CFD and Real-Time Data: Impact on F1 Design

Explore how CFD and real-time data are revolutionizing F1 car design, enhancing performance and efficiency through innovative technologies.

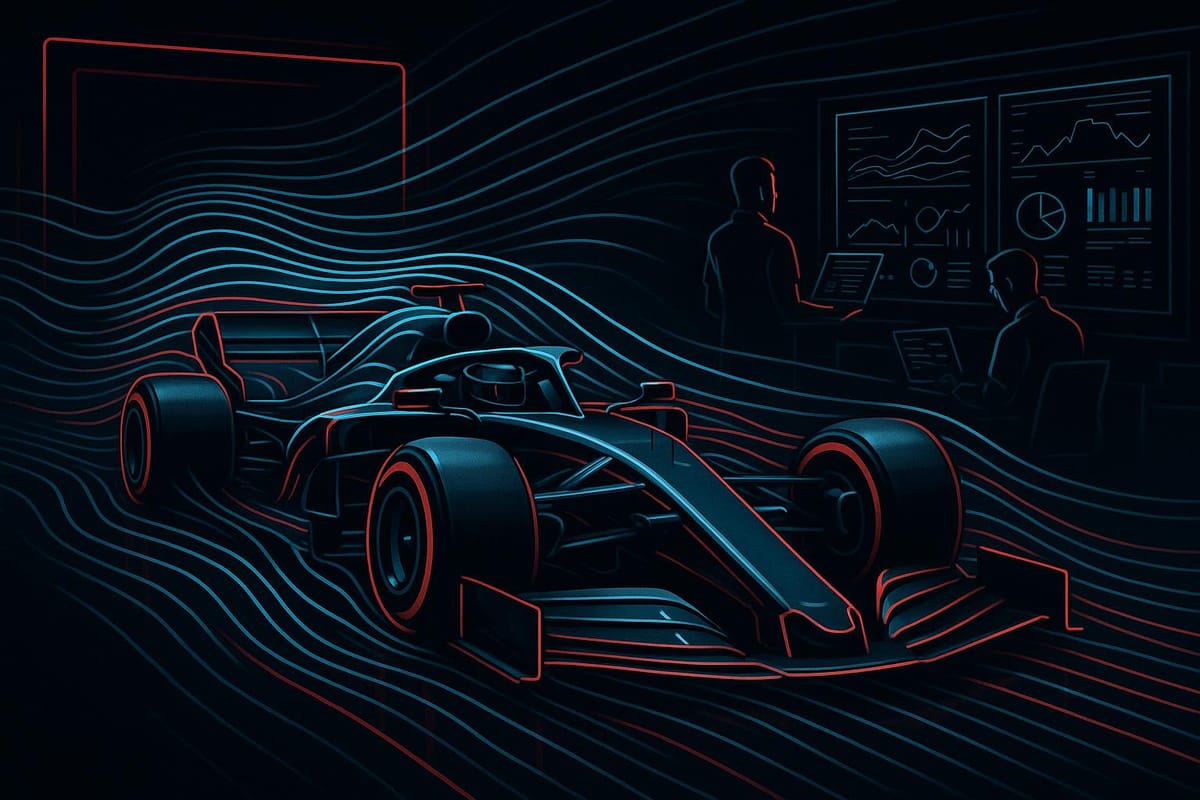

Formula 1 car design has evolved into a precise, data-driven process. Teams now rely on Computational Fluid Dynamics (CFD) and real-time telemetry to refine aerodynamics and improve performance. CFD allows engineers to simulate airflow digitally, reducing the need for physical prototypes, while real-time sensors provide instant feedback during races. Together, these technologies create a feedback loop where simulations are validated and adjusted based on actual track data.

Key Takeaways:

- CFD: Simulates airflow to optimize car components like wings and diffusers.

- Real-Time Data: Sensors provide live metrics (e.g., tire temperature, downforce).

- Integration: Combining CFD with telemetry ensures accurate designs and faster problem-solving.

- Benefits: Faster development cycles, reduced costs, and track-specific performance tuning.

