How Teams Execute Sub-2-Second Pit Stops

Inside the choreography, tools, and training behind sub-2-second F1 pit stops: crew roles, laser parking, pneumatic guns, jacks, and relentless practice.

In Formula 1, a pit stop can make or break a race. Teams like McLaren have mastered this art, achieving record-breaking stops as fast as 1.80 seconds during the 2023 Qatar Grand Prix. How do they do it? It’s all about precision, practice, and teamwork. With 20–23 crew members performing specific roles, every millisecond counts. From high-speed pneumatic tools to laser-guided car positioning, every detail is optimized to perfection.

Here’s what goes into a sub-2-second pit stop:

- Key Roles: Each crew member has a defined task, from wheel gunners to jack operators, all working in sync.

- Driver’s Role: Precision parking within 20 cm is critical to avoid delays.

- Equipment: Specialized tools like pneumatic guns and carbon-fiber jacks ensure speed and reliability.

- Practice: Teams perform thousands of drills annually to refine their process.

The result? Lightning-fast stops that give teams a competitive edge. Let’s break down how it all comes together.

NEW PIT STOP WORLD RECORD! McLaren Service Lando Norris in 1.80s | 2023 Qatar Grand Prix | DHL

Pit Stop Crew Roles and Responsibilities

A Formula One pit stop is a finely tuned operation involving 20 to 23 crew members working in perfect harmony. Each person has a specific job, and even the smallest delay can throw everything off. The team is divided into roles, with most crew members stationed at the car's four corners to handle the wheel changes.

Key Roles in a Pit Stop Crew

The front jack operator positions themselves at the front of the pit box, ready to lift the car with a carbon-fiber quick-release jack. This tool not only absorbs the car’s momentum but also raises the front end in just 0.3 seconds, after which the operator quickly swivels aside to clear the driver’s exit path. At the same time, the rear jack operator steps in after the car has passed, lifting the rear. This role requires considerable strength due to the car’s weight and the mechanical disadvantage of the jack.

Each wheel is handled by a team of three specialists. The wheel gunner uses a high-speed pneumatic gun capable of spinning at over 10,000 RPM to remove and secure the wheel nut. These guns operate at about 26 bar of pressure and are not cheap - base models cost around $6,250, while F1-specific versions can go up to $12,500. Once the nut is loosened, the tire-off crew member removes the old tire, which weighs between 20.9 and 25.4 pounds. Simultaneously, the tire-on crew member fits the new tire onto the hub.

Two stabilizers grip the car near the airbox or radiator inlets to prevent wobbling and clear any debris. Front wing adjusters use torque drivers to tweak the wing flaps’ angles based on the driver’s feedback. Overseeing it all is the crew chief, who manages the semi-automated traffic light system that replaced the old "lollipop" sign, ensuring the car re-enters the pit lane safely.

"Going from three to two [seconds] is like going from Division 4 to Premier League!" - Dave Redding, Team Manager, Williams

Every role is part of a carefully choreographed process, which includes precise positioning.

Positioning Around the Pit Box

With such specialized tasks, exact positioning is non-negotiable. Crew members are assigned specific spots, often marked with laser guides, ensuring every tool and hand is in the right place during the 15–20 seconds of preparation.

The front jack operator must make contact with the nosecone 0.1 seconds before the car comes to a complete stop. By 0.8 seconds into the stop, they must activate the swivel mechanism to clear the car’s path. For wheel gunners, who can’t see the approaching car over their shoulders, a teammate’s tap signals its arrival. If a gunner crosses their arms in an "X" shape, it’s a sign of a critical issue - like a cross-threaded nut - and the car cannot be released.

This entire sequence is so precise that a perfect stop can often be identified by the synchronized sound of two bursts from the wheel guns. It’s a flawless performance that sets the driver up for their next move, keeping the race strategy on track.

