How ERS Software Optimizes Hybrid Power Units

Explore how advanced software optimizes hybrid power units in racing, enhancing performance, efficiency, and adaptability on the track.

ERS software is the key to unlocking peak performance in hybrid power units, especially in Formula One. It manages energy recovery, storage, and deployment efficiently, providing up to 161 hp (120 kW) of additional power for 33 seconds per lap. Here's how it works:

- Core Components: The MGU-K recovers energy during braking, while the MGU-H converts exhaust heat into electricity.

- Energy Management: Advanced software balances energy recovery and deployment in real-time, ensuring efficiency and regulatory compliance.

- Battery Control: Lithium-ion batteries store energy, with software optimizing power flow based on race conditions.

- Temperature Control: Predictive algorithms maintain optimal operating temperatures for reliability and performance.

- AI Integration: AI enhances energy predictions, adjusts for driver styles, and improves heat management.

Quick Overview of ERS Benefits:

- Boosts Power: Adds up to 161 hp to the drivetrain.

- Improves Efficiency: Reduces fuel consumption with precise energy use.

- Adapts to Conditions: Tailors performance to track layouts and weather.

- Future Ready: Prepares for 2026 regulation changes, focusing on MGU-K improvements.

ERS software transforms hybrid power units into high-performance systems, blending efficiency with power. Dive into the article to explore its role in modern motorsport and beyond.

ERS Components in Hybrid Units

Motor Generator Units

In today's hybrid Energy Recovery Systems (ERS), two motor generator units play a key role. The MGU-K (Motor Generator Unit - Kinetic) captures energy during braking and can deliver up to 160 horsepower (120 kW). This makes it a critical component for energy recovery and performance enhancement.

The MGU-H (Motor Generator Unit - Heat), on the other hand, is connected to the turbocharger shaft and operates continuously. Its software performs several tasks: converting exhaust heat into electricity, controlling the turbocharger shaft speed to minimize turbo lag, and ensuring efficient power distribution.

| Function | Software Control | Performance Impact |

|---|---|---|

| Energy Recovery | Converts exhaust heat to electricity | Powers the MGU-K or charges the battery |

| Turbo Management | Regulates turbo shaft speed | Reduces turbo lag |

| Power Distribution | Manages energy routing | Optimizes energy delivery timing |

Power Storage Systems

Once energy is captured by the motor generator units, efficient storage becomes essential to ensure consistent power delivery. Modern ERS systems rely on lithium-ion battery packs, which are managed by sophisticated Energy Storage (ES) controllers. These controllers use advanced algorithms to regulate the flow of energy between components while adhering to strict technical regulations.

One standout feature of the ES controller is its ability to adapt energy routing based on race conditions. For example, it can transfer energy directly from the MGU-H to the MGU-K during high-demand moments, minimizing energy conversion losses and ensuring peak performance.

Temperature Control

Managing temperature is another vital aspect of ERS functionality. Predictive thermal modeling helps maintain components within their optimal operating range. Software algorithms dynamically adjust energy recovery rates based on real-time temperature data, ensuring the system remains efficient under varying conditions.

The system takes into account several factors, including the thermal state of components, track-specific cooling needs, ambient temperatures, and power deployment strategies. This precise approach to temperature management not only improves reliability but also ensures the ERS operates at peak efficiency throughout a race.

Software Energy Management

Energy Prediction Systems

Using advanced algorithms, energy prediction systems analyze real-time sensor data to optimize energy recovery, particularly in braking zones. These systems calculate the perfect balance between mechanical braking and energy recovery via the MGU-K (Motor Generator Unit-Kinetic). Several key factors influence this calculation:

| Parameter | Software Analysis | Impact on Recovery |

|---|---|---|

| Vehicle Speed | Tracks real-time velocity | Determines how much energy can be recovered. |

| Battery State | Monitors charge and temperature | Adjusts recovery rates to prevent overheating or overcharging. |

| Track Position | Uses GPS-based location data | Prepares for upcoming corners to maximize efficiency. |

| Weather Conditions | Relies on environmental sensors | Adapts recovery to conditions like rain or extreme heat. |

By combining these inputs, the software provides predictive insights that allow for dynamic, in-race energy adjustments.

