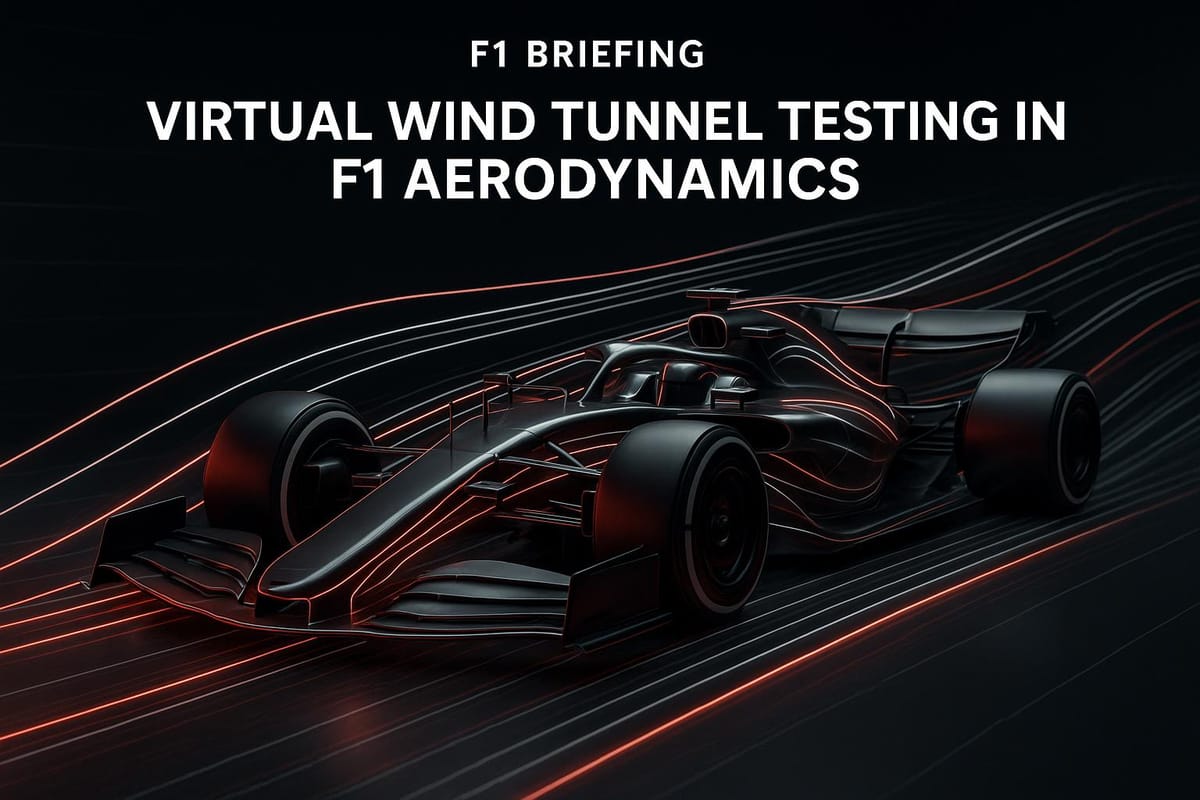

Virtual Wind Tunnel Testing in F1 Aerodynamics

Explore how virtual wind tunnel testing using CFD is revolutionizing Formula 1 car design, enhancing performance while reducing costs.

Virtual wind tunnel testing has transformed how Formula 1 teams design their cars, replacing physical wind tunnels with Computational Fluid Dynamics (CFD) simulations. This digital approach allows engineers to analyze full-scale car models, saving time and reducing costs compared to traditional methods. Here's what you need to know:

- What it is: CFD uses advanced math and computing to simulate airflow around F1 cars, replacing the need for physical prototypes.

- Why it matters: Teams can test thousands of designs faster, stay within cost caps, and adapt to regulatory limits on wind tunnel use.

- How it works: Engineers create 3D car models, define airflow conditions, and run simulations to measure drag, downforce, and pressure patterns.

- Validation: Virtual results are cross-checked with physical wind tunnel data and track performance for accuracy.

- Tools used: Software like ANSYS Fluent and Siemens Simcenter, along with custom tools, help teams run up to 1,000 simulations weekly.

This method has reshaped F1 car development, offering faster design cycles and more precise aerodynamic insights. While physical wind tunnels are still used for final validation, virtual testing has become a cornerstone of modern F1 engineering.

