2026 F1 Rules: Impact on ERS Costs

Explore the 2026 F1 regulations, focusing on the impact of new power unit rules on costs, performance, and sustainability for teams.

Formula 1 is changing fast, and here’s what you need to know about the 2026 power unit regulations:

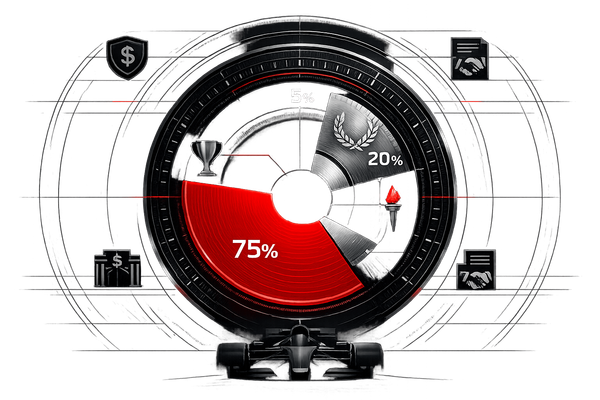

- 50/50 Power Split: Internal combustion engines (ICE) and electric power will now share energy generation equally, moving from the current 80/20 ratio.

- No More MGU-H: The complex and costly MGU-H component is being removed, reducing expenses and simplifying engine designs.

- Increased Electrical Power: The MGU-K output jumps from 120 kW to 350 kW, and energy recovery under braking rises from 2 to 8-9 megajoules per lap.

- Cost Cap: Teams must develop power units under a $130 million budget, covering all ERS-related research, manufacturing, and testing.

- Standardized Components: Sensors and electronics will be standardized to lower costs and encourage new manufacturers to join the sport.

- Environmental Focus: 100% sustainable fuels and stricter recycling rules for rare earth materials are now mandatory.

These changes aim to balance performance, cost-efficiency, and sustainability while opening the door for new manufacturers like Audi, Ford, and Honda. Teams face a challenge: innovate within tight budgets while meeting new technical and environmental demands.

Quick Overview of Key Changes:

| Aspect | Current (2023-2025) | 2026 |

|---|---|---|

| Power Split (ICE/Electric) | 80/20 | 50/50 |

| MGU-H Component | Included | Removed |

| MGU-K Output | 120 kW | 350 kW |

| Energy Recovery (Braking) | ~2 MJ/lap | 8-9 MJ/lap |

| Power Unit Cost Cap | $95M | $130M |

| Sustainable Fuels | Not mandatory | 100% required |

The 2026 regulations mark a turning point for F1, blending electrification, cost control, and environmental responsibility. Let’s dive into how these changes impact teams, manufacturers, and the future of the sport.

The 2026 Regulations Explained | F1 TV Tech Talk | Crypto.com

How 2026 Power Unit Changes Affect ERS Costs

The 2026 regulations are set to shake up ERS development in two major ways: one change significantly reduces costs by removing a pricey component, while the other introduces a need for substantial investment in advanced technology.

Eliminating the MGU-H Component

The removal of the MGU-H, an intricate and expensive system, is expected to deliver notable cost savings. Currently, the combined MGU-H and MGU-K components cost teams between $1 and $2 million, so eliminating this part allows teams to redirect resources to other areas of development. Beyond the upfront manufacturing costs, teams will also save on ongoing development and maintenance expenses.

"An engine-specific cost cap, plus banning of expensive manufacturing materials and systems such as the MGU-H (Motor Generator Unit – Heat) – plus the use of standardised components – will help to bring costs down."

– Samarth Kanal, Staff Writer, Formula1.com

While removing the MGU-H simplifies the power unit's architecture, it also requires a complete redesign. This redesign eliminates the intricate integration between the turbocharger and the energy recovery system, aligning with the FIA’s goal of lowering barriers for new engine suppliers. By doing so, the regulations aim to encourage competition in the sport.

Even as teams save costs by shedding the MGU-H, new challenges arise with the increased electrical demands of the updated power units.

Increased MGU-K Power and New Battery Challenges

The MGU-K’s power output will nearly triple to 350 kW, placing new demands on battery systems. Despite a 4-megajoule maximum state of charge, these systems will now require advanced designs to handle rapid energy depletion and recovery.

