Behind the Scenes: Packing Up After an F1 Race

Explore the intricate logistics of packing up after an F1 race, where precision, speed, and sustainability collide in a high-stakes operation.

Packing up after an F1 race is a race of its own. Teams dismantle, pack, and transport 50 tons of equipment per race - equivalent to eight elephants - under tight deadlines. Here's how they do it:

- Speed Matters: Packing starts 15 minutes after the race ends. Teams clear the circuit within eight hours to meet a strict 6 AM deadline.

- Massive Scale: Each season involves 130,000 km (80,800 miles) of logistics, using up to seven Boeing 747s per event.

- Precision and Organization: Every part is labeled, packed in custom containers, and tracked to avoid delays or damage.

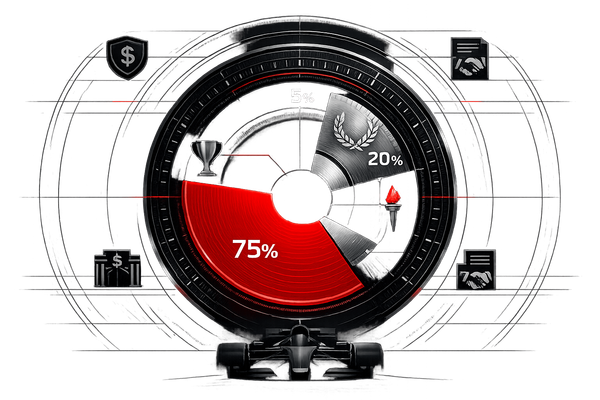

- Costs and Sustainability: Logistics make up 10–20% of F1's $200–$400M annual expenses. Teams are adopting greener practices like biofuel trucks and adjusted race calendars to cut emissions.

Packing isn't just moving gear; it’s a high-stakes operation where every second counts. Keep reading to see how teams like Mercedes, Red Bull, and McLaren tackle this logistical challenge.

How F1 Moves An Entire Sport Across Continents Every Week!

Breaking Down the Garage: Dismantling Operations

As soon as the checkered flag waves, Formula 1 teams kick into high gear. The teardown process begins almost immediately, following a detailed strategy outlined on Thursday before the race weekend even starts. In just seven hours after the race concludes, every team member - mechanics, engineers, and beyond - works together to disassemble the garage and prepare everything for transport. This rapid operation highlights the precision and care required to handle high-tech equipment while ensuring everything is properly labeled for the journey ahead.

Taking Apart Technical Equipment

The cars themselves are off-limits until the FIA completes post-race inspections to confirm compliance with regulations. Once cleared, the real work begins. Teams strip down the vehicles, dismantle garage walls, and secure key components like computer racks and cabling. Fragile and high-value equipment gets extra attention: custom-built containers are used to protect these parts. For instance, Red Bull Racing uses chassis containers with shock-absorbing materials and temperature controls, while Mercedes-AMG employs GPS trackers and IoT sensors to monitor shipments in real-time. Meanwhile, data analysts ensure the IT infrastructure is safely packed, as they process the massive amounts of data collected during the weekend.

Labeling and Packaging

When you're handling up to 50 tons of equipment per team, staying organized is non-negotiable. Every item is labeled and accounted for, with mechanics sorting tools and spare parts into carefully marked cases using strict checklists. Sea freight cases are often marked with photos on the outside, showing their origin, box number, and a full inventory of contents. Cars are stripped down to their smallest components, with parts stored in foam-slotted boxes, chassis wrapped in custom shields, and additional layers of bubble wrap for extra security. Teams also rotate five sets of garage paneling and internal equipment via sea freight, ensuring the right gear is always ready at the next destination.

Simon Price, Event Manager for DHL Motorsport, emphasizes the urgency of these operations:

"Teams will never be without anything... Our deadlines are not like commercial deadlines where if you can't deliver it on Friday you could deliver it on Monday morning - that doesn't work here because the race is on Sunday. It has to be here."

Engines and tires are typically returned to their manufacturers, while heavy equipment like cranes and forklifts is used to load and unload bulkier items safely. Altogether, this intricate operation costs teams around $8 million each year, with logistics making up 10–20% of Formula 1's total industry expenses - amounting to an estimated $200 million to $400 million annually.