By merging simulations with live data, F1 teams can refine designs throughout the season, making cars faster and more efficient.

CFD Results - How to Interpret an Aerodynamic Analysis

How F1 Teams Combine CFD with Real-Time Race Data

In Formula 1, blending Computational Fluid Dynamics (CFD) with real-time telemetry is a game-changer. Teams use this combination to turn simulation insights into tangible performance boosts, refining their models and strategies with every lap.

From CAD Models to CFD Simulations

The process begins with aerodynamicists designing precise CAD models of key components that interact with airflow, like wings and floor elements. These models are used to create a computational mesh - essential for running accurate simulations. With this mesh in place, CFD analyses simulate various conditions, such as different front wing angles, to study their effects on downforce, drag, and pressure distribution.

CFD simulations rely on solving the Navier-Stokes equations, which govern fluid flow. F1 teams subject their models to race-specific scenarios, like high-speed straights or sharp cornering, to ensure the car's aerodynamic performance is optimized for any challenge. These simulations aren’t quick - each full-car model can require hours of processing on cutting-edge computing clusters.

But teams don’t stop at a single simulation. They test a wide range of design variations, tweaking parameters like the front wing angle in small increments. This allows engineers to evaluate how even subtle changes influence critical aerodynamic factors. These simulations lay the groundwork for integrating live telemetry data into performance optimization.

Adding Real-Time Data to CFD Models

Once the simulations are complete, the next step is overlaying them with telemetry data gathered during practice sessions and races. Modern F1 cars are packed with sensors that measure everything from aerodynamic forces to thermal performance.

For example, pressure sensors on the front wing, floor edges, and rear wing validate the accuracy of CFD predictions. Temperature sensors in brake ducts and radiators help refine cooling models, while ride height and suspension data allow engineers to fine-tune boundary conditions for dynamic scenarios.

If a CFD simulation predicts a performance gain - such as increased downforce from a redesigned floor - teams verify these results using telemetry from practice sessions. This feedback loop enables them to make precise adjustments before qualifying, ensuring the car performs as expected under real-world conditions.

High-Performance Computing in F1 Simulations

Handling these intricate simulations and validation cycles requires immense computational power. F1 teams depend on high-performance computing clusters capable of running multiple simulations simultaneously. Parallel processing ensures that design iterations are tested efficiently, even under tight deadlines.

Artificial intelligence and machine learning are now playing a larger role in CFD workflows. By pinpointing the most critical design parameters, these technologies help engineers focus their efforts where it matters most. Machine learning models can also predict the outcomes of minor geometry changes much faster than traditional simulation methods, speeding up the design process.

Cloud computing has further revolutionized CFD in F1, offering teams the ability to scale their computational power as needed. During critical development phases, teams can tap into additional cloud resources to run specialized simulations tailored to a particular track's unique demands. This flexibility ensures they’re always ready to adapt and innovate, no matter the challenge ahead.

How This Integration Improves Car Performance and Design

Bringing together CFD simulations and real-time telemetry has revolutionized F1 car development. By combining predictive simulations with live data, teams can quickly address issues, fine-tune car setups for specific circuits, and streamline the overall development process. This combination doesn’t just speed up problem-solving - it also enhances car design to meet the unique demands of different tracks.

Identifying and Resolving Issues Faster

Real-time telemetry provides immediate feedback, enabling teams to quickly detect aerodynamic problems. When CFD simulations are updated with this live data, engineers can zero in on trouble spots and test solutions almost instantly. This rapid feedback loop minimizes delays and allows for focused design improvements, even during the high-pressure environment of race weekends.

Customizing Cars for Each Track

Once problems are resolved, teams use real-time insights to adapt car setups to the unique challenges of each circuit. Every track has its own requirements, and the combination of CFD and telemetry data allows engineers to fine-tune critical elements like downforce and drag. Whether it’s the tight, twisting corners of a street circuit or the flat-out straights of a high-speed track, this approach helps optimize performance by aligning the car’s design with actual track conditions.