How Virtual Wind Tunnel Testing Works

Computational Fluid Dynamics (CFD) Basics

CFD uses the Navier-Stokes equations to model how air flows and interacts with surfaces. These equations help engineers analyze airflow patterns and pressure distribution around an F1 car.

This approach is especially useful for solving complex fluid flow problems that would be impossible to handle manually. For example, when air hits the front wing of an F1 car at speeds of about 186 mph (300 km/h), it creates intricate flow patterns, including turbulence and regions where the airflow separates from the surface. By breaking these interactions into millions of small calculations, CFD predicts how air behaves around various parts of the car.

F1 teams rely on CFD to calculate key aerodynamic metrics like the drag coefficient (Cd) and lift coefficient (Cl). These values measure the car's aerodynamic resistance and the amount of downforce it generates, respectively. Comparing these metrics across different designs helps engineers strike the right balance between speed and stability, ensuring optimal performance.

Steps in CFD Simulation

The CFD simulation process builds on its core principles and involves several stages. First, engineers create a detailed 3D model of the car, which is then divided into a computational mesh. This mesh forms a grid where the fluid dynamics equations are solved. A finer mesh typically yields more precise results but also demands more computational power and time.

Next, boundary conditions are defined. Engineers input parameters like airspeed, temperature, and pressure to simulate real-world conditions.

The simulation runs on high-powered computer clusters using advanced software such as ANSYS Fluent or Siemens Simcenter STAR-CCM+. Some teams even develop their own proprietary tools. Once the simulation is complete, post-processing tools visualize the results, showing airflow patterns, pressure distributions, and forces acting on the car. These visualizations can pinpoint critical details, such as where airflow separates from the surface or where vortices form.

Making Simulations Match Real Conditions

To ensure virtual simulations align with reality, teams validate their digital models against physical data. They frequently compare CFD results with data from wind tunnel tests and real-world track performance. This cross-referencing ensures that any simulated improvements translate to actual gains on the track.

Precision is key. Engineers meticulously model every aerodynamic feature, even seemingly minor ones like brake ducts or suspension components, as these can significantly affect overall performance.

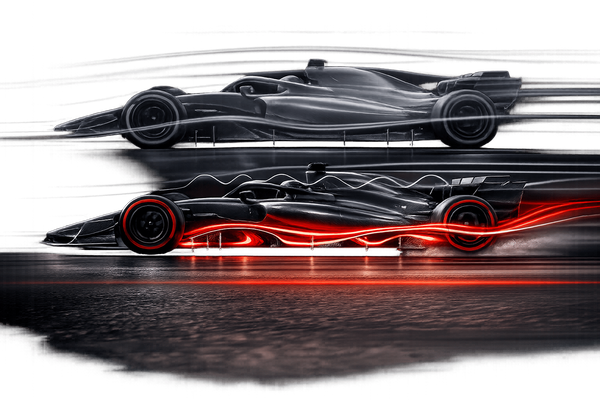

CFD also accounts for real-world variables often overlooked in traditional wind tunnel tests. While physical wind tunnels typically use 60% scale models and test speeds up to 112 mph (180 km/h), CFD enables full-scale simulations at actual race speeds. This allows engineers to study aerodynamic effects that only appear under full-speed conditions.

Cloud computing and high-performance clusters take this process a step further, enabling teams to run multiple simulations at once. This capability lets engineers explore various scenarios, such as different ride heights, steering angles, or crosswind conditions. These detailed simulations play a critical role in guiding design updates and improving race-day performance.

How F1 Teams Use Virtual Wind Tunnel Testing

Software and Tools Teams Use

F1 teams rely on advanced platforms like Siemens Simcenter and ANSYS Fluent for turbulence modeling and high-performance computing. These specialized tools handle the complex airflow dynamics around F1 cars, which involve intricate geometries and turbulent wake patterns, far more effectively than standard CFD programs.

One standout feature of these platforms is their ability to process large datasets and deliver fast simulation results. They also integrate seamlessly with F1 engineering workflows, allowing teams to quickly transition from design concepts to testing. Some teams even develop their own custom software to fine-tune simulations for greater accuracy and speed, giving them an edge over competitors.

The software choice directly influences how many simulations a team can run at once. With these tools and high-performance computing setups, F1 teams conduct up to 1,000 CFD simulations weekly, a stark contrast to the limited number of physical wind tunnel tests allowed under regulations. Although this requires a significant investment in computing infrastructure, it dramatically accelerates the design and testing cycle, forming the backbone of modern aerodynamic development.