Preparing the Car for Transport

When it’s time to ship $12–15 million race cars, teams face an intricate and high-pressure task: tearing down and prepping these engineering marvels for transit. This involves carefully disassembling components, draining fluids, and meeting strict regulations - all while racing against the clock. Every step ensures the cars and their parts are safe, compliant, and ready for the next destination.

Car Disassembly and Fluid Removal

Disassembling a race car isn’t just about taking it apart - it’s about protecting its most sensitive and valuable components. Teams remove wings, engines, and tires, safeguarding fragile electronics and high-cost parts from potential damage during shipping. Each piece is handled with precision to ensure it arrives intact.

One of the most critical steps in this process is fluid removal. Specialized fuel carts extract and weigh the fuel with precision. Using a dry break connection at the base of the tank, the fuel is pumped out efficiently. The designated 'Fueler' wears extra fireproof gear to handle this potentially hazardous task.

Once fluids are removed, every component is packed with care. Wings are placed in protective cases, while engines are secured in shock-absorbing packaging. This detailed preparation begins about a week before the next race. To avoid any mix-ups, teams meticulously label and inventory every part. This attention to detail not only prevents losses but also ensures smooth operations, avoiding costly delays or damage.

Post-Race Scrutineering and Compliance

Before the teardown can even begin, cars must pass the FIA’s mandatory post-race inspections. As soon as a car crosses the finish line, FIA officials step in to perform scrutineering and weighing. This creates a challenging balance between meeting regulatory requirements and starting the packing process.

Due to time constraints, only about one-fifth of the cars are selected for detailed inspections after each race. These checks include weighing, measuring dimensions, and verifying aerodynamic components to ensure everything complies with regulations. Occasionally, officials conduct deeper inspections, partially disassembling cars and comparing parts to CAD files, which can further complicate the already tight packing schedule.

Teams know that any car could be randomly selected for inspection, keeping them on high alert. The FIA underscores this element of unpredictability:

"each team is aware that selection is possible and understand that the chance of any lack of compliance being uncovered is strong"

This constant vigilance ensures teams maintain strict compliance while quickly transitioning to the teardown and packaging process. Meeting these demands is crucial to staying on schedule for the next race weekend.

Logistics and Freight Coordination

Behind every Formula 1 race lies a logistical marvel, ensuring equipment and resources reach their destinations without a hitch. With cargo loads equivalent to the weight of eight elephants per race and costs exceeding $8 million, the coordination required is staggering. This global operation spans five continents, involving a mix of transport methods, customs management, and precise scheduling.

Over the course of a season, DHL freight covers more than 130,000 kilometers, relying on up to six or seven Boeing 747 cargo planes for each event. For European races, the logistics shift to road transport, with convoys of up to 300 trucks stretching over 5 kilometers.

Air Freight vs. Sea Freight

When it comes to choosing transport methods, F1 teams weigh speed against cost. The decision largely hinges on the distance between venues and the time available. Planning starts early - by January, teams are already shipping multiple cargo sets for the season's initial fly-away races.

Air freight is the go-to for time-critical deliveries, offering unmatched speed but at a high price. On the other hand, sea freight, while slower, is far more economical. Mark Baker, McLaren's Head of Sea Freight & Infrastructure, shares their approach:

"We are actually trying to slow things down. One, to save emissions, and two to reduce our storage costs".

This strategy allows teams to send bulkier, non-essential equipment by sea when time isn't a pressing factor.

| Transport Method | Advantages | Disadvantages | Use Case |

|---|---|---|---|

| Air Freight | Fast and reliable for long distances | Expensive; limited space; high carbon emissions | Critical components, overseas races, time-sensitive items |

| Sea Freight | Cost-efficient; large cargo capacity | Slow transit; requires advance planning | Spare parts, garage setups, non-urgent equipment |

| Road Transport | Flexible and quick for regional travel | Limited to shorter distances; traffic-dependent | European circuits, specialized car transport |

Logistics make up a significant portion of F1's expenses, accounting for 10–20% of the industry's total spending - roughly $200 million to $400 million annually. For individual teams, air freight alone can cost several hundred thousand dollars per race.

Environmental factors are also shaping decisions. Logistics contribute about 45% of Formula 1's baseline carbon footprint, with air, road, rail, and sea freight making up 10% of McLaren's emissions. To address this, F1 has begun grouping races geographically to cut down air miles and exploring biofuels for freight operations. Once the transport method is finalized, the next hurdle is navigating global customs.

