Mercedes vs McLaren: 2025 Power Unit Performance Analysis

Explore the performance dynamics between two teams using the same power unit, revealing integration challenges and future implications in motorsport.

Mercedes and McLaren both use the same 2025 Mercedes-AMG power units, but their integration methods create noticeable on-track performance differences. While Mercedes benefits from seamless factory integration with its W15 chassis, McLaren has had to adapt its car extensively to fit the engine, impacting reliability and aerodynamics. Here’s a quick breakdown:

- Mercedes: Factory team advantage with optimized engine-chassis integration, achieving better packaging and system efficiency. Holds a performance edge of 0.7% over McLaren.

- McLaren: Modified chassis to accommodate Mercedes' power unit, balancing benefits with challenges. Extended contract with Mercedes HPP until 2030 ensures long-term collaboration.

Quick Comparison

| Performance Factor | Mercedes Factory Team | McLaren |

|---|---|---|

| Power Unit Integration | Seamless, factory-optimized | Adapted for existing chassis |

| Development Input | Full control from the start | Improved early collaboration |

| Reliability Focus | High priority with updates | Balancing reliability challenges |

| Performance Gap | 0.7% faster than McLaren | Slightly behind Mercedes |

| Contract Stability | Works team advantage | Secured partnership until 2030 |

Both teams push the limits of the 1.6-liter V6 turbo-hybrid engine, but Mercedes' works team setup currently holds the upper hand. However, McLaren's strengthened partnership positions it as a future contender.

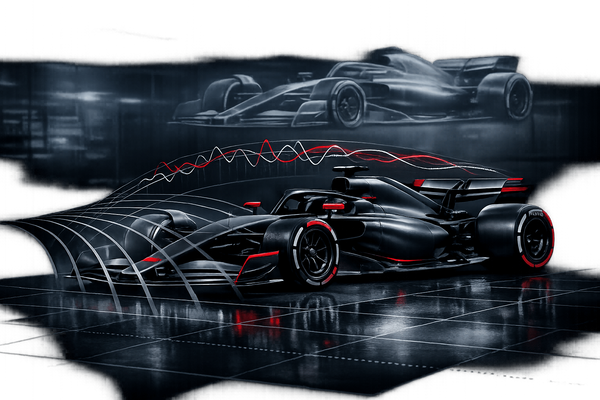

1. Mercedes Power Unit Specs

Power Output and Efficiency

Mercedes' 2025 power unit delivers over 50% thermal efficiency during dynamometer tests - a significant leap from the 29% efficiency seen in earlier V8 engines.

Here’s a breakdown of the key engine specs:

| Component | Specification |

|---|---|

| Engine Configuration | V6 with a 90° bank angle |

| Displacement | 1.6 liters |

| Valve Count | 24 |

| Maximum RPM | 15,000 |

| Fuel Injection | Direct injection (up to 500 bar max) |

| Total Power Output | Over 1,000 horsepower |

| Fuel Flow Limit | 100 kg/hour above 10,500 rpm |

Reliability and Durability

For the 2025 season, Mercedes has prioritized reliability alongside performance. Power Unit Chief Hywel Thomas shared their strategy:

"We have been looking at reliability updates, and some calibration upgrades, to deliver robustness, squeeze the last little bits of performance out of the Power Unit and give ourselves the best opportunity this season. We've made good progress and hopefully that can add performance on track."

These updates aim to ensure the power unit not only performs better but also integrates smoothly with the chassis for optimal results.

Chassis Integration

The power unit works in tandem with two key Motor Generator Units (MGUs):

- MGU-K: Captures kinetic energy during braking.

- MGU-H: Converts exhaust gas energy into usable power, with improved efficiency.

Compared to the 2014 engine, the new power unit generates an additional 109 bhp while maintaining the same fuel consumption. This is a stark contrast to the 2005 V10 engines, which consumed fuel at a rate of 194 kg/hour. Mercedes highlighted this achievement as:

"A remarkable milestone for any hybrid, and especially a flat-out racing engine".

2. McLaren Power Unit Specs

Power Output and Efficiency

Integrating the Mercedes power unit into McLaren's car meant reworking several key areas of the chassis. This included adjustments to the fuel cell, cooling system, and rear chassis to align with the new engine's requirements.

| Integration Aspect | Technical Details |

|---|---|

| Fuel Cell Design | Adjusted to meet Mercedes power unit specifications |

| Cooling System | Redesigned to suit Mercedes architecture |

| Rear Chassis | Modified extensively for proper installation |

| Aerodynamic Impact | Minimal changes to maintain aerodynamic philosophy |

These changes were essential for ensuring compatibility, but they also introduced challenges in terms of reliability and durability.

Reliability and Durability

McLaren's Technical Director, James Key, highlighted the challenges of adapting to Mercedes' engine philosophy:

"The Mercedes is a great engine, they're great people to work with...It's a great engine package, it is very chassis-friendly in many respects but it did have its challenges in that it was a different philosophy to Renault. So some of the geometries or installation details which naturally complemented the Renault installation last year were just not possible at all with a Mercedes this year."

This shift in engine design required McLaren to rethink certain aspects of their car, balancing the benefits of the Mercedes engine with the realities of their existing chassis design.

Chassis Integration

Fitting the Mercedes power unit into a chassis initially designed for a different engine brought its own set of technical hurdles. James Key offered further insights:

"In normal times you'd install it and use the benefits of a tighter package – which is what you get with the architecture of Mercedes engine – to the full. Whereas we've had to make minimal changes to our car to allow us to effectively put a Mercedes engine in our car designed for our current engine."