Virtual Testing Process

Using these advanced tools, the virtual testing process begins with defining test parameters based on specific aerodynamic goals. Engineers set variables like car configuration, ride height, steering angles, and environmental conditions, then run simulations to assess performance.

High-performance computing clusters allow teams to run multiple simulations simultaneously. Engineers often conduct sensitivity analyses, tweaking variables such as wing angles or bodywork details to see how small changes affect performance. This iterative approach helps pinpoint the most effective design adjustments.

During analysis, engineers focus on key aerodynamic metrics like drag (Cd), lift (Cl), and downforce. They also study pressure maps, velocity fields, and phenomena like flow separation and vortex formation to understand how these factors influence performance. Collaboration between design, simulation, and validation teams ensures that the virtual models, CFD results, and real-world data align with the team's performance targets.

Checking Virtual Results Against Real Data

Modern F1 development blends digital simulations with physical testing to ensure accuracy. Teams compare CFD predictions, such as aerodynamic coefficients and flow visualizations, with data from wind tunnel tests and on-track telemetry. This process helps identify discrepancies and refine simulation models. Adjustments include improving mesh resolution, tweaking boundary conditions, and enhancing turbulence models to bring virtual results closer to real-world measurements.

For instance, teams like Mercedes and Aston Martin combine CFD with wind tunnel data to refine their designs. Mercedes uses this hybrid approach to optimize its aerodynamic map, while Aston Martin leverages advanced simulations alongside traditional testing to enhance performance. These methods allow for quicker design updates and better-targeted improvements throughout the season.

Although CFD is excellent for identifying trends and exploring design possibilities, physical testing remains essential for final validation. Virtual testing enables teams to evaluate concepts quickly and efficiently, reserving physical tests for confirming designs before race weekends. This combination of virtual and physical testing has revolutionized aerodynamic development in F1, enabling teams to explore more ideas while reducing reliance on costly prototypes, ultimately making their design process faster and more precise.

Benefits and Drawbacks of Virtual Wind Tunnel Testing

Main Benefits Over Physical Wind Tunnels

Virtual wind tunnel testing has reshaped the way F1 teams approach aerodynamics by significantly cutting costs and speeding up the design process. Physical wind tunnels come with hefty price tags - Ford’s facility cost $200 million, while Honda spent $124 million on theirs. In contrast, virtual testing eliminates these infrastructure expenses, requiring only high-performance computing systems and software licenses.

Speed is another huge advantage. Adjusting and testing digital car models in virtual environments can be done in hours, far outpacing the days or even weeks needed to construct and test physical scale models. This efficiency enables teams to evaluate thousands of design variations that would otherwise be too costly and time-intensive with physical prototypes.

Virtual simulations also allow for testing full-size car models without the constraints of scale or regulatory wind speeds that physical tunnels face. This provides a more realistic analysis of how a car behaves aerodynamically in real-world conditions.

Another key benefit is the flexibility of virtual testing. Multiple simulations can be run at the same time, allowing engineers to experiment with various configurations - like wing angles, ride heights, and bodywork adjustments - all in parallel. Physical wind tunnels, on the other hand, require time-consuming setup changes for each test. This ability to quickly explore multiple scenarios offers teams a significant edge in the fast-paced world of F1 development.

Limitations and Challenges

That said, virtual testing isn’t without its hurdles. The computational power required for CFD (Computational Fluid Dynamics) simulations is substantial, which means teams still need to invest in high-performance hardware and skilled engineers who can navigate both aerodynamics and complex software. While these costs are lower than building a physical wind tunnel, they’re far from negligible.

Accuracy can also be an issue. Virtual simulations often struggle with replicating intricate aerodynamic phenomena like turbulent flows, flow separation, and vortex formation. These challenges are why top teams like Mercedes and Red Bull still rely on physical testing for critical aerodynamic developments.

To ensure reliable results, virtual data must be cross-checked against physical wind tunnel findings and on-track telemetry. Discrepancies often arise, requiring adjustments to the simulation parameters. This iterative process can make virtual testing less predictable.