Driver Approach and Precision Parking

Pit Lane Entry and Speed Control

The driver’s role in a pit stop begins long before the car actually reaches the pit box. Once the team signals the pit call, the driver must decelerate from speeds exceeding 200 mph to the pit lane speed limit of 50 mph (80 km/h) in a matter of seconds. This maneuver requires flawless execution - any error, like overshooting the speed limit, could result in a drive-through penalty that costs valuable race time.

This rapid deceleration isn’t just about hitting the brakes. The driver must navigate through traffic while keeping an eye on marker boards along the pit wall. Modern F1 cars are equipped with pit lane speed limiters that automatically cap the car’s speed, but the driver’s job doesn’t end there. They need to remain hyper-aware of other cars entering or exiting nearby pit boxes while making split-second decisions on braking and approach angles. Every move here sets the tone for a precise pit stop, where even the slightest misstep can ripple through the entire team’s operation.

Precision Parking with Laser Accuracy

Once the car is in the pit lane, the focus shifts to parking with pinpoint accuracy. Teams use painted scales on the pit box floor and laser markers projected from overhead gantries to create an exact stopping zone. The driver, guided by these laser markers and the front jack operator’s hand signals, must bring the car to a halt within 20 cm of the ideal position. This level of precision is critical for the pit crew to perform their tasks without unnecessary delays.

Charlie Hooper, McLaren's Director of Car Operations and Engineering, highlights how critical this accuracy is:

"It's amazing how big of a difference 20cm is, slightly off in the box, because these guys [the crew] are sat in the four corners, and they're lined up. If the car stops a little bit forward, then they've got to move... and it can really put them off."

Being even 20 cm (about 8 inches) off can disrupt the rhythm of the 23-person crew, costing precious fractions of a second. Once the car reaches its mark, the driver must immediately apply the brakes and firmly grip the steering wheel. This stabilizes the car, preventing movement when high-torque pneumatic tools are in use. Without this stability, the car could shudder or even experience axle rotation, jeopardizing the pit stop’s efficiency.

In October 2023, during the Qatar Grand Prix, Lando Norris demonstrated this incredible precision. By stopping exactly on target, McLaren’s crew completed a record-breaking 1.80-second pit stop, showcasing the seamless coordination between driver and team.

