Budget Caps and Aerodynamic Development in F1

Budget caps and ATR forced F1 teams to shift from spending to engineering efficiency, prioritizing high-impact aero upgrades, advanced CFD and 2026 prep.

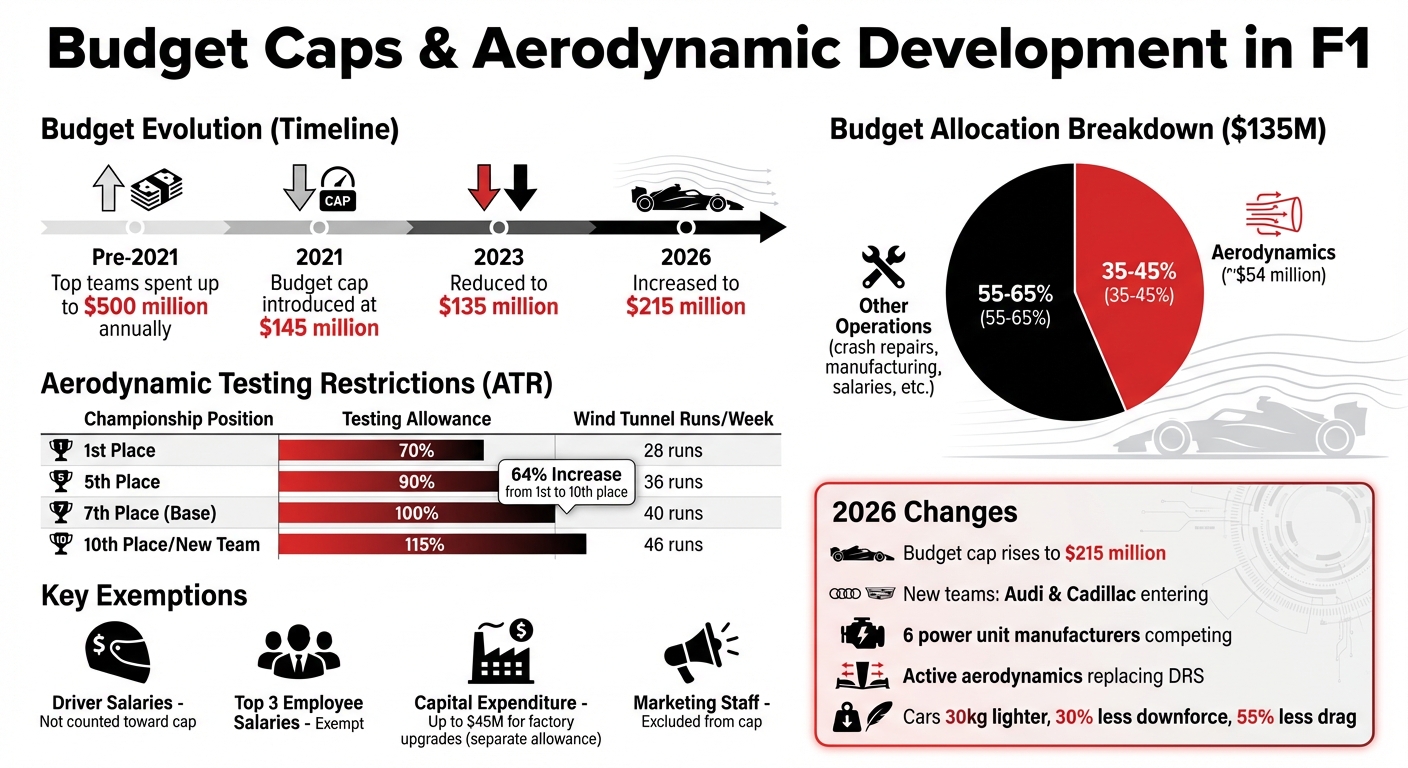

Formula 1's budget cap, introduced in 2021, reshaped the way teams manage resources, particularly in aerodynamic development. Starting at $145 million and reduced to $135 million by 2023, the cap aims to create a level playing field by limiting excessive spending by top teams like Mercedes and Ferrari, which previously spent up to $500 million annually. Alongside this, Aerodynamic Testing Restrictions (ATR) allocate more wind tunnel and CFD testing time to lower-ranked teams, further balancing competition.

Key points to know:

- Budget Cap Impact: Teams now prioritize spending, balancing crash repairs, aerodynamic upgrades, and long-term development.

