How F1 Teams Adjust Setups for Track Types

F1 teams optimize car setups for different tracks, balancing aerodynamics, suspension, and tire performance to achieve peak racing efficiency.

Formula 1 teams tailor car setups to handle the unique challenges of each track. Whether it's the high-speed straights of Monza or the tight corners of Monaco, every circuit demands specific adjustments for peak performance. Here's a quick breakdown:

- Aerodynamics: Balance between downforce (for grip) and drag (for speed). High-speed tracks like Monza need low downforce for faster straights. Street circuits like Monaco require maximum downforce for cornering.

- Suspension: Stiffer setups for smooth tracks (Silverstone), softer for bumpy circuits (Monaco).

- Tires: Adjust pressure, camber, and compound selection based on surface type, temperature, and wear.

- Track Features: Elevation, corner types, and surface conditions dictate ride height and mechanical tweaks.

- Simulations & Testing: Teams use advanced simulators, practice sessions, and driver feedback to refine setups.

| Track Type | Aerodynamics | Suspension | Focus |

|---|---|---|---|

| High-Speed Circuits | Low downforce, drag | Stiff | Straight-line speed |

| Street Circuits | High downforce, grip | Soft | Cornering agility |

Every small adjustment matters, as it can mean the difference between victory and defeat. Read on to dive deeper into the science behind F1 car setups.

The ULTIMATE F1 24 SETUP GUIDE

How Track Features Determine Setup Requirements

Every Formula 1 circuit presents its own set of challenges, demanding precise adjustments to car setups. Track designers intentionally create layouts that push different performance aspects - whether it's top-end speed or sharp cornering ability. This means teams must fine-tune aerodynamics, mechanics, and tire configurations for each race, as explored below.

High-Speed Circuits vs. Street Tracks

High-speed circuits and street tracks represent two ends of the spectrum, requiring completely different car setups to meet their unique demands.

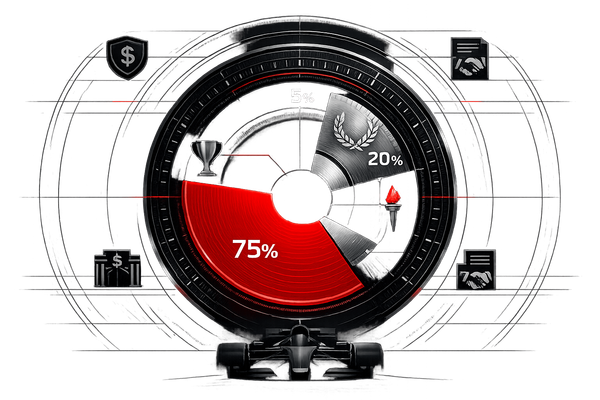

High-speed circuits, like Monza, are all about straight-line performance. At Monza, drivers spend approximately 75% of the lap with the throttle fully open. To maximize speed, teams strip away downforce-generating elements, sacrificing cornering grip for reduced drag. Suspension setups are stiffened to maintain stability through the few fast corners and heavy braking zones. It's a track that often requires a setup tailored exclusively for its demands.

On the other hand, street circuits like Monaco and Singapore demand maximum downforce. These tracks prioritize grip over raw speed, as their tight corners and narrow layouts require precision and agility. Teams adjust rear wings to steep angles and soften suspension settings to handle bumps and kerbs, enhancing mechanical grip while ensuring driver comfort.

| Circuit Type | Aerodynamic Setup | Suspension Configuration | Primary Focus |

|---|---|---|---|

| High-Speed | Low downforce, minimal drag | Stiff settings for stability | Straight-line speed |

| Street Tracks | High downforce, maximum grip | Soft settings for bumps | Cornering agility |

Tire strategies also differ between these circuit types. High-speed circuits can cause tires to overheat due to prolonged high speeds, forcing teams to balance grip with longevity to prevent performance issues. Meanwhile, street circuits like Monaco and Sochi typically have smoother surfaces, resulting in lower tire degradation compared to traditional tracks.

Key Factors: Elevation Changes, Corner Types, and Surface Conditions

Beyond general track types, specific features like elevation changes, corner variety, and surface conditions play a big role in setup decisions.

