5 Ways F1 Teams Save Time in Logistics

Formula 1 teams utilize advanced logistics strategies to efficiently transport equipment worldwide, ensuring seamless operations during race weekends.

Formula 1 teams manage one of the most complex logistical operations in sports, moving 50 tons of equipment across the globe for race weekends. With races often scheduled just days apart, saving time is critical. Here’s how they do it:

- Pre-Event Planning: Teams plan transport routes months in advance, coordinating with local authorities and using GPS tracking to ensure smooth operations. Backup plans are always ready to handle unexpected issues.

- Multimodal Transport: They combine air, sea, and road transport to balance speed and cost. Air freight handles critical items like cars, while sea freight is used for bulkier, less urgent cargo.

- Efficient Packing: Modular containers and custom-built flight cases allow for quick setups and breakdowns, reducing time spent on-site.

- Real-Time Tracking: GPS and IoT sensors provide constant updates on shipments, helping teams predict and avoid delays.

- Backup Equipment: Spare parts, tools, and alternative shipping options ensure teams can recover quickly from disruptions.

How Formula 1 Travels Across The World | F1 Logistics Explained | DHL

1. Detailed Pre-Event Planning and Scheduling

The backbone of F1's lightning-fast logistics is careful planning, which kicks off 6–12 months before each race. Teams craft detailed schedules that outline every step of the equipment’s journey - from leaving their headquarters to arriving at the circuit. This process involves orchestrating a mix of trucks, planes, ships, and customs clearances, all while juggling multiple time zones.

A big part of this planning is mapping out transport routes. Teams study the race calendar and the geographical layout to pinpoint the most efficient ways to move their gear. For European races, they rely on custom trucks and modular containers, while for intercontinental events, air and sea freight take center stage. They factor in everything - weather, traffic, and infrastructure challenges - to ensure smooth operations. This strategic route planning lays the groundwork for seamless logistics.

A great example of this scale is from January 2018, when F1 teams shipped five sets of containers by sea to destinations like Australia, Bahrain, China, Azerbaijan, and Canada months ahead of the season. After each race, these containers were repacked and sent to the next venue, showcasing the precision and effort that goes into pre-event logistics planning.

Working with local authorities is another crucial piece of the puzzle. Teams collaborate with government officials well in advance to secure permits, arrange police escorts, and streamline customs processes. This is especially critical in places like Monaco, where narrow streets and limited access make logistics a headache. Here, teams schedule precise unloading times and carefully navigate the tight spaces to ensure everything runs on time.

Modern technology has become a game-changer for F1 logistics. Teams now use real-time tracking tools like GPS, IoT sensors, and advanced inventory software to monitor shipments constantly. These tools allow them to predict and tackle potential issues before they cause delays.

Backup plans are also part of the equation. Teams prepare alternative routes and shipping methods to deal with unexpected problems. For example, McLaren often sends additional shipments as a safeguard against disruptions. While these extra measures may seem expensive, they’re a small price to pay compared to the cost of missing practice sessions or arriving unprepared for race weekend.

Specialized logistics partners, such as DHL, play a vital role in this process. They handle tasks like chartering cargo planes and managing customs, allowing teams to focus entirely on racing. With their expertise in handling high-value, time-sensitive cargo, these partners ensure that everything arrives exactly when and where it’s needed. Their involvement adds another layer of efficiency to F1's dynamic pre-event logistics.

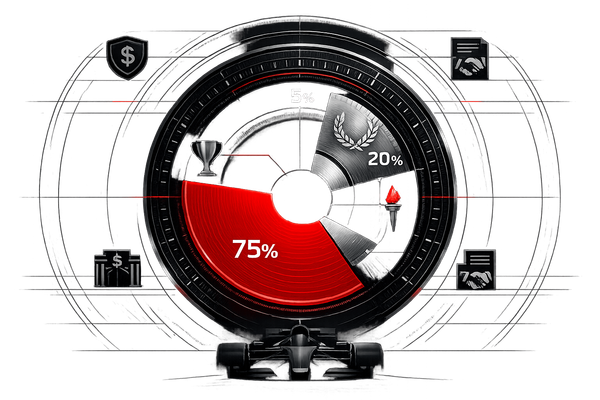

2. Combined Transport Methods

F1 teams have mastered the art of multimodal logistics, seamlessly blending air, sea, and land transport to move their massive operations across the globe. Each team carries up to 50 tons of equipment per race, and the right mix of transport methods is crucial for staying on schedule and within budget.

