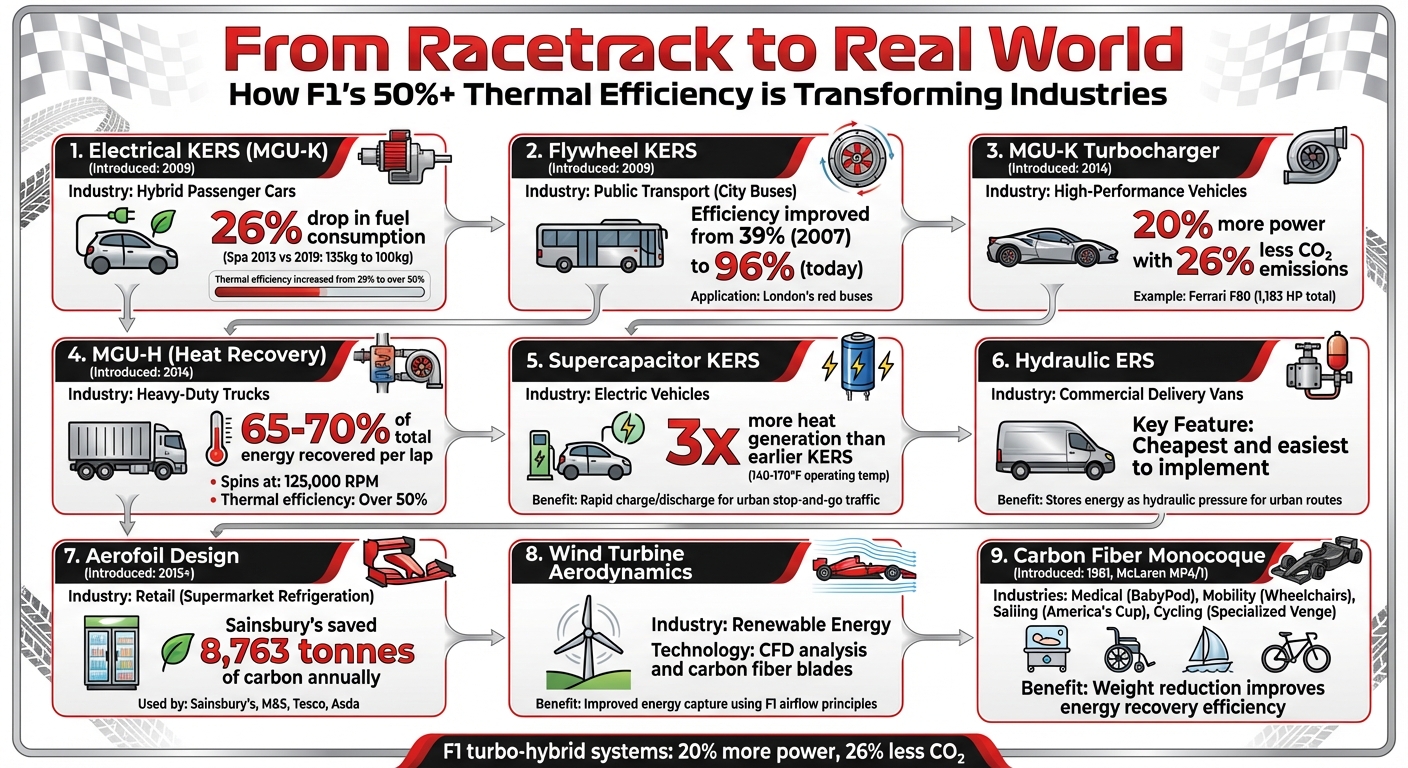

9 F1 Energy Recovery Techs Used in Other Industries

Nine F1-derived energy-recovery technologies adapted for buses, trucks, retail refrigeration, EVs and wind to boost efficiency and cut emissions.

