up focus for tactical decisions and create opportunities for overtaking.

Race Strategy Effects

Today’s transmissions play a key role in shaping race strategies, largely due to the massive amounts of data they generate. With over 300 sensors on each car producing more than 1.1 million data points per second, teams analyze approximately 4TB of data per car during a single race. This data is used to fine-tune decisions, including crucial pit stop timing. For instance, data-driven adjustments at the 2019 British Grand Prix helped secure race victories.

Transmission data is also integrated into fuel efficiency strategies, enabling precise calculations for each stint. AI and machine learning tools analyze this data to predict optimal transmission settings based on evolving race conditions.

"Data is in the team's lifeblood. Every element of performance – how we run a race, how we develop a car, how we select and analyze drivers – it's all driven by data." – Christian Horner, CEO of Oracle Red Bull Racing

Real-time telemetry further enhances strategy by alerting teams to potential issues, such as overheating brakes or low oil pressure. A notable example occurred during the Istanbul 2021 race when delayed detection of a problem impacted Mercedes’s strategy. By leveraging this data, teams not only improve pit stops but also enhance overall driver performance.

Driver Performance and Workload

The evolution from manual to modern sequential transmissions has dramatically reduced driver workload. In the past, manual gear changes demanded significant attention, often at the cost of focus during critical moments. Today’s automated systems eliminate gearshift errors, allowing drivers to concentrate on tire management, positioning, and racecraft. This consistency reduces the risk of human error, which could otherwise lead to lost time or mechanical failures.

Additionally, modern systems shorten the learning curve for new drivers. Without the need to master complex manual gear shifts, rookies can focus on refining their racing skills from the outset.

"The risk averse teams never win in Formula One – the ones which embrace and manage risk are more likely to try new things, innovate in ways both small and large, and ultimately drive competitive advantage." – Mark Gallagher, Author, Broadcaster and Formula 1 guru

Future F1 Transmission Development

The world of Formula 1 is on the brink of a major shift, especially when it comes to transmission technology. By 2026, new regulations and advancements will reshape how transmissions work, particularly in their integration with hybrid systems and the use of artificial intelligence to enhance performance.

Hybrid System Integration

The 2026 regulations bring a dramatic change to F1’s hybrid technology. One of the most notable shifts is the move from the current 80:20 energy split between internal combustion engines and electric power to an even 50–50 balance. This adjustment will require transmissions to handle power delivery from both sources with precision.

Additionally, the hybrid systems in F1 cars will see a significant boost in battery power, climbing from 120 kW to an impressive 350 kW - a 300% increase. Energy recovery during braking will also double, reaching approximately 8.5 megajoules per lap. Alongside these changes, the MGU-H system, which has been a complex and costly component since 2014, will be removed. This simplification shifts the focus to electric power, presenting new challenges for engineers tasked with designing transmissions that can handle the instantaneous power demands of both electric motors and combustion engines.

"The biggest change in the technical regulations for 2026 is the power unit. The headline figure is that 50 per cent of the power will be generated from the internal combustion engine and 50 per cent from the battery. The ratio at the moment is about 80:20. We will be losing the MGU-H which, since its introduction in 2014, has added significant complexity and expense to the current generation of power units." – Bob Bell, Executive Director

Future transmissions will also need to balance energy recovery during braking with smooth power delivery during acceleration. This concept isn’t entirely new - Mercedes-Benz has already implemented similar systems in their EQ-Boost mild hybrids, a technology inspired by F1’s kinetic energy recovery systems first introduced in 2007.

AI and Predictive Control Systems

As hybrid systems redefine power management, artificial intelligence is set to revolutionize how transmissions operate. AI’s ability to process vast amounts of data in real time opens up opportunities to optimize gear changes and refine race strategies. These systems can analyze track conditions, tire wear, fuel levels, and even predict the likelihood of a safety car deployment, enabling smarter and faster decisions.

McLaren has been leading the charge with their advanced data streaming system, capable of processing 100,000 data points per second. This allows them to create highly accurate digital twins of race conditions, running millions of simulations to perfect transmission strategies before they’re implemented on the track.

"We're going with prototype cars that are changing nearly race-on-race … different tracks, different tires … the right way of doing that is to use modeling tools that will run millions of race scenarios." – James Vowels, Williams Boss

Looking ahead, AI-driven transmission systems could go beyond optimizing gear changes. These systems might provide real-time virtual coaching, offering drivers insights on racing lines, braking points, and overtaking opportunities. They could also adjust car settings - like suspension, aerodynamics, and engine performance - based on live telemetry and predicted race conditions. The potential doesn’t stop there: AI could influence pit stop timing, tire selection, and even replace physical sensors to reduce weight and minimize crash damage risks.