Elevation changes require careful adjustments to suspension and ride height. Spa-Francorchamps, with its dramatic height shifts, is a prime example. The iconic Eau Rouge/Raidillon section demands a setup that can handle rapid elevation changes without compromising aerodynamic efficiency .

Corner variety also complicates setups. Tracks with long straights, such as Monza or Spa, push teams toward low-downforce configurations, while twisty circuits like Monaco and Hungary rely on high downforce for optimal cornering. Many circuits combine fast and slow corners, forcing teams to strike a balance between competing demands.

Surface conditions add yet another layer of complexity. Track temperature, air temperature, and tarmac roughness all influence tire performance. For instance, at the 2020 Turkish Grand Prix, teams struggled to heat their Pirelli tires due to unusually cold and slippery conditions, leading to slower lap times.

Precision is everything. At Monaco, teams prioritize maximum downforce in qualifying by using higher ride heights and softer setups to maximize grip in tight bends. Similarly, Singapore’s Marina Bay Street Circuit, the only F1 night race, introduces unique challenges like reduced visibility and high humidity, while the Hungaroring’s narrow, twisty layout demands setups optimized for medium- and low-speed corners.

These intricacies explain why teams rely so heavily on simulation tools and data analysis. Each circuit's unique features create a puzzle that teams must solve to get the most out of their cars, and the stakes couldn’t be higher. A perfect setup can mean the difference between a podium finish and a frustrating weekend.

Aerodynamic Changes for Different Track Types

Just like fine-tuning mechanical and tire setups, adjusting aerodynamics is a major factor in turning a car's potential into performance. F1 teams carefully modify their aerodynamic packages to suit the unique demands of each track, whether it's a high-speed circuit or a tight and technical street track. These changes, from wing configurations to DRS strategies, often make the difference between leading the pack and falling behind.

Downforce and Drag Balancing

Finding the right balance between downforce and drag is one of the most critical challenges teams face on race weekends. Tracks like Hungary, Imola, Singapore, Spain, and Monaco demand high levels of downforce to maximize grip, even if it sacrifices top speed on straights. To achieve this, teams increase the angles of their wings, prioritizing cornering ability over straight-line speed.

On the flip side, circuits like Monza - where drivers spend roughly 75% of a lap at full throttle - require low downforce setups. Teams use streamlined rear wings to reduce drag and boost straight-line speed, even though this approach compromises grip in corners.

Aerodynamics in F1 have come a long way. Back in the 1990s, cars generated about 40–50% of their downforce from front wings and 50–60% from rear wings. Today, rear wings play a much larger role in creating downforce, making adjustments to this component even more critical when adapting to different tracks.

To tackle the variety of circuits on the calendar, teams typically develop three types of wing packages: low, medium, and high downforce. Low-downforce setups shine at tracks like Monza and Spa, while high-downforce configurations are essential for circuits like Hungary. Medium-downforce setups strike a balance for tracks with mixed demands.

Altitude is another factor that influences aerodynamic choices. At the Mexican Grand Prix, held at an altitude of 2,285 meters (about 7,500 feet), the thinner air reduces both downforce and drag. Teams compensate by using full-downforce setups that would typically create too much drag at sea level. This approach helps maintain grip without severely impacting straight-line speed.

DRS and Low-Drag Configurations

While static aerodynamic adjustments are important, dynamic tools like the Drag Reduction System (DRS) add another layer to a team's strategy. DRS, which reduces drag by opening a flap on the rear wing, can boost a car's speed by 10 to 15 mph on straights, providing a crucial advantage in overtaking scenarios.

Teams often factor DRS into their base aerodynamic setups, especially on circuits with long straights. This allows them to run higher downforce configurations while still achieving competitive straight-line speeds when DRS is activated.

The impact of DRS is evident in race situations. For example, during the 2021 Saudi Arabian Grand Prix, Max Verstappen gained a 20 mph advantage over Lewis Hamilton while overtaking with DRS. Similarly, tracks like Albert Park, which features four DRS zones, offer multiple opportunities for teams to capitalize on reduced drag.