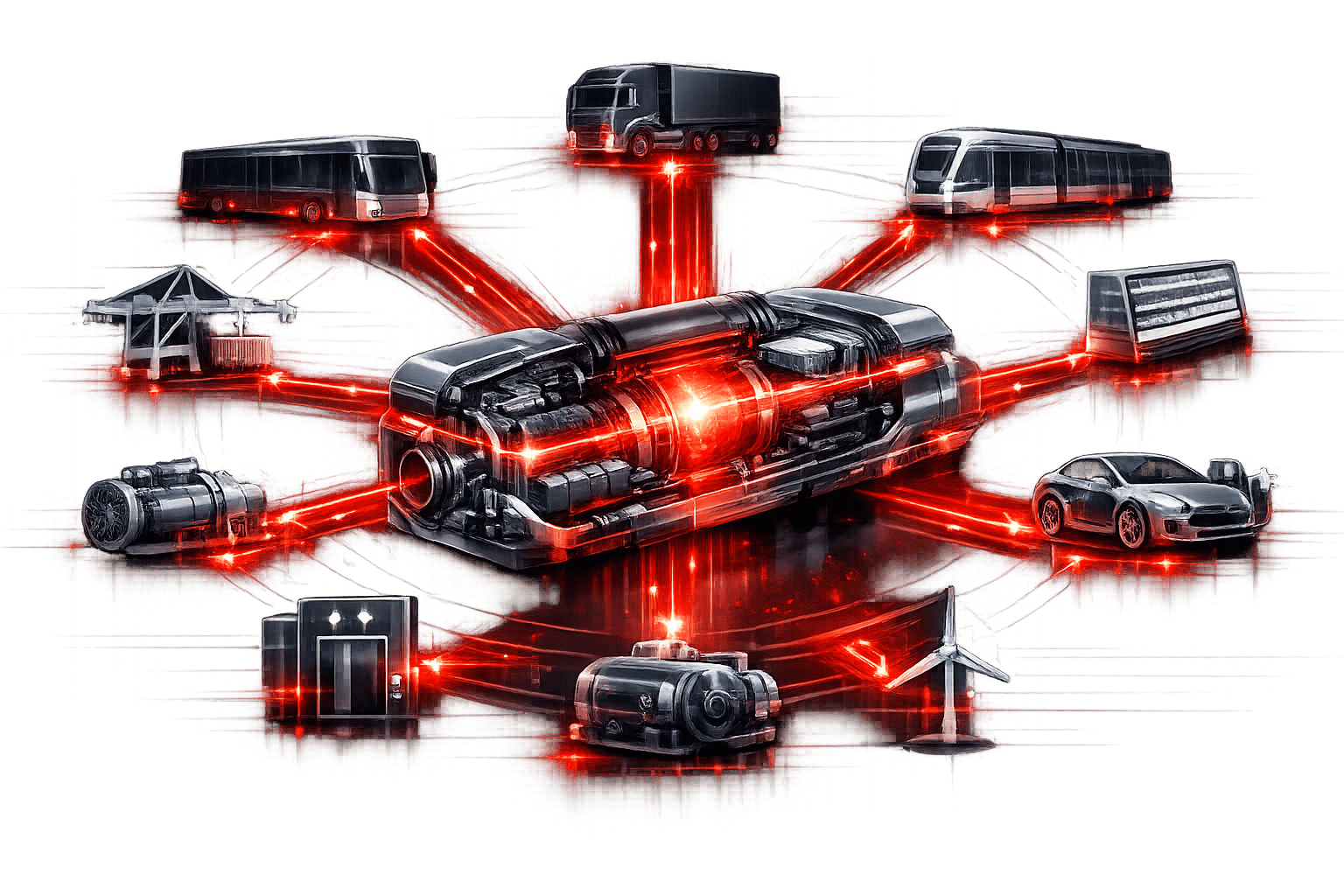

Formula 1's energy recovery technologies aren't just revolutionizing motorsport - they're making everyday industries more efficient. From reducing fuel consumption in buses to improving refrigeration systems in supermarkets, these innovations are creating practical solutions far beyond the racetrack.

Key takeaways:

- KERS (Kinetic Energy Recovery System): Captures braking energy for hybrid passenger cars, cutting fuel use and emissions.

- Flywheel KERS: Helps city buses save energy during braking cycles.

- MGU-K and MGU-H: Boosts engine efficiency in high-performance vehicles and heavy-duty trucks.

- Aerofoil Designs: Reduces energy waste in supermarket refrigerators.

- Carbon Fiber Monocoque: Minimizes weight for better energy recovery in vehicles and other applications.

- Supercapacitor KERS: Optimizes braking energy for electric vehicles.

