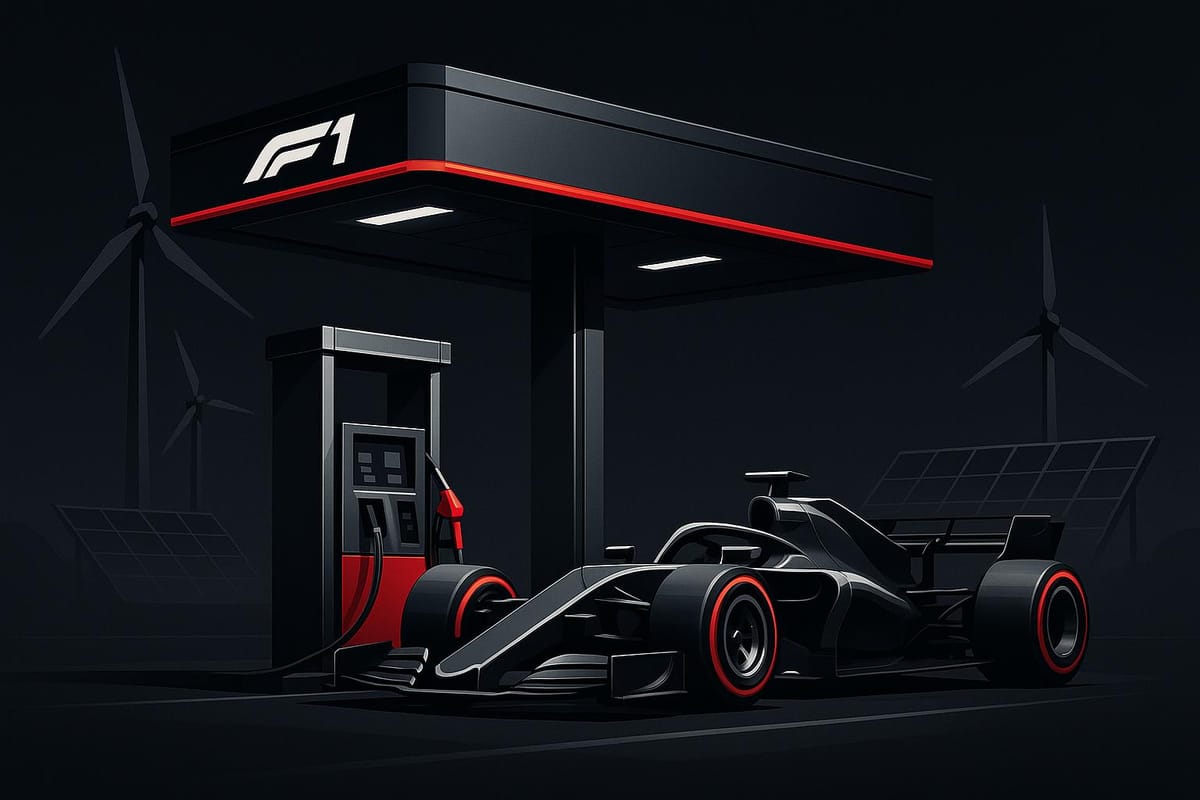

Cost Breakdown for F1 Sustainable Fuel Infrastructure

Explore the significant costs and challenges Formula One faces in transitioning to 100% sustainable fuels by 2026, including infrastructure and logistics.

Formula One is making a major shift by committing to 100% sustainable fuels by 2026, aligning with its goal of achieving net-zero carbon emissions by 2030. This transition involves significant costs and challenges, from building specialized production plants to upgrading logistics and storage systems at circuits. Here's what you need to know:

- Fuel Types: F1 is focusing on synthetic fuels (e-fuels) and advanced biofuels. Both can work with current engines but have different production costs and energy demands.

- Infrastructure Costs: Synthetic fuel plants cost over $100 million, while biofuel refineries range from $50–80 million. Transport and storage upgrades add further expenses.

- Fuel Costs: Synthetic fuels cost $200–$300 per barrel, while biofuels are around $119 per barrel - both far higher than traditional fuels, which are under $80 per barrel.

- Logistics Challenges: Transporting these fuels globally requires specialized containers and strict safety protocols, with costs up to 8x higher than conventional fuel logistics.