Technical Breakdown of the Sub-2-Second Pit Stop

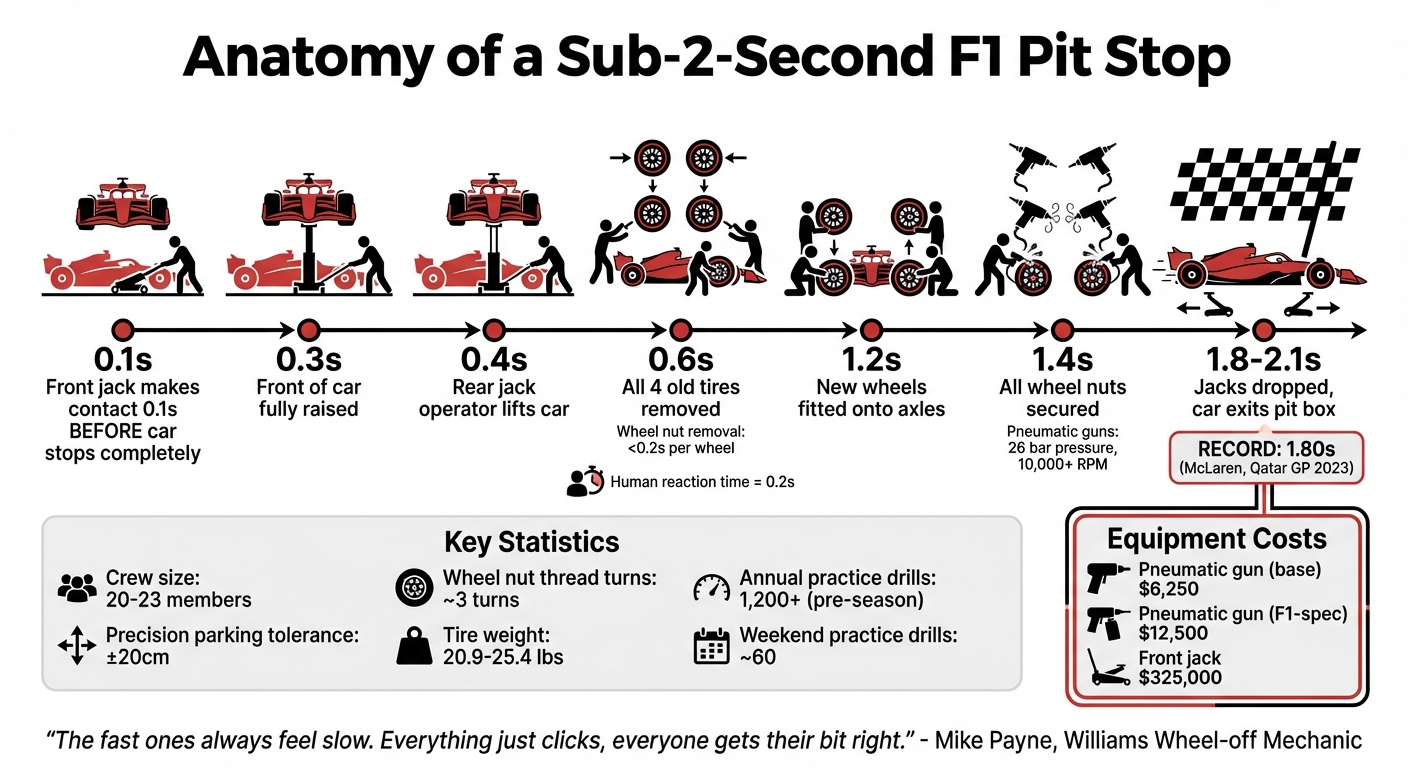

Formula 1 Sub-2-Second Pit Stop Timeline and Breakdown

Wheel Nut Removal and Replacement

In Formula 1, achieving a pit stop in under two seconds requires precision and cutting-edge tools. Wheel gunners use pneumatic guns operating at an intense 26 bar pressure - 13 times the standard tire pressure - to handle the job efficiently. As soon as the car halts, gunners spring into action. In fact, front gunners often start positioning their tools even before the car is fully stationary.

These pneumatic guns are lightning-fast, loosening wheel nuts in less than 0.2 seconds. Chris Stafford, a Right Rear Gunner for Williams, explains it best:

"The gun off time – that's the time taken for the bolt to be removed - is less than two-tenths."

To put that into perspective, 200 milliseconds is roughly the average time it takes for a human to react.

Modern F1 wheels utilize captive nut systems, secured with O-rings or circlips, ensuring the nuts stay attached during the swap. This design eliminates the risk of dropped or misaligned nuts. To save even more time, teams reduce the thread count - some designs need just three turns to fully secure the nut. Pat Symonds, former Chief Technical Officer at Williams, offers a relatable analogy:

"The simplest way to explain it is the difference between unscrewing the top of a plastic water bottle compared with something like a pickle jar... The larger wheel nuts of the blown hubs are like that - it may only take a tenth longer but when you're talking about tiny fractions, it matters."

Once the new wheel is in place, the gun automatically switches to tightening mode. Gunners press a button on the gun to signal the task is complete, feeding this information into a semi-automated traffic light system for the car's release. With the nuts secured in milliseconds, the focus shifts to swapping the tires as swiftly as possible.

Tire Removal and Installation

Each wheel is handled by a three-person team: one gunner to loosen and tighten the nut, a "wheel-off" mechanic to remove the old tire, and a "wheel-on" mechanic to attach the new one. In a flawless pit stop, all four old tires are removed by the 0.6-second mark, and the new ones are mounted by 1.2 seconds.

Gunners position themselves facing away from the pit lane and rely on a tap from a teammate to signal the car's arrival. The hubs are equipped with drive pins, which act as guides to ensure the wheels lock into place perfectly on the first try, eliminating the need for manual adjustments. Mike Payne, a Wheel-off Mechanic at Williams, captures the experience:

"The fast ones always feel slow. I don't know why. Everything just clicks, everyone gets their bit right."