"We want to have the focus of the development on the energy storage and the MGU-K, which means the combustion engine is not supposed to become as big a performance differentiator as it potentially is now."

– Jan Monchaux, FIA Single-Seater Technical Director

These upgrades will increase the power unit’s weight from 151 kg to 185 kg and enhance energy recovery from braking to approximately 8.5 megajoules per lap. This means teams will need to invest in more advanced power electronics, robust cooling systems, and durable components to manage the increased demands. The added complexity of these systems has even led to predictions that the overall cost of these cars could double due to their technical sophistication.

To manage these financial pressures, the FIA has introduced cost controls in the 2026 regulations. Teams will have to juggle the need for cutting-edge ERS technology with staying within tighter budget limits, creating a delicate balance between innovation and cost efficiency.

Cost Caps and Financial Rules for ERS Development

The FIA has introduced strict financial regulations for ERS (Energy Recovery System) development, reshaping how teams innovate their power units. These rules emphasize financial discipline alongside technical expertise, creating a competitive environment where managing resources is as important as engineering brilliance. Here's a closer look at how these financial controls and standardization measures are shaping the future of ERS development.

FIA's $130M Power Unit Spending Limit

Starting in 2026, the cost cap for power unit development will rise from $95 million (the limit set for 2022–2025) to $130 million. This adjustment reflects the increased costs associated with developing redesigned power units under the new regulations, while still maintaining a strict cap compared to the previous era of unrestricted spending.

The $130 million budget must cover all aspects of power unit development, including ERS research, manufacturing, and testing. Teams are now tasked with making tough decisions about how to allocate their resources effectively, balancing performance goals with financial constraints.

To ensure compliance, the Cost Cap Administration requires detailed financial reporting from all teams and has the authority to investigate any suspected violations. Penalties for breaches are tiered based on the severity of the overspend:

- Minor breaches (less than 5% over the cap) result in financial penalties and minor sporting sanctions.

- Major breaches (5% or more) lead to mandatory championship point deductions for both teams and drivers.

Teams failing to submit required financial reports face the harshest penalties, including constructor championship point deductions and additional financial and sporting sanctions. These measures highlight the significant impact non-compliance can have on championship standings.

Standard Parts for Lower Costs

The 2026 regulations also introduce standardized components for ERS systems, such as sensors and electronics. This move aims to reduce development costs while allowing teams to concentrate their budgets on areas that can deliver a competitive edge.

"Standardisation isn't about a quest to 'dumb down' motorsport, but about lowering the barrier to entry so that new teams and manufacturers can participate without facing a near-vertical wall of unnecessary cost." – Rodi Basso, Director of Motorsport, McLaren Applied Technologies

By using standardized parts, teams avoid duplicating efforts on basic components, simplifying supply chains and freeing up resources to refine their ERS designs. For instance, standardized sensors and electronics enable engineers to focus on optimizing energy recovery strategies rather than reinventing fundamental systems.

This approach is particularly advantageous for new manufacturers entering Formula 1. Instead of building every component from scratch, they can rely on proven standardized parts and channel their efforts into developing unique ERS designs that set their power units apart. This strategy preserves competitive diversity while keeping costs in check, ensuring that spending focuses on performance-enhancing innovations rather than redundant development.

Technology and Environmental Requirements Affecting ERS Costs

The 2026 Formula 1 regulations bring a new wave of environmental mandates that intertwine technological advancements with cost management. These rules are reshaping how teams approach the development of energy recovery systems (ERS), as they now have to juggle performance goals with sustainability requirements.

Working with 100% Sustainable Fuels

Starting in 2026, Formula 1 will transition to using 100% sustainable fuels, a move that demands teams recalibrate their ERS strategies to accommodate changes in combustion dynamics. While this fuel is designed to function as a "drop-in" replacement for traditional gasoline engines, adapting ERS designs to its properties will require significant testing and development - an effort that inevitably increases costs.

An example of this shift can be seen in Aramco's collaboration with Aston Martin to develop sustainable fuels tailored for F1. Such partnerships are becoming critical as teams navigate the complexities of integrating sustainability into their designs.