- Aerodynamics Focus: Aerodynamics accounts for 35-45% of team budgets (~$54 million). Testing restrictions force efficiency, with top teams allowed fewer wind tunnel runs compared to lower-ranked teams.

- Challenges: Smaller teams face data correlation issues and manufacturing delays, while top teams manage reduced testing allowances.

- Solutions: Teams focus on impactful upgrades, advanced simulation tools like AI-driven CFD, and redirect funds from non-capped areas like driver salaries and factory investments.

- 2026 Changes: The budget cap rises to $215 million, with new technical regulations introducing active aerodynamics, lighter cars, and sustainable power units. New teams like Audi and Cadillac will also enter the competition.

The budget cap has shifted F1's focus from spending power to efficiency, pushing teams to innovate under financial and technical constraints.

F1 Budget Cap Impact: Spending Limits and Aerodynamic Testing Restrictions by Team Position

Problems Budget Caps Create for Aerodynamic Development

Reduced R&D Budgets

With the $135 million budget cap in place, teams are forced to make tough choices about where to allocate their resources. Crash repairs now eat into funds that would otherwise go toward wind tunnel testing and CFD simulations. This means teams must weigh the benefits of aerodynamic upgrades against the need to keep some budget reserved for potential damage. To cope, many teams delay their design-freeze dates to maximize wind tunnel usage and extend the lifespan of components, freeing up funds for aerodynamic development.

These financial constraints present unique challenges for both top-tier and smaller teams.

Different Effects on Top Teams vs. Smaller Teams

The budget cap doesn’t hit all teams in the same way - it’s a very different story for powerhouse teams like Mercedes and Red Bull compared to smaller operations. Larger teams, with their previously massive workforces of 800–900 employees, have had to downsize significantly to stay within the cap. While these teams have streamlined their operations, smaller teams face a different set of hurdles. Despite having more allotted testing time, they often struggle with aerodynamic data correlation and manufacturing limitations.

Top teams make the most of every wind tunnel run, thanks to years of refining their processes. Smaller teams, however, frequently face correlation issues, where their wind tunnel data doesn’t match real-world track performance. This mismatch diminishes the benefits of their extra testing time. On top of that, smaller teams often encounter manufacturing bottlenecks. They’re forced to prioritize crash repairs and routine maintenance over producing all the upgrades they design.

Testing Restrictions Based on Championship Position

The challenges don’t stop at budget constraints. Testing allowances, determined by the Aerodynamic Testing Restrictions (ATR), further complicate team strategies. This sliding scale system effectively penalizes success. For example, the championship-winning team is limited to just 70% of the base testing allowance, which translates to 28 wind tunnel runs per week. In contrast, the team finishing 10th gets 115% of the base allowance, or 46 runs per week - a 64% increase in testing capacity for teams lower in the standings. These allocations are recalculated twice a year: once at the start of the season based on the previous year’s standings, and again on June 30th based on current rankings.

| Championship Position | Testing Allowance (% of Base) | Wind Tunnel Runs per Week |

|---|---|---|

| 1st Place | 70% | 28 |

| 5th Place | 90% | 36 |

| 7th Place (Base) | 100% | 40 |

| 10th Place / New Team | 115% | 46 |

ATR rules don’t just limit the number of wind tunnel runs. They also cap active "wind-on" time and how long teams can occupy testing facilities. CFD usage is similarly restricted, measured by computing power units. For teams like Red Bull and McLaren, who shifted 90% of their technical focus to 2026 by mid-2025, this creates a tough decision: use limited testing time to refine their 2025 car for marginal gains, or invest in 2026 development where early aerodynamic work could yield more substantial performance improvements down the line.

Financial Regulations in Formula One - How the 145 million Dollar Budget Cap works

Solutions Teams Use to Optimize Aerodynamic Development

Faced with tighter R&D budgets and stricter testing limits, teams have leaned on three key strategies to push aerodynamic performance while staying within the cost cap.

Prioritizing High-Impact Upgrades

With limited resources, teams have fine-tuned their approach to upgrades by focusing on the components that deliver the most performance per dollar. Aerodynamic parts like the floor, rear brake duct inlets, and rear wings are consistently prioritized because they provide the greatest lap time improvements. Rather than spreading their budgets thin across numerous smaller updates, teams zero in on one major component at a time, aiming to maximize its impact.

This strategy extends to choosing between specialized track-specific aero packages or a more flexible, universal design that’s easier to manage with spare parts. Many teams also stick to the same mechanical layouts, such as chassis and gearboxes, for multiple seasons. By extending the lifespan of components - like designing suspension parts to last three races instead of two - they free up resources for aerodynamic advancements.