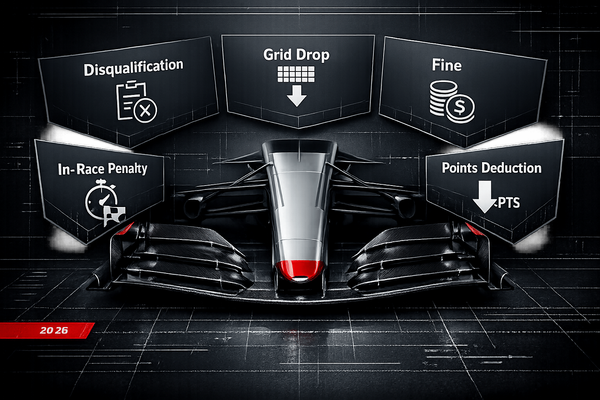

Regulatory constraints further complicate matters. The FIA imposes strict limits on CFD computational hours, similar to the restrictions on physical wind tunnel time, to maintain fairness and control costs. These limitations mean teams must carefully balance their use of virtual testing with other development tools.

Virtual vs Physical Wind Tunnel Comparison

The strengths and weaknesses of virtual and physical wind tunnel testing make each uniquely suited for different stages of car development. Here’s how they stack up across key factors:

| Factor | Virtual Wind Tunnel (CFD) | Physical Wind Tunnel |

|---|---|---|

| Initial Cost | Lower (computing infrastructure) | Very high ($100+ million facilities) |

| Operating Cost | Moderate (electricity, software licenses) | High (maintenance, model building) |

| Testing Speed | Fast iterations, parallel testing | Slower, sequential testing |

| Model Scale | Full-size possible | Limited to 60% scale (FIA rules) |

| Accuracy | High for basic flows, limited for complex turbulence | Very high for real-world phenomena |

| Flexibility | Easy scenario changes | Limited by physical model constraints |

| Regulatory Limits | CFD hour caps (FIA) | Wind tunnel time caps (FIA) |

| Validation Needs | Requires physical confirmation | Used for final validation |

Virtual testing shines in the early stages of design, where speed and flexibility are crucial for exploring a wide range of concepts. Physical wind tunnels, on the other hand, are indispensable for final validation and fine-tuning, particularly when dealing with complex aerodynamic behaviors. Most F1 teams combine these methods, using virtual testing to narrow down designs quickly and cost-effectively, then turning to physical wind tunnels to validate and refine the most promising options before hitting the track.

Impact on F1 Performance and Development

Role in Car Development and Updates

Virtual wind tunnel testing has revolutionized how F1 teams develop their cars. During the initial design stages, teams can digitally analyze thousands of aerodynamic concepts before committing to expensive physical prototypes. This approach opens the door to bold, creative designs without the financial risk of traditional methods.

At the height of development cycles, teams often conduct hundreds of CFD simulations each week, reducing evaluation times from weeks to mere days. These simulations don't just improve aerodynamic performance - they also guide race strategies by helping teams decide which upgrades to prioritize for specific track conditions.

With the FIA imposing strict limits on physical wind tunnel usage and CFD computational hours, virtual testing has become indispensable. By digitally evaluating countless design variations, teams can make the most of their limited physical testing time, ensuring every second spent in a wind tunnel is as productive as possible. This digital-first approach integrates seamlessly with traditional aerodynamic testing methods, creating a more efficient development process.

Real Examples from F1 Teams

Take Aston Martin Aramco F1, for instance. The team has heavily invested in advanced simulations to fine-tune their aerodynamics, leading to noticeable performance gains throughout the season. Similarly, McLaren and Mercedes have utilized virtual wind tunnel testing to refine their designs and roll out impactful mid-season upgrades. These cases highlight how virtual testing not only improves design precision but also provides a deeper understanding of how aerodynamic components interact.

The cost savings are another game-changer. Virtual testing slashes development expenses compared to physical wind tunnels. This efficiency has leveled the playing field, giving smaller teams access to cutting-edge simulation tools without the need for massive, expensive facilities.

Beyond cost and accessibility, virtual testing allows engineers to push boundaries in a risk-free digital environment. They can experiment with extreme design concepts, identify potential failure points, and explore ideas that might never make it to physical prototypes. This freedom often leads to innovations that redefine what's possible in car performance.

Future of Virtual Testing in F1

Looking ahead, virtual testing is set to become even more advanced. With ongoing improvements in computing power, simulation algorithms, and data integration, the technology will continue to evolve. As F1 regulations increasingly emphasize aerodynamic ingenuity, teams will rely more heavily on virtual tools to remain competitive and solve emerging technical challenges.