- Hydraulic ERS: Lowers fuel consumption in delivery vans.

- Wind Turbine Aerodynamics: Improves energy capture using F1 airflow principles.

These technologies are driving efficiency in transportation, retail, renewable energy, and more, showing how F1's relentless push for performance is reshaping industries worldwide.

9 F1 Energy Recovery Technologies and Their Industrial Applications

1. Electrical KERS in Hybrid Passenger Cars

Energy Recovery Efficiency

Electrical KERS, or the Motor Generator Unit-Kinetic (MGU-K) as it's called in Formula 1, is designed to capture braking energy that would otherwise be wasted as heat. This energy is stored in a battery and later used during acceleration, reducing the workload on the engine. In F1, this technology has pushed thermal efficiency from 29% to over 50%. Essentially, more of the fuel’s energy is converted into forward motion rather than being lost.

To put this into perspective, at Spa-Francorchamps in 2013, Sebastian Vettel completed his fastest lap using 135 kg of fuel. Fast forward to 2019, and a turbo-hybrid power unit managed a quicker lap - 1 minute 46.409 seconds - using just 100 kg of fuel. That’s a 26% drop in fuel consumption while achieving faster lap times.

These advances required careful adaptation to make the technology practical for everyday driving.

Adaptation for Industry-Specific Needs

Bringing F1-level efficiency to road cars wasn’t a simple copy-paste. These systems had to be reworked to fit the needs of everyday drivers and vehicles. For instance, while F1 drivers manually manage energy recovery and deployment, road cars rely on automated systems. In passenger vehicles, the Electronic Control Unit (ECU) takes over, deciding when to recover energy and when to use it.

Ferrari’s LaFerrari, released in 2013, is a prime example of this transition. Its HY-KERS system added an extra 163 hp to the V12 engine, resulting in a combined output of 963 hp. Unlike F1 systems, it was optimized for regular fuel and automated operation. Another standout example is the Mercedes-AMG One, which debuted in 2022. Powered by a road-legal version of Mercedes' F1 1.6-liter V6 turbo-hybrid engine, it produces over 1,000 hp. This system includes both MGU-K and MGU-H units, modified to run on pump gas and comply with road regulations.

Environmental Impact (Emissions Reduction)

The environmental benefits of these systems are hard to ignore. F1’s turbo-hybrid power units emit 26% less CO2 while generating 20% more power compared to the older V8 engines. This efficiency carries over to hybrid passenger cars.

Take Ferrari’s LaFerrari, for example. Its HY-KERS system cut fuel consumption and CO2 emissions by 40% compared to a non-hybrid equivalent, with emissions at 330 g/km of CO2. Even mass-market cars are reaping the benefits. Fiat’s mild-hybrid Panda uses KERS-inspired regenerative braking to capture energy during deceleration. This energy is stored in a small lithium battery and assists with acceleration, cutting emissions in urban settings.

Cost-Effectiveness in Implementation

Making this technology affordable and scalable is key to its success in passenger vehicles. The MGU-K, for instance, has proven feasible for road cars and is found in models ranging from the Volvo S60 T5 to the Mercedes S-Class, as well as hypercars like the LaFerrari. However, the MGU-H (heat recovery), while powerful, remains too costly and complex for widespread use. It’s currently reserved for ultra-high-performance vehicles.

The MGU-K strikes a middle ground. It’s advanced enough to deliver real efficiency improvements, yet simple enough to be produced at scale, making it a practical choice for mainstream hybrid cars.

ERS: What It Is and How It Works

2. Flywheel-Based KERS in Buses

The advancements in Formula 1's KERS technology have found a new purpose - helping buses recover energy during braking.

Energy Recovery Efficiency

In conventional braking systems, kinetic energy is lost as heat. Flywheel-based KERS, however, captures this energy during deceleration and stores it as rotational momentum in a flywheel. When the bus accelerates again, this stored energy is released back into the drivetrain, easing the engine's workload and improving efficiency.

The early hybrid KERS systems in F1 reached an efficiency of 70%, with improvements skyrocketing from 39% in 2007 to an impressive 96% today. Unlike electrical KERS, which relies on lithium-ion batteries to store energy chemically, flywheel systems use mechanical storage. This approach is particularly beneficial for heavy-duty vehicles like buses, where durability and reliability are key.