"We're geared-up to make sure there's minimum compromise on the aerodynamics side, because that's where a lot of the performance lives."

- Jody Egginton, Technical Director, Racing Bulls

Leveraging Advanced Simulation Technology

With restrictions on physical wind tunnel usage, teams have embraced Computational Fluid Dynamics (CFD) and artificial intelligence to streamline development. Machine learning and physics-informed neural networks now play a pivotal role, delivering feedback up to 100,000 times faster than traditional methods. For context, conventional CFD simulations can take 8–24 hours for a single configuration.

In 2022, the Mercedes AMG Petronas Formula 1 Team used AWS SageMaker and a design-of-experiments approach to refine their front wing geometries. This workflow tripled CFD throughput while cutting turnaround times in half. Similarly, in March 2024, researcher Ken Cheng demonstrated a hybrid method combining CFD with a neural network, achieving a 43% drag reduction and a 7% boost in downforce after training on 90 simulated designs. Currently, around 40% of F1 teams rely on Neural Concept's "NCS" aerodynamic AI, which acts as a co-pilot for designers, suggesting aerodynamic improvements.

"The technical office are, give or take, a couple of people, fully focused on the 2026 car now."

- Neil Houldey, Engineering Technical Director, McLaren

These cutting-edge tools, paired with strategic reallocations of funds, help teams push aerodynamic boundaries.

Redirecting Money from Non-Capped Areas

To protect their aerodynamic budgets, teams take advantage of regulatory exclusions. Salaries for drivers, marketing staff, and the top three employees are exempt from the $135M cap. This allows teams to hire top-tier technical directors without eating into their R&D funds.

Additionally, the Capital Expenditure (CapEx) allowance lets teams invest up to $45 million in factory upgrades through 2024, separate from the annual operational budget cap. These funds are used to modernize wind tunnels, install advanced CFD computing clusters, and improve manufacturing equipment - investments that directly boost aerodynamic development without affecting the capped budget.

"The more technology and more efficiency you can get into the production side of things, the more time you can devote to aero development."

- Jody Egginton, Technical Director, Racing Bulls

How Specific Teams Handle Budget Cap Challenges

Looking at how different teams tackle the budget cap sheds light on their unique aerodynamic development strategies. Red Bull Racing and Williams sit at opposite ends of the Formula 1 grid, yet both face distinct challenges that demand tailored approaches.

Red Bull Racing: Managing Success Penalties

Red Bull’s dominance comes with its own set of challenges, particularly in the form of restricted testing. As the 2023 championship winner, the team had significantly less wind tunnel time compared to lower-ranked teams. On top of this, they faced an additional 10% reduction in wind tunnel time due to a minor breach of the 2021 budget cap.

Even with these limitations, Red Bull managed to dominate the 2023 season, winning 21 out of 22 Grand Prix races with the RB19. They achieved this by focusing on upgrades that deliver maximum lap-time improvements while staying cost-efficient. To align with the budget cap, the team also reduced its workforce by over 90 positions starting in 2022, ensuring they maintained technical excellence within financial constraints.

Red Bull relies heavily on its proprietary simulation tools, which integrate real-time data to streamline production processes and delay design freezes. This approach maximizes the time available for aerodynamic research and development. By July 2025, Team Principal Christian Horner revealed that 90% of the team’s development efforts had shifted to the 2026 regulations. This strategic move allows the team to address balance issues on the 2025 car while making the most of their limited wind tunnel time.

While Red Bull leans on advanced technology to overcome its testing restrictions, other teams take different routes.

Williams: Investing in Better Facilities

Unlike Red Bull, Williams benefits from a more generous testing allowance due to its lower position in the standings. This advantage gives the team more wind tunnel time each week, enabling them to explore a wider range of aerodynamic concepts. Rather than focusing solely on short-term performance, Williams has chosen to invest in long-term infrastructure improvements.

The team has utilized the Capital Expenditure (CapEx) allowance, which permits up to $45 million in spending through 2024, to upgrade its facilities outside the operational budget cap. These upgrades aim to modernize manufacturing technology, reducing production times and extending the window for aerodynamic development. However, this transition hasn’t been without hiccups. At the March 2024 Australian Grand Prix, Williams had to withdraw Logan Sargeant, leaving only 19 cars on the grid, because they didn’t have a third spare chassis. Team Principal James Vowles explained that the team prioritized aerodynamic updates and complex car production over spare parts, leading to delays in their 8-10 week chassis production timeline.