This strategy builds on meticulous pre-event planning, ensuring both efficiency and cost control. The key factors driving these decisions are urgency, cost, and reliability. Teams prioritize their cargo, assigning the fastest and most secure transport methods to essential items like race cars, electronics, and critical spare parts. These high-priority items always travel by air freight. On the other hand, bulkier, less critical items - such as hospitality setups and non-essential tools - are shipped by sea to save on costs.

Air Freight: Speed for Critical Gear

When it comes to transporting time-sensitive cargo, air freight is the go-to option. Using massive planes like Boeing 747s, Antonov An-124s, and Boeing 777s, teams ensure that critical equipment arrives quickly and securely. To keep costs manageable, multiple teams often share chartered flights, splitting expenses based on the space each occupies. This collaborative approach ensures that vital gear reaches its destination within hours, not weeks - a speed advantage that’s essential for the fast-paced F1 calendar.

Road Transport: The European Solution

For races within Europe, road transport takes the lead. Teams rely on fleets of specialized trucks, each costing around $600,000, to transport modular containers efficiently between circuits. Mid-sized teams typically operate 4-5 trucks, while larger teams like Mercedes manage up to 8. Road transport offers flexibility, allowing teams to adjust schedules and navigate directly to circuits that might be harder to reach using other methods.

Sea Freight: Cost-Effective Planning

Sea freight is the most cost-effective option, but it requires careful advance planning. Non-urgent items are shipped months ahead of time, with teams often sending multiple sets of containers to various continents at the start of the season. This ensures that essential equipment is already in place, waiting for them at future race locations. While it’s the slowest method, the savings make it a vital part of the logistics strategy.

Technology for Seamless Coordination

To keep everything running smoothly, teams rely on GPS and IoT sensors for real-time tracking. These tools allow logistics managers to identify potential delays early and make quick adjustments - whether switching to faster transport methods or rerouting shipments to avoid weather-related disruptions.

| Transport Mode | Primary Use | Speed | Cost Level | Best For |

|---|---|---|---|---|

| Air Freight | Cars, critical parts, garage setups | Fastest | Highest | Time-sensitive equipment |

| Sea Freight | Bulk items, hospitality units | Slowest | Lowest | Non-urgent, bulky cargo |

| Road Transport | European circuits, flexible delivery | Moderate | Moderate | Regional races, last-mile delivery |

The Financial Impact

This combined approach doesn’t come cheap - logistics costs can reach $100 million per team per season. However, by strategically using sea freight for non-urgent items and reserving air and road transport for critical shipments, teams keep expenses under control while maintaining reliability.

Specialized logistics partners, like DHL, play a key role in this process. Their expertise in handling high-value, time-sensitive cargo ensures smooth coordination across all transport modes. From navigating customs to managing the unique challenges of each race location, these partners ensure nothing is left to chance.

This efficient logistics model sets the stage for the on-site setups that follow.

3. Efficient Packing and Quick Setup Systems

Efficient packing has revolutionized F1 logistics, turning what could be a chaotic process into a streamlined operation. By using modular systems and meticulous planning, teams can quickly and systematically set up at each venue, saving time and effort.

At the heart of this efficiency are custom-built containers and flight cases designed specifically for F1 equipment. Every piece - whether it’s a car component or a garage tool - has a designated spot. These containers are lined with specialized foam to protect delicate parts and feature quick-release mechanisms for fast unpacking. The precision of these designs ensures that every item is not only safe but also easily accessible when needed.

The Modular Revolution

F1 teams have adopted modular packing systems, which use standardized units that fit perfectly into transport vehicles like trucks and cargo planes. This approach eliminates wasted space and reduces the time spent handling equipment. At European races, these modular containers allow teams to set up fully operational garages within just a few hours.

Breaking Down the Numbers

The scale of F1 logistics is nothing short of massive. In 2021, DHL transported 1,540 tons of F1 equipment and 532 cars over an astonishing 74,500 miles using these advanced systems. Equipment typically arrives at racetracks two weeks before an event and is cleared out within a week afterward. Even motorhomes, once a logistical challenge that took days to disassemble, can now be broken down in just 24 hours thanks to refined protocols.