Adaptation for Industry-Specific Needs

Williams Advanced Engineering has tailored flywheel technology specifically for London's iconic red buses. While F1 teams prioritize speed and lap times, bus operators focus on maximizing fuel efficiency and distance covered. The mechanical flywheel system is better suited for the rigorous demands of city buses, as it handles high-duty cycles more effectively than lithium-ion systems, which often require intricate cooling mechanisms.

F1's attention to weight optimization has also influenced bus KERS designs. For every additional 10 kg, performance can be noticeably affected. To address this, manufacturers have fine-tuned the KERS units to ensure their weight does not negate the fuel-saving benefits. This careful design enhances both fuel economy and environmental performance.

Environmental Impact (Emissions Reduction)

After the 2009 F1 season, Williams Advanced Engineering repurposed the flywheel-based KERS from the FW31 race car for use in London's bus fleet. While F1 adopted electrical battery systems due to space constraints, the mechanical flywheel proved a better fit for public transport.

"Regenerative braking has since been implemented in public transport across the rest of the UK, helping to reduce carbon emissions, improve fuel efficiency and lower air pollution."

- Katy Roberts, Writer, Formula 1

3. MGU-K Turbocharger Coupling in Race-Derived Engines

Formula 1's cutting-edge energy recovery systems are no longer confined to the racetrack - they’ve found their way into high-performance road engines. These systems rely on two critical components: the MGU-K (Motor Generator Unit – Kinetic), which captures energy during braking, and the MGU-H (Heat), which is connected to the turbocharger shaft to recover heat energy from exhaust gases. Remarkably, the MGU-H can spin at speeds reaching 125,000 RPM, contributing a staggering 65–70% of the total energy recovered per lap in an F1 car. Together, these technologies have driven thermal efficiency in F1 engines beyond 50%, a massive leap from the 29% efficiency seen during the V8 engine era.

In October 2024, Ferrari introduced the F80 hypercar, a marvel of engineering that blends an F1-inspired 3.0L V6 engine with both MGU-K and MGU-H systems. This powerhouse generates a combined 1,183 HP - 887 HP from its internal combustion engine and an additional 296 HP from hybrid assistance. The F80 can rocket from 0 to 62 mph in just 2.1 seconds, showcasing how F1-derived energy recovery systems can deliver jaw-dropping performance in a road-legal car.

Adaptation for Industry-Specific Needs

Bringing F1 technology to everyday vehicles isn’t as simple as copying and pasting. Race cars are designed to run on specialized fuels, while commercial vehicles must work seamlessly with standard pump gas. Mercedes-AMG tackled this challenge with the "One" hypercar, which features a re-engineered 1.6L V6 Turbo F1 engine adapted for pump gas. This setup combines MGU-H and MGU-K systems with an 800V lithium battery, delivering over 1,000 HP (782 kW) and maintaining thermal efficiency above 50%.

However, there are hurdles. The MGU-H unit is highly complex and expensive, making it impractical for mass-market use. On top of that, these advanced systems need sophisticated ECUs to balance everyday drivability with high performance. Components that endure extreme conditions in racing also have to be redesigned for durability and reliability in daily use. These adaptations not only make the technology accessible for regular drivers but also help reduce emissions and improve fuel efficiency.

Environmental Impact (Emissions Reduction)

F1 turbo-hybrid engines have achieved a remarkable balance between performance and efficiency. Compared to the older V8 engines, these systems deliver 20% more power while cutting CO₂ emissions by 26%. Fuel consumption has also seen a dramatic drop, going from about 160 kg per race in 2013 to just 100 kg by 2020.

"F1 engines have become 10% more efficient in six years, such is the rapid pace of development."