F1's efforts are already reducing emissions, with a 26% cut since 2018, and feeder series like Formula 2 are testing 100% sustainable fuels. However, scaling production and lowering costs remain key hurdles as the sport aims to lead broader adoption of these fuels.

F1 Fuel - The Hidden Development Race - And why E-Fuels are so EXPENSIVE

Production Infrastructure: How Sustainable Fuels Are Made

Formula One's commitment to using 100% sustainable fuels by 2026 hinges on advancements in production infrastructure. This shift toward more environmentally responsible racing relies on two distinct methods for creating sustainable fuels, each with its own cost and technological challenges.

Fuel Production Methods and Technologies

Synthetic fuels, often called e-fuels, are one of the more complex options. They are created by combining hydrogen - produced through electrolysis powered by renewable energy - with carbon monoxide or carbon dioxide captured from the air or biomass. This process involves advanced technologies like electrolysis units, carbon capture systems, and catalytic reactors, which convert these inputs into fuel suitable for racing.

The challenge lies in sourcing carbon. Synthetic fuel plants must either use direct air capture technology to extract CO₂ from the atmosphere or rely on biomass gasification to obtain carbon from organic materials. Both methods demand significant energy, with synthetic fuel production requiring up to five times more renewable electricity than what's needed to power a battery-electric vehicle.

On the other hand, advanced biofuels take a different route. These fuels are made from non-food biomass sources like agricultural waste, algae, or other byproducts. The process typically involves fermentation or thermochemical methods to break down materials into usable fuel. This approach avoids competing with food production while repurposing waste that might otherwise go unused.

Both synthetic fuels and advanced biofuels are "drop-in" solutions, meaning they can be used in current F1 engines without requiring modifications. However, producing these fuels demands substantial investment, as outlined in the next section.

Production Plant Construction Costs

Building the infrastructure for sustainable fuel production comes with a hefty price tag. Synthetic fuel plants often cost more than $100 million to construct. These facilities require specialized equipment like electrolysis units, carbon capture systems, and catalytic reactors to produce the final fuel.

In comparison, biofuel refineries are less expensive, with construction costs ranging between $50 million and $80 million. However, they still need advanced systems to process non-food biomass and convert it into high-performance fuel.

For synthetic fuels, the reliance on renewable electricity significantly impacts operating expenses, while the complexity of carbon capture and hydrogen production systems drives up initial costs. Biofuel refineries, though cheaper to build, still face challenges like regulatory compliance and the need for sophisticated processing technologies.

Companies like ARAMCO are already investing in synthetic fuel plants in Saudi Arabia and Spain to meet F1's needs. These facilities highlight the scale of infrastructure required to support the sport's global operations, which span 24 race locations.

| Fuel Type | Construction Cost | Key Infrastructure Requirements |

|---|---|---|

| Synthetic Fuel Plants | $100+ million | Electrolysis units, carbon capture, catalytic reactors |

| Biofuel Refineries | $50-80 million | Biomass processing, fermentation/thermochemical systems |

Raw Material Sourcing and Supply Chain Costs

Beyond infrastructure, securing raw materials plays a critical role in the overall cost of sustainable fuels. For biofuels, maintaining a steady supply of non-food biomass - such as agricultural residues or algae - is essential. This requires careful planning to avoid competing with food production or causing deforestation.

Synthetic fuels face different hurdles. Producing renewable hydrogen and capturing carbon dioxide demands substantial infrastructure and reliable access to renewable energy. Regional variations in renewable energy availability directly impact the feasibility and cost of synthetic fuel production.

Fluctuations in raw material prices can also drive up costs, making long-term contracts a necessity. However, these contracts often come with high price tags. Additionally, regional policies and sustainability certifications add complexity. For example, regulations mandating second-generation biofuels or carbon-captured synthetic fuels can limit feedstock options, increasing costs. Certifications from groups like the Roundtable on Sustainable Biomaterials are also required to meet F1's stringent environmental standards.

The production costs reflect these challenges. Biofuels cost around $119 per barrel, while synthetic fuels range from $200 to $300 per barrel. In contrast, traditional fossil fuels typically cost less than $80 per barrel, illustrating the financial commitment F1 is making to sustainable racing.

