How F1 Teams Use Telemetry for Predictive Maintenance

Telemetry lets F1 teams predict failures and extend component life by combining real-time sensor feeds, AI models, and digital twins.

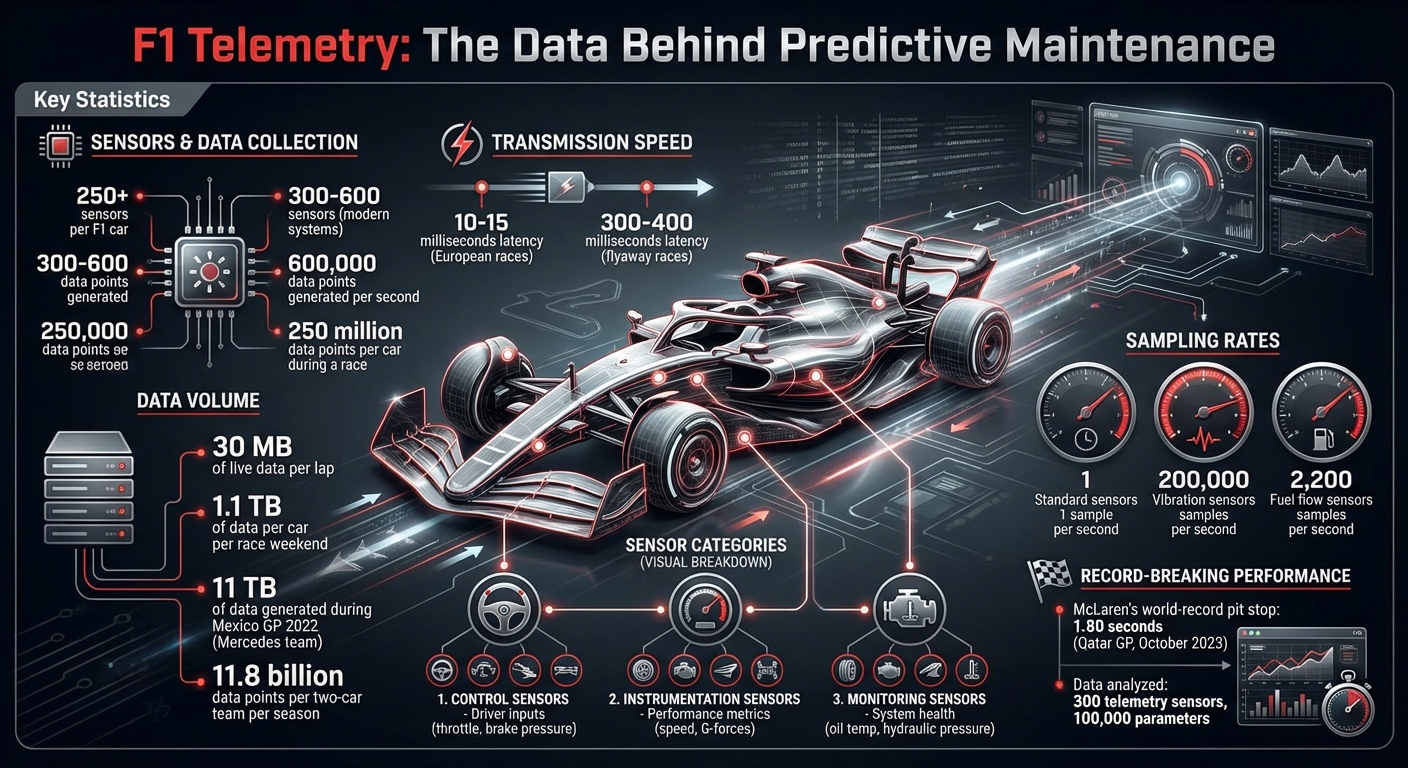

Telemetry in Formula One is all about using real-time data to keep cars running at their peak and prevent failures. F1 cars are equipped with over 250 sensors, generating up to 600,000 data points every second. This data helps teams monitor performance, predict potential issues, and make quick decisions during races.

Here’s the key takeaway: telemetry allows engineers to spot early warning signs of wear and tear - on components like brakes, tires, and engines - before they fail. For example, vibration sensors can detect mechanical problems invisible to the human eye, while AI tools analyze trends to predict when parts need attention.

