How F1 Teams Optimize Ride Height with Suspension

How F1 teams use suspension (pushrod/pullrod, heave springs, dampers) to control static and dynamic ride height, maximize downforce and limit plank wear.

In Formula 1, ride height - the distance between a car's floor and the track - is a critical factor for performance. A lower ride height increases downforce by improving airflow under the car, but it also risks excessive plank wear, which can lead to disqualification under FIA rules. Suspension systems play a key role in maintaining this balance, managing both static and dynamic ride height to maximize performance while staying within regulations.

Key points:

- Ride Height Basics: Front ride height is typically 30–35 mm, and rear is 75–80 mm. These values change dynamically due to downforce, braking, and cornering forces.

- Aerodynamics: Lower ride height improves downforce but can cause the car to bottom out, disrupting airflow and damaging the plank.

- Regulations: The FIA requires the underfloor plank to retain at least 9 mm of its original 10 mm thickness after a race.

- Suspension Systems: Pushrod and pullrod designs help adjust ride height. Heave springs and anti-dive geometry ensure stability under varying loads.

- Track-Specific Adjustments: Smooth tracks allow lower setups, while bumpy circuits require higher ride heights to avoid excessive wear.

Suspension tuning, including spring stiffness and damper settings, helps teams maintain optimal ride height across different tracks and conditions. This delicate balance is essential for achieving competitive performance without breaking the rules.

F1 Ride Height EXPLAINED: Sparks, Ground Effect, Risks & 2025 Controversy

What Is Ride Height and Why It Matters

Ride height refers to the distance between a car's floor and the track surface. It's measured both when the car is stationary (static) and while it's in motion (dynamic). For modern Formula 1 cars, the typical static ride height is about 1.18–1.38 inches (30–35 mm) at the front and 2.95–3.15 inches (75–80 mm) at the rear.

Static vs. Dynamic Ride Height

When the car starts moving, things get more complicated. Aerodynamic downforce compresses the suspension, altering the ride height. Braking forces the front of the car lower, acceleration pushes the rear down, and cornering causes the car to tilt, changing the floor's distance from the track.

This creates a tricky situation for teams. The car's setup in the garage may look perfect, but out on the track, the ride height is constantly shifting. With modern ground-effect cars generating over 60% of their total downforce from the floor, these changes are critical. A car that seems ideal while stationary might scrape the ground on a straight or lose its aerodynamic balance in high-speed corners.

These constant fluctuations in ride height directly affect the car's aerodynamic performance and pose challenges for staying within regulatory limits.

Regulatory and Physical Limits

Managing ride height isn’t just about performance - it’s also about following the rules. The FIA mandates a 10 mm (0.39 inch) thick plank, known as the skid block, under the car. After a race, this plank must measure at least 9 mm (0.35 inch) at four specific points, meaning it can only wear down by 1 mm (0.04 inch) during the event.

If the car is set too low, it risks bottoming out, which disrupts the airflow through the diffuser. This can also cause porpoising - a bouncing motion that makes the car harder to control. To avoid these issues and stay within FIA limits, teams often have to raise the car.

How Ride Height Affects Aerodynamics and Performance

A lower ride height improves the seal between the car’s floor and the track, enhancing diffuser efficiency and increasing downforce. This setup also reduces body roll, resulting in sharper handling during braking and cornering.

However, not all tracks allow for the same approach. On smooth circuits like Zandvoort, teams can use aggressive low setups to maximize downforce. In contrast, bumpy street tracks require higher ride heights to protect the plank from excessive wear. For example, during the 2025 season, Ferrari's SF-25 struggled at the Circuit of the Americas. The uneven asphalt, built on reclaimed swampland prone to subsidence, forced the team to raise the car, pushing it out of its optimal performance range.

"Whichever team has managed to put it [plank wear] to the front, that means they are actually able to run the car lower than the rest of us. So, this is something quite clever."

– Inaki Rueda, Sporting Director, Sauber

Leading teams like McLaren and Red Bull have found ways to shift plank wear toward the front of the car. This clever strategy allows them to keep the rear - where most of the downforce is generated - closer to the ground without exceeding wear limits at the back.