Live Power Distribution

The Electronic Control Unit (ECU) plays a critical role in managing power distribution between the combustion engine and the electric systems in real time. This system ensures a seamless balance of power output while staying within regulatory limits, such as the 161 hp (120 kW) cap on ERS power output. Drivers can select from pre-programmed power maps, which adapt the ERS response to throttle inputs. This flexibility allows for strategic adjustments based on the race phase, whether focusing on acceleration, overtaking, or conserving fuel. The real-time coordination between software and hardware gives the hybrid unit a competitive advantage on the track.

Performance Results

The enhanced ERS software translates directly into better performance, boosting acceleration and improving fuel efficiency during key moments in a race. Whether it's powering through acceleration zones, executing overtakes, defending positions, or conserving fuel, the system delivers tangible benefits. Tools like AWS's "Hybrid Energy System" graphics provide teams with detailed lap-by-lap data on electrical energy usage. This visualization helps teams fine-tune their energy deployment strategies while offering a clear picture of the system's overall performance.

Formula One ERS Analysis

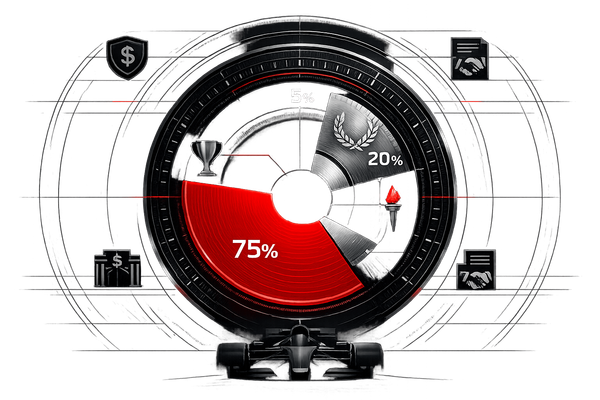

Race Performance

In Formula One, ERS (Energy Recovery System) software plays a pivotal role in shaping race outcomes by managing energy deployment during key moments. Teams fine-tune their software settings based on specific race phases to maximize performance:

| Race Phase | ERS Strategy | Software Configuration |

|---|---|---|

| Qualifying | Maximum Attack | Focuses on full power deployment to achieve the fastest lap times. |

| Race Start | Race Start | Delivers concentrated power for rapid acceleration off the grid. |

| Overtaking | Tactical Boost | Reserves energy for decisive passing opportunities. |

| Defense | Defense | Balances power usage to maintain position against challengers. |

Track-Specific Settings

ERS software isn't a one-size-fits-all solution - it adapts to the unique demands of each circuit. Track characteristics, like layout and conditions, shape how energy is recovered and deployed.

Take high-speed circuits, such as Monza, for example:

- Energy is deployed strategically on long straights.

- Recovery is maximized in the few braking zones available.

- Software is tuned to maintain consistent performance at high speeds.

On the other hand, technical circuits like Monaco demand a different approach:

- Rapid acceleration is optimized for exiting tight corners.

- Frequent braking points are leveraged for efficient energy recovery.

- Power delivery is carefully controlled to ensure precise traction.

Modern ERS systems now allow energy to flow directly between the MGU-K (Motor Generator Unit - Kinetic) and MGU-H (Motor Generator Unit - Heat), bypassing the battery. This minimizes conversion losses and improves efficiency. Environmental factors also come into play - at high-altitude tracks like Mexico City, where thinner air reduces engine performance, teams adjust ERS deployment to compensate.

What’s more, today’s ERS software uses predictive algorithms that analyze GPS data, historical performance, and real-time metrics. This enables dynamic energy management that adapts to evolving race conditions, competitor strategies, and even tire wear. By doing so, ERS software has become an indispensable tool for maintaining a competitive edge in Formula One.

Next-Gen ERS Software

AI Applications

AI is reshaping ERS software by using real-time telemetry to fine-tune energy management on the fly. Here’s how it’s making a difference:

- Smarter Predictions: Neural networks can forecast the best energy usage several corners ahead, outperforming traditional algorithms.

- Driver-Specific Adjustments: The software identifies individual driving styles and automatically adapts energy deployment to suit them.

- Heat Management: AI anticipates potential performance dips caused by heat and takes steps to prevent them.

Data from real-world implementation shows these AI-driven enhancements deliver a 5–8% boost in efficiency compared to older deployment maps. As AI continues to push performance boundaries, upcoming changes in regulations will require teams to innovate further.

