Top Sensor Calibration Tools for F1 Engineers

Compare top F1 sensor calibration tools—hardware and software evaluated for accuracy, speed, and FIA compliance across knock, force/torque and telemetry sensors.

In Formula 1, precision matters. Sensor calibration tools ensure that every piece of data from the car is accurate, avoiding costly mistakes or penalties during races. This article explores the best calibration tools for F1 teams, focusing on their accuracy, speed, and compliance with FIA regulations.

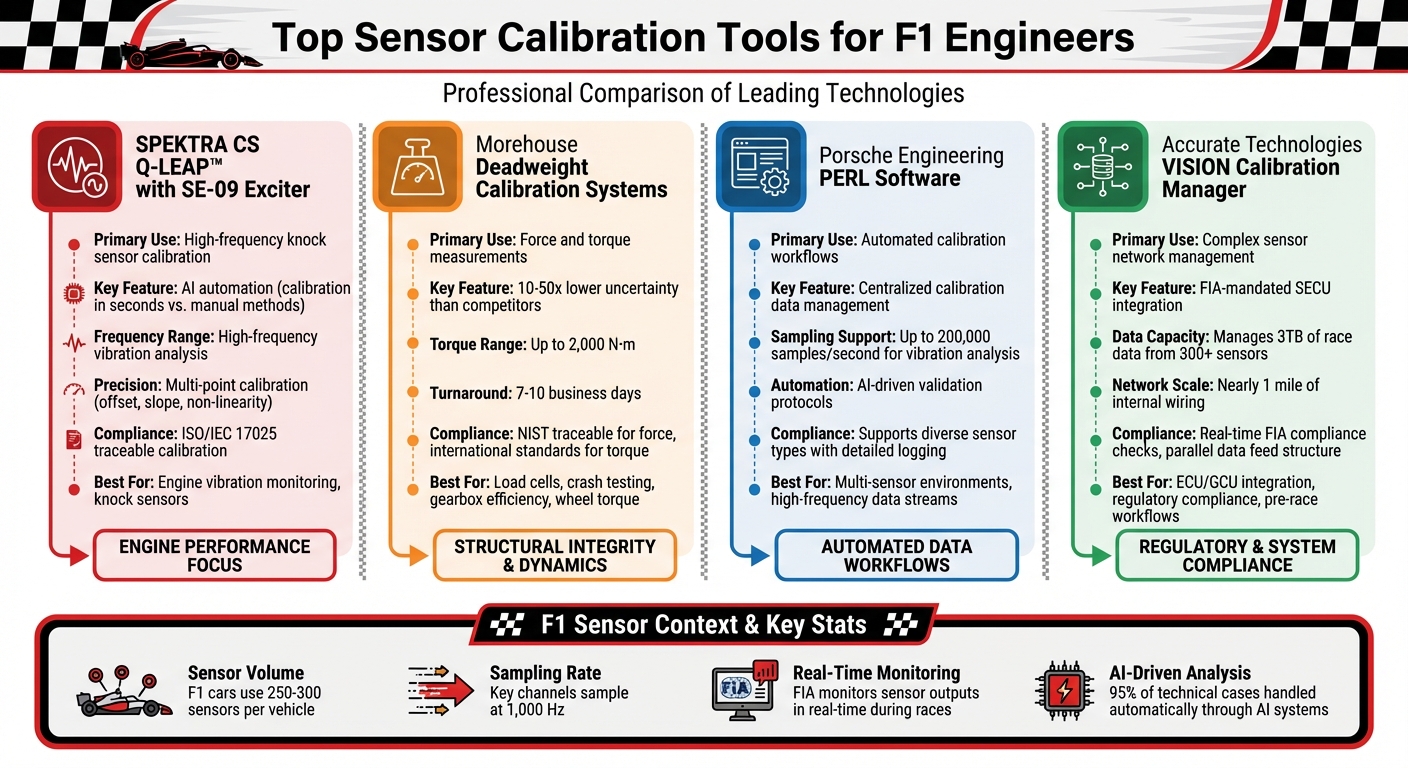

Key Tools and Features:

- SPEKTRA CS Q-LEAP™ with SE-09 Exciter: Specializes in high-frequency knock sensor calibration, offering AI automation for fast and precise results.