F1 teams also rely on telemetry to fine-tune pit stop timing, adjust race strategies, and ensure drivers get the most out of their cars without risking a breakdown. From real-time alerts to long-term maintenance planning, telemetry is a game-changer for performance and reliability in one of the most demanding sports on the planet.

F1 Telemetry Data: Sensors, Data Points, and Real-Time Performance Metrics

The Amazing Role Of Data, AI And Cloud In Formula 1

How Telemetry Works in Formula One

At the core of every Formula One car is an Electronic Control Unit (ECU), essentially the car's brain. This system coordinates input from sensors scattered throughout the vehicle. These sensors communicate with the ECU via about 17 Controller Area Network (CAN) buses, which act as high-speed data highways, ensuring smooth communication between various systems. This setup allows for a seamless flow of data, enabling teams to analyze information from every part of the car in real time.

Christine Steven, Lead Electronics Development Engineer at Mercedes F1, sheds light on the sensor setup:

"There are over 250 sensors on the car during an average race weekend, and these can be divided into three main categories: control, instrumentation, and monitoring".

- Control sensors focus on driver inputs, such as throttle position and brake pressure.

- Instrumentation sensors measure performance metrics like speed and G-forces.

- Monitoring sensors oversee system health, tracking factors like oil temperatures and hydraulic pressures.

These sensors gather a wide variety of data, from tire pressures to vibration levels. For instance, Tire Pressure Monitoring Systems (TPMS) measure internal pressure and surface temperature, pitot tubes assess aerodynamic forces, and accelerometers record vibrations at up to 200,000 samples per second. Engine sensors monitor critical elements like fuel flow and energy recovery, ensuring no performance detail goes unnoticed.

Sensors and Data Points

The sampling rates of these sensors vary significantly. Some update once per second, while others, like vibration sensors, operate at incredibly high rates of up to 200,000 samples per second. This detailed monitoring generates approximately 30 MB of live data per lap and around 250 million data points per car during a race [5].

In October 2023, McLaren Racing set a world-record pit stop of 1.80 seconds for Lando Norris during the Qatar Grand Prix. Dan Keyworth, McLaren's Director of Business Technology, highlighted how the team utilized data from 300 telemetry sensors and 100,000 parameters, including wheel gun RPMs and car release timing, to shave off milliseconds [5]. This meticulous approach to data analysis directly contributes to on-track success.

| Sensor Category | Specific Sensor Types | Data Points Monitored |

|---|---|---|

| Tires & Wheels | TPMS, Thermal Imaging | Internal pressure, surface temperature, degradation |

| Engine & Power Unit | Pressure & Temperature Probes, Fuel Flow Meters | Oil/coolant temperatures, fuel usage, gearbox state |

| Aerodynamics | Pitot Tubes, Aero Pressure Sensors | Downward force, airflow behavior, drag, wing pressure |

| Chassis & Dynamics | Accelerometers, Displacement Sensors, Gyroscopes | G-forces, suspension travel, steering angle, vibration [5] |

| Driver Inputs | Potentiometers, Hall Effect Sensors | Throttle position, brake pressure, gear shifts |

Real-Time Data Transmission

The ability to transmit data in real time is critical for monitoring component performance and predicting maintenance needs. Every F1 team uses a standardized telemetry system, which is supported by a shared infrastructure around the racetrack. Evan Short, Team Leader of Trackside Electronics Systems at Mercedes F1, explains:

"The telemetry system is common across all the F1 teams, so there's quite a big infrastructure around the racetrack to ensure we get 100% coverage. That system is common to all the teams, a unique example of cooperation between the F1 teams".

This infrastructure includes strategically placed masts and radios to eliminate any dead zones. Data transmission is impressively fast, with live telemetry being processed within 10–15 milliseconds during European events. Daniel Boddy, Manager of Trackside and Technical Support at Mercedes F1, notes:

"The live data, such as on car telemetry or voice or video calls in a European event, are processed within 10 to 15 milliseconds, almost instantaneous".

For races held in distant locations like Australia or Japan, satellite links are used, increasing latency to 300–400 milliseconds. Even with this slight delay, the system remains fast enough for real-time decision-making.