- Samarth Kanal, Staff Writer, Formula 1

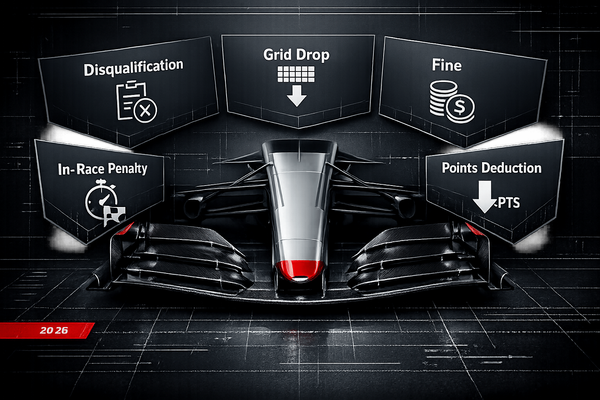

Looking ahead, Formula 1's 2026 regulations aim to further reduce fuel loads to approximately 70 kg per race by increasing electrification. This ambitious target sets a new standard for commercial engine development, proving that efficiency and performance can go hand in hand.

4. Exhaust Energy Recovery (MGU-H) in Heavy-Duty Trucks

MGU-H technology, originally developed for Formula 1 (F1), is now being adapted to enhance energy recovery in heavy-duty trucks. These trucks, which spend countless hours on highways consuming large amounts of diesel, generate significant exhaust heat - an energy source that often goes unused. By capturing this waste heat and converting it into electrical power, trucking companies can lower fuel consumption and cut operating expenses.

Energy Recovery Efficiency

In F1, MGU-H systems recover an impressive 65–70% of total energy per lap by integrating a motor-generator unit directly onto the turbocharger shaft. This setup helps push thermal efficiency beyond 50%. For heavy-duty trucks, which typically operate at steady speeds on highways, this technology is especially advantageous. Unlike passenger cars that deal with frequent stop-and-go traffic, long-haul trucks maintain consistent exhaust temperatures and flow rates, making them ideal for continuous energy recovery. When paired with modern energy storage systems, these units can achieve efficiency rates as high as 96%, ensuring that most of the captured energy is stored and reused effectively.

Adaptation for Industry-Specific Needs

Translating MGU-H technology from F1 to the trucking industry requires careful adjustments. While F1 vehicles are engineered for short bursts of peak performance, commercial trucks focus on durability, affordability, and reliability over long distances. For instance, the extreme rotational speeds of 125,000 RPM seen in F1 must be scaled down to improve bearing life and reduce maintenance demands. Additionally, the high cost of F1-grade components must be addressed to make the technology practical for widespread use.

Long-haul trucks are built to handle hundreds of thousands of miles under challenging conditions, so MGU-H systems for these vehicles must be designed with longevity in mind. To minimize energy loss, the industry is moving toward high-voltage systems operating at nearly 1,000 volts - an approach inspired by F1. These adaptations ensure the technology remains durable, cost-effective, and efficient, while also contributing to environmental benefits.

Environmental Impact (Emissions Reduction)

For long-haul operations, where exhaust temperatures remain steady, the energy recovered can lead to meaningful reductions in emissions. In F1, turbo-hybrid systems incorporating MGU-H technology reduced CO₂ emissions by 26% compared to older naturally aspirated engines, all while delivering 20% more power. In the trucking industry, which is a major contributor to transportation emissions, adopting similar systems could significantly lower the sector's carbon footprint.

With stricter environmental regulations being implemented worldwide, F1-derived hybrid technologies are becoming increasingly relevant for commercial applications. By enabling engines to generate more power while using less fuel, MGU-H systems tackle both efficiency and emissions challenges. For fleet operators, this means the potential for substantial fuel savings and lower operating costs over time, making it a win-win for both businesses and the environment.

5. Supercapacitor KERS in Electric Vehicles

Supercapacitor-based Kinetic Energy Recovery Systems (KERS), inspired by Formula 1's (F1) Energy Recovery System (ERS), are transforming how energy is managed in electric vehicles, especially in urban settings. Unlike traditional batteries, which can struggle to handle the intense energy bursts generated during braking, supercapacitors excel in these scenarios. This makes them ideal for electric vehicles frequently navigating stop-and-go traffic conditions, where efficient energy recovery is crucial.

Energy Recovery Efficiency

Supercapacitor KERS are particularly effective at capturing and storing the high-energy bursts produced during braking. They can rapidly charge and discharge, ensuring that almost all the energy recovered is immediately available for acceleration. This quick energy transfer is a game-changer for electric vehicles operating in urban environments, where frequent starts and stops demand efficient energy management.