"In terms of the chassis, if you put all of your resource – everything you possibly had within the organization on it – you could be eight, 10 weeks to pretty much get a chassis done."

- James Vowles, Team Principal, Williams

Williams has directed much of its increased testing capacity toward preparing for the 2026 regulation changes, rather than focusing on immediate updates for the 2025 car. By upgrading its infrastructure now, the team aims to build a foundation for stronger aerodynamic performance and future competitiveness, betting on long-term gains over short-term fixes.

Budget Caps and Aerodynamics After 2026

The $215 Million Cap for 2026

In 2026, the budget cap will rise to $215 million, giving teams the resources to juggle the demands of refining their 2025 cars while tackling next-generation designs. Ferrari Team Principal Frederic Vasseur describes this as a "complete reset", requiring teams to rebuild every aspect of their cars - tires, fuel, engines, chassis, and even the sporting regulations themselves.

This bump in spending power allows teams to run parallel development programs. The learning curve for the 2026 regulations is much steeper than for the more settled 2025 cars. Early investment in understanding the new rules could yield tenths of a second in lap time, whereas late-stage 2025 upgrades might only offer marginal improvements measured in hundredths. McLaren's Engineering Technical Director Neil Houldey acknowledged this shift, stating, "The technical office are, give or take, a couple of people, fully focused on the 2026 car now".

This financial boost not only provides breathing room but also lays the groundwork for the sweeping technical changes on the horizon.

Designing for New Technical Rules

The 2026 regulations bring a dramatic overhaul to aerodynamic development. Active aerodynamics will replace the traditional DRS system, introducing movable front and rear wings designed to optimize performance. These systems will operate in two distinct modes: "Z-mode" for cornering and "X-mode" for straight-line speed.

The chassis design will also see a major transformation. Teams will move away from the long ground-effect tunnels that have dominated recent seasons, opting instead for flatter floors and larger diffusers. This change aims to reduce the dependency on ultra-stiff suspensions and address the porpoising issues that have plagued cars in recent years. Key areas such as the outer sections of the front wing and new in-washing wheel wake control boards on the sidepods are emerging as hotbeds for aerodynamic innovation. According to F1 Correspondent Lawrence Barretto, "The outer sections of the front wing will also offer potential new areas of development and this will certainly be a critical battleground for teams".

Integrating the new power units presents another major challenge. The shift to a 50-50 power split between internal combustion and electric systems, alongside the adoption of 100% sustainable fuels, demands a more efficient design. Teams will need to accommodate entirely new power units while dealing with the removal of the MGU-H and reduced internal combustion engine output. Aerodynamicists face the task of maximizing performance despite simpler geometries, as overall downforce is expected to drop by 30% and drag by 55% to enhance efficiency and improve racing quality.

The new cars will also be at least 30kg lighter and feature a shorter, narrower profile. These changes, coupled with narrower tires, will require teams to rethink aerodynamic balance, weight distribution, and compliance with ongoing ATR restrictions.

New Teams Entering F1

The sweeping technical changes for 2026 have also attracted new competitors to Formula 1. A record six power unit manufacturers - Ferrari, Mercedes, Audi, Honda, Red Bull-Ford, and Renault (with Alpine switching to Mercedes power) - are set to compete, reshaping the competitive landscape. Additionally, two new teams, Audi and Cadillac, are preparing to join the grid with unique approaches to development under the budget cap.

New entrants will benefit from 115% of the base testing allowance, equating to roughly 46 wind tunnel runs per week. Teams falling more than 4% behind the top benchmark may also qualify for additional test time and budget flexibility under the Additional Development and Upgrade Opportunities (ADUO) system.

Audi is leveraging Sauber's established facilities to fast-track its progress, while Cadillac plans to use Ferrari power units and gearboxes initially, focusing on chassis and aerodynamic integration before aiming to develop its own engine by 2029. However, the road ahead won't be easy. Retired engineer Robin Ducker cautions, "For Audi it's a big wake-up call: this isn't WEC, this is the big boys club".

With enhanced testing allowances and these new measures, the hope is to tighten the competitive field and bring the grid closer together.

Conclusion: Balancing Cost Control with Performance

The budget cap has transformed the way Formula 1 teams approach aerodynamic development. Winning now depends on efficiency rather than outspending competitors. Andrew Green, Technical Director at Racing Point/Aston Martin, summed it up well: "I think those teams now are dinosaurs. You've got to be small, lean, efficient, and I think that's our strength". The era of massive budgets and unlimited testing is over.