Speed in Action

Race weekends are where these systems truly shine. Teams can pack up and hit the road in as little as five hours after a race finishes. In some cases, the first truck is already rolling into the pit lane just 90 minutes after the checkered flag. For example, after the Las Vegas Grand Prix, teams began packing non-essential items within 15 minutes of the race’s conclusion. Essential equipment was quickly loaded onto chartered Boeing 777s, ensuring everything arrived together at the next venue. This level of coordination allows for real-time monitoring and continuous improvement in logistics.

Technology and Training

Behind this efficiency is a highly trained logistics crew. These teams practice regularly and bring technical expertise to the table, ensuring smooth assembly and disassembly. Detailed packing lists and carefully planned sequencing strategies also play a critical role in keeping operations running like clockwork. This precision ensures teams meet F1’s strict operational standards.

Maintaining Fair Play

F1’s strict regulations ensure no team has an unfair advantage when it comes to logistics. Teams are prohibited from accessing their equipment until all competitors’ shipments have arrived at the venue. This rule not only upholds fairness but also highlights the importance of standardized packing procedures in balancing competition while maintaining efficiency.

These refined packing methods, combined with advanced tracking systems, create a logistics process that is as efficient as it is fair, ensuring the entire chain operates seamlessly.

4. Real-Time Tracking and Predictive Technology

In the fast-paced world of Formula 1, logistics relies heavily on cutting-edge GPS and IoT technology to keep everything moving smoothly. These tools allow teams to track their shipments from the moment they leave until they arrive at their destination. By equipping transport vehicles and containers with advanced tracking systems, teams gain instant insight into both the location and condition of their equipment. This real-time data opens the door to smarter monitoring and quicker responses when things don’t go as planned.

GPS Tracking in Action

Take Mercedes-AMG, for example. Their transport vehicles and shipping containers are outfitted with GPS trackers, enabling logistics managers to keep tabs on their shipments at all times. They even receive instant alerts if a shipment strays from its intended route. Considering that an F1 team typically moves up to 50 tons of equipment for each Grand Prix - including cars, spare parts, and everything needed to set up the garage - this level of precision is absolutely essential.

IoT Sensors: Keeping Shipments Safe

IoT sensors take things a step further by monitoring conditions like temperature, humidity, shock, and vibration. These details are critical for protecting sensitive components such as electronics and tires, which must remain in perfect condition. If a problem arises - say, a temperature spike - these sensors send immediate alerts, giving teams a chance to act before the issue becomes a major setback.

This constant monitoring doesn’t just stop at problem-solving. Teams also use the data to predict and prevent potential disruptions.

Predictive Analytics at Work

Predictive analytics combines real-time tracking with historical data and external factors like weather or customs processes. This allows teams to spot and address potential issues before they happen. For instance, in 2023, Mercedes-AMG’s system detected a possible customs delay at the Hungarian border. Acting on this information, the team rerouted critical components through another crossing, avoiding what could have been a costly delay.

These proactive measures work hand-in-hand with meticulous planning and efficient packing systems, forming a seamless logistics approach.

Collaboration with Logistics Specialists

F1 teams don’t handle these challenges alone. They work closely with expert logistics partners who provide tailored tracking solutions. These partnerships integrate GPS and IoT data, enabling swift and informed decision-making when time is of the essence.

The Financial Payoff

Real-time tracking and predictive analytics don’t just improve operations - they save money. Spotting delays early helps teams avoid costly last-minute shipping adjustments or emergency air freight. Plus, having access to backup charter flights and alternative shipping routes ensures that teams stay flexible, even when unexpected challenges arise. The money saved here can then be redirected into car development and performance upgrades, giving teams a competitive edge.

5. Backup Equipment and Flexible Scheduling

When things go off track - literally and figuratively - F1 teams rely on backup equipment and adaptable scheduling to recover quickly and keep operations on course.

Strategic Equipment Redundancy

F1 teams don’t leave anything to chance. They send extra spare parts, tools, and even spare chassis (when feasible) to every race. Take McLaren, for instance - they ensure that every Grand Prix is stocked with additional components so any damaged parts can be swapped out without delay. Alongside car parts, teams also bring duplicate tools, extra tire sets, and backup IT and communication systems to ensure paddock operations run seamlessly. This level of preparation not only keeps performance steady but also allows teams to pivot quickly when logistical hiccups arise.