Artificial intelligence and machine learning are already making their mark in CFD workflows, accelerating design optimization. These technologies can identify subtle aerodynamic patterns that might otherwise go unnoticed, giving teams a competitive edge.

Another exciting development is the integration of real-time race data. Teams are exploring ways to link CFD predictions with live telemetry from practice sessions. This connection allows them to validate and adjust simulation models on the fly, enabling quick setup changes between sessions.

Regulatory changes will also shape the future of virtual testing. As the FIA continues to balance cost control with technical progress, teams may be pushed to adopt even more efficient computational methods. If virtual simulations reach the accuracy of physical tests, wind tunnels might eventually shift to a secondary role - used mainly for final validation rather than primary development.

F1 Aerodynamics CFD Course : Virtual Wind Tunnel & Replicating Vehicle Setup

Conclusion

Virtual wind tunnel testing has reshaped the way Formula 1 teams develop their cars, offering a powerful tool that balances the need for peak performance with strict regulations and budget constraints. By leveraging Computational Fluid Dynamics (CFD), teams can experiment with aerodynamic concepts in a digital environment before committing to costly physical prototypes.

This approach not only trims expenses and shortens development timelines but also plays a critical role in delivering competitive performance on race day. The combination of AI and CFD insights has further accelerated development, allowing teams to fine-tune aerodynamic efficiency throughout the season. Moreover, this digital-first strategy has made advanced simulation tools more accessible, reducing dependence on massive, multimillion-dollar physical facilities.

With FIA-imposed restrictions on physical testing, virtual methods have become indispensable. From shaping initial designs to planning mid-season upgrades, CFD simulations now guide nearly every aspect of car development.

Looking ahead, advancements in artificial intelligence and machine learning promise to take CFD workflows to the next level. As computing power grows and simulation algorithms become more refined, virtual testing will uncover subtle aerodynamic insights and allow for risk-free experimentation with bold design ideas. This evolution positions virtual wind tunnels as a cornerstone of future car development in Formula 1, driving innovation and redefining the sport’s technical frontiers.

For fans eager to dive deeper into how these technologies impact race performance, F1 Briefing offers detailed coverage of aerodynamic breakthroughs, regulatory updates, and team strategies shaping the ever-evolving world of Formula 1.

FAQs

How does virtual wind tunnel testing enhance the precision of F1 car designs compared to traditional wind tunnels?

Virtual wind tunnel testing has revolutionized how F1 car designs are refined, offering engineers incredibly detailed aerodynamic simulations. Unlike traditional wind tunnels, this approach eliminates the hefty time and cost investments tied to building physical prototypes, while allowing for a much broader range of configurations to be tested.

Another key advantage is the speed. Virtual testing delivers results much faster, enabling teams to tweak and refine designs with greater efficiency. Using advanced computational tools, engineers can pinpoint subtle aerodynamic adjustments that might go unnoticed in physical tests, ultimately giving teams a crucial performance boost on the track.

What are the main challenges F1 teams face when using CFD for aerodynamic testing?

F1 teams encounter several hurdles when leveraging Computational Fluid Dynamics (CFD) for aerodynamic testing. One of the biggest challenges is the immense computational power needed to simulate airflow with precision. High-resolution simulations require advanced processing capabilities, which can be both expensive and time-intensive.

Another obstacle is maintaining the accuracy of these simulations. Since CFD relies on mathematical models, it can sometimes oversimplify real-world conditions. This can create a gap between the virtual results and how the car actually performs on the track. To address this, teams are constantly fine-tuning their models to align more closely with on-track behavior.

On top of that, regulatory restrictions on CFD use - like limits on computing hours - add another layer of complexity. Teams must carefully strategize their testing schedules to make the most of their allocated resources while still achieving meaningful results.

How do F1 teams ensure virtual wind tunnel simulations match real-world track performance?

F1 teams rely on a mix of cutting-edge computational fluid dynamics (CFD) tools, wind tunnel testing, and on-track telemetry to fine-tune their virtual simulations. By comparing the results from simulations with data collected during real-world testing, they can pinpoint any inconsistencies and tweak their models for greater precision.

To further enhance accuracy, teams carry out correlation studies. This involves testing specific car components or setups in both virtual simulations and controlled environments, like wind tunnels or track sessions. This back-and-forth process ensures the virtual wind tunnel reflects real-world conditions, enabling teams to refine their car's aerodynamics for maximum performance on race day.