During the 2022 Mexico GP weekend, the Mercedes-AMG Petronas F1 Team generated approximately 11 TB of data, which was shared between the trackside team and their two factories. This constant data flow supports engineers in running simulations and delivering strategic recommendations to the pit wall. When the car returns to the garage, even more detailed data is offloaded - up to two or three times the live telemetry volume - for deeper analysis. This process ensures that every piece of information contributes to refining race strategies and improving performance.

Using Telemetry for Predictive Maintenance

Telemetry has revolutionized how teams approach maintenance, shifting the focus from reacting to failures to proactively preventing them. By analyzing data from hundreds of sensors, teams can predict potential issues before they lead to costly breakdowns.

Modern F1 cars are equipped with 300 to 600 sensors, collecting data on everything from temperature and pressure to torque and speed. Engineers keep a close watch on critical systems - like the gearbox and hydraulics - looking for any signs of trouble. For example, high-frequency vibration sensors, which can sample up to 200,000 times per second, catch mechanical issues invisible to the human eye.

Monitoring Component Wear and Tear

F1 components endure intense stress throughout a race weekend. To stay ahead of potential failures, teams use AI-driven predictive models that analyze both historical data and live telemetry. By comparing real-time sensor readings to established benchmarks, these systems can flag components that are wearing out faster than expected, potentially avoiding a dreaded DNF (Did Not Finish).

One example of this technology in action is the Atlas software used by the Mercedes-AMG Petronas F1 Team. Developed by McLaren Applied, Atlas allows engineers to monitor gearbox performance and practice starts in real time. Engineers like Chris Nelson use it to simulate scenarios and ensure components are operating within safe limits.

Another powerful tool in this process is the digital twin - a virtual replica of the car. By running simulations with both historical and live telemetry data, engineers can predict performance issues and identify early signs of wear. Geoff McGrath, Chief Innovation Officer at McLaren Applied Technologies, explains:

"We measure whatever we need to manage during the race, and then we model to get the predictive intelligence on how the cars are going to perform".

These insights guide preemptive repairs and strategic adjustments, helping teams stay ahead of potential problems.