To address these challenges, partnerships between fuel companies and engine manufacturers have become essential. Companies like Petronas, Shell, and TotalEnergies are collaborating with engine manufacturers such as Mercedes and Red Bull Powertrains to share costs and ensure compatibility with F1's technical requirements. These alliances are critical for optimizing supply chains and building the necessary infrastructure to support the sport's ambitious sustainability goals.

Distribution and Logistics: Transporting Fuels Worldwide

Getting sustainable fuels to F1 circuits isn't as straightforward as moving conventional fuels. Synthetic and biofuels come with their own set of challenges, requiring specialized infrastructure, strict safety measures, and higher costs. Here's a closer look at what goes into making it all work.

Transport Infrastructure Requirements

Moving sustainable fuels requires changes to the traditional fuel transport setup. Their unique chemical properties - such as differences in volatility and stability - mean that specialized tanker trucks, upgraded pipelines, and advanced storage facilities are essential.

Safety measures are another layer of complexity. Teams handling these fuels must adhere to international regulations like the ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road) for land transport and the IMO (International Maritime Organization) standards for shipping by sea. On top of that, every shipment must include documentation verifying the fuel's sustainable origin and its full lifecycle carbon footprint to maintain transparency and integrity throughout the supply chain.

ARAMCO has taken a proactive approach with its dual-plant setup in Saudi Arabia and Spain. These facilities rely on advanced transport networks that include temperature-controlled containers, sealed transfer systems, and rigorous testing to ensure the fuels meet the necessary standards.

Transportation Costs and Carbon Impact

The cost of moving sustainable fuels is significantly higher than traditional fuels. For synthetic fuels, logistics costs range from $500 to $1,200 per ton - roughly 4 to 8 times more than conventional gasoline. This price hike comes from the need for specialized containers, enhanced safety protocols, and the added complexity of maintaining sustainability certifications throughout the supply chain.

Among transport options, maritime shipping is the most economical for bulk deliveries. However, F1's tight race schedules often call for road and air freight for last-mile or urgent shipments. Air freight, while the fastest option, can cost up to 10 times more than maritime shipping and has the highest carbon footprint among the three.

The production model also plays a big role in costs and emissions. ARAMCO's centralized system, with large plants in Saudi Arabia and Spain, benefits from economies of scale but requires long-distance transport, which drives up both costs and emissions. Decentralized production closer to race locations could cut transport distances and emissions, though it would likely mean higher production costs due to smaller, less efficient facilities.

F1 is actively working to reduce the environmental impact of its fuel logistics. For example, the sport has introduced biofuel-powered trucks for European freight, achieving a 9% reduction in logistics-related carbon emissions. Additionally, reshuffling the race calendar - like adjusting the timing of the Japanese Grand Prix - has helped minimize equipment movement, further cutting emissions. Still, the energy-intensive nature of fuel production and transport remains a hurdle for F1's net-zero ambitions. To tackle this, the sport is investing in alternative fuels for its logistics operations as part of its broader sustainability goals.

| Transport Method | Relative Cost Increase | Primary Use Case | Carbon Impact |

|---|---|---|---|

| Maritime Shipping | 4–8× higher | Bulk transport | Lowest per ton |

| Road Freight | Higher than maritime | Last-mile delivery | Medium |

| Air Freight | Up to 10× more than maritime | Urgent, emergency shipments | Highest |

Circuit Storage and Race Operations

When sustainable fuels arrive at F1 circuits, they require upgraded storage and handling systems. The unique characteristics of synthetic and biofuels - such as their varying volatility and potential to cause corrosion - mean circuits need specialized infrastructure, often involving substantial financial investment.

Fuel Storage Systems and Safety Requirements

F1 circuits face a choice between temporary and permanent storage solutions. Temporary systems, which are used on a race-by-race basis, cost between $20,000 and $40,000 per weekend, while permanent installations demand a much larger initial investment, exceeding $200,000. Additionally, above-ground storage tanks that meet regulatory standards can cost anywhere from $50,000 to $200,000 per unit.

Strict safety measures are non-negotiable for sustainable fuel storage. Circuits must implement features like double-walled tanks, advanced leak detection systems, fire suppression equipment, secondary containment mechanisms, and adhere to rigorous inspection schedules. These measures ensure compliance with FIA guidelines and local environmental laws.

Some circuits, such as Silverstone and the Circuit of the Americas, have already upgraded their storage and safety systems to meet these demands.

