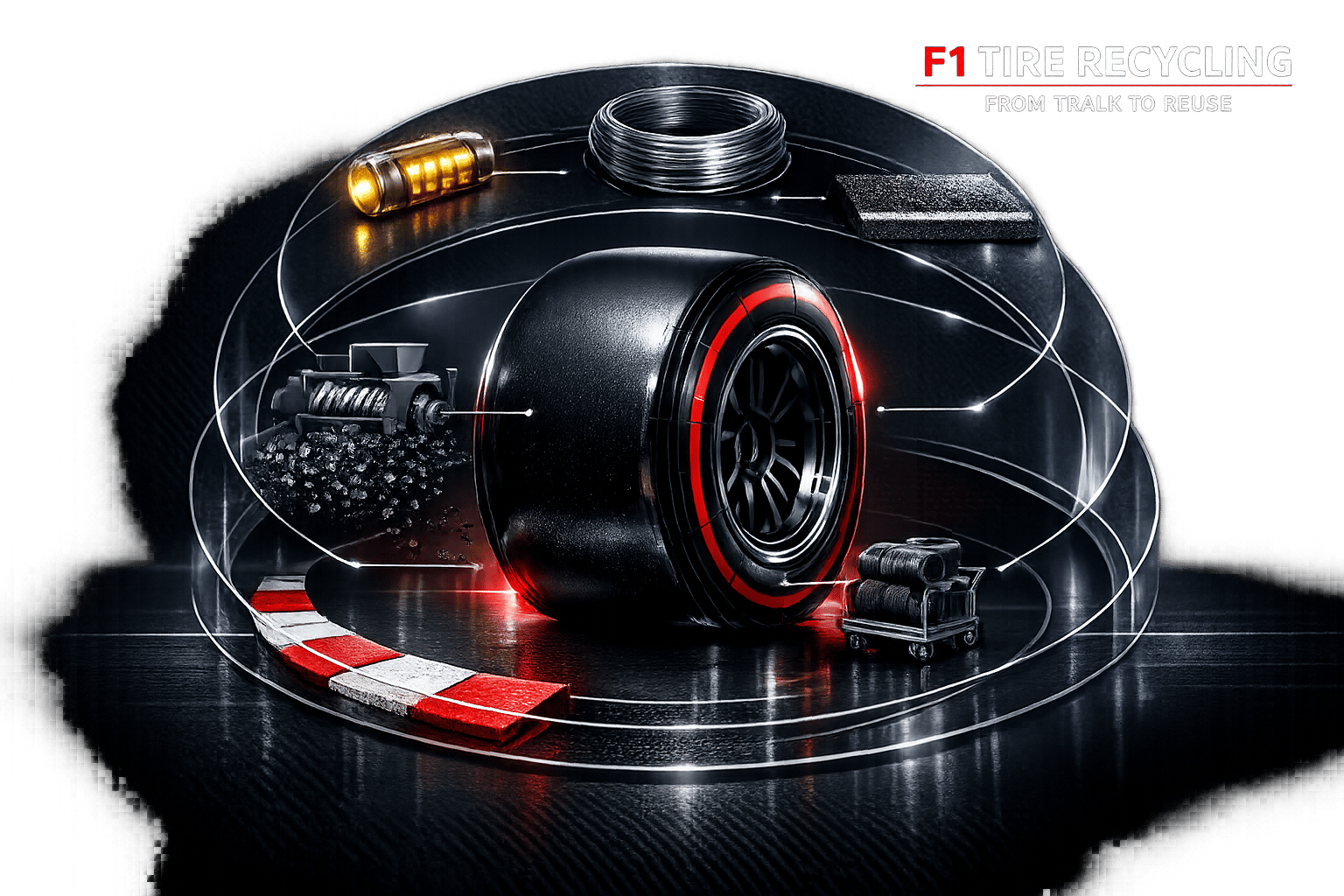

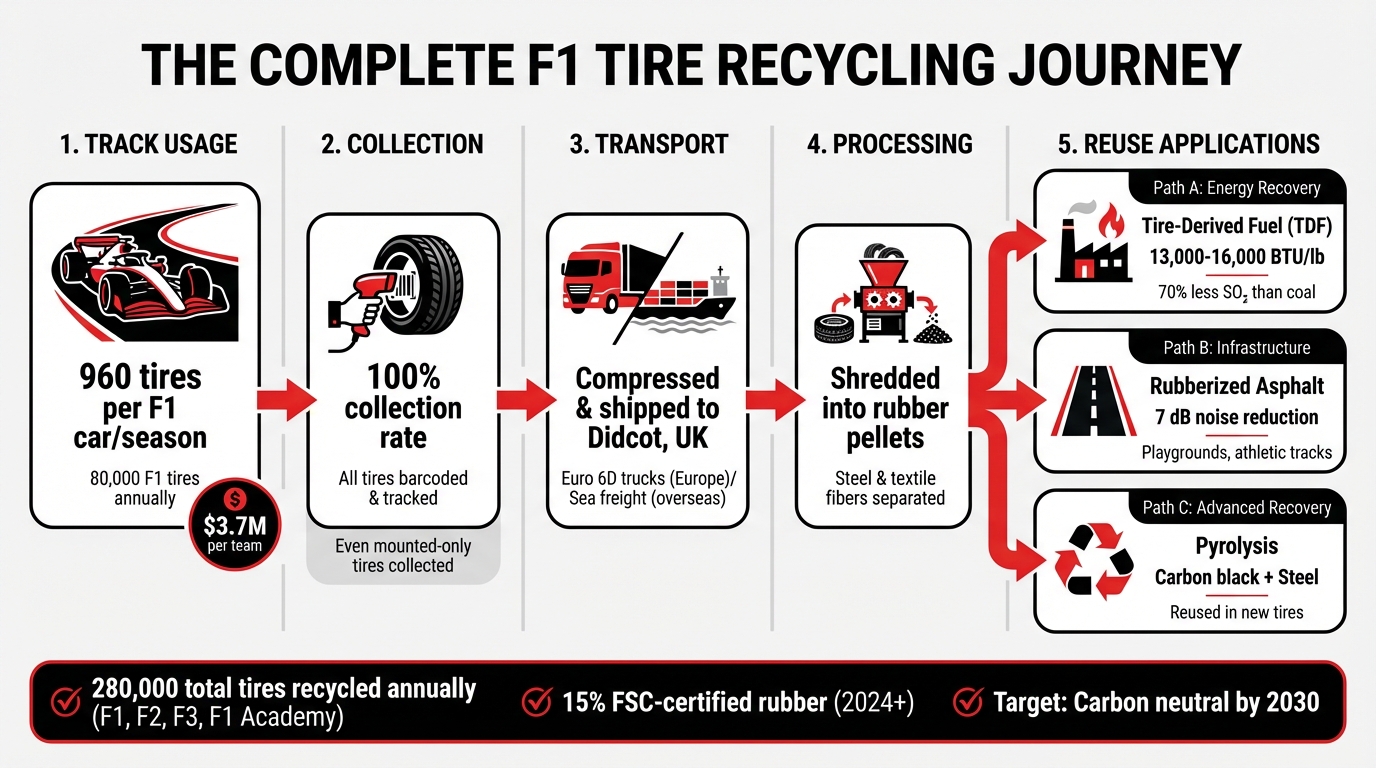

F1 Tire Recycling: From Track to Reuse

How F1 tires are collected, shredded and transformed into energy, recovered materials and rubberized asphalt—supporting F1's push toward carbon neutrality.

Formula 1 generates massive tire waste, with Pirelli recycling 280,000 tires annually across F1, F2, F3, and F1 Academy. Each F1 car uses up to 960 tires per season, costing teams over $3.7 million. Pirelli ensures 100% of these tires are collected, tracked, and processed for recycling, contributing to F1's goal of achieving carbon neutrality by 2030.

Key points:

- Tire Usage: 80,000 F1 tires recycled yearly; 280,000 including other series.

- Recycling Process: Tires are shredded into rubber pellets for fuel or repurposed for asphalt, playgrounds, and more.

- Energy Recovery: Rubber pellets power cement factories, reducing emissions compared to coal.

- Advanced Methods: Pyrolysis recovers carbon black and steel for reuse.

- Sustainability Milestone: FSC-certified rubber introduced in 2024, with 15% responsibly sourced materials.

Pirelli's program highlights efficient recycling and reuse, turning waste into resources while reducing environmental impact.

F1 Tire Recycling Journey: From Track to Reuse

Post-Race Tire Collection and Analysis

How Tires Are Collected After Races

At the end of every Grand Prix weekend, all tires - those used during practice, qualifying, and the race, as well as any unused sets - are returned to Pirelli. Each tire is embedded with a barcode at the circuit, a measure designed to protect the proprietary technology within and ensure meticulous tracking. This process guarantees that even unused tires meet the company's strict quality standards.

Interestingly, any tire that has been mounted on a rim is considered "used", even if it never touches the track. The mounting and removal process can potentially damage the bead, which makes it unsuitable for reuse due to safety concerns.