Customs and Regulatory Compliance

After determining how to transport their cargo, teams must tackle the complexities of international shipping regulations. Every destination comes with its own set of customs rules, documentation requirements, and inspection procedures.

The sheer volume of paperwork is daunting. For every Grand Prix, DHL processes over 2,800 documents, from customs declarations to temporary import permits. Teams rely on meticulous planning and specialized brokers to ensure compliance and avoid delays.

Recent geopolitical changes have added new layers of complexity. Brexit introduced additional customs procedures, fees, and documentation for goods moving between the UK and the European Union. Teams had to quickly adapt to these changes to maintain smooth operations.

The stakes are high, as demonstrated by real-world incidents. In 2019, customs delays during the Brazilian Grand Prix caused critical equipment to arrive late for several teams. In a more dramatic example, Haas missed the first round of pre-season testing in Bahrain when their cargo plane was grounded in Istanbul due to technical issues.

Steve Nielson, F1's Sporting Director, encapsulates the pressure:

"You're working right on the edge of what's possible logistically, and any hiccup has a knock-on effect on the teams."

To mitigate risks, teams collaborate with logistics companies specializing in high-value, time-sensitive cargo. These experts provide emergency solutions when needed, such as issuing ATA Carnets - documents that allow duty-free and tax-free imports for up to a year.

In some cases, customs checks are conducted directly at race circuits instead of airports, speeding up the process. To maintain fairness, all teams' crates are placed in the pit lane and remain sealed until everyone's cargo has arrived, ensuring no team gains an advantage.

The intricate nature of F1 logistics demands constant coordination with partners to anticipate delays and have contingency plans ready. From weather disruptions to customs issues and mechanical failures, teams understand that in Formula 1, logistical precision is non-negotiable.

Team-Specific Approaches and Methods

When it comes to post-race operations, Formula 1 teams tackle their logistical challenges with strategies tailored to their unique priorities. While all teams face similar hurdles, their approaches highlight distinct methods and philosophies.

Mercedes-AMG Petronas Formula One Team

Mercedes relies heavily on advanced data analytics and cutting-edge technology to streamline its post-race processes. Throughout the race weekend, the team generates a staggering amount of data - over 7 billion data points - and uses this information to enhance efficiency and prepare for upcoming events. With support from Tata Communications, Mercedes ensures continuous access to car data, transmitting crucial insights from the racetrack to its headquarters in Brackley, England.

Michael Taylor, IT Director for Mercedes-AMG PETRONAS Formula One Team, elaborates:

"Over the course of one race weekend, we can generate more than 7 billion data points. We capture this huge, disparate data set that we bring together to prepare for race weekends as well as enhance our race day performance".

The team’s commitment to precision is reflected in its "zero defects" philosophy, which ensures full traceability for every car component. Additionally, the adoption of Pure Storage all-flash solutions has significantly improved their data management, cutting response times for key database queries by 95% and reducing data handling efforts by 90%. Matt Harris, Head of IT for Mercedes-AMG Petronas Motorsport, explains their focus:

"Our plan is about filtering out the norm. You don't need to look at the data if it's the same as every other lap – ignore that and focus on where the differences are".

While Mercedes emphasizes precision and data-driven decisions, Red Bull Racing takes a different approach.

Red Bull Racing

Red Bull Racing is renowned for its fast-paced and agile approach to post-race logistics. This strategy reflects the intense competitive pressures of Formula 1, where quick turnarounds are critical. Their focus lies in swiftly cataloging and securely transporting sensitive components, ensuring that essential parts are always ready for the next race. This approach prioritizes speed and readiness over long-term sustainability or cost considerations, setting them apart from other teams.

McLaren Racing

McLaren, on the other hand, has committed to an environmentally conscious strategy for its post-race logistics. The team employs innovative transport solutions and strategic partnerships to balance speed, cost, and environmental impact. One standout practice is their use of a continental kit strategy, which involves shipping duplicate kits via ocean freight to serve as contingency storage in key locations. For instance, they reduce regional movement by reusing the same kits at both the Bahrain and Saudi Arabian Grands Prix, cutting costs and emissions.