Fuel transfer in pit lanes also requires specialized infrastructure. This includes pumps, filtration units, and secure pipelines tailored to the specific properties of each fuel type. For circuits using temporary systems, the costs range from $10,000 to $50,000 per event, while permanent setups provide a more cost-effective solution over time.

Maintenance adds another layer of expense. Annual costs for inspections, safety system upkeep, and staff training typically fall between $5,000 and $20,000. These investments in storage systems pave the way for the additional infrastructure upgrades needed during race events.

Race Event Infrastructure Costs

Beyond storage, circuits must also adapt their race event operations to incorporate low-carbon energy systems. For instance, solar panel installations can cost between $100,000 and $500,000, while biofuel generators are priced at $20,000 to $100,000 each.

These upgrades are already showing results. By integrating biofuels into transportation logistics and improving energy systems at circuits, F1 has achieved a 9% reduction in carbon emissions from logistics operations. Overall, by the end of 2024, F1's total carbon emissions are projected to be 26% lower than the 2018 baseline of 256,551 tonnes of CO₂ equivalent.

To ensure success, circuits must engage with regulatory authorities early, provide comprehensive training for staff, and adopt modular solutions that can scale as needed. Circuits that take these steps are better equipped to meet regulatory requirements while improving operational efficiency as sustainable fuels become the norm in motorsport.

Fuel Type Cost Comparison

F1's shift toward sustainable fuels focuses on two main options: synthetic fuels (e-fuels) and advanced biofuels. Each comes with unique costs, performance traits, and scalability challenges that will shape the sport's financial and operational landscape as it moves toward 2026 and beyond. Understanding these differences is key to grasping how each fuel type will influence F1's future.

Pros and Cons of Each Fuel Type

Synthetic fuels are custom-built for F1's hybrid engines, but they come at a steep price - ranging from $500 to $1,200 per ton. This high cost stems from their energy-intensive production, which can demand up to five times more renewable electricity than electric vehicles (EVs) require. Additionally, sourcing pure, concentrated CO₂ adds technical hurdles and expense. On the plus side, synthetic fuels are designed to achieve a completely neutral carbon cycle, meaning the carbon used in production is balanced by the amount released during combustion.

Advanced biofuels, on the other hand, offer a more budget-friendly alternative. These fuels have already proven their value in Formula 2 and Formula 3 since 2025, showing they can perform well in competitive motorsport settings. While exact pricing remains undisclosed, advanced biofuels generally cost less due to their lower energy demands during production.

Here’s how the two fuel types compare across key factors:

| Aspect | Synthetic Fuels (E-Fuels) | Advanced Biofuels |

|---|---|---|

| Production Cost | $500–$1,200 per ton | Lower than synthetic fuels |

| Energy Requirements | ~5× more renewable electricity than EVs | Much lower |

| Supply Chain Risk | Dependent on renewable energy and CO₂ capture | Relies on sustainable biomass |

| Carbon Impact | Fully carbon-neutral with green H₂ | Lower lifecycle emissions |

| Current Capacity | Two ARAMCO plants globally | Established production networks |

Both options integrate seamlessly with F1's existing engines, a critical factor in the sport's broader push for sustainability.

Long-Term Financial Impact

Beyond production costs, the long-term economic impact of these fuels is another major consideration. Starting in 2026, the engine manufacturer budget cap will rise from $95 million to $130 million, adding an extra $35 million annually to help support sustainable fuel development. However, team principals have raised concerns that even this increase might not fully offset the high costs associated with these fuels.

Synthetic fuels show promise for scalability. Currently, ARAMCO produces them at two facilities - one in Saudi Arabia and another in Spain. As production ramps up and expands beyond F1's relatively small consumption, economies of scale could help bring costs down. Additionally, since F1's fuel needs represent only a tiny fraction of global demand, synthetic fuels could potentially be adapted for everyday vehicles.

Advanced biofuels, while less expensive now, face challenges tied to sustainable biomass availability and the need for non-food feedstocks. As global demand for biofuels rises, raw material costs could increase, potentially narrowing the price gap between biofuels and synthetic fuels. Red Bull team principal Christian Horner has suggested introducing cost regulations to address these disparities. Meanwhile, the FIA is exploring ways to tweak fuel ingredient specifications to reduce production costs without sacrificing performance or environmental goals.