Once collected, the tires are compressed to maximize transport efficiency and then sent to Pirelli's facility in Didcot, England. For European races, this journey is handled by a fleet of Euro 6D trucks. For events outside Europe, sea freight is the preferred option, as it helps minimize the carbon footprint.

Performance Analysis and Data Use

Back at Pirelli's hub, the tires undergo a detailed performance evaluation. Engineers examine wear patterns, degradation rates, and structural integrity, while telemetry data from the cars - such as temperature, pressure, and forces - provides additional insights. This combination of physical inspection and data analysis plays a critical role in refining future tire compounds.

Using this information, Pirelli fine-tunes its six compound options (C1–C6) to identify the three best-suited for upcoming races. These decisions are often finalized just a couple of weeks before an event, ensuring the compounds are tailored to the latest track conditions and team strategies.

Mario Isola, Pirelli's Head of F1 and Car Racing, highlights the variability in tire performance:

"The life span of a tyre in a Formula 1 race can vary a lot depending on the conditions and the strategy. We've seen races where a driver can make a soft tyre last for more than 30 laps, but in other cases, they might need to pit after just a few laps."

This rigorous analysis also reduces reliance on physical prototypes, as engineers can adjust designs based on simulations and real-world performance data. By doing so, Pirelli ensures its compounds are not only efficient but also aligned with the demands of each race.

Transportation and Initial Processing

Shipping to Pirelli's Didcot Facility

After being compressed at the circuit, the tires are sent to Pirelli's engineering and logistics hub in Didcot, England. This facility acts as the main collection point for all Formula 1 tires. To maintain confidentiality, these high-performance compounds are mixed with road car tires upon arrival, making them harder to identify.

Security is a top priority throughout transportation. Tires are often shipped in unmarked trucks to protect the proprietary materials involved. Once they reach the facility, the recycling process kicks off immediately.

Mario Isola highlights the importance of both protecting sensitive information and promoting sustainability in handling tire returns:

"From day one, we collected all the tires, for confidentiality of course, but also to have the possibility to recycle them in a sustainable way."

Shredding Tires into Rubber Pellets

At the Didcot facility, the compressed tires are shredded into rubber pellets. During this process, steel and textile fibers are separated for recycling.

Since vulcanized rubber cannot be melted or remolded, shredding is the key step. These rubber pellets are then used in various recycling applications. One common use is as fuel in cement factories, where they are burned at extremely high temperatures - over 2,700°F (1,500°C). This ensures complete combustion and eliminates the risk of toxic emissions.

Tire-Derived Fuel (TDF) and Energy Recovery

After tires undergo initial processing, the resulting rubber pellets are transformed into a reliable energy source.

Using Shredded Tires in Cement Production

Rubber pellets produced in Didcot are sent to cement factories in Oxfordshire, where they serve as a primary fuel alternative. With a heating value of 13,000–16,000 BTU per pound, TDF rivals the energy output of approximately 1.2 tons of thermal coal per ton.

Cement kilns operate at extreme temperatures - 1,800–2,200°F (1,000–1,200°C) - ensuring complete combustion with minimal emissions. During this process, shredded tires are either fed as whole units into preheater chambers or as smaller chips (0.2 to 0.4 inches) injected into precalciner combustion zones. To maintain ash content below 5%, steel and textile fibers are removed. Interestingly, the steel belts in tires contribute iron to the cement mix, making them doubly useful. For example, Pirelli processes around 40,000 Formula One tires annually using this method.

Environmental Benefits of TDF

TDF offers several environmental perks compared to traditional fuels like coal. For instance, it emits roughly 70% less sulfur dioxide (SO₂) during combustion. The inclusion of natural rubber in F1 tires - comprising 15% of each tire's weight - also lowers the carbon intensity of the burning process.

Cement plants using a fuel mix of 40% scrap tires and 60% petroleum coke achieve significant emission reductions: 17% less nitrogen oxides (NOx), 28% less SO₂, and up to 60% less carbon monoxide (CO) at the kiln exit compared to petroleum coke alone. Additionally, the process generates useful byproducts like non-toxic fine ash and bitumen, which can be repurposed for road construction and roofing materials.

New Research and Reuse Methods

Formula 1’s efforts toward sustainability are driving fresh research into advanced material recovery methods. While burning tires for energy recovery is a well-established practice, the focus is shifting to recovering high-value materials for reuse. This approach prioritizes preserving the technological qualities of rubber rather than converting it into heat. Such advancements are opening doors to new applications, including improved asphalt mixes and cutting-edge pyrolysis processes.