Recycling Rules for Rare Earth Materials

Another major factor affecting ERS costs is the introduction of stricter recycling regulations for rare earth elements (REEs), which are crucial for ERS batteries and electric motor components. Currently, only about 1% of rare earth elements are recycled globally, but the European Union has set an ambitious goal to meet 25% of its critical mineral demand through recycling by 2030. For F1 teams, this means factoring in the entire lifecycle costs of ERS components, as low recycling rates and supply chain uncertainties could lead to higher material prices.

Adding to the challenge, the global market for rare earth elements is heavily reliant on China, which dominates over 80% of production, creating additional cost volatility.

To address these challenges, extended producer responsibility is emerging as a potential solution. Bernd Schaefer, CEO of EIT RawMaterials, highlights the hurdles involved:

"Extended producer responsibility is seen as a key solution, but challenges like high recycling costs and inadequate collection systems exist".

In response, teams are partnering with specialized recycling companies to ensure compliance and manage expenses. For instance, the French start-up Carester plans to process 2,000 tons of old permanent magnets annually by 2026, potentially meeting 6% of the EU's rare earth demand by 2030. Similarly, Germany's Heraeus Remloy has launched a facility to recycle obsolete electronic devices into magnetic alloy powder, which could supply around 1% of demand.

Although these recycling initiatives come with added costs - such as collection systems and processing fees - they could offer long-term savings. Recycling rare earth elements may eventually prove more economical than mining new materials. However, balancing recyclability with performance optimization remains a significant engineering challenge under the new 2026 regulations.

Future Cost Effects and Money-Saving Opportunities

The 2026 regulations present a balancing act for teams: managing the upfront costs of Energy Recovery System (ERS) investments while aiming for long-term savings. Although the initial expenses for adopting advanced ERS technology are steep, they open the door to significant cost reductions over time and even potential revenue streams through commercial applications. These rules build on prior cost cap strategies by encouraging teams to shift their focus toward virtual development and broader commercial opportunities.

Limited Dyno Testing and the Rise of Computer Simulations

To keep costs in check, the FIA has introduced operational restrictions that reshape how teams approach ERS development. Starting in 2026, dyno testing hours will be strictly capped to reduce expenses. On top of that, teams will face tight limits on real-world testing and Computational Fluid Dynamics (CFD) or wind tunnel evaluations through 2025. These constraints push teams to rely heavily on simulation-based development. While this shift requires upfront investment in advanced computing systems, it offers more predictable costs by allowing engineers to refine designs virtually before committing to costly physical prototypes.

Commercial Applications of F1 Technology

Beyond cost controls, the commercial adaptation of F1 technologies helps offset development expenses. Examples abound: Mercedes-AMG's Project One and Aston Martin's Valkyrie utilize F1-inspired power units. Hybrid technologies initially developed in F1 have found their way into consumer vehicles like the S-Class, while KERS (introduced in 2009) has been adapted for hybrid buses and energy storage systems on the Isle of Eigg. Another standout example is Aerofoil Energy’s collaboration with Williams Advanced Engineering, which led to the development of aerofoils now used in supermarket refrigerators to cut energy use and reduce carbon emissions.

The 2026 regulations, with their focus on electrification and a new 50/50 split between electric and combustion power, are driving innovation in battery management, thermal control, and energy deployment technologies. The increase in MGU-K power output from 120kW to approximately 350kW is another key factor. Teams see ERS development not just as a compliance measure but as an opportunity to create technologies with applications across industries, potentially generating new revenue streams while aligning with the broader goal of managing ERS costs under the updated rules.

Conclusion: Managing Cost, Performance, and Environmental Goals in 2026

The 2026 Formula One regulations mark a turning point for the sport, reshaping how teams tackle ERS development while juggling financial limits, performance demands, and environmental responsibilities. These changes reflect the FIA's dedication to evolving F1 into a more sustainable and financially responsible competition, without losing its edge as the ultimate platform for motorsport innovation.