- Morehouse Deadweight Calibration Systems: Delivers ultra-accurate force and torque measurements, ideal for load cells and crash testing.

- Porsche Engineering PERL Software: Automates sensor calibration workflows, supports diverse sensor types, and centralizes calibration data.

- Accurate Technologies VISION Calibration Manager: Integrates with FIA-mandated SECU, managing real-time compliance and complex sensor networks.

These tools are tailored to meet the high demands of F1 racing, where every fraction of a second counts. Below, we dive into their specific features, use cases, and benefits.

Comparison of Top 4 F1 Sensor Calibration Tools: Features and Capabilities

1. SPEKTRA CS Q-LEAP™ with SE-09 Exciter

Frequency Range and Precision

The SPEKTRA CS Q-LEAP™ system, combined with the SE-09 high-frequency vibration exciter, is specifically designed for calibrating knock sensors in Formula 1 race cars. These sensors play a critical role in monitoring engine vibrations to detect abnormal combustion patterns that could lead to severe engine damage. To function effectively, they require calibration at extremely high frequencies that match the resonances of F1 power units, making the SE-09 exciter indispensable for precise calibration.

The Q-LEAP system uses multi-point calibration methods to address key error types - offset, slope, and non-linearity. This ensures the sensors provide accurate data even in the extreme conditions of F1 racing, where exhaust temperatures can soar to 1,832°F (1,000°C) and intense G-forces might affect sensor baselines.

AI Automation and Efficiency

The Q-LEAP system revolutionizes the calibration process by replacing time-consuming manual methods with automated procedures that take only seconds. For F1 teams, where every moment counts during testing sessions, this automation means cars don’t need to be pulled offline for extended calibration, drastically reducing downtime. This efficiency directly impacts race performance, allowing teams to make quicker, data-driven decisions on the track.

In addition to speed, the system's AI-driven diagnostics can pinpoint hardware issues, such as improperly machined sensor mounts, and calculate Mean Time Between Failure (MTBF) for components. This proactive approach helps teams avoid potential calibration issues during critical track sessions, ensuring smoother operations.

Compliance with FIA Regulations

One F1 team adopted the SPEKTRA CS Q-LEAP™ system with the SE-09 exciter to meet the demanding requirements of high-precision knock sensor calibration while staying compliant with FIA technical regulations. The system delivers traceable calibration that conforms to ISO/IEC 17025 standards, a key requirement for documentation during FIA inspections. Since the FIA monitors sensor outputs in real time during races via a direct link to each team's data center, the accuracy and traceability provided by Q-LEAP are essential. This combination of technological precision and regulatory compliance sets a new standard for calibration systems in motorsport.

2. Morehouse Deadweight Calibration Systems

Scalability for F1 Applications

Morehouse deadweight systems are designed to deliver precise force calibration, reducing measurement uncertainty for critical F1 load cells. In Formula One, cars rely on as many as 250–300 sensors to monitor factors like pressure, temperature, inertia, and displacement. The adaptability of Morehouse systems makes them indispensable for calibrating sensors used in various critical areas, including vertical aerodynamic loads, cornering forces, steering response, and drivetrain torsion analysis.

Their torque calibration capabilities extend up to 2,000 N·m with exceptionally low uncertainty. This range is ideal for tasks like gearbox efficiency testing and wheel torque output verification - both of which have a direct impact on race performance. On top of that, Morehouse offers a quick calibration turnaround of 7–10 business days, a crucial benefit for F1 teams working within tight timeframes. This combination of precision and speed ensures seamless integration with Morehouse's high-frequency and precision performance tools.

Frequency Range and Precision

In Formula One, where even the smallest margin can make a difference, Morehouse's measurement precision plays a pivotal role. As stated by Morehouse Instrument Company:

Our measurement uncertainties are 10-50 times lower than the competition, providing you with more accuracy and precision in force measurement.