Detecting Performance Anomalies

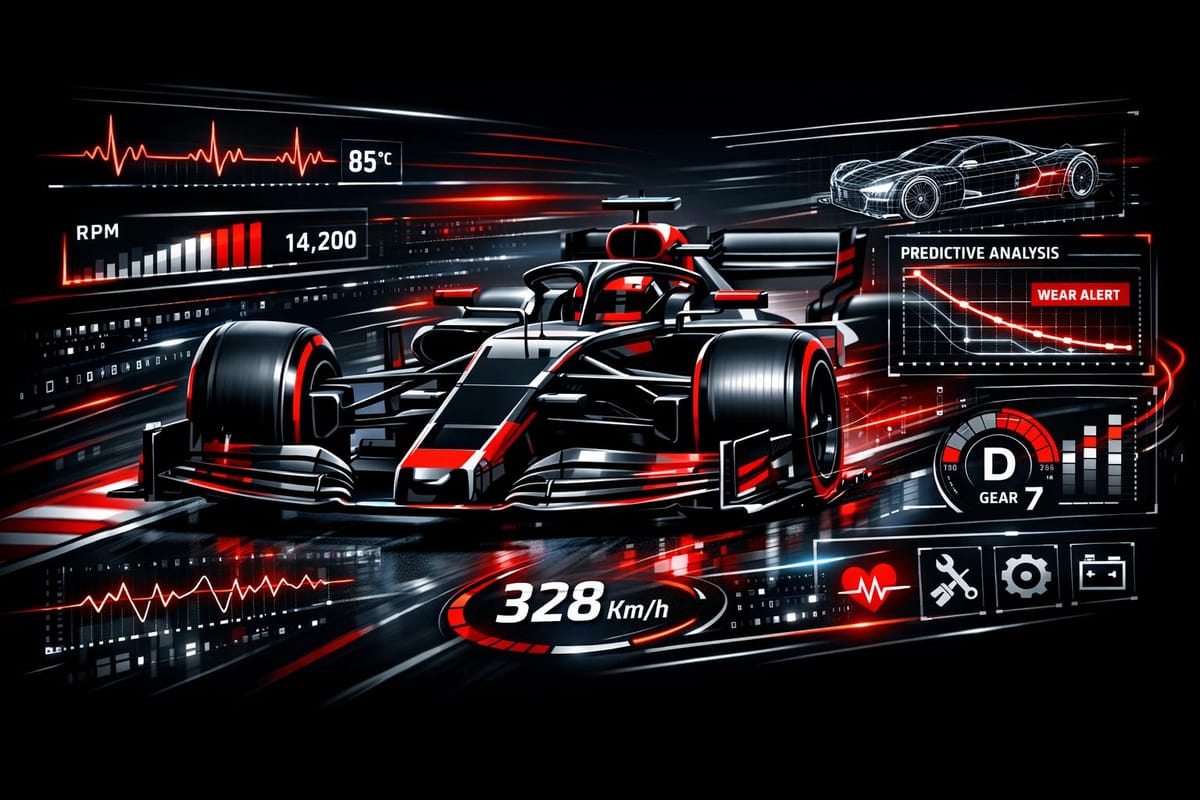

Telemetry is also invaluable for spotting subtle performance irregularities that could signal mechanical trouble. Systems continuously track metrics like brake balance, power unit stress, battery temperature, tire wear, and gearbox health. When anomalies occur, engineers are alerted immediately.

For instance, thermal imaging sensors monitor tire surface temperatures in real time, helping teams prevent blowouts or sudden performance drops. Similarly, vibration analysis can detect issues like bearing wear or loose components well before they become critical.

AI dashboards play a crucial role here, instantly flagging issues and enabling engineers to make real-time adjustments. Drivers might be instructed to change their pace, switch engine modes, or tweak braking behavior to reduce stress on the car. As noted by IMD research:

"AI models enable predictive maintenance by analyzing historical and live telemetry data to anticipate component failures before they happen, often making the difference between a podium finish and a DNF".

These real-time insights not only protect the car but also refine race strategies.

Pit Stop Strategies Based on Predictive Data

Telemetry doesn't just prevent failures - it also shapes pit stop strategies. By analyzing tire degradation data, teams can pinpoint the best times to pit, enabling tactics like the "undercut," where a driver gains an advantage by pitting earlier for fresh tires [5].

A vivid example occurred during the Dutch Grand Prix in September 2022. Using an Azure-powered AI tool, BWT Alpine F1 Team’s strategist Matthieu Dubois intercepted McLaren’s radio communication. At 59 minutes and 27 seconds into the race, the system flagged the word "window" in a message to Lando Norris, indicating a pit stop. Acting quickly, Alpine called Fernando Alonso in for fresh tires. Alonso then delivered one of the fastest laps of the day (averaging 128 mph) and overtook Norris by 0.5 seconds, finishing in 6th place.

Telemetry also informs mid-race adjustments to protect components. As Pierre d'Imbleval explains:

"Almost every race, there is a moment of truth where you get a combination of data that tells you to slow down a bit to save the lifetime of your brakes or your engine".

Balancing performance with mechanical longevity is a delicate art, but it often determines whether a team finishes on the podium or ends the race prematurely.

Examples from F1 Teams

Preventing Engine and Gearbox Failures

During the Monaco Grand Prix qualifying session in May 2024, McLaren Racing demonstrated how telemetry can help avoid costly misdiagnoses and retirements. When Lando Norris unexpectedly lost pace, real-time telemetry flagged a significant drop in downforce. Using their Dell Technologies AI Factory, the team analyzed the data and confirmed there was no internal mechanical issue with the MCL38. Andrew McHutchon, McLaren’s Head of Data Science, explained:

"AI can help understand that there's nothing wrong with the car – and therefore, the problem is likely to be debris in the duct. Knowing this means it's something you can fix... If you don't diagnose the problem, the brakes can easily overheat and that's race over".

A quick pit stop revealed an advertising banner stuck under the car’s floor, confirming the telemetry’s accuracy in distinguishing external debris from internal failure. After removing the debris, Norris advanced to Q2 and earned points in the race. This incident highlights how telemetry can turn a potential race-ending issue into a manageable one. McLaren’s use of advanced AI models has significantly reduced mechanical DNFs in recent years, with only a handful of failures across the last five seasons. For comparison, the team suffered five mechanical DNFs in just 19 races back in 2005. Beyond engines and gearboxes, telemetry also plays a critical role in managing other components like tires and brakes, ensuring greater reliability across the board.