DRS also plays a role in race strategies beyond overtaking. At the 2023 Singapore Grand Prix, Carlos Sainz deliberately kept Lando Norris within DRS range to help fend off faster competitors. Since its introduction in 2011, DRS has increased overtaking by around 10 moves per race.

However, DRS isn't always available. In rainy or unsafe conditions, the FIA disables it, requiring teams to rely on aerodynamic setups that perform well even without this tool.

Aerodynamics account for about 80% of the grip needed to achieve competitive lap times. The choices teams make in this area reflect the intricate balancing act that defines modern Formula 1 design and strategy.

Mechanical Changes: Suspension, Ride Height, and Differentials

When it comes to Formula 1, aerodynamic tweaks might steal the spotlight, but the car's mechanical setup is just as crucial for translating that aerodynamic grip into faster lap times. Adjustments to suspension settings, ride height, and differential configurations play a huge role in tailoring the car to the specific demands of each track. These changes influence how the car handles bumpy surfaces, navigates tight corners, and performs on everything from the winding streets of Monaco to the smooth asphalt of Silverstone. These mechanical tweaks also lay the groundwork for optimizing tire performance, which we'll dive into in the next section.

Suspension Setup for Bumps and Kerbs

The suspension is essentially the car's connection to the track surface, and getting the balance right between stiffness and flexibility is key. On smoother tracks like Silverstone, teams often opt for stiffer suspension setups. This approach sharpens handling and keeps the aerodynamic platform steady during high-speed turns. But for bumpier circuits like Sebring in Florida or Germany's Nürburgring, a softer suspension setup combined with a slightly increased ride height is necessary to prevent the car from bottoming out.

Engineers also fine-tune spring rates to adapt to track irregularities. This might involve tweaking gas pressure in the springs or swapping out specific metallic components for better responsiveness. For a track like Monaco, where tight corners dominate, teams may even add steering arms to improve maneuverability on the narrow streets. Adjustments to toe and camber angles further help ensure the tires maintain optimal contact with the track, enhancing grip through various cornering scenarios.

Ride Height and Ground Clearance

Ride height - the gap between the car's floor and the track - is one of the most critical variables in an F1 car's setup. Teams have to strike a delicate balance between aerodynamic efficiency and the risk of scraping the car's underside on the track. Lower ride heights (around 30–35 mm at the front and 75–80 mm at the rear) enhance stability and boost downforce by maximizing the air pressure differential around the car. On bumpier tracks, however, a higher ride height is necessary to avoid bottoming out.

"Simply put, the lower the ride height, the more the difference in air pressure above and below the car (Bernoulli principle in a nutshell), and more downforce is generated." - Harshit Jain

Take Monaco, for example: its uneven surfaces demand a higher ride height, while smoother circuits allow teams to lower the car to squeeze out maximum downforce. Another key factor is the rake angle - the difference in ride height between the front and rear - which influences weight distribution and overall handling. Static ride height can be adjusted using spacers or shims on suspension pushrods, while dynamic ride height depends on factors like suspension stiffness and tire pressure. In wet conditions, raising the ride height can even help reduce the risk of aquaplaning.

Once the car's stance is locked in, the focus shifts to fine-tuning how power is delivered to the wheels.

Differential Settings and Traction Control

The differential system, which manages how power is distributed between the rear wheels, is a critical tool for optimizing traction on a variety of track surfaces. F1 cars use limited-slip differentials, controlled by electro-hydraulic systems, to adjust torque distribution dynamically as the car moves through corners. These settings have a major impact on understeer and oversteer. For instance, a more locked differential provides better traction when exiting corners by limiting the inside wheel from spinning too fast, but it needs careful calibration to avoid destabilizing the car.

"Differential locking is a highly tuneable thing and has great effects on the handling of the chassis into, mid, and out of the corner. Think of this as power on, power off, and neutral throttle." - Hoffman900

A closed differential can lead to oversteer when the outside wheel receives more torque. For tight, slow-speed corners, a higher lock-up helps with hard acceleration and compensates for reduced downforce. On the other hand, faster corners often require less lock-up to reduce tire wear and prevent unnecessary scrubbing. Drivers can adjust differential settings on the fly via controls on the steering wheel, allowing real-time adaptations for different sections of the track. Additionally, electronic differentials provide engineers with even more flexibility, enabling them to program torque adjustments based on throttle input, steering angle, and other variables.