Rules and Standards

With AI-driven strategies gaining traction, evolving regulations are set to redefine the framework for ERS software. The 2026 technical regulations, for instance, will eliminate the MGU-H component, signaling a shift in development priorities.

| Focus Area | Current Development | 2026 Target |

|---|---|---|

| Energy Recovery | Standard MGU-K and MGU-H systems | Enhanced MGU-K with 30% better recovery |

| Deployment Strategy | Balanced between two systems | Focused on single MGU-K optimization |

| Power Management | Split between heat and kinetic recovery | Emphasis on kinetic energy recovery |

To meet these changes, teams are working on modular designs aimed at maximizing the efficiency of MGU-K systems and improving algorithms for braking energy recovery. Security is also a growing priority, with encrypted firmware and hardware security modules (HSMs) now protecting control units.

Looking ahead, ERS software is expected to adopt a hybrid model, blending cloud computing for pre-race strategy simulations with edge processing for real-time decisions during races. This combination allows teams to craft detailed strategies while still making lightning-fast adjustments on the track. These advancements promise to make energy management even more precise, paving the way for more effective race strategies.

F1 Uncovered: How Do We Keep the ERS Cool?

Conclusion

ERS software has become a game-changer in the world of hybrid racing, blending cutting-edge algorithms with precision energy management to deliver both efficiency and power when it matters most.

Main Points

ERS software has transformed racing strategies by providing a boost in critical moments, such as overtaking, all while adhering to strict fuel efficiency standards. Let’s take a closer look at its impact and where it’s heading:

| Performance Metric | Current Impact | Future Direction |

|---|---|---|

| Power Output | 161 hp boost | Improved MGU-K efficiency |

| Total System Power | ~850 hp | Sustainable and reliable delivery |

| Energy Deployment | 33 seconds per lap | AI-driven optimization |

These advancements highlight how ERS software continues to redefine hybrid racing performance. With regulatory changes on the horizon - like the removal of the MGU-H component - teams will rely even more on optimized software to stay ahead. By pushing the limits of hybrid technology, ERS systems are not only enhancing performance but also addressing the growing call for environmental responsibility in motorsport.

FAQs

How does AI improve the efficiency and performance of ERS software in hybrid power units?

Artificial intelligence (AI) is transforming how Energy Recovery Systems (ERS) operate within hybrid power units, making energy management smarter and more efficient. By analyzing real-time data and adapting to changing conditions, AI optimizes energy recovery and distribution. This means power sources are used more effectively, leading to better fuel efficiency and lower emissions.

AI's role doesn’t stop there. It’s also a game-changer for predictive maintenance. For example, it can detect early signs of issues like battery overheating before they escalate into major problems. This not only boosts reliability and safety but also helps hybrid power units consistently perform at their best while ensuring they remain durable over time.

How will the 2026 Formula One regulations affect the development of ERS software?

Changes to ERS Software Development in 2026 Formula One Regulations

The 2026 Formula One regulations are set to shake things up, especially when it comes to the Energy Recovery System (ERS). One of the biggest updates? The electrical power output from the ERS will triple, jumping to around 350 kW. This boost means hybrid power units will have a much greater capacity for energy recovery, but it also puts more pressure on software development. Teams will need cutting-edge software to manage energy recovery and distribution efficiently, ensuring every ounce of performance is maximized on the track.

Another major shift is the removal of the MGU-H component, leaving the MGU-K to take center stage. Without the MGU-H, teams will have to rethink their strategies and develop innovative software to make up for the loss. The focus will be on perfecting energy deployment strategies to stay competitive and adapt to the new regulations. These changes will demand a blend of creativity and precision from software engineers to keep teams ahead in the race.

How does ERS software adjust energy management for different track conditions and race phases?

The Energy Recovery System (ERS) in Formula 1 Cars

The Energy Recovery System (ERS) in Formula 1 cars is powered by software that works tirelessly to adjust to track conditions and race phases in real time. By analyzing live data, it fine-tunes energy recovery and deployment to maximize performance at every turn.

Take heavy braking zones, for instance. Here, the software adjusts the Motor Generator Unit-Kinetic (MGU-K) to capture and store kinetic energy more effectively. This feature is especially useful on tracks with frequent or intense braking, where every bit of recovered energy can make a difference.

But the system doesn’t stop there - it also adapts energy deployment based on the demands of different race phases. During qualifying sessions, the focus shifts to delivering maximum power for the fastest possible lap times. In contrast, during the race, the software strikes a balance between performance and efficiency, ensuring consistent lap times while also helping to manage tire wear. This level of flexibility is essential for staying competitive under constantly changing race conditions.