"An F1 track is five kilometers long with 20 cars on it. So the TV can only concentrate on one, two or three cars at a time … there's another four and a half kilometers of track where there are various actions going on that could be really key to how the race strategy is going to unfold." – Zak Brown, Managing Director of McLaren

However, regulatory hurdles remain. The FIA is exploring limits on electrical boost usage at high-speed circuits like Monza, Spa, and Silverstone. Starting in 2027, gearbox structures will be frozen until 2030, with only minor modifications allowed, such as changes to gear ratios. Despite these constraints, the future of F1 transmissions lies in intelligent systems that can adapt to changing conditions faster than any human could.

As F1 continues to push technological boundaries, these advancements won’t just shape the sport - they’ll also influence the design and performance of road cars, following the same path that brought us from manual gearboxes to today’s advanced sequential systems. The road ahead is as exciting as it is transformative.

Conclusion

The evolution from manual gearboxes to today’s cutting-edge transmission systems marks one of Formula 1’s most transformative advancements. What started with simple H-pattern mechanisms has grown into highly sophisticated components that have redefined the sport.

Each breakthrough brought tangible benefits. Ferrari’s transverse gearbox improved handling, and the 1989 debut of semi-automatic paddle shifters gave drivers the ability to shift gears without taking their hands off the wheel, enhancing both control and safety. Modern electro-hydraulic systems have taken this progress even further, reducing the chances of missed shifts while offering unmatched reliability.

As the sport continues to evolve, transmissions have become integral to hybrid and AI technologies. These advancements have not only lessened driver workload but also opened the door to more aggressive racing and intricate strategies. Teams can push their cars to the limit, confident in the durability of their transmissions. Moreover, the compact and lightweight designs of modern gearboxes contribute to better aerodynamics and weight distribution, influencing both performance and overall car design.

Looking forward, the future holds even more exciting possibilities. The deeper integration of hybrid systems and AI-driven predictive controls promises to refine gear selection and enhance performance further. These innovations not only uphold Formula 1’s reputation for engineering ingenuity but also set benchmarks that trickle down to high-performance road cars.

In the high-stakes world of Formula 1, where precision and innovation are everything, the quest for the perfect gear change is far from over. As teams gear up for the next wave of transmission technology, one thing is clear: the relentless drive for engineering progress will remain at the heart of the sport.

FAQs

How did switching from manual to semi-automatic gearboxes improve driver performance and safety in Formula One?

The move from manual to semi-automatic gearboxes changed the game in Formula One, boosting both driver performance and safety. With semi-automatic systems, drivers no longer needed to use a clutch for gear changes. This meant they could keep both hands firmly on the wheel, concentrating fully on steering, precision, and race strategy. It also cut down on errors like missed shifts or over-revving - mistakes that could lead to accidents or damage to the car.

These gearboxes also allowed for quicker and smoother gear changes, giving drivers an edge by improving lap times and maintaining consistency. By reducing the physical and mental strain during races, semi-automatic transmissions made it easier for drivers to maintain control of their vehicles, especially in high-speed, high-stakes situations. This innovation didn’t just make racing more efficient; it also made it significantly safer.

How do modern F1 transmissions support hybrid power systems and enhance performance?

Modern Formula 1 transmissions play a crucial role in the smooth integration of hybrid power systems. They expertly balance the interaction between the internal combustion engine and the electric components, ensuring an uninterrupted flow of energy and peak performance. With advanced gearshift algorithms, these systems recover energy efficiently during braking and strategically release it during acceleration for maximum impact.

These transmissions also synchronize the power from the batteries with the engine, boosting both responsiveness and efficiency on the track. But the influence doesn’t stop there - these advancements are paving the way for the next generation of hybrid road cars, as Formula 1 continues to serve as a proving ground for cutting-edge automotive innovations.

How could future advancements in AI and hybrid technology reshape F1 transmissions and race strategies?

Future developments in AI and hybrid technology are poised to transform F1 transmissions and race strategies, bringing new levels of precision and efficiency to the sport. With AI-driven systems, teams could analyze real-time data to fine-tune gear shifts, manage energy consumption, and refine race tactics - delivering critical advantages when it matters most.

Hybrid systems are also expected to evolve, with AI seamlessly handling energy recovery and deployment. This could mean quicker power delivery, improved fuel efficiency, and greater flexibility in strategy - key factors in the intense, fast-paced world of Formula One. These breakthroughs aim to push performance boundaries and change the way races are contested and won.