Reducing Costs and Development Time

Replacing extensive wind tunnel testing with integrated CFD analysis significantly cuts both time and expenses. Digital simulations provide a faster way to evaluate design changes, eliminating the need for prolonged physical tests. This efficiency not only accelerates the development process but also allows teams to allocate resources more effectively, ultimately boosting their performance on race day.

CFD vs Wind Tunnel Testing: Which Works Better

In Formula 1, the debate between Computational Fluid Dynamics (CFD) simulations and wind tunnel testing is a key driver of aerodynamic development. Teams rely on both methods to fine-tune performance, but each comes with its own set of strengths and challenges. Deciding how to balance these tools is crucial for achieving optimal results.

CFD: Strengths and Limitations

CFD simulations offer engineers an efficient way to experiment with a wide range of design options. By running virtual tests, teams can quickly and cost-effectively evaluate different configurations without the need for physical prototypes. This makes CFD particularly useful during the early stages of development, where rapid iteration is essential. Plus, the ability to adjust parameters digitally allows engineers to explore designs at a level of detail that would be impractical with physical testing.

However, CFD isn't without its flaws. It struggles to accurately model highly complex or chaotic airflow, especially in regions where turbulence dominates. These limitations mean that while CFD is a powerful tool, it often needs to be complemented by physical testing to validate results.

Wind Tunnel Testing: Strengths and Limitations

Wind tunnel testing, on the other hand, excels at delivering precise, real-world measurements of aerodynamic forces and airflow behavior. It allows engineers to directly observe how air interacts with a physical model, providing insights that are difficult to replicate in a simulation. Flow visualization techniques in wind tunnels can also reveal subtle interactions that might otherwise go unnoticed, making it an essential step for final design validation.

But this precision comes at a cost. Wind tunnel testing is expensive, requiring significant resources to build and modify physical models. The setup process is time-intensive, and testing multiple configurations within a limited window can be challenging. Additionally, integrating real-time race data into wind tunnel analyses is more cumbersome compared to the seamless adjustments possible with CFD.

Comparing CFD and Wind Tunnel Testing

Here's a quick breakdown of how these methods stack up:

| Aspect | CFD Simulations | Wind Tunnel Testing |

|---|---|---|

| Cost | Lower test costs | Higher expenses for facilities/models |

| Setup and Iteration Time | Quick setup with rapid iterations | Slower setup, fewer iterations |

| Design Flexibility | Ideal for exploring early-stage ideas | Limited by physical modifications |

| Accuracy in Complex Flows | Struggles with chaotic turbulence | Excels in precise flow measurement |

| Data Integration | Easy to integrate digital telemetry | More challenging for real-time data |

A Balanced Approach

Most F1 teams combine both methods to maximize their advantages. CFD is often used early in the design process to test and refine concepts quickly. Once promising designs are identified, wind tunnel testing is employed to validate and fine-tune aerodynamic performance. This complementary approach allows engineers to harness the efficiency of simulations and the precision of physical testing, creating a robust strategy for aerodynamic development.

New Technologies Shaping F1 Design

Formula 1 continues to push the boundaries of innovation, with cutting-edge tools like digital twins, predictive analytics, AI, and advanced sensor networks transforming how teams approach car design and performance optimization.

Digital Twins and Predictive Analytics

Digital twin technology has become a game-changer in F1. By creating virtual replicas of race cars that mirror real-world performance in real time, teams can simulate various scenarios and test potential upgrades without ever touching the physical car. These virtual models are constantly updated with telemetry data, offering engineers a dynamic testing ground for refining designs.

Predictive analytics builds on this by analyzing historical data to forecast potential outcomes. For instance, teams can predict how specific aerodynamic tweaks will perform under race conditions, minimizing the risk of unsuccessful changes. This approach not only saves time but also ensures resources are directed toward the most promising developments.

AI and Machine Learning in Aerodynamics

Artificial intelligence is reshaping aerodynamics in Formula 1. Machine learning algorithms excel at detecting patterns in airflow behavior that might go unnoticed by human engineers, uncovering opportunities to improve aerodynamic efficiency.

