ERS and Hybrid Power Units: Long-Term Impact

Examines how F1’s ERS reshaped performance, efficiency and reliability — and how removing the MGU‑H and boosting MGU‑K under 2026 rules will change strategy.

Formula 1’s Energy Recovery System (ERS) and hybrid power units have transformed how race cars generate and use energy. By combining electrical and thermal systems, these power units not only improve performance but also increase efficiency. The introduction of ERS in 2014, replacing the simpler KERS system, marked a major step forward in energy recovery, with modern systems recovering energy from braking and exhaust gases.

Key insights:

- ERS Components: Includes MGU-K (braking energy recovery), MGU-H (exhaust heat recovery), Energy Store (battery), and Control Electronics.

- Energy Boost: ERS adds up to 160 horsepower, with MGU-H contributing 65-70% of energy recovery per lap.

- Reliability Challenges: Thermal loads, battery degradation, and energy cycling require precise management to meet strict usage limits.

- 2026 Regulations: Major changes include removing the MGU-H, tripling MGU-K power output to 350 kW, and shifting power balance to 50% electrical.

These advancements not only reshape racing strategies but also influence technology for road vehicles. The 2026 updates will simplify systems while increasing electrical power, posing new challenges and opportunities for teams.

This is how the hybrid system of a F1 engine works | RacingNews365

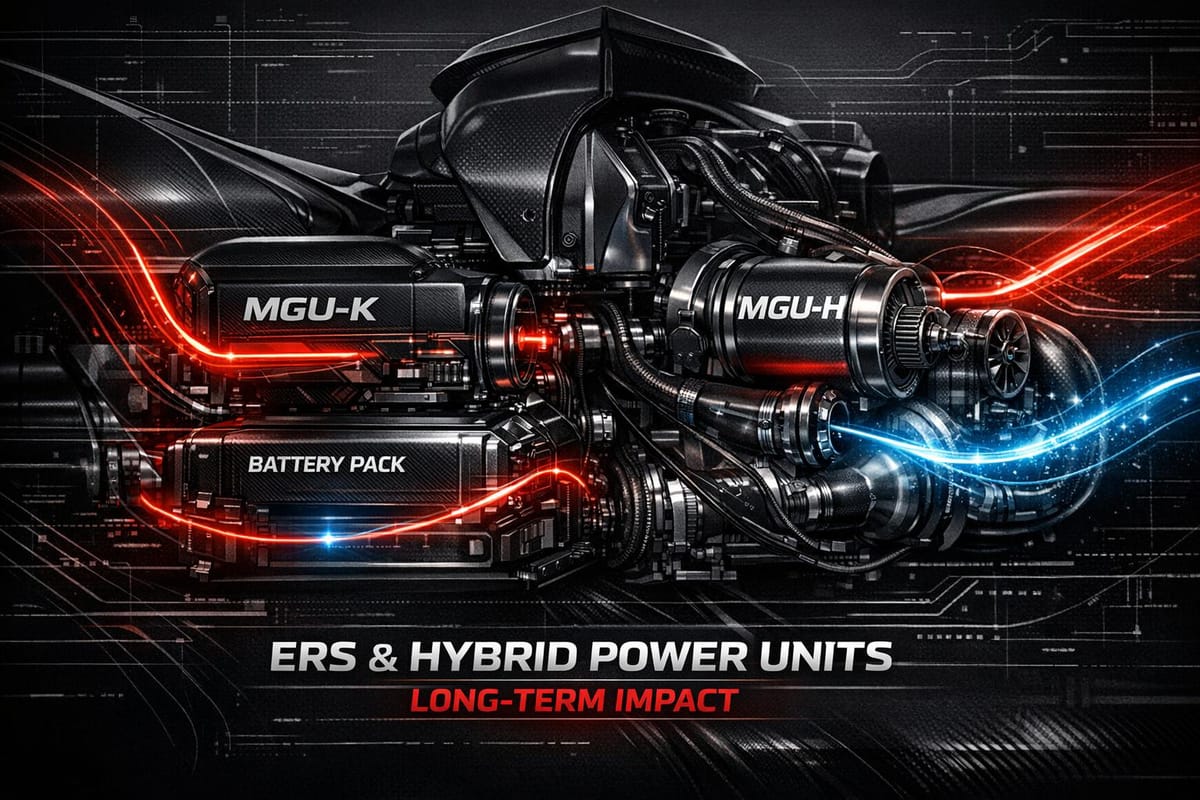

ERS Components and How They Work

The Energy Recovery System (ERS) is a critical part of modern F1 power units, seamlessly integrating multiple components to capture, store, and deploy energy during a race. These components include the Motor Generator Unit-Kinetic (MGU-K), the Motor Generator Unit-Heat (MGU-H), the Energy Store (ES), and the Control Electronics (CE). Each plays a unique role in ensuring optimal energy management throughout a lap.