Adjustments for Everyday Use

While the technology stems from F1, adapting it for everyday vehicles involves some key changes. In race cars, energy deployment is often manually controlled, but road vehicles rely on Electronic Control Units (ECUs) to manage energy recovery and usage automatically. This ensures a seamless experience for drivers.

Another critical challenge is heat management. F1's MGU-K units generate three times more heat than earlier KERS designs, with operating temperatures ranging from 140–170°F. For road vehicles, which require sustained performance rather than short bursts, advanced cooling systems are essential to maintain safe and efficient operation.

Benefits for the Environment

The advantages of supercapacitor KERS extend beyond performance. By recovering and reusing braking energy, these systems reduce overall energy consumption, which directly lowers emissions. This aligns with the goals of turbo-hybrid systems that aim to cut CO₂ output while enhancing power. Public transport, like buses, has already adopted this technology, helping to improve air quality in cities. The ability to reduce energy demand and emissions makes supercapacitor KERS an eco-friendly solution for urban mobility.

6. Hydraulic ERS in Commercial Delivery Vans

Hydraulic Energy Recovery Systems (ERS) are another example of Formula 1's influence on improving efficiency in commercial vehicles. Similar to electrical and flywheel systems, hydraulic ERS capture braking energy, but they do so by compressing fluid into a high-pressure accumulator filled with nitrogen. When the vehicle accelerates, the stored pressure powers a hydraulic motor, providing additional energy to the engine and cutting fuel consumption.

Energy Recovery Efficiency

This system shines in urban settings where delivery vans frequently stop and start. Each time the brakes are applied, energy that would otherwise dissipate as heat is stored as hydraulic pressure. During acceleration, this stored energy directly supplements the vehicle's power output. This makes hydraulic ERS an ideal fit for the constant braking and accelerating typical of delivery routes.

Cost-Effectiveness in Implementation

One of the standout advantages of hydraulic systems is their affordability and straightforward design compared to more complex electric alternatives. Adrian Newey, Chief Technical Officer, highlighted this point:

"While the hydraulic system is the least technically favorable, it was the cheapest and easiest to implement"

. By sidestepping the need for expensive lithium-ion batteries and intricate electronics, hydraulic ERS offers fleet operators a budget-friendly way to improve fuel efficiency without requiring significant upfront investment.

Tailored for Commercial Use

Hydraulic KERS (Kinetic Energy Recovery System) has its roots in Formula 1, with McLaren experimenting with the technology as early as 1998. Although it was eventually banned in the sport, its potential found a new home in commercial vehicles. For delivery vans, which endure heavy stop-and-go traffic, the focus shifts from peak performance to reliability and consistent operation. Built with durable components, these systems are designed to handle the demands of everyday use, showcasing how F1 innovations can be reimagined for practical, real-world applications.

7. Aerofoil Energy Recovery in Supermarket Refrigerators

The world of Formula 1 aerodynamics has made its way into supermarket refrigeration, thanks to a collaboration between Aerofoil Energy and Williams Advanced Engineering. Together, they developed aluminum aerofoil strips inspired by F1 rear wing designs. These strips are mounted on the fronts of open refrigerators, cleverly redirecting cold air back into the units. This reduces the strain on cooling systems and demonstrates how F1 technology can deliver practical energy savings far from the racetrack.

Open-front refrigerators rely on an "air curtain" to keep cold air inside. When this curtain weakens, cold air escapes into the store aisles, forcing the cooling units to work harder. The aerofoil strips solve this issue by improving airflow control, keeping cold air contained within the refrigerators. This not only boosts energy efficiency but also makes store aisles noticeably warmer for shoppers.

Adapting F1 aerodynamic principles for refrigeration wasn’t straightforward. Williams Advanced Engineering had to modify the rear wing design into a compact aluminum device tailored for refrigerators. The effort paid off, with major UK retailers like Sainsbury's, M&S, Tesco, and Asda now using these devices in their stores.

The results speak volumes. In April 2025, Sainsbury's announced annual carbon savings of 8,763 tonnes after implementing the aerofoil strips, a significant step toward its goal of achieving net zero emissions by 2040. Beyond reducing energy costs, this technology improves the overall shopping experience by keeping the aisles warmer and more comfortable.