This process wasn't just about mechanical fitment. It also had implications for the car's aerodynamics. Key explained the careful considerations involved:

"Whenever we've discussed with the FIA areas which will have an impact on aero for the purposes of installing the engine – that's predominately through the cooling system side of things – that sort of thing, they've always recognised that where we're trying to do the best thing to make sure it works and doesn't exploit things that other people can't exploit, for example."

These efforts reflect McLaren's commitment to maintaining performance and reliability while ensuring compliance with FIA regulations during this challenging transition.

How McLaren's 2021 F1 car is influenced by Mercedes engine ...

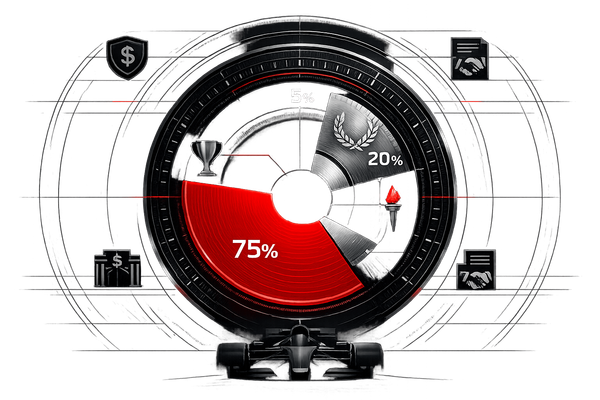

Performance Comparison

Let’s dive into how different approaches to integrating the same Mercedes power units affect race performance. While both Mercedes and McLaren rely on identical power units, their methods of implementation lead to distinct results on the track.

Implementation Differences

The Mercedes factory team has a clear edge thanks to its seamless integration of the power unit with the W15 chassis. This alignment optimizes packaging and boosts system efficiency. On the other hand, McLaren had to modify its chassis extensively to fit the Mercedes architecture. While their approach has been effective, it required significant adjustments.

As Toto Wolff, Head of Mercedes-Benz Motorsport, explains:

"McLaren's strong performances underline the importance of transparent and equal supply to all customer teams in the sport, if we wish to achieve the goal of 10 teams capable of fighting for podium finishes."

Performance Impact

These integration approaches directly impact performance on the track. Currently, the Mercedes factory team holds a performance gap of about 0.7% over McLaren. This highlights how chassis integration can influence outcomes in today’s highly competitive Formula One environment.

Hywel Thomas, head of the Mercedes Power Unit division, shares insight into their ongoing improvements:

"We have been looking at reliability updates, and some calibration upgrades, to deliver robustness, squeeze the last little bits of performance out of the Power Unit and give ourselves the best opportunity this season."

This relentless focus on refinement, paired with the factory team's integration advantage, keeps Mercedes ahead while helping customer teams like McLaren make the most of the power unit's capabilities.

Key Findings

Our analysis reveals notable performance differences between Mercedes and McLaren in 2025. Mercedes benefits from its works team setup, allowing for better integration of key components and early input during power unit development.

By strategically positioning power unit components, Mercedes achieves seamless engine-chassis integration. Mercedes engine boss Andy Cowell highlights this advantage:

"All the bits [in the Mercedes power unit] are positioned exactly where the engine would like them to be positioned and exactly where the car would like them to be positioned"

On the other hand, McLaren strengthens its position through an extended contract with Mercedes HPP, running until 2030. This agreement enhances McLaren's involvement in power unit development, addressing potential gaps that come with being a customer team. McLaren CEO Zak Brown shares his perspective:

"I'm of the view that you can win a world championship with a customer engine. I know that in our new contract, without going into great detail, the areas in which you would have shortcomings by being a customer versus a works team, we've addressed that and we have a great agreement with HPP"

Key Performance Factors Comparison

| Performance Factor | Mercedes Factory Team | McLaren |

|---|---|---|

| Power Unit Integration | Seamless factory integration | Adapted for customer chassis |

| Development Input | Full control from the start | Improved early collaboration |

| Contract Stability | Works team advantage | Secured until 2030 |

While Mercedes currently holds an edge through its integrated approach, McLaren's strengthened partnership positions it as a strong contender in the future.

FAQs

Why does Mercedes perform better than McLaren even though they use the same power unit?

Mercedes often outperforms McLaren despite sharing the same power unit due to their superior chassis design and seamless integration of the power unit with the car. The factory team invests heavily in optimizing how the engine works with the aerodynamics and suspension, ensuring maximum efficiency and performance.

Additionally, Mercedes has addressed past weaknesses, such as improving slow-corner handling and stabilizing tire temperatures. Innovations like a redesigned rear suspension and refined aerodynamic elements further enhance their competitive edge. These advancements give Mercedes a more balanced and reliable car, allowing them to extract more performance than McLaren.

What challenges did McLaren face in adapting the Mercedes power unit to their chassis?

McLaren encountered several challenges when integrating the Mercedes power unit into their chassis. A key issue was optimizing the car's mechanical and aerodynamic design to ensure seamless compatibility with the power unit. This required significant adjustments to improve overall performance, particularly in areas like tire management and weight distribution.

Additionally, the team had to align the power unit's capabilities with the new Formula 1 regulations, which imposed stricter limits on aerodynamics and energy efficiency. These changes demanded precise engineering to maintain competitive lap times while adhering to the updated rules.

What does McLaren's extended partnership with Mercedes mean for their future performance in Formula 1?

McLaren's decision to extend its partnership with Mercedes through the 2030 season highlights the team's confidence in Mercedes' power units and their alignment with McLaren's long-term goals. This continuity provides McLaren with a reliable foundation to build competitive cars and refine their technical capabilities.

Starting in 2026, McLaren will become Mercedes' first customer team under the new engine regulations, further strengthening their collaboration. This extended agreement ensures stability and positions McLaren to consistently challenge at the front of the grid, leveraging Mercedes' proven expertise in power unit development and integration.