Flexibility in Transport Planning

To stay ahead of potential delays, teams design transport plans with built-in flexibility. They map out alternative shipping routes and keep backup charter options ready to go. This allows them to adjust on the fly, whether it’s due to unexpected weather, customs holdups, or other disruptions. The goal? To make sure equipment is in place before critical practice sessions begin.

Balancing Costs and Backup Capacity

F1 teams strike a delicate balance between preparedness and cost. They typically own essential vehicles and equipment but rent additional resources only when necessary. For speed, critical backup gear is sent by air, while less urgent spares take the more economical route - by sea or land.

Modular Systems for Fast Response

To make quick fixes even faster, teams use modular systems to organize and deploy spare components efficiently. These packing and inventory systems ensure everything is easy to locate and ready to go upon arrival. Once at the circuit, logistics crews waste no time unloading and setting up crucial spares, enabling engineers and mechanics to tackle replacements or repairs immediately.

Expertise Through Partnerships

Specialized logistics partners play a key role in keeping everything on track. These experts handle contingency planning, backup transport options, and customs challenges, ensuring that backup equipment and alternative schedules are executed without a hitch. Their know-how is a critical part of the smooth operation behind the scenes.

Conclusion

The logistics strategies used by Formula 1 teams turn global operations into finely tuned systems that prioritize precision and efficiency. This approach not only saves critical time but also helps avoid disruptions that could jeopardize an entire race weekend. By combining meticulous pre-event planning, multimodal transport methods, real-time tracking, smart packing systems, and robust backup plans, teams ensure that every link in the chain remains intact. A breakdown in logistics could have severe consequences, affecting everything from car setup to practice sessions, qualifying, and ultimately, race results.

With logistics expenses reaching as high as $100 million per team annually, managing time effectively becomes a top priority. These investments directly support performance on the track. Teams have discovered that advanced systems and specialized partnerships are essential when every second matters during the setup and teardown processes.

Beyond the racetrack, these strategies offer a blueprint for businesses worldwide, particularly those managing time-critical operations. The use of real-time tracking, predictive analytics, and AI continues to evolve, with F1 teams constantly pushing the boundaries of what's possible in logistics management.

Formula 1 demonstrates that when speed, accuracy, and dependability align, the result is a level of efficiency that can mean the difference between success and failure.

FAQs

How do F1 teams manage to deliver their equipment on time despite the demanding race schedule and global travel?

Formula 1 teams depend on precise planning and streamlined logistics to ensure their gear reaches its destination on time, even with the challenges of tight schedules and global travel. They rely on specialized freight services, such as cargo planes and trucks, to move cars, parts, and tools both quickly and securely.

To keep up with the demanding race calendar, many teams prepare duplicate sets of equipment. This approach allows them to ship items to the next race location well in advance, saving valuable time. On top of that, teams follow detailed schedules and work closely with local customs authorities to navigate international regulations, reducing the risk of delays. These well-orchestrated strategies ensure F1 teams are always ready to compete, no matter where in the world the race takes place.

How do logistics partners like DHL contribute to the efficiency of F1 teams' global operations?

Logistics partners such as DHL are essential in keeping Formula 1 teams on track - literally and figuratively - as they compete worldwide. They manage the intricate process of moving cars, equipment, and all the necessary team gear to more than 20 race venues each season, often working against the clock.

From air, sea, and land transportation to handling customs clearances for international events, these partners oversee every logistical detail. Their precision and reliability allow F1 teams to concentrate on what matters most: delivering top-notch performance on race day.

How do real-time tracking and predictive analytics improve the logistics efficiency of F1 teams?

Real-time tracking and predictive analytics are game-changers when it comes to improving the logistics of Formula 1 teams. With GPS and advanced tracking technology, teams can keep tabs on the movement of equipment, vehicles, and personnel across their global operations. This constant monitoring means any delays or disruptions are spotted instantly, allowing teams to address issues on the spot and reduce downtime.

Predictive analytics takes it a step further by using historical data and machine learning to predict potential obstacles. Whether it’s unexpected weather, customs delays, or equipment breakdowns, this technology helps teams anticipate challenges before they arise. By doing so, they can fine-tune their plans, adjust routes, and allocate resources more effectively - all critical steps to saving time during the high-pressure racing season. Combined, these tools ensure F1 teams can maintain precision and tackle logistical challenges head-on.