The MGU-K is directly connected to the engine's crankshaft, capturing kinetic energy during braking and contributing additional power during acceleration. Meanwhile, the MGU-H is linked to the turbocharger shaft, positioned between the turbine and compressor. Operating at speeds of up to 125,000 RPM - far exceeding the MGU-K's 50,000 RPM limit - it recovers energy from exhaust gases. Beyond energy recovery, the MGU-H also eliminates turbo lag by keeping the compressor spinning even when the driver eases off the throttle.

The Energy Store is a high-voltage lithium-ion battery pack weighing between 44 and 55 pounds. It operates at nearly 1,000 volts and boasts an impressive 96% efficiency, storing energy harvested by both the MGU-K and MGU-H. Finally, the Control Electronics oversee energy distribution, performing over 43 trillion calculations during a single race. Together, these components form a highly efficient system that powers F1 cars while enhancing their performance.

Main Components: MGU-K and MGU-H

The MGU-K and MGU-H differ significantly in how they recover and deploy energy. The MGU-K can recover up to 2 MJ per lap from braking and deploy up to 4 MJ per lap back to the crankshaft. This process provides an extra 160 horsepower, which is especially useful for overtaking or accelerating out of corners. In contrast, the MGU-H operates without any recovery or deployment limits under current regulations. It continuously harvests energy from exhaust gases and can transfer this energy directly to the MGU-K, bypassing the battery entirely.

A notable advancement came during the 2014 season, when Mercedes-AMG High Performance Powertrains introduced a "split turbo" design to improve heat management and packaging efficiency. As FlowRacers explains:

"The MGU-H can eliminate [turbo lag] by spinning the compressor without requiring enough exhaust gases to be passing through it".

This innovation ensures that drivers experience an immediate boost in pressure when accelerating out of corners, highlighting the MGU-H's pivotal role in maintaining seamless power delivery.

Energy Flow and Connection with the ICE

In F1's hybrid power units, energy flows through multiple channels. The MGU-K can either charge the battery or supply power directly to the drivetrain. Meanwhile, the MGU-H can bypass the battery entirely, transferring energy directly to the MGU-K. This direct routing of energy ensures consistent power delivery throughout the race.

At the core of the system, the internal combustion engine (ICE) provides the base power, while the ERS adds an extra 160 horsepower. This integration of recovered energy with the ICE not only boosts power but also improves efficiency. Honda F1's Technical Director, Toyoharu Tanabe, has highlighted the complexity of managing such systems:

"Compared to the pure ICE car, the modern hybrid PU is very complicated. The current PU has extra hardware such as MGU-H, MGU-K and Battery... and it requires more complex control logic calibration".

Additionally, the MGU-K's energy recovery impacts braking, creating resistance that alters the braking feel. To address this, F1 cars use sophisticated brake-by-wire systems, ensuring drivers experience consistent pedal response despite the added complexity.

Long-Term Effects on Reliability

Formula 1 regulations limit each car to just three of each key power unit component over a grueling 23-race season. This forces teams to find a delicate balance between peak performance and long-term durability. Honda's Technical Director, Toyoharu Tanabe, highlights the challenges this presents, especially as components face increased thermal loads and relentless energy cycling.

Higher Thermal Load and Cooling Requirements

ERS (Energy Recovery System) components generate immense heat, creating a tough challenge for engineers: how to keep everything cool without compromising the car's aerodynamics. Engine designers often want larger cooling systems for reliability, while aerodynamicists prefer smaller radiators to reduce drag and shave off precious lap time. This tug-of-war becomes even more critical at high-altitude circuits like Mexico City or in extreme climates like Abu Dhabi, where turbochargers and the MGU-H face extra strain due to higher thermal loads and reduced air density.

Tanabe explains the complexity of this balancing act:

"With something like cooling requirements, we have to achieve that balance for meeting the PU's cooling needs but also not compromising chassis weight, design layout and aerodynamic performance".

Mercedes-AMG tackled this issue head-on during the early hybrid era by innovating with a split turbocharger design. By placing the MGU-H between the turbine and compressor, they effectively separated the "hot" and "cold" sides of the turbocharger. This clever layout significantly improved heat management, giving them a reliability edge over competitors like Ferrari and Renault during the 2014 season transition.