Managing Tire and Brake Performance

Telemetry is just as crucial for managing tires and brakes. For example, during the 2022 season, the Mercedes-AMG Petronas F1 Team equipped their W13 car with over 250 sensors. Trackside control systems engineer Chris Nelson used real-time data to monitor tire degradation during long runs, allowing drivers to adjust braking and throttle for optimal performance under changing conditions. This proactive strategy prevented premature tire failures and helped maintain a competitive pace throughout the race.

At the Qatar Grand Prix in October 2023, McLaren set a world-record pit stop time of 1.80 seconds for Lando Norris. By leveraging data analytics to fine-tune wheel gun RPMs and car release timing, the team turned pit stops into a strategic advantage, helping Norris climb from 10th to 3rd place.

Another example comes from the British Grand Prix in July 2022, where the BWT Alpine F1 Team focused on brake preservation. After analyzing telemetry from Friday practice, engineers at the Enstone factory redesigned the car’s floor overnight to improve aerodynamic downforce. This upgrade enhanced tire grip in corners, enabling Fernando Alonso to secure 5th place - finishing 2.37 seconds ahead of a key rival. These examples show how telemetry not only prevents failures but actively improves performance, turning data into a competitive edge on race day.

Challenges and Limitations of Telemetry-Driven Maintenance

Telemetry plays a vital role in predictive maintenance within Formula 1, but it also introduces significant challenges, particularly around managing massive amounts of data and navigating technical constraints.

Data Volume and Processing Requirements

The amount of data generated during an F1 race weekend is staggering. For instance, a single car can produce around 1.1 terabytes of data over a weekend. During the 2022 Mexico Grand Prix, the Mercedes team transferred approximately 11 terabytes of data between the track and their factories. Across an entire season, a two-car team gathers an incredible 11.8 billion data points.

This relentless stream of data poses a major challenge. Modern F1 systems generate over 1 million data points per second, with some modules sampling up to 600,000 numbers per second. It’s impossible for human engineers to monitor this manually, so teams rely heavily on AI systems to filter out the noise and highlight actionable insights. Without this, engineers could quickly become overwhelmed. As Pierre d'Imbleval, VP of Information Systems and IT at BWT Alpine F1 Team, emphasized:

"During races, we are so close to the failure point on certain parts that it's super important to monitor all data at every moment".

Geographical factors further complicate data management. While European circuits offer data transmission speeds of 10–15 milliseconds, flyaway races in locations like Australia or Japan can experience latencies of 300–400 milliseconds. This delay means teams must occasionally make split-second decisions based on slightly outdated information.

Yet, even with this massive data flow, the quality of insights ultimately depends on the reliability of the sensors collecting the information.

Sensor Accuracy and Reliability

Each F1 car is outfitted with hundreds of sensors, but ensuring their accuracy is no small feat. Delays or inaccuracies in sensor data can weaken AI-driven predictions, creating inconsistencies in maintenance forecasts. A significant challenge lies in aligning real-world sensor readings with the outputs of digital twin simulations. When these two sources diverge, it can undermine engineers' confidence in the entire predictive maintenance process.

Adding to the complexity, F1 sensors must perform under extreme conditions, including high temperatures, intense vibrations, and powerful G-forces. For example, vibration data often requires processing rates of up to 200 kilo-samples per second to filter out noise effectively. MEMS sensors, commonly used for vibration and acoustic measurements, are particularly prone to noise compared to piezoelectric sensors. Without proper calibration, these sensors might fail to detect emerging problems until it’s too late.

Despite the sophistication of telemetry, some critical factors remain beyond the reach of sensors. As Geoff McGrath, Chief Innovation Officer at McLaren Applied Technologies, pointed out:

"The driver is still the best sensor we have".

For elements like lateral track position and precise tire grip, driver feedback remains irreplaceable, leaving gaps in the telemetry's ability to provide a complete picture.