8. Wind Turbine Blade Design from ERS Aerodynamics

Formula 1's expertise in aerodynamics has found a surprising application in renewable energy, particularly in wind turbine design. Decades of perfecting airflow management to boost downforce and cut drag on racecars are now being applied to improve the efficiency of wind turbines. This demonstrates how aerodynamic principles can be scaled and tailored for entirely different purposes.

Tailoring F1 Techniques for Wind Turbines

F1's aerodynamic advancements have provided a foundation for engineers working on large-scale wind turbine systems. However, translating these innovations to wind turbines requires significant modifications. Unlike the compact, high-speed designs of F1 cars, wind turbines operate at lower speeds and are much larger. One standout contribution from F1 is the use of carbon fiber materials. This technology allows turbine blades to be both lighter and stiffer compared to conventional materials, enhancing their performance.

Additionally, tools like computational fluid dynamics (CFD) and wind tunnel testing - staples in F1 engineering - are now pivotal in refining wind turbine blade designs. These methods help engineers analyze airflow over turbine blades, identifying areas where energy is lost and making precise adjustments to improve efficiency, similar to optimizing a racecar's wing.

Boosting Energy Conversion

The emphasis on efficiency that drives F1 innovation is directly applicable to wind energy. By incorporating aerodynamic insights from F1, turbine blades are better equipped to harness wind's kinetic energy and convert it into electricity with minimal waste. The use of carbon fiber not only reduces weight but also ensures blades maintain their ideal shape under fluctuating wind conditions, further improving energy capture. This cross-industry application highlights how F1's relentless focus on performance continues to inspire advancements in renewable energy.

9. Carbon Fiber Monocoque for Weight Reduction

The carbon fiber monocoque chassis, introduced to Formula 1 by McLaren with the MP4/1 in 1981, marked a major shift in vehicle design. While it’s not an energy recovery system itself, this lightweight structure plays a critical role in improving the efficiency of such systems across various fields. By cutting down vehicle weight, carbon fiber technology allows energy recovery systems to function more effectively, delivering noticeable performance improvements.

Energy Recovery Efficiency

Lighter vehicles are inherently more efficient when it comes to energy recovery. The reduced weight allows these systems to capture and use a greater share of available energy. Formula 1 data shows that this approach not only improves performance but also significantly lowers fuel consumption. In essence, trimming weight enhances the overall functionality of energy recovery systems.

Tailored for Various Industries

The impact of carbon fiber technology extends far beyond motorsport. Engineers have adapted it for diverse applications, each benefiting from its lightweight and durable properties.

- Medical Innovations: The "BabyPod" is a carbon fiber-based transport device designed to safely carry infants in hospitals. Its lightweight structure ensures both security and ease of handling.

- Mobility Solutions: Custom-fit wheelchairs made with F1-inspired carbon fiber enhance mobility while reducing user fatigue.

- Competitive Sailing: America's Cup yachts incorporate F1 carbon composite expertise to optimize hydrodynamics and reduce structural weight. Experts like Adrian Newey and Martin Whitmarsh have applied their racing knowledge to design these high-performance vessels.

- Cycling: McLaren partnered with Specialized to develop the "Venge" racing bike, which combines reduced weight with increased stiffness. This innovation led to immediate success in competitive cycling, showcasing how weight savings translate to energy efficiency - whether powered by a cyclist or a motor.

Environmental Impact (Emissions Reduction)

Carbon fiber’s environmental benefits are tied to its ability to lower vehicle mass, leading to reduced emissions over time. Martin Whitmarsh, former McLaren Team Principal, highlighted this efficiency-driven philosophy:

"I think that it is often over looked just how efficient Formula 1 cars are... it's that drive for efficiency that is so relevant to all sorts of walks of life and challenges outside of motor racing".

The lighter a vehicle, the less energy it requires to operate, which directly cuts emissions. This aligns with Formula 1’s broader focus on advancing efficiency through technology.

Balancing Costs and Benefits

Despite its advantages, carbon fiber technology remains costly, making it most viable for high-performance and premium applications. Manufacturers often integrate it selectively - using it for body panels or specific chassis components instead of full monocoque structures - to balance performance gains with production expenses.