With drivers shifting gears roughly 50 times per lap - adding up to about 3,000 shifts in a single Grand Prix - getting the differential settings right is crucial for ensuring smooth and efficient power delivery during these rapid transitions.

Tire Setup: Pressure, Camber, and Compound Selection

Once the aerodynamic and mechanical setups are dialed in, the final piece of the puzzle is optimizing the tires. Tires are the car’s only connection to the track, so getting their setup right - adjusting pressure, camber, and selecting the proper compound - is critical. From the smooth surface of Silverstone to the tight, twisty streets of Monaco, these adjustments vary significantly to suit the unique demands of each track.

Tire Pressure and Camber Changes

Tire pressure is a delicate balancing act that directly affects how the tire meets the track. Teams typically run pressures close to the minimum allowed - about 25 psi at the front and 23 psi at the rear - to maximize grip. Temperature plays a big role here: for every degree increase in air or track temperature, tire pressure rises by roughly 0.1 psi. Engineers use this relationship, along with scaling factors (ratios between hot and cold pressures, usually between 1.2 and 1.5), to calculate the ideal cold pressures needed to hit target performance levels.

Modern sensors gather over 1,000 data points every second, feeding millions of simulations. This data helps engineers monitor tire temperature, wear, and performance in real time, enabling quick decisions about adjustments or pit strategies.

Camber adjustments work alongside tire pressure to fine-tune performance. Camber refers to the tilt of the wheel when viewed head-on, and teams usually set it to a negative angle to ensure that the outer part of the tire maintains optimal contact during cornering. Typical settings include about 3.5° of negative camber at the front and between 0° and 1° at the rear. While negative camber improves grip in corners by loading the outside tires, too much can cause uneven wear on the inside of the tire and hurt braking performance.

To understand how tires behave under different conditions - whether accelerating, braking, or cornering - teams use tire pressure mapping. This involves studying how the tire’s footprint changes under varying pressures and camber angles. Although dynamic footprint testing is banned, teams rely on static test rigs to gather this data.

Once pressure and camber are optimized, the next step is choosing the right compound for the track.

Compound Selection and Usage

After fine-tuning tire pressure and camber, teams turn their attention to compound selection. Pirelli provides three dry-weather compounds - hard, medium, and soft - for each race weekend. Drivers get 13 sets for a standard weekend (2 hard, 3 medium, 8 soft) or 12 sets for sprint weekends (2 hard, 4 medium, 6 soft). Choosing the right compound depends on track characteristics and historical data. Hard tires are better for abrasive surfaces and high temperatures, soft tires offer quick warm-up and superior grip for qualifying, and medium tires strike a balance between durability and performance.

Teams also analyze degradation curves for each compound to predict how tires will perform over a stint, especially when track conditions shift unexpectedly. A great example is the 2020 Turkish Grand Prix, where a newly resurfaced track offered minimal grip in both dry and damp conditions, forcing teams to rethink their compound strategies.

As Maurizio Boiocchi, Pirelli's executive vice president, puts it:

"There is a balance in a lot of the choices we have. The balance is a trade-off from performance, durability, and integrity. This is the magic in which we have to develop."

Mario Isola, Pirelli's motorsport director, adds:

"The grip of the tire is a function of the temperature. We try to design a compound with a wide working range as much as possible. We move this working window depending on where we want to use the tire."

Throughout the race weekend, teams continuously refine their compound choices using a mix of track data, historical trends, and real-time simulations. This meticulous process ensures that the tires, along with the car’s mechanical and aerodynamic setups, work seamlessly together on race day.

Testing and Validation: How Teams Confirm Setup Changes Work

Once setups are finalized, teams rely on cutting-edge simulators and on-track evaluations to ensure the theoretical improvements translate into actual performance gains.