This level of accuracy is critical when managing data from hundreds of sensors. For example, essential channels like engine RPM and pressure require sampling rates as high as 1,000 Hz.

Morehouse systems are also crucial for crash testing, where they calibrate load cells that measure chassis stress distribution, helmet G-force impacts, and torque stress on HANS devices. These safety-critical tests demand the highest precision, giving F1 teams an edge in both performance and driver protection. The ultra-low uncertainty of Morehouse systems ensures they meet the rigorous demands of these applications.

Compliance with FIA Regulations

Morehouse systems provide traceability to SI units through NIST for force measurements and adhere to international standards for torque, ensuring compliance with FIA regulations. In Formula One, precise sensor calibration isn't just a performance booster - it's a regulatory requirement. The FIA mandates calibration to maintain strict oversight and ensure proper operation of control systems. Additionally, the FIA receives parallel data feeds directly from each team's data center, making calibration accuracy and regulatory compliance inseparable.

This documented traceability not only enhances performance but also guarantees adherence to FIA mandates, ensuring smooth and uninterrupted race operations. For F1 teams, this dual benefit of precision and compliance makes Morehouse systems an invaluable asset on and off the track.

3. Porsche Engineering PERL Software

AI Automation and Efficiency

Porsche Engineering's PERL Software goes beyond hardware by offering a streamlined solution for sensor calibration in Formula One. It automates the calibration process, cutting down on manual tasks and ensuring consistent accuracy. By leveraging AI, PERL simplifies complex calibration workflows, freeing up engineers to concentrate on performance analysis.

This automation proves especially useful when dealing with high-frequency data streams. For example, key channels such as engine RPM and pressure demand sampling rates of 1,000 Hz, while vibration analysis can push that requirement up to 200,000 samples per second. PERL’s automated validation protocols safeguard calibration precision, even during high-stakes race sessions, ensuring no detail is overlooked.

Scalability for F1 Applications

PERL Software is built to handle the wide range of calibration needs found in Formula One. Whether it’s the geometric calibration of aerodynamic load cells for measuring downforce or verifying the frequency response of temperature sensors monitoring brake disc heat, the platform supports diverse sensor types. This flexibility is especially valuable when recalibrations are needed between practice runs, qualifying rounds, and race day, aligning perfectly with the demanding schedules of F1 teams.

In addition, PERL’s centralized management of calibration data is a game-changer in F1’s data-heavy environment. By consolidating calibration records, the software minimizes the risk of errors during critical moments. Teams can maintain detailed logs, quickly identify sensors requiring recalibration, and ensure compliance with both internal quality benchmarks and external regulations. This centralized approach not only enhances efficiency but also provides peace of mind during the most crucial phases of competition.

4. Accurate Technologies VISION Calibration Manager

Compliance with FIA Regulations

Since 2008, F1 teams have been required to use the standardized McLaren Applied SECU (Standard Electronic Control Unit). This mandate means calibration tools must integrate seamlessly to ensure precise data logging and monitoring. VISION's architecture is designed with the FIA-mandated parallel data feed structure, allowing real-time compliance checks during practice sessions, qualifying rounds, and races. This system ensures that sensor calibrations meet regulatory standards while maintaining secure data transmission protocols, minimizing the chance of accidental rule violations.

This robust compliance system is essential for handling the immense data flows that are a hallmark of modern F1 racing.

Scalability for F1 Applications

Beyond regulatory compliance, VISION Calibration Manager is built to handle the massive sensor networks found in today’s F1 cars. Each car generates about 3 terabytes of data during a race, with over 300 sensors connected by nearly a mile of internal wiring. VISION manages this complexity by centralizing calibration records across multiple sources, including the ECU, Gearbox Control Unit (GCU), and various data loggers.

This centralized system simplifies pre-race calibration workflows. Engineers can quickly cross-check data between control units to spot inconsistencies, compare raw sensor outputs with manufacturer specifications, and manually verify ranges for components like damper potentiometers. These steps are crucial, as sensors continuously transmit data to an onboard server before encryption and RF transmission to the team.