Suspension Components and Ride Height Adjustment

F1 Pushrod vs Pullrod Suspension Systems Comparison

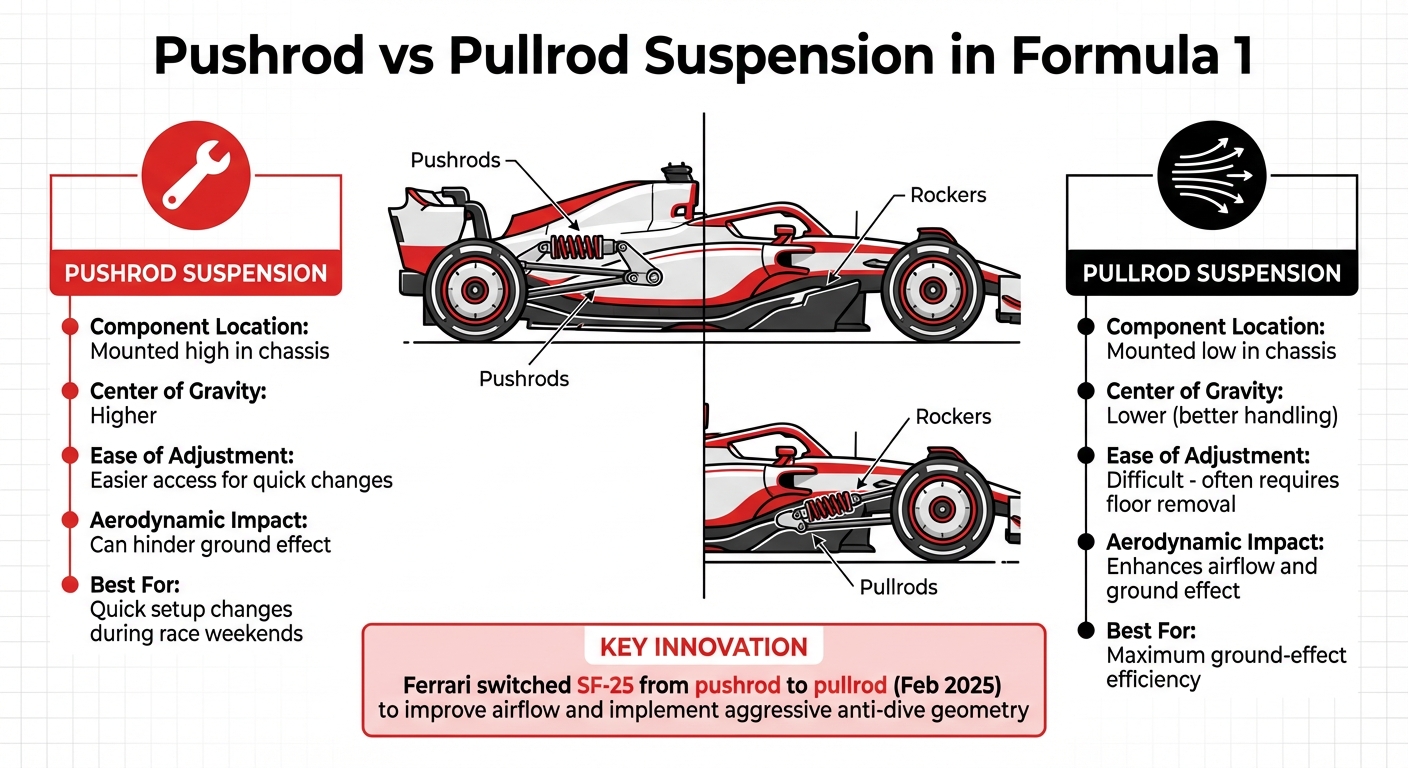

F1 suspension systems are meticulously designed to control a car's ride height, a crucial factor in performance. The choice between pushrod and pullrod suspension layouts significantly influences how teams adjust and fine-tune these settings during a race weekend.

Pushrod and Pullrod Systems

Pushrod systems position the springs and dampers higher in the chassis, making them more accessible for quick adjustments. On the other hand, pullrod systems mount these components lower, which helps lower the car’s center of gravity and boosts ground-effect efficiency. However, this design comes with a trade-off - adjustments are more challenging, often requiring engineers to remove the car's floor to access the front suspension.

Red Bull tackled this challenge on the RB18 by integrating static ride height adjustments into the external suspension components. As technical contributor Mark Hughes explained:

"Having the static ride height adjustment incorporated in the external part of the suspension is a beautiful detail of the Red Bull and gets around the more difficult access inherent in a pullrod layout".