Although initial costs are high, the potential for economies of scale could make sustainable fuels more viable over time. F1’s commitment to these fuels is part of its broader ambition to achieve net-zero carbon emissions by 2030. If successful, reducing sustainable fuel costs could not only benefit F1 but also encourage adoption in other transportation sectors where electrification isn't practical. While synthetic fuels require a higher upfront investment, their carbon-neutral design and scalability could make them a worthy choice for competitive teams. Advanced biofuels, meanwhile, remain a practical and cost-effective option, as demonstrated by their successful use in F1's feeder series.

Conclusion: F1's Sustainable Fuel Infrastructure Future

Formula One's shift toward sustainable fuel infrastructure represents a bold leap, both financially and technologically. The investments required to develop production, distribution, and storage systems go far beyond the immediate demands of racing. These efforts directly address the challenges of fuel production, delivery, and operational integration discussed earlier.

The progress is already measurable. F1's infrastructure investments have led to noticeable emission reductions, showcasing the real-world impact of these initiatives.

By taking the lead in sustainable fuel development, F1 positions itself as a pioneer for broader change. The "drop-in" fuel technology being advanced is particularly promising because it can work seamlessly with current internal combustion engines, requiring no modifications.

Of course, there are hurdles. Sustainable fuels currently cost between 4 and 8 times more than traditional fuels. However, F1's commitment to achieving net zero carbon emissions by 2030 sends a powerful message. As explored in earlier sections, the sport's investments in key production facilities highlight its dedication to this transformation.

What sets F1 apart is its ability to experiment on a smaller scale, allowing for quicker innovation and refinement. This approach not only benefits motorsport but could also pave the way for cost reductions in other industries. Formula 2 and Formula 3 adopting 100% advanced sustainable fuels by 2025 further proves that this infrastructure can support high-performance racing across different levels, setting the stage for broader adoption.

Looking ahead, the future of F1's sustainable fuel infrastructure depends on scaling up production and optimizing supply chains. While the financial and regulatory challenges are significant, achieving economies of scale could eventually bring costs down and make these fuels more competitive. In doing so, F1 could solidify its role as a key player in advancing sustainable transportation technologies for years to come.

FAQs

What challenges does F1 face in adopting 100% sustainable fuels by 2026, and how can they be addressed?

Transitioning to 100% sustainable fuels by 2026 is no small feat for Formula One. The sport faces several hurdles, including the steep costs tied to developing and scaling up sustainable fuel production, ensuring these fuels are available worldwide, and modifying existing engines to hit sustainability targets while keeping performance intact.

To tackle these challenges head-on, Formula One is pouring resources into advanced research and teaming up with fuel manufacturers to find affordable solutions. Progress in synthetic fuel technologies and the integration of renewable energy in production are at the heart of these efforts. At the same time, F1 teams are fine-tuning engine designs to ensure they work seamlessly with sustainable fuels - all while preserving the exceptional performance the sport is known for.

How do the costs of synthetic and advanced biofuels compare to traditional fuels, and what could this mean for the future of F1 racing?

Synthetic fuels and advanced biofuels come with a higher price tag compared to traditional fossil fuels. This is largely because their production involves cutting-edge technologies and complex processes. For instance, synthetic fuels rely on energy-intensive steps like carbon capture and hydrogen production, while advanced biofuels require sustainable feedstocks and specialized refining methods.

In Formula One, these elevated costs could present hurdles for widespread use at first. But as production scales up and technology improves, prices are likely to come down. Shifting to sustainable fuels is a key part of F1's goal to achieve carbon neutrality by 2030, potentially setting a precedent for sustainability in motorsports and beyond.

How do partnerships between fuel companies and engine manufacturers contribute to F1's sustainable fuel initiatives?

Partnerships between fuel producers and engine manufacturers play a key role in Formula One's push toward sustainable fuel solutions. These collaborations focus on creating advanced biofuels and other energy alternatives specifically designed to meet the intense performance requirements of F1 engines.

By blending the knowledge of fuel production with cutting-edge engine technology, these alliances ensure that sustainable fuels deliver more than just compliance with regulations - they also uphold the speed, efficiency, and reliability that Formula One demands. This combined effort is a cornerstone of F1's pledge to achieve carbon neutrality by 2030.