In industries where weight and strength are critical - such as elite cycling, competitive sailing, and specialized medical equipment - the benefits clearly outweigh the costs. As production methods improve and scale increases, it’s likely that carbon fiber will become more accessible for broader applications, especially in vehicles with hybrid systems that benefit from weight reduction.

Technology Comparison Table

The table below highlights key F1 energy recovery technologies and their applications across various industries.

| F1 Technology | Year Introduced | Target Industry | Efficiency Gains |

|---|---|---|---|

| Electrical KERS | 2009 | Hybrid Passenger Cars | Improved fuel efficiency and reduced emissions |

| Flywheel KERS | 2009 | Public Transport (Buses) | Lower emissions and cleaner urban transit |

| MGU-K | 2014 | Race-Derived Engines | 20% more power with 26% less CO₂ emissions |

| MGU-H | 2014 | Automotive | Over 50% thermal efficiency |

| Aerofoil Design | 2015+ | Retail (Supermarket Refrigerators) | Reduced energy consumption and carbon output |

| Carbon Fiber Monocoque | 1981 | Sports Equipment (Cycling) | Lighter, stiffer frames for competitive advantages |

F1's cutting-edge technologies now deliver power units with thermal efficiencies exceeding 50%. Beyond motorsport, these advancements have spurred progress in diverse fields. For example, GlaxoSmithKline doubled its toothpaste production by adopting McLaren’s pit stop-inspired synchronization techniques. Similarly, the University Hospital of Wales enhanced neonatal resuscitation procedures using protocols adapted from Williams F1. These examples highlight how F1's pursuit of efficiency is driving tangible benefits in manufacturing, healthcare, and environmental efforts.

Conclusion

F1's drive for efficiency doesn't stop at the racetrack - it stretches into industries far beyond motorsport. For instance, innovations born in F1 now help power London's buses and improve Sainsbury's refrigeration systems, significantly reducing emissions. Today's F1 turbo-hybrid power units are a marvel of engineering, achieving over 50% thermal efficiency, cutting CO₂ emissions by 26%, and delivering 20% more power compared to older models.

Industries outside of motorsport have also reaped the rewards of this technological edge. Back in 2011, GlaxoSmithKline borrowed McLaren's pit-stop strategies for their toothpaste production lines, slashing changeover times by 60% and producing an additional 20 million tubes annually - all without increasing costs. Similarly, Heathrow Airport has leaned on McLaren's data systems to streamline flight paths, leading to less ground congestion and reduced aircraft emissions.

The impact of F1 innovation goes even further. On the Isle of Eigg, F1-inspired flywheel storage technology ensures stable power for residents. Hospitals have also adopted F1's pit-stop efficiency techniques, enhancing neonatal care and improving patient outcomes. And as these technologies continue to evolve, they're starting to shape the future of road car manufacturing.

To dive deeper into how F1 advancements are transforming industries worldwide, visit F1 Briefing for expert insights and behind-the-scenes stories.

FAQs

What’s the difference between MGU-K and MGU-H?

The MGU-K captures kinetic energy during braking, delivering up to 161 horsepower directly to the rear wheels for roughly 33 seconds per lap. Meanwhile, the MGU-H harvests heat energy from exhaust gases, boosting the turbocharger and channeling energy to either the MGU-K or the battery.

Why isn’t MGU-H common in normal road cars yet?

The MGU-H (Motor Generator Unit - Heat) is rarely seen in road cars, and for good reason. Its design involves highly complex components, including advanced materials, sophisticated cooling systems, and precise control electronics. These factors drive up both production costs and technical challenges, making it unsuitable for mass-market vehicles.

Adding to its decline, Formula 1 plans to eliminate the MGU-H from its power units in 2026. This decision aligns with a move toward simpler and more budget-friendly hybrid systems, further reducing any potential crossover into consumer car technology.

Which F1 energy-recovery tech is easiest to adopt at scale?

The Kinetic Energy Recovery System (KERS), first introduced in Formula 1 in 2009, is one of the most accessible energy-recovery technologies for broader use. It works by capturing energy generated during braking and converting it into power that can be reused. Thanks to its relatively simple design, which relies on familiar mechanical and electrical components, KERS is well-suited for industries like public transportation, hybrid cars, and even aerospace. Unlike more intricate systems such as the MGU-H, KERS stands out for being practical and cost-efficient when applied on a larger scale.