"The 2026 Formula 1 Power Unit Regulations are the most high-profile example of that mission [to push forward on innovation and sustainability]." - FIA President Mohammed Ben Sulayem

A key component of these regulations is the $130 million spending cap on power units, which compels teams to rethink their development priorities. The focus on cost-effective solutions is more critical than ever.

At the same time, performance remains a cornerstone of the sport. Moving to a 50/50 power split between combustion engines and electric systems signals F1's intent to maintain the thrilling on-track action fans expect, while showcasing cutting-edge technology.

Environmental responsibility is another driving force behind the 2026 rulebook. From mandates for sustainable fuels to recycling requirements for batteries and rare earth materials like cobalt, the regulations emphasize principles of a circular economy.

The FIA has also prioritized competitive fairness through strategic flexibility. As Nikolas Tombazis, FIA Single-Seater Director, explained:

"We don't want to have somebody who's eternally condemned to misery and humiliation."

This philosophy allows teams to balance weaknesses in one area with strengths in another, ensuring no single aspect of car design overshadows the rest. Such an approach paves the way for hybrid technologies to evolve in new and exciting directions.

Beyond the racetrack, these advancements are poised to influence the broader automotive industry. The push for high-power electrical systems and sustainable fuels aligns with commercial trends, potentially offsetting development costs through real-world applications. Teams that master this transition could not only dominate the championship but also become key players in the automotive sector's electrification journey.

Striking the right balance between technological progress and cost control will be essential for F1 to maintain its leadership in innovation while becoming more inclusive and environmentally conscious.

FAQs

How will removing the MGU-H in 2026 affect F1 car performance and team strategies?

The removal of the MGU-H in the 2026 Formula One regulations is set to shake things up, both in terms of car performance and team strategies. The MGU-H was key to reducing turbo lag by capturing energy from exhaust gases, but without it, turbo lag could make a comeback - especially noticeable during corner exits. This means throttle response might feel less sharp, potentially impacting lap times and adding a new layer of complexity for drivers trying to manage acceleration during critical moments on the track.

To compensate, the MGU-K will take on a more prominent role, with its output bumped up to 350 kW. Teams will need to get creative with energy recovery strategies, putting greater emphasis on regenerative braking and smarter battery management. While these adjustments simplify engine designs and help cut costs, they’ll also push teams to find fresh ways to fine-tune hybrid systems and stay competitive.

What challenges will F1 teams face with the increased MGU-K power and energy recovery requirements under the 2026 regulations?

The Challenges of the 2026 Formula One Regulations

The 2026 Formula One regulations are set to shake things up, pushing teams to tackle some tough engineering hurdles. One of the biggest changes is the increase in MGU-K (Motor Generator Unit - Kinetic) power, which will jump to 350 kW - almost three times its current capacity. This massive boost means teams will need to master energy recovery, particularly during braking, where efficiency could make or break performance on the track.

But that's not all. Teams will also face stricter car weight limits, making it tricky to balance the added power without compromising handling and overall performance. On top of that, the upgraded MGU-K systems will produce significantly more heat, forcing teams to design new cooling systems to ensure reliability.

These updates aren’t just tweaks - they demand bold engineering solutions and cutting-edge technology. Staying competitive in this new era of F1 will require teams to rethink their designs and innovate like never before.

How will the switch to 100% sustainable fuels and stricter recycling rules impact F1 teams' costs and environmental efforts in 2026?

The shift to 100% sustainable fuels in Formula 1 by 2026 is set to bring a steep rise in fuel costs for teams. Currently, fuel prices hover between $22 and $33 per liter, but sustainable alternatives are projected to cost anywhere from $170 to $300 per liter. For just one race, teams could be looking at fuel expenses between $80,000 and $100,000. This jump in costs could create financial hurdles, especially for smaller teams operating on tighter budgets.

On the environmental front, these sustainable fuels aim to eliminate the release of new fossil carbon emissions by relying on sources such as municipal waste and non-food biomass. This effort aligns with Formula 1's broader mission to reach net-zero carbon emissions by 2030. Alongside this, the sport is also implementing stricter recycling regulations to minimize waste and encourage a more eco-friendly approach across its operations. These initiatives reflect Formula 1's commitment to merging technological progress with environmental care.