Ferrari made a notable change in February 2025, switching the SF-25’s front suspension from pushrod to pullrod. This adjustment aimed to improve airflow around the car and implement more aggressive anti-dive geometry. Anti-dive setups reduce nose-down movement during braking, keeping the car stable and maintaining optimal underbody downforce. These changes also paved the way for more precise ride height adjustments in the garage.

| Feature | Pushrod Suspension | Pullrod Suspension |

|---|---|---|

| Component Location | Mounted high in chassis | Mounted low in chassis |

| Center of Gravity | Higher | Lower (better handling) |

| Ease of Adjustment | Easier access | Often requires floor removal |

| Aerodynamic Impact | Can hinder ground effect | Enhances airflow and ground effect |

Adjusting Static Ride Height

Once the suspension layout is chosen, engineers focus on fine-tuning the car’s static ride height. This involves using tools like shims, spring preload adjustments, and balancing corner weights. Anti-dive geometry is another critical area, achieved by positioning the suspension's upper forward links higher and the rear links lower. This configuration minimizes the rear’s upward movement during braking, ensuring a stable aerodynamic platform.

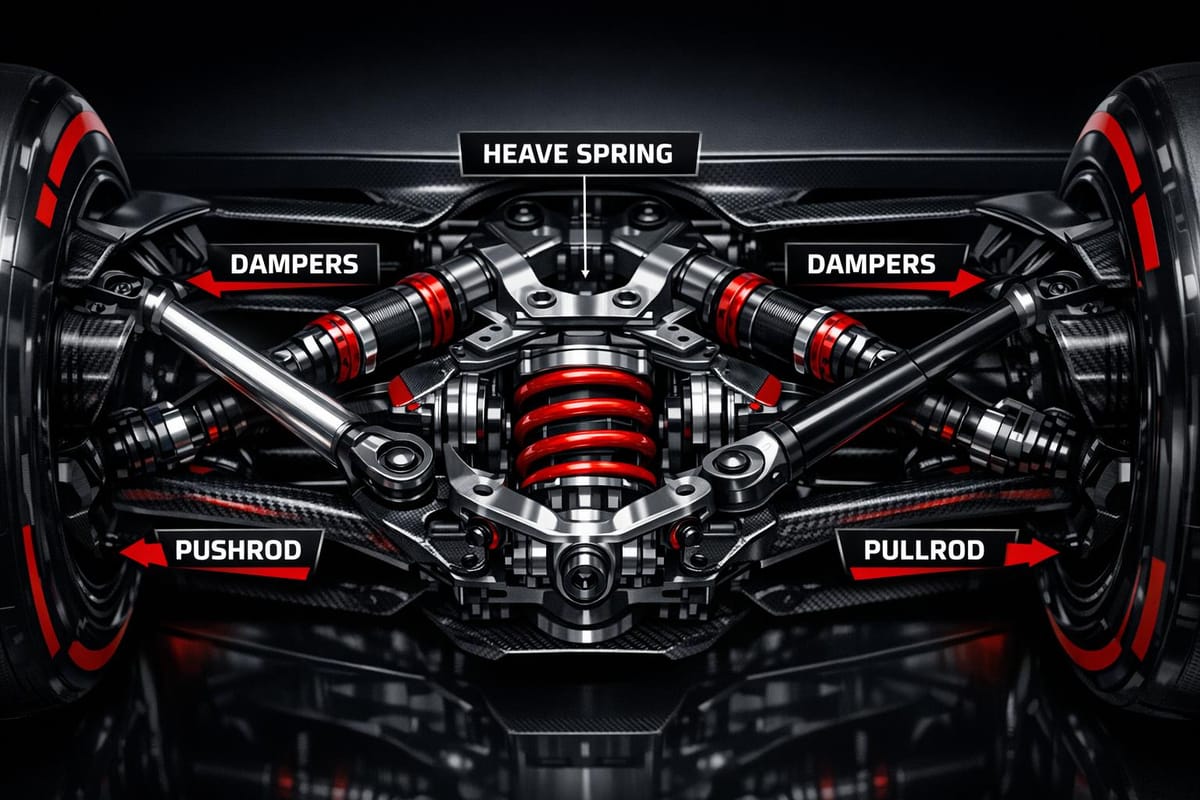

A key component in this process is the third spring - commonly referred to as the heave spring or T-bar. This device manages vertical movement independently of roll, allowing the car to stay low and stiff on straights under heavy aerodynamic loads while maintaining flexibility in corners. Achieving these precise adjustments requires cutting-edge measurement tools and techniques.

Tools and Techniques

To set the ride height with accuracy, teams rely on advanced tools like laser ride height sensors and setup pads. Managing plank wear is another critical factor, as exceeding FIA limits can result in penalties. Engineers often shift the primary wear point to the front of the plank, enabling the rear of the car - where most downforce is generated - to run lower. Sauber Sporting Director Inaki Rueda highlighted this clever approach:

"Whichever team has managed to put it [wear] to the front, that means they are actually able to run the car lower than the rest of us. So, this is something quite clever".