Rubber Powder for Asphalt and Playgrounds

Recycled tires from F1 are finding a second life in infrastructure and safety applications. One prominent use is in Rubberized Modified Asphalt, which strengthens roads and improves resistance to cracking. Interestingly, adding rubber powder to asphalt can also reduce vehicle noise by as much as 7 decibels. As Pirelli's Motorsport Director Paul Hembery put it:

"The road surfaces that spectators drive on to get to grands prix in future could well be made up of some of our recycled tyres".

Beyond road construction, powdered rubber is used in shock-absorbing surfaces for athletic tracks, playgrounds, football pitches, and basketball courts. Its cushioning properties make it ideal for impact protection. In construction, it serves as acoustic insulation, anti-vibration layers, and materials designed to withstand earthquakes.

The industry is also venturing into chemical recovery techniques, with pyrolysis leading the charge.

Pyrolysis: Recovering Carbon Black and Steel

Pyrolysis is a process that involves heating tires in an oxygen-free environment, breaking down rubber into gas, mineral oil, and recovered carbon black. This recovered carbon black can be repurposed for use in the chemical industry or even reincorporated into new tire production. Additionally, steel reinforcements from the tires are separated and reused across various industries.

Microwave pyrolysis is a newer method that ensures more uniform heating, resulting in higher yields of pyrolytic oil and gas while producing fewer emissions compared to traditional methods. Globally, about 60% of end-of-life tires are processed through circular economy practices, with 40% contributing to the production of secondary raw materials. Mario Isola, Pirelli’s Head of F1 and Car Racing, highlighted the ongoing progress:

"At the moment, we recycle all the tires. There are also projects in the works to recycle the tires to create plastic materials, flooring".

Conclusion

F1's tire recycling program is a game-changer, repurposing 280,000 tires every year into useful materials. Once the tires leave the track, Pirelli ensures they're processed and transformed into resources for cement production and infrastructure projects. These recycled materials find new life in everything from construction to road development.

The move from basic energy recovery to advanced material recovery through pyrolysis marks a big leap forward. Pyrolysis allows for the recovery of carbon black and steel, which can be used in making new tires. Plus, rubberized asphalt created from F1 tires can cut road noise by as much as 7 decibels, and recycled rubber is used in playground surfaces and athletic tracks around the globe.

F1's commitment to sustainability begins long before the tires hit the track. Starting in March 2024, all F1 tires will include 15% responsibly sourced natural rubber from FSC-certified forests. This step aligns with the sport's broader mission to lower emissions and achieve carbon neutrality.

The numbers speak for themselves. F1 aims to slash CO2 emissions by 25% by 2025 and reach full carbon neutrality by 2030. While 60% of end-of-life tires globally are integrated into circular economy practices, F1 boasts a 100% collection and processing rate for its tires.

This program highlights how cutting-edge technology and environmental responsibility can go hand in hand. By investing in initiatives like FSC certification and pyrolysis research, F1 is setting a standard for how motorsports can reduce their environmental impact without compromising the spirit of competition.

FAQs

What steps does Pirelli take to recycle F1 tires after each race?

Pirelli takes responsibility for recycling all Formula 1 tires by collecting them after each race and transporting them to their facility in Didcot, UK. Once there, the tires are shredded into smaller pieces and processed under high heat to produce a non-toxic ash. This ash is then repurposed as an alternative fuel for cement production.

This approach underscores Pirelli's dedication to reducing waste and aligns with Formula 1's efforts to meet its environmental objectives.

How does using tire-derived fuel in cement production benefit the environment?

Using tire-derived fuel (TDF) in cement production offers a practical way to address both energy needs and waste management challenges. By repurposing old tires as an alternative energy source, it cuts down on the reliance on coal, which helps decrease greenhouse gas emissions. Cement kilns, with their high-temperature combustion process, effectively break down tires, leaving behind fine ash and releasing gases that are neutral to the environment. This method not only helps manage tire waste but also promotes cleaner energy use in industrial operations.

How is F1 advancing tire recycling technology?

Formula 1 is taking big steps to improve tire recycling, focusing on reusing materials without compromising performance. After race weekends, used tires are collected and processed using advanced techniques like shredding. This method separates the rubber, steel, and textile fibers, allowing the rubber to be repurposed into everyday products like shoe soles, floor mats, or even fuel for cement factories. Another approach, pyrolysis, extracts valuable materials such as carbon black and oil, which can be reused in manufacturing - including the production of new tires.

Teams are also testing recycled carbon fiber, a material that keeps up to 95% of its original strength while cutting emissions by as much as 90% compared to producing new carbon fiber. These initiatives are part of Formula 1's larger plan to reach net-zero emissions by 2030, reflecting the sport's commitment to sustainability and adopting circular economy principles.