Simulator Testing and Data Analysis

Modern racing simulators are incredibly advanced, operating with a latency of just 3–5 milliseconds to closely replicate real-world conditions. Engineers feed these simulators with GPS data, laser scans, and historical race data to create highly detailed track models. This allows teams to test a wide range of variables - like aerodynamic tweaks, tire pressures, suspension settings, and engine modes - before the car even touches the track. Simulators can also mimic weather changes and other dynamic race conditions, helping teams refine their strategies.

Driver feedback plays a huge role in this process, enabling engineers to refine setups in real time. Nick Yelloly from Aston Martin F1 explains how the simulator team collaborates with the track crew:

"We will do some pre-emptive set-up work to predict what they may ask for at the track. Sometimes, it isn't the direction they want to go, but it could give them extra information on ways not to go for Free Practice 2."

Yelloly elaborates on this dynamic relationship:

"We'll start working on correlation, making sure grip levels are correct, and ride height and downforce levels are aligned. Once we've done that, we will listen in to debriefs, driver comments and engineer thoughts. There are so many different departments in Formula 1 that it's quite a sizeable debrief length. As that's happening, we will start to get test requests from the track. I like to think of it as them using us as an extended test session, for stuff they couldn't get done in FP2 or ideas they have. Each direction they would like to try, they will send to us, and we give our feedback on yes or no, in terms of balance, feeling, drivability, general lap time consistency, and whether it's more of a qualifying set-up or race style."

To ensure simulated results align with real-world performance, teams rigorously calibrate and validate their simulators. This involves comparing simulator outputs with data collected on the track. Trust in the simulator's accuracy is critical, as it allows engineers to confidently apply simulation-based insights to actual race setups.

Regulatory changes can complicate this process. Yelloly highlights how Aston Martin had to recalibrate their simulator when Formula 1 introduced ground-effect cars and new tire designs:

"Every simulator will have some subtle form of latency, whether that's from the platform or tyre model behaviour. When we had our current simulator installed, we did a lot of work on trying to minimise that and getting the car feel correct, in terms of how it slides, what type of slide it is and how fast the car or tyre recovers. Then, [F1] changed the style of the car to ground effect and a different tyre. So, we had to do a different step to make this closer again, which we've managed to do."

The insights gained from simulators are then put to the test during track walks and practice sessions.

Track Walks and Practice Sessions

While simulators are powerful, on-track validation remains indispensable. Simulator data helps engineers focus on specific details during track walks, ensuring a thorough evaluation of the circuit.

Track walks are a critical part of the process, giving drivers and engineers the chance to assess the track's unique features - like curbs, bumps, sightlines, and runoff areas - that might not be fully captured in digital models. Even seasoned drivers benefit from this step. For example, Max Verstappen walked the Zandvoort circuit to familiarize himself with changes made since his last visit. Skipping a track walk can lead to costly mistakes, as Daniel Ricciardo learned when he damaged his car on a hidden culvert at the start line of his home race.

Practice sessions are the final stage of setup validation. Teams use these sessions to test baseline setups, evaluate new parts, and address any remaining uncertainties. Data from these sessions, combined with driver feedback, helps teams fine-tune their setups and finalize race strategies .

Lando Norris underscores the importance of real track time:

"You can do as many laps as you want on the simulator but still, when you get to the track, it's real and it's always different."

The pressure to optimize setups during practice is immense. Will Joseph, Lando Norris's race engineer, explains:

"After FP1, you just want to know anything you can do to make the car go quicker in FP2."

During a race weekend, teams analyze an extraordinary amount of data - up to 10,000 data points per second from 300 sensors on each car . Over the course of the weekend, a two-car team generates 11.8 billion data points, all of which are scrutinized to ensure setup changes are delivering the desired results.

The stakes are high - pole position times are often several seconds faster than the first flying laps on the softest tires. This highlights just how critical the setup validation process is. By blending insights from simulations with on-track testing, teams continuously adapt their setups to meet the unique demands of each circuit. Those who excel in this area gain a decisive edge in the relentless quest for speed.