Managing Dynamic Ride Height Through Suspension Tuning

When an F1 car hits the track, dynamic forces come into play, compressing the suspension and altering the car's ride height. At high speeds, these cars generate several times their own weight in downforce. To handle this immense pressure, teams rely on a meticulous balance of springs, dampers, and suspension geometry.

Springs and Dampers

Once static adjustments are set, teams shift their focus to fine-tuning dynamic performance. A key tool in this process is the heave spring - also called the third spring or T-bar. This component allows engineers to separate vertical (heave) stiffness from roll stiffness. The result? The car stays firm under heavy aerodynamic loads on straights while maintaining enough flexibility in corners to keep tire grip intact.

Pneumatic springs have become a popular choice for their precision, offering teams greater control over spring rates and platform stability. Dampers, on the other hand, manage both compression and rebound, ensuring the tires maintain consistent contact with the track. Anti-roll bars also play a significant role, accounting for roughly 50% of the front roll resistance. This gives teams an additional tool to fine-tune cornering stability.

Balancing Stiffness and Compliance

Getting the balance right between stiffness and compliance is no easy feat. As Pat Symonds, a former F1 Chief Technical Officer, put it:

"This very limited ground clearance leads to needing extremely stiff springs to maintain the low ride heights under the immense downforce that's trying to compress the springs and tires".

However, going too stiff can lead to excessive tire wear and make the car harder to drive. On smoother circuits, teams often favor stiffer setups for better aerodynamic consistency and floor performance. But on bumpier tracks or street circuits, they soften the suspension to prevent the car from bouncing off curbs or damaging the underfloor plank. Additional tools like packers and bump rubbers help limit suspension travel, while adjusting tire pressures provides another layer of control for managing ride height.

On-Track Testing and Adjustments

Even with the best pre-season simulations, surprises can happen. During the 2025 United States Grand Prix in Austin, Ferrari's SF‑25 encountered unexpected skid block wear - something the team hadn’t anticipated during testing. To avoid penalties from the FIA, they had to raise the car’s ride height, sacrificing downforce in the process.

Real-time telemetry is crucial for validating suspension settings. Engineers study wear patterns on the underfloor plank to gauge how close the car is running to the track. Adjustments to suspension components are made in tiny increments - sometimes as small as 0.02 inches (0.5 mm) - to maintain an optimal aerodynamic window.

Red Bull showcased the importance of this approach in 2025. After introducing a new floor design at Monza in August, they adopted what Max Verstappen described as:

"It's more about a different philosophy... listening more to the driver, relying less blindly on data".

This shift allowed the RB21 to run at lower ride heights, contributing to three consecutive victories at Monza, Baku, and Austin.

Adapting Ride Height Strategies to Different Tracks

Circuit-Specific Setups

Every Formula 1 track brings its own challenges, requiring teams to fine-tune their ride height strategies to suit specific conditions. On smoother tracks like Silverstone and Zandvoort, engineers aim to run the car as low as possible with stiff suspension. This approach maximizes the ground effect, boosting aerodynamic performance.

On the flip side, bumpier circuits like COTA or Monaco demand a different approach. Teams often raise the ride height and opt for softer springs to avoid the car bottoming out. For instance, during the October 2025 race at COTA, Ferrari's SF-25 struggled with the uneven asphalt. The team had to raise the car, sacrificing some downforce as turbulent air entered from the sides. Meanwhile, Red Bull's updated floor design, introduced at Monza earlier that August, allowed them to run lower without exceeding plank wear limits. This innovation played a key role in their victories at Monza, Baku, and Austin.

Monaco, however, presents a unique set of challenges beyond just bumpy surfaces. The Fairmont hairpin, for example, requires an extraordinary amount of steering lock. To handle this, Mercedes-AMG F1 uses a specialized front suspension that offers about 40% more steering lock than what’s needed at tight corners like Montreal’s Turn 10.

These circuit-specific tweaks are just the starting point, with further adjustments often required to account for weather changes and evolving track conditions.

Weather and Track Evolution

Ride height decisions aren’t just about the track layout - they also depend heavily on environmental conditions. In wet weather, teams raise the ride height and use softer springs to maintain grip and reduce the risk of aquaplaning. Even in dry conditions, as the track "rubbers in" over the course of a race weekend and grip improves, teams may lower the car to gain additional downforce. However, this strategy comes with a risk: excessive plank wear, which could lead to disqualification.

Staying Within FIA Rules During Race Weekends

All these adjustments must stay within the boundaries of FIA regulations. The rules require the 10 mm under-car plank to retain at least 9 mm of thickness by the end of the race. To comply, teams often shift wear to the front of the plank, allowing them to lower the rear ride height without breaking the rules. Sauber's Sporting Director, Inaki Rueda, explained:

"Whichever team has managed to put it [plank wear] to the front, that means they are actually able to run the car lower than the rest of us. So, this is something quite clever".