McLaren has further diversified its transport methods by incorporating rail freight, biofuel-powered trucks that reduce greenhouse gas emissions by 75%, and electric trucks that use up to 50% less energy. The team manages the unpacking of nine 40-foot containers within 24 hours to set up its garage, Paddock Performance Centre, Paddock Club, and hospitality units. Mark Baker, Head of Sea Freight & Infrastructure at McLaren, highlights their approach:

"People always think we are going 100mph and trying to get from A to B as quickly as possible, but in a lot of cases, we are actually trying to slow things down. One, to save emissions, and two to reduce our storage costs".

He also emphasizes the importance of staying flexible:

"The calendar for this upcoming season is quite forgiving, but the timelines are still tight. We have some plans already in place, but we have to be open-minded, and we have to constantly search for even better solutions".

From Mercedes’ data-driven precision to Red Bull Racing’s rapid readiness and McLaren’s focus on sustainability, each team showcases how thoughtful planning and technology enable smooth post-race operations.

Future Trends in F1 Packing and Logistics

As Formula 1 evolves, so do its logistics and packing strategies. Teams are embracing new technologies and sustainable practices to align with the sport's goal of achieving net zero carbon emissions by 2030. These efforts not only cut emissions but also make operations more efficient, reflecting the sport's shift toward smarter, greener logistics.

Environmental Impact Reduction

Sustainability is reshaping every corner of F1 logistics, from transportation to packaging. Formula 1 now incorporates zero-waste initiatives, circular supply chains, and 100% renewable electricity in its operations.

One standout development is Sustainable Aviation Fuel (SAF). In 2024, Formula 1 partnered with DHL and Qatar Airways to use SAF, cutting emissions by over 8,000 tCO2e - an impressive 19% reduction compared to traditional aviation fuel during flyaway events.

"Innovation and community drove Formula 1's work in 2024. We are thrilled to outline our progress and continued work in this space. Formula 1 as a sport is uniquely positioned to take action through our global reach and technological leadership."

- Ellen Jones, Head of ESG at Formula 1

Ground transportation is also going greener. DHL doubled its fleet of biofueled trucks in 2024, increasing from 18 to 37 vehicles. These trucks reduce carbon emissions by 83% compared to diesel models.

Adjusting the race calendar is another step toward sustainability. For example, the Japanese Grand Prix will move from September to April, and the Azerbaijan Grand Prix will align with Singapore. Starting in 2026, the Canadian Grand Prix will take place earlier in the year, streamlining the European leg and cutting down transatlantic travel.

"The change will make the future flow of our calendar not only more sustainable, but logistically more sensible for our teams and personnel. Our net zero by 2030 commitment continues to be a priority for us as a sport and it is thanks to changes like this that we are on track to hitting our goal."

- Stefano Domenicali, President & CEO of Formula 1

F1 teams are also rethinking materials. Starting in 2025, the Mercedes-AMG Petronas Formula One Team will use sustainable carbon fiber composites in its cars, incorporating recycled fibers and bio-based resins. Given that carbon fiber makes up about 75% of a car's structural components, this shift is a big step forward.

Technology Advances

As sustainability takes center stage, technology is playing a critical role in making these changes possible. Artificial intelligence and automation are revolutionizing logistics, helping teams manage the massive task of transporting around 1,200 tons of equipment per race. AI systems analyze traffic, weather, and road conditions to find efficient delivery routes, while predictive maintenance tools prevent equipment breakdowns. Real-time tracking systems also minimize human error.

Digital twin technology is making waves in logistics. These virtual replicas of warehouses and transport networks allow teams to test and optimize layouts, inventory management, and fleet routing before making changes in the real world.

The Aston Martin Aramco Formula One Team is a prime example of how advanced platforms are shaping F1 logistics. In 2025, the team expanded its partnership with ServiceNow to enhance operations further. Since 2023, ServiceNow has streamlined IT and facilities processes, centralized employee experiences, and improved data analytics for faster decision-making. The new phase of the partnership will extend these benefits to HR and finance functions (PEX Network, 2025).

Supply Chain Management (SCM) software is another critical tool, optimizing warehouse operations and distribution. Machine learning systems sift through large datasets to highlight key metrics that demand immediate attention.

Formula 1's collaboration with tech partners is fueling these advancements. For instance, its partnership with Globant has produced the Team Content Delivery System, which helps teams process trackside data more efficiently.

"The Team Content Delivery System will further evolve the ways teams consume and process key trackside data to support them in making faster and more informed decisions when they need it most."

