How F1 Teams Meet Energy Recovery Standards

Explore how F1 teams are adapting their energy recovery systems to meet new regulations and enhance performance with sustainable fuels.

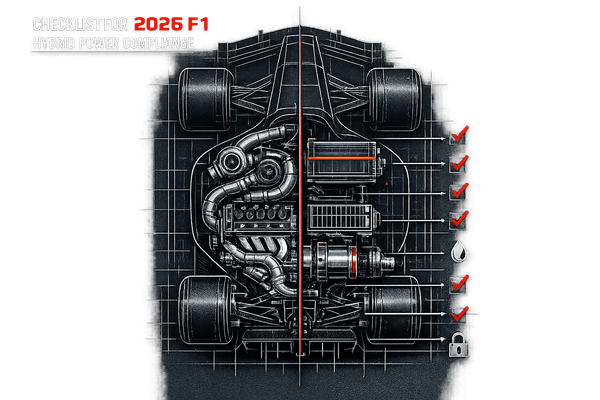

Formula 1 teams use advanced energy recovery systems (ERS) to boost performance and align with evolving regulations. These systems focus on recovering energy during braking and exhaust heat, storing it in batteries for later use. Key components include the Motor Generator Unit-Kinetic (MGU-K) and Motor Generator Unit-Heat (MGU-H). Starting in 2026, teams will face major changes, including:

- MGU-K power increase: From 160 hp to 475 hp.

- Energy recovery jump: From 2 MJ to 8–9 MJ per lap.

- MGU-H removal: Simplifying systems but requiring more from kinetic recovery.

- Power unit weight increase: From 151 kg to 185 kg to support larger batteries.

- 100% sustainable fuels: Mandated for all teams.

These updates will demand cutting-edge battery design, better energy management, and compliance with stricter FIA rules. By balancing power, weight, and recovery efficiency, teams aim to optimize performance while meeting the new standards.

Heat Energy Recovery I The F1 Power Unit Explained I Honda Racing F1

Main Components of F1 Energy Recovery Systems

Formula One's energy recovery technology revolves around three key components that work together to capture, store, and deploy electrical power. These systems are at the heart of the sport's cutting-edge hybrid technology.

Kinetic Energy Recovery Systems (KERS) and Motor Generator Units

Back in 2009, the introduction of KERS allowed teams to recover up to 60 kilowatts (82 horsepower) of energy during braking. Fast forward to 2014, and F1 regulations brought in the Motor Generator Unit-Kinetic (MGU-K) and Motor Generator Unit-Heat (MGU-H). The MGU-K captures energy typically lost as heat when braking and converts it into electrical energy for storage. Currently, it can recover 2 megajoules per lap and provide an extra 120 kilowatts (160 horsepower) of power.

The MGU-H, on the other hand, recovers thermal energy from the exhaust gases and turbocharger. Unlike the MGU-K, there’s no cap on how much energy it can recover. This energy can either be sent directly to the MGU-K or stored in the battery for later use.

Big changes are coming in 2026. The MGU-K’s power will jump from 120 kW (160 hp) to 350 kW (475 hp), and teams will need to recover 8–9 megajoules per lap, a massive increase from the current 2 MJ. However, the MGU-H will be completely removed, simplifying the system and shifting the focus entirely to kinetic energy recovery.

These developments will significantly reshape how teams approach battery design and energy integration.

Battery Systems and Energy Storage

At the core of the energy recovery system is the Energy Store (ES), which houses the lithium-ion battery packs that store energy captured by the motor generator units. These batteries are engineered to handle rapid charge and discharge cycles while maintaining reliability throughout demanding race weekends.

Under current rules, the maximum state of charge is capped at 4 megajoules. Although this limit will remain the same in 2026, the increased power output means the batteries will drain three times faster than they do now. This presents a tough challenge for teams as they develop next-generation batteries that can handle these demands without compromising performance.

The battery system must strike a careful balance. It needs enough capacity to store energy effectively while staying lightweight to avoid negatively impacting the car’s overall performance. As part of the 2026 regulations, the minimum weight of the power unit will increase from 151 kg to 185 kg, largely to accommodate the enhanced battery requirements.