Another challenge comes from parc fermé rules, which lock suspension settings after qualifying. This means teams must find the perfect balance between performance and compliance during their initial setups. Red Bull’s dominance in late 2025 showcased how critical it is to master this balance. Knowing exactly how low a car can run on different tracks proved to be a game-changer in their success.

Conclusion

Adjusting ride height in Formula 1 is anything but straightforward. It’s a meticulous process that blends aerodynamic efficiency, mechanical grip, and strict adherence to regulations. Teams depend on sophisticated suspension systems - like pushrod and pullrod designs, heave springs, and anti-dive geometry - to maintain "platform control." This ensures the car’s pitch and ride height stay within millimeter precision, allowing the floor and diffuser to produce optimal downforce without the risk of bottoming out. It’s this intricate dance of engineering and rules that drives the constant evolution in the sport.

One of the key challenges is the "stiffness paradox." To handle the immense downforce, the suspension needs to be extremely stiff, but softer settings are essential for maintaining tire contact during cornering. Heave springs offer a clever solution, providing high stiffness when both wheels compress simultaneously under heavy downforce, while still keeping the suspension flexible enough for cornering dynamics.

Regulations, like the FIA’s skid block rule, add another layer of complexity. Teams that effectively manage plank wear gain the advantage of safely lowering rear ride heights, which can unlock critical aerodynamic benefits.

On top of all this, teams must adapt their setups to suit different circuits and weather conditions. Smooth tracks favor low ride heights for maximum performance, while bumpier circuits require higher, more forgiving setups to ensure stability and grip.

FAQs

How do F1 teams adjust ride height to suit different tracks?

Ride height - the distance between a Formula 1 car's floor and the track - is a critical factor in both aerodynamics and handling. Lowering the ride height increases downforce by speeding up the airflow beneath the car, boosting grip without significantly increasing drag. However, teams must strike a delicate balance. A ride height that's too low risks the car scraping against bumps or curbs, and maintaining the proper rake angle (where the front is slightly lower than the rear) is essential for peak performance.

To handle the varying demands of different circuits, teams tweak the ride height through adjustments to springs, rake angle, and suspension geometry. On twisty, high-downforce tracks, the car is set slightly higher to improve cornering stability and avoid excessive drag. On the other hand, high-speed tracks call for a lower ride height and a steeper rake to enhance the underbody suction, delivering better performance. These adjustments allow teams to fine-tune the car's aerodynamics, grip, and stability to meet the specific challenges of each Grand Prix.

How do pushrod and pullrod suspension systems help F1 teams adjust ride height?

Pushrod and pullrod suspension systems play a crucial role in translating wheel movements into the car's internal suspension components. In a pushrod setup, the rod transmits force upward into the suspension when the wheel moves. On the other hand, a pullrod system works by pulling force downward as the wheel compresses. These systems are key in determining how suspension components are arranged relative to the car's floor, which directly impacts the car's ride height.

Pullrod systems are often preferred for their ability to lower the car's center of gravity and enhance aerodynamics. By positioning suspension components lower, teams can achieve a reduced ride height, which improves airflow beneath the chassis. This optimized airflow increases downforce, a critical factor for maintaining stability and performance, especially in high-speed corners and intense braking zones.

These systems also influence how the car reacts to braking and acceleration. Pullrod setups are known for improving anti-dive characteristics, helping keep the front end stable during heavy braking. Meanwhile, pushrod systems can be adjusted to fine-tune rear-end behavior. This level of dynamic control ensures consistent aerodynamic efficiency throughout a lap, providing teams with a valuable performance advantage on the track.

How do F1 teams prevent excessive plank wear to meet FIA rules?

F1 teams keep plank wear in check by carefully managing the car's ride height and suspension setup. The wooden plank beneath the vehicle serves as a compliance tool for FIA regulations, as excessive wear can lead to disqualification. To avoid this, engineers adjust the car's static ride height so that even under the immense aerodynamic downforce at high speeds, the plank doesn’t scrape the track.

Key suspension components - like springs, dampers, and anti-roll bars - are meticulously fine-tuned to handle bumps and prevent the car from bottoming out. Throughout race weekends, teams closely monitor plank wear, making minor tweaks such as raising the ride height or softening suspension settings. Using telemetry data and precise measurements, they aim to strike the perfect balance: maximizing downforce without exceeding the FIA's plank-wear limits.