- Chris Roberts, Director of IT at Formula 1

Emerging technologies like 5G, IoT, and edge computing are also streamlining post-race logistics. These tools enable real-time tracking, document management, and status updates, allowing teams to make quick, data-driven decisions that save time and cut costs.

Automation is set to expand further with the use of robotic fleets. Advanced platforms will coordinate these systems in warehouses and loading zones, ensuring smooth operations even as supply chains grow more complex. This kind of automation is essential for maintaining the high standards of performance that F1 demands.

Conclusion: The Art of Smooth Logistics

Packing up after an F1 race is no small feat. It’s a high-stakes operation involving hundreds of people, millions of dollars’ worth of equipment, and a race against the clock where even the tiniest mistakes can snowball into major issues.

Each team moves up to 50 metric tons (55 short tons) of gear for every Grand Prix, with logistics making up 10–20% of F1’s total industry spending - an eye-watering $200 million to $400 million annually. For individual teams, logistics budgets range between $8 million and $20 million per season, and just one air freight shipment can cost over $1 million per race. With numbers like these, every decision and every second count.

Even minor hiccups, like weather delays, can throw the entire operation off balance. These disruptions highlight just how delicate and tightly orchestrated the process really is.

To keep things running smoothly, teams rely on detailed packing strategies, work closely with logistics partners, and use custom-built containers to protect their high-value components. And it’s not just about speed - fairness is a critical factor. Teams ensure no one has access to their equipment until all shipments have arrived. Crossing international borders adds another layer of challenge, with strict customs regulations requiring meticulous planning.

Sustainability is also reshaping the way F1 approaches logistics. Transport accounts for 45% of the sport’s emissions, so teams are adopting sustainable aviation fuels and adjusting race calendars to align with F1’s goal of achieving net-zero emissions by 2030.

Precision is the backbone of F1 logistics. With DHL cargo covering 130,000 km (80,800 miles) each season and deploying up to seven Boeing 747s per event, there’s no room for error. By refining these processes, teams ensure the seamless execution that keeps F1’s high-speed spectacle roaring forward, race after race.

FAQs

How do F1 teams reduce the environmental impact of their global logistics operations?

Formula 1 teams are making strides to reduce the environmental footprint of their logistics operations by prioritizing efficiency and greener practices. Logistics plays a major role in the sport's carbon emissions, accounting for nearly half of the total. This includes the transportation of equipment and freight across the globe. To tackle this challenge, teams are turning to solutions such as more sustainable transportation options, smarter shipping route planning, and bolstering recycling programs.

Additionally, Formula 1 has joined forces with logistics experts to fine-tune operations and cut emissions further. These initiatives align with the sport's ambitious goal of reaching net-zero carbon emissions by 2030. This broader plan also involves energy-saving measures and carbon offset projects. By constantly improving their logistics processes, teams are working to reduce their environmental impact while ensuring Formula 1 remains a truly global spectacle.

What challenges do F1 teams face when transporting cars and equipment to international races?

Transporting Formula 1 cars and equipment across the globe is no small feat - it’s a meticulous process that demands careful planning and flawless execution. Teams start by breaking the cars down into key components, which are then packed into climate-controlled containers to keep them safe during transit. From there, they rely on a mix of air, sea, and road transport to get everything where it needs to go.

Timing is everything in this operation. Even a small delay can throw off critical race preparations. While air transport is often the go-to option for overseas events due to its speed, it comes with a hefty price tag and requires extra care to protect the delicate and expensive car parts. On top of that, teams must navigate customs regulations, stick to tight schedules, and handle millions of dollars’ worth of equipment - all while ensuring every piece arrives in perfect condition.

How do F1 teams manage post-race logistics to balance speed, cost, and sustainability?

F1 teams juggle speed, expenses, and environmental concerns in their post-race logistics by implementing smart strategies. Many rely on sea freight and biofuel-powered trucks to move equipment while cutting down on carbon emissions. Logistics partners like DHL contribute by using Sustainable Aviation Fuel (SAF), which helps lower emissions during air transport.

Teams are also upgrading to energy-efficient equipment and looking into alternative fuels to align with Formula 1's ambitious target of reaching net-zero carbon emissions by 2030. These measures allow teams to stay efficient while supporting the sport's push for a greener future.