Conclusion: The Science Behind F1 Setup Changes

Setting up a Formula 1 car is like solving a high-stakes puzzle, where every piece needs to fit perfectly to unlock peak performance. Each race weekend, teams face the daunting task of turning a baseline car into a finely tuned machine ready to conquer the unique challenges of a specific track.

The importance of these setup decisions can’t be overstated. As David Atwell explains: "The setting up of a car is extremely important in F1 and can make all the difference in the world when it comes to either taking pole position, not to mention a victory, or coming tenth if not lower". In fact, teams can shave an impressive five to ten seconds off lap times between the first practice and qualifying simply through meticulous setup adjustments.

What makes this process so intricate is the domino effect of every tweak. Adjusting something as seemingly simple as ride height impacts ground effect, grip, and weight distribution. To navigate these complexities, teams rely on massive amounts of data - Mercedes alone processes a staggering 10,500 GB of data per season. This data helps them understand how every variable, from cornering ratios to elevation changes, interacts with the car's performance.

Modern Formula 1 teams also leverage machine learning and advanced data analytics to uncover patterns that would otherwise go unnoticed. Real-time telemetry adds another layer of insight, offering instant feedback during practice sessions, which is critical given the limited track time - just three 90-minute sessions per weekend. With such tight windows, there’s no room for trial and error when fractions of a second can determine pole position.

Aerodynamics, which account for 90% of lap time differences, play a central role in these decisions. From wing angles to suspension geometry and tire pressures, every detail matters. Teams that master the art of interpreting track conditions and making bold, data-driven choices often find themselves with a decisive edge.

As Gareth Lewis succinctly puts it: "It's not just important, it's critical. A bad setup will cost time and that is the be all and end all in F1". This relentless focus on precision and performance is what makes Formula 1 such a fascinating blend of engineering and competition. Every finely tuned setup reflects the sport’s unyielding pursuit of perfection, where even the smallest adjustment can separate champions from the rest of the field.

FAQs

How do F1 teams adjust car setups for different types of tracks?

F1 teams meticulously tweak their car setups to strike the perfect balance between downforce and drag, tailoring their approach to the unique demands of each track. For high-downforce circuits like Monaco, where tight corners dominate, the focus shifts to maximizing downforce. This enhances grip and improves cornering ability, which is crucial for navigating the track's sharp twists and turns. On the flip side, low-downforce tracks like Monza, known for their long straights, require reducing drag to achieve higher top speeds.

To achieve this, teams adjust aerodynamic components, such as wing angles, to align with the specific challenges of the circuit. This careful balancing act ensures their cars are ready to tackle sharp corners or unleash maximum acceleration on the straights, depending on the demands of the race.

How does the Drag Reduction System (DRS) impact car setups for high-speed tracks?

The Drag Reduction System (DRS) Explained

The Drag Reduction System (DRS) plays a crucial role in fine-tuning car performance on high-speed tracks. By cutting down on aerodynamic drag when activated, DRS enables cars to hit higher speeds on straight sections. This not only makes overtaking easier but also boosts overall race performance.

When activated, DRS can add approximately 12 mph to a car's speed - an advantage that’s especially noticeable on tracks with extended straights. Teams carefully incorporate DRS into their car setups, aiming to strike the perfect balance between straight-line speed and cornering ability for peak performance during races.

How do F1 teams adjust tire pressure and camber for different track conditions?

F1 teams pay close attention to tire pressure and camber settings to get the best performance out of their cars, tailoring these adjustments to the unique demands of each track. Lowering tire pressure increases the tire's contact area with the track, which boosts grip - especially useful on high-speed circuits. But there's a trade-off: if the pressure is too low, tires can overheat and wear out faster. On the flip side, higher pressures help maintain tire structure and reduce wear, though this often comes at the cost of grip. Teams carefully balance these factors based on the track's surface and layout.

When it comes to camber adjustments, negative camber is a common choice to improve cornering. It ensures the tire stays in better contact with the track during turns, enhancing handling and reducing wear in those moments. However, pushing camber settings too far - particularly with excessive negative camber - can cause uneven tire wear and overheating, especially on circuits with tight, twisty sections. Teams fine-tune these settings for each race to deliver peak performance while keeping tire longevity in check.