To stay competitive, teams are adopting smarter strategies to enhance performance while staying within financial limits. Racing Bulls Technical Director Jody Egginton highlighted their focus on production technology to save manufacturing time: "The more technology and more efficiency you can get into the production side of things, the more time you can devote to aero development". This mindset - extending component lifespans, postponing design freezes, and prioritizing impactful upgrades - has become a common approach across the paddock.

These adjustments not only improve performance but also contribute to leveling the playing field. Testing restrictions and ATR measures provide lower-ranked teams with opportunities to close the gap, fostering a more competitive environment. As discussed earlier, success now relies on engineering creativity rather than unchecked spending.

Aerodynamics remains a cornerstone of F1 performance, even with tighter budgets. The game has shifted from who can spend the most to who can achieve the most with limited resources. Teams must juggle immediate improvements with future regulatory requirements, ensuring every dollar and testing hour counts. By focusing on resourcefulness, teams are redefining what it means to succeed under the budget cap. The cap hasn’t reduced the importance of aerodynamics - it has made the race to master it more intense and fair than ever.

FAQs

How do budget caps impact F1 teams and their aerodynamic development?

Budget caps in Formula 1, introduced in 2021, have dramatically changed how teams manage their resources and develop their cars. The FIA now limits core car development spending to around $130 million per season (2025 figure, with certain exemptions). This means teams must carefully decide where to allocate funds - whether on aerodynamic upgrades, spare parts, or other areas - rather than relying on endless budgets. For smaller teams like Williams or Alpine, this creates an opportunity to focus their spending on specific strategies, helping them close the gap with traditionally wealthier teams.

In addition, the FIA has implemented aerodynamic testing restrictions (ATR) to further balance competition. Under this system, teams that finish higher in the championship are allocated fewer wind tunnel and CFD testing hours for the following season. This approach rewards efficiency and creativity over raw financial power. While top teams still benefit from their advanced infrastructure and expertise, the combination of budget caps and ATR has brought more unpredictability to the sport. Midfield teams that manage their resources effectively now stand a better chance of competing for podium finishes.

How do F1 teams manage aerodynamic development under budget caps?

Under the $130 million cost cap, F1 teams must carefully manage their aerodynamic testing strategies. The FIA’s sliding-scale system plays a big role here, restricting wind tunnel runs and CFD (computational fluid dynamics) hours based on championship standings. Teams higher in the rankings get fewer resources, making every test count. To get the best results, teams focus on key areas like the front wing, bargeboards, and diffuser. They also lean heavily on high-resolution CFD simulations to refine designs before moving to physical tests, often reusing data to stretch their resources further.

Timing is another crucial factor. By finalizing aerodynamic designs early in the season, teams can shift their focus - and resources - toward future car development, such as planning for the 2026 regulations. Modular designs are particularly useful here, allowing teams to make smaller, cost-effective updates without pushing testing limits. This approach helps them strike a balance between current performance and long-term goals.

Budget allocation is equally important. Early in the season, when token allowances for aerodynamic work are higher, teams pour more resources into this area. As the year progresses, attention shifts to other priorities like the power unit or chassis. Teams also use selective outsourcing and streamline internal processes to stay within the budget while remaining competitive on the track.

How will the 2026 F1 regulations change aerodynamic strategies for teams?

The 2026 F1 regulations are set to shake things up, especially when it comes to aerodynamics. Teams will have to shift their focus toward ground-effect aerodynamics, making the car's underfloor the primary source of downforce. To support this, front and rear wings will be simplified, reducing their influence and cutting down on turbulence behind the cars. This change aims to promote closer racing but puts extra pressure on teams to perfect their underfloor and diffuser designs for peak performance.

Another big change is the introduction of active-aero elements and smaller DRS (Drag Reduction System) windows. Teams will now need to incorporate movable aerodynamic components that can only be activated in specific track zones. Add to that the updated power unit layouts and stricter cooling requirements, and it’s clear designers face a tough balancing act. They'll need to manage airflow effectively - not just for engine cooling and brake performance but also to optimize ground-effect efficiency.

On top of these technical challenges, teams must operate under a $130 million budget cap and adhere to strict Aerodynamic Testing Regulations (ATR), which limit wind tunnel runs and CFD (computational fluid dynamics) simulations. This means resources must be allocated wisely. To stay ahead, many teams are turning to modular floor designs and advanced simulations. In this new landscape, success will hinge on creating innovative underfloor geometries and making the most of the limited testing opportunities.