Advantages and Disadvantages

When evaluating tools for F1 sensor calibration, it's important to weigh their precision, scope, and integration. Here's a closer look at the strengths and limitations of some key options.

The SPEKTRA CS Q-LEAP™ stands out for its high-frequency vibration analysis, making it a go-to choice for calibrating knock sensors in F1 race cars. However, its specialized nature means it may fall short for sensors measuring other parameters like force or torque, or for applications requiring comprehensive data management.

Morehouse Deadweight Calibration Systems excel in delivering highly accurate force and torque measurements, with uncertainties that are 10–50 times lower than those of competing systems. This level of precision is crucial for tasks like crash testing and suspension load analysis. As Morehouse Instrument Company explains:

If force measurements are inaccurate, even by a fraction of a percent, handling characteristics can be compromised, leading to instability, excessive tire wear, or even catastrophic failure.

On the software side, PERL Software and VISION Calibration Manager streamline sensor data management. By centralizing data, they enhance pre-race preparation and ensure compliance with the Standard ECU.

In F1 racing, calibration precision isn't just important - it's mandatory. FIA's real-time monitoring systems demand immediate responses to even the slightest calibration shifts. With about 95% of technical cases now handled automatically through AI-based systems, teams must rely on tools that not only meet technical specs but also maintain traceability to NIST or other international standards. Ultimately, any tool chosen must strike a balance between delivering high performance and adhering to FIA's stringent regulatory requirements.

Conclusion

The discussion above underscores how calibration needs differ depending on the application. Choosing the right calibration tool hinges on your F1 team's specific priorities.

For powertrain and ECU management, Cosworth CalTool stands out with its differencing mode and detailed change logs, making it easier to track setup adjustments over time. If your focus is on achieving high sensor precision for force and torque measurements, Morehouse Deadweight Calibration Systems provide unmatched accuracy, with uncertainties up to 10–50 times lower than other systems.

Teams handling multi-sensor fusion can benefit significantly from Deepen Calibrate, which cuts calibration time by nearly 90% while maintaining millimeter-level accuracy for safety-critical systems. As Cheuksan Wang, Co-Founder of Deepen AI, explained:

Companies can bring down calibration time by almost 90% while ensuring accuracy.

For those prioritizing geometric calibration, dSPACE RTMaps is a strong option, minimizing reprojection errors to just 1 ± 0.1 pixel. These tools highlight the variety of solutions tailored to different technical challenges.

Incorporating multi-point calibration is essential not just for sensor accuracy but also for meeting regulatory standards, ensuring overall system reliability. Regularly verifying sensor ranges can help prevent calibration-related issues, while cross-referencing data between your master control unit, ECU, and GCU can catch inconsistencies early on.

Ultimately, the best calibration tool will effectively balance speed, precision, and diagnostic capabilities to help your F1 team achieve top-tier performance.

FAQs

Which sensors need calibration most often on an F1 car?

In Formula 1, certain sensors require constant attention to maintain their accuracy. These include those that monitor tire pressures, suspension travel, and aerodynamic pressures. Since these sensors play a critical role in gathering precise data, regular recalibration is essential to ensure the car performs at its peak.

How do teams prove sensor calibration compliance to the FIA?

Teams prove their sensor calibration compliance to the FIA by carrying out detailed calibration procedures. This process involves using specialized tools like test benches and systems to confirm that sensors are both accurate and consistent. For instance, knock sensor calibration systems are employed to ensure sensors comply with FIA regulations by meeting rigorous performance standards.

How do engineers choose between calibration hardware and calibration software?

Engineers decide between calibration hardware and software by considering factors like the type of sensor, required precision, and how the tools will be used. Hardware tools, such as calibration baths or turntables, are ideal for achieving high accuracy, especially when dealing with intricate sensors. On the other hand, software solutions rely on algorithms to process data and correct errors, offering a more adaptable and budget-friendly option. In Formula 1, teams often combine both approaches to ensure sensors deliver precise and reliable data - essential for optimizing performance and refining race strategies.