To stabilize the car, two team members hold onto the airbox and radiator inlets, preventing any rocking that could interfere with the wheel guns or tire handlers. The driver also plays a role by pressing the brake pedal firmly, keeping the hubs steady while the gunners work. Every step, from nut removal to lowering the car, is perfectly synchronized to maintain the rapid pace.

Jacking and Car Release Mechanisms

After the tires are swapped, lifting and lowering the car quickly and safely is crucial. F1 regulations prohibit onboard or powered jacks, so teams rely on manual jacks operated by mechanics. The front jack operator stands directly in the car's path, ready to engage the jack just as the car comes to a stop. The nosecone typically makes contact with the carbon-fiber jack about a tenth of a second before the car fully halts. The operator absorbs this momentum and lifts the car within 0.3 seconds.

Christian Horner, Red Bull Racing's Team Principal, highlights the pressure of this role:

"Front jack is the job you don't want, in case you overshoot... you've got to have nerves of steel for that."

Frazer Burchell, No. 2 Mechanic at McLaren, adds a vivid description:

"The best way to describe the front jack is, well, it's a bit like being punched in the face."

Once the front is raised, the rear jack operator steps in, positioning the jack's "cup" onto the lifting point. This is typically completed by 0.4 seconds into the stop. Modern front jacks are designed to swivel, allowing operators to step aside while the car remains lifted, ensuring a clear exit path for the driver.

Many teams now use systems where the jacks automatically drop once all four wheel-gun operators have signaled that their nuts are secure. This final step - lowering the car - takes less than 0.1 seconds. Precision engineering plays a big role here. For instance, high-performance front jacks can cost as much as $325,000 each, reflecting their importance in these critical moments.

| Phase of Pit Stop | Timing (Seconds) | Key Action |

|---|---|---|

| Front Jack Engagement | 0.3s | Car lifted at the front |

| Rear Jack Engagement | 0.4s | Car lifted at the rear |

| Wheel Removal | 0.6s | All four wheel nuts loosened |

| Wheel Installation | 1.2s | New wheels fitted onto axles |

| Nut Tightening | 1.4s | Guns re-engaged and torque applied |

| Car Release | 2.1s | Jacks dropped and car departs the pit box |

The Role of Practice and Repetition

Consistently achieving sub-2-second pit stops is no accident - it’s the result of relentless practice and meticulous performance analysis.

Daily Pit Stop Drills

For Formula 1 teams, pit stop practice is as intense and disciplined as a professional sports team preparing for a championship. During a Grand Prix weekend, crews typically complete around 60 drills, while pre-season training ramps up to over 1,200 practice stops.

These drills aren’t just about routine tire changes. Teams also prepare for unpredictable situations - like swapping out a damaged nosebox or clearing debris - ensuring they’re ready for anything. Additionally, "live stops" during Friday and Saturday practice sessions simulate real conditions, helping crews and drivers adapt to challenges like varying pit lane grip and scorching brake temperatures.

Charlie Hooper, McLaren’s Car Operations & Engineering Director, highlights the importance of consistency over record-breaking:

"It's no good breaking a world record if the next pit stop is five seconds. We make it clear to the crew that meeting our consistency targets... will ultimately lead to the best on-track performance."

This philosophy paid off during the October 2023 Qatar Grand Prix. McLaren reduced the number of practice drills to keep the crew fresh, and it worked - they set a world record of 1.80 seconds during the race. Modern teams also rely on a "squad" system, where members are cross-trained for multiple roles. This approach helps manage fatigue across the demanding 24-race calendar.

Reviewing and Analyzing Performance

Practice alone isn’t enough. Teams constantly refine their techniques through detailed performance reviews. After every drill, high-speed camera footage and tool data are analyzed to track the timing of guns, jacks, and wheel swaps. Some teams even monitor crew members' heart rates and core temperatures with biometric sensors during races.