Regulatory Constraints on Data Usage

Beyond the technical challenges, regulatory limits also shape how telemetry is used in F1. FIA regulations enforce a shared telemetry infrastructure across all teams to prevent a technological arms race in data transmission. As Evan Short, Team Leader of Trackside Electronics Systems at Mercedes F1, explained:

"The telemetry system is common across all the F1 teams... We used to set up our own masts, radios, and telemetry systems, and we decided in the end that that wasn't the competition we were in".

These rules also restrict the number of on-site personnel to about 60 engineers per team. To manage this, teams rely on Mission Control centers, where hundreds of engineers analyze live telemetry remotely. However, this setup introduces bandwidth and latency constraints, which can directly impact real-time decision-making.

The $175 million cost cap adds another layer of complexity. Teams must now use telemetry not just to optimize performance but also to track the lifecycle and cost of every component. Edward Green, Head of Commercial Technology at McLaren, highlighted the challenge:

"Working under resource-restricted regulations is quite a complex data challenge".

During the 2021–2022 season, McLaren integrated data from 20 different sources to calculate the cost of their car for each race. By using predictive wear data, they determined whether to manufacture new parts or extend the life of existing ones. These restrictions also limit track time, wind tunnel usage, and CFD simulations, making sensor accuracy even more critical for validating upgrades.

The Future of Predictive Maintenance in Formula One

The next era of predictive maintenance in Formula One is being shaped by the integration of AI-powered automation and cutting-edge sensor technology. Teams are pushing the limits to make failure prediction faster and more precise. Here’s a closer look at how these advancements are transforming maintenance strategies.

AI and Machine Learning Integration

AI is revolutionizing how teams handle the massive amounts of data generated during a race weekend - roughly 1 terabyte per car. Modern machine learning algorithms analyze this data alongside years of historical race information to predict potential issues. This shift from reactive to proactive maintenance allows engineers to pinpoint the exact moment a component might fail, whether it’s due to brake imbalance or stress on the power unit.

As Andrew McHutchon, Data Scientist at McLaren, explains:

"AI speeds all of that up, and the faster we can answer these questions, the faster we can develop the car and the more likely we are to win championships".

Digital twin technology plays a key role in this evolution. McLaren, for instance, runs 30 million simulations per race to evaluate how components will perform under different conditions, including shifts in temperature and weather [5]. Generative AI also assists by analyzing thousands of pages of FIA regulations in seconds to ensure compliance. This predictive approach is especially valuable under Formula One’s strict budget caps, helping teams allocate resources effectively and avoid costly, unexpected repairs.

While AI handles continuous monitoring, human experts remain essential for interpreting nuanced insights and making critical decisions.

Advances in Sensor Technology

Sensor technology is evolving rapidly, with next-generation sensors becoming lighter, faster, and more accurate. These optimized sensors can gather more data without compromising the car’s speed or aerodynamics. High-frequency sampling and advanced wireless setups detect subtle changes in car behavior, catching potential issues before they escalate into failures.

For example, infrared cameras and laser ride-height sensors are used to monitor aerodynamic performance in real time, identifying issues like plank bottoming or debris in brake ducts. Ultrasonic sensors measure fuel flow 2,200 times per second to ensure compliance with FIA regulations, while DRS actuator sensors confirm that the wing opens or closes within 0.4 seconds of deactivation.

Biometric sensors in drivers’ gloves and helmets track vital signs, while specialized cooling systems - mandatory for temperatures above 88°F (31°C) - use fluid-circulating shirts with 48 meters (157 feet) of tubing to regulate body temperature.

Vehicle-to-everything (V2X) communication technology is another game-changer, providing drivers with instant cockpit alerts about track incidents - often faster than traditional flags or human spotters. Additionally, precise wheel torque sensors ensure smooth power delivery between the internal combustion engine and the electric motor, preventing wheelspin during energy recovery.

These advancements are crucial for aligning real-world performance with digital twin predictions. As Edward Green, Head of Commercial Technology at McLaren, puts it:

"Alteryx is the final piece of the puzzle between the data that comes off the car and how it relates to the simulation".

Collaboration with tech giants like Oracle, Dell, and AWS is further enhancing these capabilities. Teams are leveraging cloud-connected "AI Factories" to process data rapidly and make real-time decisions at the track. This approach is vital for maximizing performance within the constraints of limited track time and strict regulations.