During a race, teams carefully manage battery usage to balance energy deployment with fuel consumption and performance. Drivers can tap into stored energy for critical moments, like overtaking or defending their position, making energy management a key part of race strategy.

This delicate balance between energy capacity and weight will become even more crucial as the sport evolves under the new regulations.

Efficiency and Performance Integration

The seamless integration of these systems is one of Formula One's most impressive technical achievements. These components work together to maximize efficiency and performance while adhering to strict FIA regulations.

Currently, energy recovery systems add 160 horsepower, boosting the combined output of the hybrid power unit to around 870 horsepower. This integration also makes F1 cars more fuel-efficient by capturing and reusing energy that would otherwise be wasted as heat.

Advanced control systems manage the flow of energy between the MGU-K, MGU-H, and battery. Teams can transfer unlimited energy from the MGU-H to the MGU-K or the battery, giving them flexibility in how they manage energy during a race.

| Component | Current System (2014-2025) | 2026 System |

|---|---|---|

| MGU-K Power | 120 kW (160 hp) | 350 kW (475 hp) |

| Energy Recovery | 2 MJ per lap | 8-9 MJ per lap |

| MGU-H Status | Active (unlimited recovery) | Eliminated |

| Battery Capacity | 4 MJ maximum | 4 MJ maximum |

| System Weight | 151 kg minimum | 185 kg minimum |

The 2026 regulations will bring new challenges. With the removal of the MGU-H, teams will rely entirely on kinetic energy recovery while managing much higher power outputs. The increased electrical power will bring F1 closer to the levels seen in Formula E, signaling a major step toward greater electrification in the sport.

These changes highlight how F1 continues to evolve, blending performance with sustainability. As teams prepare for the 2026 season, energy recovery will play an even bigger role in shaping race-winning strategies.

FIA Regulations and Compliance Standards

The FIA enforces strict rules on Formula One's energy recovery systems, dictating how teams can harvest, store, and use electrical energy. These regulations aim to maintain fair competition while pushing the sport toward more sustainable practices.

Energy Limits and Recovery Restrictions

Under current rules, the MGU-K is limited to recovering 2 MJ of energy per lap, with a total ERS energy deployment cap of 4 MJ per lap. The MGU-K can deliver up to 120 kW (160 hp) of extra power, so teams must carefully strategize when to use this boost during a race.

The MGU-H, on the other hand, can recover unlimited energy from exhaust heat. However, any energy it transfers to the MGU-K or battery is still subject to the overall deployment cap. The FIA uses real-time telemetry to monitor energy flows, and any breach of these limits results in immediate penalties. This real-time oversight ensures all teams adhere to the rules, making compliance a critical part of race strategy.

Future Regulations and Fuel Requirements

While the current regulations present challenges, the 2026 rules will bring a significant overhaul. One major change is the elimination of the MGU-H system. The MGU-K's maximum electrical deployment will increase to 350 kW (475 hp), and teams will be allowed to recover between 8 and 9 MJ of energy per lap - nearly quadrupling the current limits.

These updates come with other adjustments, such as raising the minimum weight of the power unit from 151 kg to 185 kg to accommodate larger batteries and enhanced safety measures. Additionally, starting in 2026, all teams will be required to use 100% sustainable fuels. This shift has already prompted teams to work closely with fuel suppliers to ensure their engines perform efficiently with these advanced synthetic fuels.

Homologation and Monitoring

Every ERS component must undergo the FIA's homologation process. Teams must submit detailed technical specifications and documentation for approval, ensuring all components meet stringent safety and performance criteria[4].

Once the season begins, the FIA conducts regular inspections, audits, and real-time telemetry checks during practice, qualifying, and races to ensure compliance[8]. Penalties for violations can range from fines and points deductions to disqualification from races. Random inspections are also carried out to verify that hardware and software remain within their approved specifications.

Maintaining open communication with the FIA is essential for teams, especially as they prepare for the significant regulatory changes coming in 2026. These evolving rules will play a pivotal role in shaping energy recovery strategies moving forward.