AI also streamlines the computational side of design. By automating thousands of CFD simulations with varying parameters, AI systems can pinpoint optimal configurations much faster than traditional methods. This frees up engineers to focus on interpreting results and making strategic decisions, rather than being bogged down by repetitive computational tasks.

Next-Generation Sensor Networks

Modern sensor networks are taking F1 data collection to unprecedented levels. Today’s F1 cars are equipped with 250–300 sensors, generating over 1 million data points every second. These sensors, combined with 5G and satellite telemetry, enable cars to gather over 1 terabyte of raw data during a single race weekend, with latencies as low as 10–15 milliseconds.

Teams are also experimenting with virtual sensors and AI-driven predictions to reduce weight and costs while maintaining the flow of critical aerodynamic data. These advancements create a seamless feedback loop where real-world data continuously refines CFD simulations, ensuring designs remain cutting-edge.

This integration of advanced sensors and AI not only enhances data precision but also accelerates the cycle of testing, simulation, and real-world validation - key to staying competitive in the high-stakes world of Formula 1.

Conclusion: How CFD and Real-Time Data Shape F1's Future

The combination of CFD simulations and real-time race data is reshaping the way F1 cars are designed, blending virtual testing with on-track insights. This modern approach moves teams away from relying solely on traditional wind tunnel testing, allowing for more precise aerodynamic refinements.

By tapping into live race data, teams can quickly tweak designs and fine-tune performance to adapt to different conditions. Virtual testing not only saves time and money but also opens up opportunities to experiment with a wider range of aerodynamic setups before physical testing even begins. These advancements are driving a shift in how teams approach car development.

As Formula 1 leans further into this mix of digital modeling and live telemetry, the sport is transitioning from intuition-led design to engineering grounded firmly in data. This shift, where digital tools work hand in hand with real-world testing, marks a significant step toward more efficient and forward-thinking car development in the ever-evolving world of F1.

FAQs

How do F1 teams validate the accuracy of CFD simulations using real-time telemetry data?

F1 teams maintain the precision of their CFD (Computational Fluid Dynamics) simulations by constantly comparing them with telemetry data gathered during races and testing sessions. This telemetry provides real-time, accurate readings of factors like airflow, temperature, and pressure, which are then matched against CFD predictions to spot any inconsistencies.

To make simulations more dependable, teams fine-tune their models by tweaking simulation settings based on actual data. This back-and-forth process narrows the gap between virtual predictions and on-track performance, ensuring car designs align with real-world demands. By blending cutting-edge computing with live data, teams can quickly adapt and create race cars that perform better on the circuit.

What makes CFD a better alternative to traditional wind tunnel testing in F1 car design?

CFD, or Computational Fluid Dynamics, brings several standout benefits to Formula One car design compared to traditional wind tunnel testing. For starters, it’s a much more budget-friendly option, cutting down on the high costs of constructing and maintaining physical models. Plus, it speeds up the testing process, giving teams the ability to simulate and analyze aerodynamic performance in record time.

What really sets CFD apart, though, is its ability to tackle intricate and ever-changing airflow scenarios - situations that are nearly impossible to recreate in a wind tunnel. This allows engineers to pinpoint potential design issues early on and fine-tune their concepts long before building physical prototypes. By embracing CFD, F1 teams can streamline their design process and keep pace with the relentless demands of motorsport innovation.

How are AI and machine learning transforming the use of CFD in Formula 1 car design?

Artificial intelligence (AI) and machine learning (ML) are transforming how computational fluid dynamics (CFD) is used in Formula 1, making simulations faster and more accurate. These technologies have slashed computation times by as much as 80%, enabling teams to complete simulations in just a few hours rather than days. This speed allows for quicker aerodynamic testing and design adjustments, all without needing physical prototypes.

With tools like neural networks, teams can fine-tune car performance more effectively, focusing on everything from aerodynamic improvements to strategic decisions on race day. AI-powered CFD doesn’t just streamline development - it also helps teams make faster, smarter choices, giving them a crucial advantage both on and off the track.