Conclusion

Telemetry-driven predictive maintenance has transformed the landscape of Formula One. With 300 sensors generating an astonishing 250 million data points per race, teams can anticipate problems and make split-second strategic adjustments that often decide the outcome of a race [5]. Whether it’s identifying overheating brakes or a gearbox under stress, engineers can intervene proactively - adjusting driver pace or strategy to prevent a costly DNF. This precision is what powers critical race-day decisions.

In Formula One, success is measured in milliseconds. Dan Keyworth, Director of Business Technology at McLaren Racing, sums it up perfectly:

"Everybody's doing everything in their power to find milliseconds. And that's what makes the difference between winning and losing" [5].

Take McLaren's record-setting pit stop, for example. It didn’t just save a fraction of a second - it played a pivotal role in climbing the grid [5]. Similarly, Alpine’s real-time data-driven strategy highlights how instant decisions can completely reshape race outcomes.

Looking ahead, advancements in technology promise even greater strides in predictive maintenance. Real-time data systems are becoming as intricate as the cars themselves, with tools like AI, digital twins, and next-gen sensors pushing the limits of mechanical reliability and strategic precision.

Formula One’s relentless focus on data-driven performance has created a model that transcends motorsport. As Pierre d'Imbleval, Vice President of Information Systems at BWT Alpine, explains:

"During races, we are so close to the failure point on certain parts that it's super important to monitor all data at every moment".

This unyielding pursuit of perfection - fueled by real-time insights and rapid decision-making - turns potential setbacks into competitive advantages, showcasing the power of predictive maintenance in the most demanding environment imaginable.

FAQs

How do Formula 1 teams use telemetry to prevent car failures?

Formula 1 teams use telemetry to keep a close eye on their cars during races, gathering real-time data from sensors placed on key components like the engine, brakes, and suspension. These sensors track things like engine temperature, oil pressure, brake wear, and even vibrations. All this information is sent back to the pit wall, where advanced algorithms and AI help engineers spot anything unusual and predict potential problems before they escalate.

By comparing the live data to historical performance records, engineers can pick up on early signs of wear or stress in a car's components. This gives them the chance to make quick adjustments - whether that's fine-tuning settings or planning a part replacement - so the car stays in peak condition and competitive for the entire race.

How do F1 teams use sensors for predictive maintenance?

Sensors play a critical role in Formula 1 telemetry, serving as the "eyes and ears" of the car. They keep tabs on essential systems like tires, brakes, the power unit, gearbox, suspension, and aerodynamics. By measuring factors such as temperature, pressure, strain, and vibration, these sensors provide real-time data to engineers in the garage. This constant flow of information helps teams track tire wear, brake efficiency, fuel consumption, and engine condition, enabling quick adjustments and spotting potential problems early.

During a race, these systems generate more than a million data points, which teams analyze using AI-powered tools. These advanced analytics can flag irregularities like unexpected vibrations or sudden temperature changes. By predicting potential failures ahead of time, teams can replace components during practice sessions or between races. This approach not only reduces the risk of breakdowns but also ensures the car is performing at its best when it matters most.

How does real-time telemetry impact pit stop strategies in Formula 1?

Real-time telemetry has revolutionized Formula 1, turning pit stops into moments of pure strategy. Every lap, an F1 car sends a staggering 100 MB of sensor data back to the team in under 60 milliseconds. This data includes everything from engine temperatures and tire wear to brake pressure, fuel levels, and even the driver’s inputs. With this constant stream of information, engineers can monitor the car’s performance live and make split-second decisions.

Take tire grip, for instance. If telemetry reveals that a tire is wearing out faster than expected, the team can call the driver in for an early pit stop to avoid losing valuable time on track. On the flip side, if brake performance and fuel levels look solid, they might delay the stop to gain a strategic advantage. These insights are crucial in finding the ideal "stop window", as demonstrated by McLaren’s lightning-fast 1.80-second pit stop at the Qatar Grand Prix, where perfect timing translated into maximum performance.

Telemetry equips F1 teams to anticipate and react to changing conditions, transforming raw data into decisions that can make or break a race.