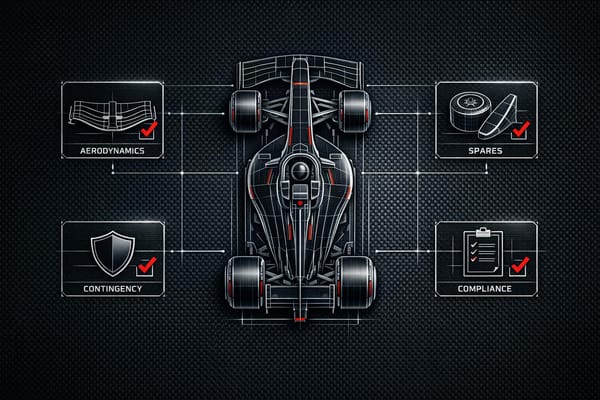

How Teams Implement Energy Recovery Strategies

Formula 1 teams take a detailed and methodical approach to developing their energy recovery systems (ERS). They combine cutting-edge simulation tools with rigorous on-track testing to ensure their ERS components deliver peak performance while adhering to the FIA's strict regulations.

Design and Simulation

The journey begins with advanced simulation tools like CFD and powertrain modeling. Engineers use these tools to predict how the MGU components will perform under various racing conditions. For instance, they simulate energy recovery during braking and capture exhaust heat to estimate how much energy can be stored within the regulatory limits.

These simulations are more than just theoretical exercises - they allow teams to experiment with different configurations without the need for physical prototypes. Engineers can fine-tune component placement, adjust electrical systems, and optimize battery capacity while balancing other factors like weight and aerodynamics. This stage is crucial for understanding how the ERS integrates with the Internal Combustion Engine (ICE), ensuring both systems work seamlessly together.

By focusing on energy capture from the MGU-K during braking and the MGU-H from exhaust gases, teams identify the most efficient designs. These virtual tests are the foundation for the next phase - real-world validation on the track.

Track Testing and Calibration

Once simulations are complete, teams move to the track to test their systems in real-world conditions. Using telemetry systems, engineers collect data on energy recovery rates during braking, battery charge levels, and energy deployment patterns. This information helps confirm that the systems operate within FIA limits and perform as expected.

Track testing is also about pushing the limits. Teams assess reliability under extreme conditions, such as high ambient temperatures or repeated high-energy braking. By fine-tuning the timing and intensity of energy deployment, they aim to maximize performance without compromising system stability. Engineers monitor metrics like recovery efficiency, battery performance, and thermal management to ensure the system holds up across various track conditions.

This phase often reveals gaps between simulation predictions and on-track performance. Engineers use these insights to refine energy management algorithms and improve deployment strategies, ensuring the system is race-ready.

Development and Updates

Armed with data from simulations and track tests, teams refine their ERS to meet current regulations and prepare for the future. Modular designs play a key role here, enabling software updates and hardware tweaks throughout the season. When the FIA introduces regulatory changes, teams can quickly adapt by updating firmware rather than overhauling hardware.

Seasonal upgrade allowances let teams implement hardware improvements, such as better battery management systems. They follow an agile process: test changes in simulations, validate them during practice sessions, and then deploy them in races. This iterative approach ensures ERS performance is continuously optimized using real-time race data.

Looking ahead to the major regulatory changes in 2026, teams are already rethinking their strategies. The new rules will allow energy recovery of 8 to 9 MJ per lap - nearly four times the current limit. This shift will require a complete overhaul of energy recovery methods and testing protocols to handle the increased power and storage demands.

| Current vs. 2026 ERS Specifications | 2024 Regulations | 2026 Regulations |

|---|---|---|

| MGU-K Power Output | 120 kW (160 hp) | 350 kW (475 hp) |

| Energy Harvested per Lap | 2 MJ | 8-9 MJ |

| Power Unit Weight | 151 kg | 185 kg |

| Power Split (ICE/ERS) | 80% / 20% | 53% / 47% |

To prepare for this shift, teams are investing in advanced simulation tools and digital twin technology. These tools allow them to model future ERS setups and ensure they're ready for Formula 1's transition to a more electrically-driven era.