Gemma Fisher, a Human Performance Specialist at Williams, explains the level of detail involved:

"We break what happens down into every single aspect and look for areas where we can improve – that's everything from the people using the kit, down to the ergonomics of the kit we're using."

This feedback loop drives continuous improvement. For example, if a wheel nut design or tool grip slows the process, engineers redesign it. In 2015, Williams identified procedural inefficiencies and overhauled their hubs, wheel nuts, and guns. By the 2016 Baku Grand Prix, they set a then-record 1.92-second stop and led the fastest pit stop rankings in 14 of 21 races.

Through this cycle of practice, analysis, and refinement, teams turn mere milliseconds into race-winning advantages.

Conclusion

Achieving sub-2-second pit stops is no accident - it’s the result of seamless teamwork, exacting precision, and relentless practice. Picture this: around 20 to 23 crew members working in perfect harmony, reacting in as little as 200 milliseconds, all while managing equipment that can cost up to $300,000. Every move, every second, every detail must align perfectly for success.

But the real advantage isn’t just about shaving fractions of a second off the clock. Consistently executing sub-2-second stops provides teams with a strategic edge. It opens up opportunities to perform undercuts, tackle midfield traffic, and even expand pit window options earlier in the race - all critical factors in a sport where strategy can make or break a race.

Rather than chasing fleeting records, the teams that focus on delivering reliable, consistent stops gain a more meaningful edge over the course of a season. Sustaining performance in the 2.1 to 2.3-second range across all 24 races holds far more value than risking inconsistency for a one-off record-breaking attempt.

When you break it down, the pit stop is the ultimate example of how human skill, cutting-edge technology, and strategy come together in a matter of seconds. In F1, where every millisecond counts, these meticulously practiced techniques and strategies can mean the difference between standing on the podium or falling behind. It’s in those tiny, relentless improvements that championships are won.

FAQs

How do F1 teams consistently perform pit stops in under 2 seconds?

F1 teams pull off pit stops in under two seconds thanks to relentless practice, precision, and seamless teamwork. During a race weekend, crews practice hundreds of stops, often rotating roles so every team member becomes proficient in tasks like lifting the car, unbolting wheels, swapping tires, and re-torquing with impeccable timing. This repetition helps build the muscle memory needed to perform under intense race-day pressure.

To push their performance even further, teams rely on high-speed cameras and slow-motion analysis, breaking down every second to identify areas for improvement. Specialists focus on optimizing everything from the tools used to the crew's positioning, ensuring every motion is as efficient as possible. With over 100,000 practice stops in a season and constant data-driven tweaks, pit stops become a perfectly coordinated routine, delivering jaw-dropping speed when it matters most.

What does the driver do to ensure a fast pit stop?

The driver is absolutely central to pulling off a flawless pit stop. It starts with them braking hard and stopping the car exactly on the pit box line. This precision ensures the crew can jump into action with the jacks and wheel guns without wasting time repositioning. Even the smallest misstep here can cost precious fractions of a second.

Once the car is lifted, the driver’s job isn’t over. They hold the brake pedal tightly and keep the steering wheel steady, giving the crew a stable car to work on. When the pit stop is done, the driver’s focus shifts to the green light. The moment it flashes, they accelerate immediately, fully trusting the system to signal it’s safe to go. In this high-pressure moment, accuracy, steady control, and lightning-fast reactions are what make those sub-2-second pit stops possible.

How do F1 teams perform pit stops in under two seconds?

F1 teams pull off lightning-fast pit stops by blending advanced technology, flawless teamwork, and relentless practice. At the core of this process are pneumatic wheel guns, capable of removing and securing wheel nuts in mere fractions of a second. Meanwhile, hydraulic jacks instantly lift the car, and sensors ensure it's positioned at the ideal height, allowing the crew to work with maximum efficiency.

To fine-tune every detail, teams rely on high-speed cameras and real-time telemetry to track every millisecond of the stop. The data collected is analyzed to perfect crew positioning, improve tool design, and fine-tune timing. Thousands of practice sessions ensure that every movement is polished, enabling pit crews to deliver consistently fast and precise results.