Conclusion: The Role of Energy Recovery in F1's Future

Energy recovery systems have evolved from being simple performance enhancers to becoming integral to Formula One's competitive strategies and its commitment to environmental responsibility. This shift reflects the technological advancements and strategic hurdles discussed earlier. As teams gear up for 2026, ERS technology will play a crucial role - not just in clinching victories but also in meeting the sport's ambitious sustainability goals.

FIA technical leaders, including Nikolas Tombazis, have described the upcoming regulatory changes as a "moderate revolution". These changes will significantly enhance power and energy recovery capabilities, pushing teams to completely rethink their power unit designs. This isn't just about compliance; it's about competitiveness, as nearly half of the car's output is set to come from electric power.

The transition to sustainable fuels in 2026 adds another layer of complexity. Teams will need to align their energy recovery systems with fuels derived from sources like non-food biomass, municipal waste, or direct air capture. Successfully integrating ERS upgrades with these new fuels will be essential to navigating this dual challenge of electrification and sustainability.

History shows that adaptability is key to staying ahead. Teams that have dominated in the past have done so by mastering advanced ERS integration, gaining both performance and compliance advantages. Their success highlights the importance of treating energy recovery as a strategic asset rather than a mere technical requirement.

Beyond the racetrack, Formula One's advancements in energy recovery are already influencing the broader automotive industry, driving progress in hybrid and electric consumer vehicles. The sport's commitment to refining ERS and adopting sustainable fuels positions it as a vital testing ground for technologies that could shape the future of transportation. Teams that fully embrace ERS as both a performance driver and a sustainability tool will play a defining role in this next chapter of Formula One. The 2026 regulations aren't just rules - they're the blueprint for the sport's future.

FAQs

How will removing the MGU-H impact F1 teams' performance and strategies starting in 2026?

The upcoming removal of the MGU-H (Motor Generator Unit-Heat) in 2026 is set to shake up how F1 teams approach both performance and strategy. For years, the MGU-H has played a critical role by converting excess heat from the turbocharger into usable energy. Without it, teams will need to lean more heavily on the MGU-K (Motor Generator Unit-Kinetic) and other energy recovery systems to stay efficient and competitive.

This shift is likely to put a spotlight on engine reliability and fuel efficiency as teams adjust to having fewer options for energy recovery. Race strategies could also see a transformation, with teams needing to fine-tune how they deploy their limited energy reserves to extract the best possible performance during each race.

What challenges do F1 teams face in designing battery systems that meet energy recovery requirements without sacrificing performance?

F1 teams encounter numerous hurdles when designing battery systems for energy recovery. These batteries need to not only store and release energy efficiently but also remain lightweight and compact to preserve the car's speed and agility. Striking the right balance between durability and performance is another key challenge, as these systems must withstand extreme temperatures and intense stress during races.

On top of that, teams must adhere to stringent environmental rules and technical standards set by the FIA, all while striving to innovate and stay ahead of competitors. Achieving this demands the use of advanced materials, precise engineering, and rigorous testing to ensure the batteries are both reliable and capable of delivering top-tier performance on the track.

How are F1 teams adapting their energy recovery systems for the shift to 100% sustainable fuels, and what does this mean for the sport?

F1 teams are reworking their energy recovery systems (ERS) to prepare for the sport's ambitious switch to 100% sustainable fuels by 2026. These next-gen fuels are designed to maintain top-tier performance while significantly cutting carbon emissions, aligning with the sport's environmental goals without sacrificing speed or efficiency.

This shift demands updates to key ERS components like the MGU-K (Motor Generator Unit - Kinetic) and MGU-H (Motor Generator Unit - Heat). These upgrades aim to optimize energy recovery and overall efficiency. Beyond meeting F1's sustainability targets, this technological leap could also pave the way for advancements in hybrid systems, potentially shaping the future of eco-friendly road cars.