The MGU-H itself is a marvel - it spins at speeds of up to 125,000 RPM, more than twice the MGU-K's 50,000 RPM limit. It also handles 65% to 70% of total energy recovery per lap, making it not just critical but also one of the most thermally demanding components.

Battery Life and Energy Cycling Issues

The Energy Store (battery) in an F1 car endures constant stress from repeated charging and discharging cycles. For instance, the MGU-K alone cycles through 4 MJ of energy per lap. Over time, this high-frequency cycling degrades the lithium-ion cells, reducing their capacity. To mitigate this, teams use batteries that exceed the 4 MJ limit - up to 6 MJ - and manage them within specific operational windows to maintain performance as the cells age.

Predictive maintenance plays a crucial role in extending battery life. Engineers rely on real-time telemetry and tools like ExxonMobil's trackside oil analysis labs, which are set up right in the team garages. These systems allow teams to spot "worrying trends" before they escalate into full-blown failures. This proactive approach ensures components can be replaced before they jeopardize a race.

Case Studies: Team-Specific Reliability Patterns

The challenges of thermal loads and energy cycling are reflected in how teams manage their power units. Honda's return to F1 in 2015 is a perfect example of the steep learning curve in ERS reliability. Initially plagued by frequent MGU-H failures and integration issues, Honda's fortunes changed when they partnered with Red Bull Racing in 2019. By 2021, they had developed what Tanabe described as a "good balance", enabling them to manage their power unit lifecycle effectively within the strict three-unit-per-season rule.

This turnaround came through close collaboration between Honda's Sakura facility in Japan and Red Bull's base in Milton Keynes, UK. Together, they redesigned cooling systems and packaging to meet both reliability and aerodynamic demands. The shift from being a "customer" engine supplier to a fully integrated "works" partner was pivotal.

Today, teams rely on dedicated "Mission Control" rooms to monitor power unit performance and health in real-time during race weekends. They also strategically manage their components, using older parts during Friday practice sessions and saving fresher ones for qualifying and race day. This meticulous planning has become essential for surviving the season without exceeding allocation limits and avoiding grid penalties.

Performance and Efficiency Benefits

While conversations about ERS (Energy Recovery System) often focus on reliability issues, it’s impossible to ignore the performance gains it has brought to Formula One. A significant part of this improvement comes from the MGU-H, which captures waste heat from exhaust gases and converts it into electrical energy that teams can use to boost performance.

Every 5 kg of saved fuel translates into a 0.2-second lap advantage. Over the course of an entire race, these incremental gains can add up to a meaningful edge. This highlights how improvements in thermal efficiency directly contribute to faster lap times and overall competitiveness.

Thermal Efficiency Gains

The MGU-H plays a central role in improving thermal efficiency by continuously recovering waste heat from the exhaust. This recovered energy is then either stored in the battery or sent directly to the MGU-K, which reduces the internal combustion engine’s workload and enhances efficiency.

Mercedes-AMG Petronas has emphasized the importance of efficiency in modern Formula One:

"The power output of the engine is determined by two factors - the fuel flow rate and the efficiency of the engine. In F1, the fuel flow rate is limited... so the only factor the teams can influence is the efficiency."

The evolution of the Energy Store (the battery) has been another game-changer. Today’s batteries achieve an impressive 96% efficiency, a massive leap from the 39% efficiency seen back in 2007. Additionally, battery weight has dropped by 81% since 2007, reducing overall car weight and allowing teams to reallocate that mass to other performance-critical areas.

How Performance Varies by Circuit

ERS performance isn't one-size-fits-all - it depends heavily on the characteristics of each track. Teams must fine-tune their energy management strategies to suit the demands of specific circuits.

At Spa-Francorchamps, for instance, drivers spend only 13% of the lap on the brakes. With its long straights and high-speed sections - where cars can hit speeds over 220 mph - the MGU-H becomes the main tool for energy recovery.

In contrast, circuits like Monaco or Montreal rely on frequent heavy braking. At Montreal’s “Epingle” hairpin (Turn 10), cars decelerate from 217 mph to 62 mph, giving the MGU-K ample opportunity to recover kinetic energy. Meanwhile, the MGU-H works to eliminate turbo lag during a 17 m/s² acceleration phase.

At Monza, however, the story is different. Fast curves like Lesmo 1, where cars maintain speeds of nearly 112 mph, limit the MGU-K’s recovery potential due to the lack of heavy braking. Here, the MGU-H ensures the turbocharger remains at 13,500 RPM, preventing turbo lag, while the MGU-K delivers braking torque of 143 Nm. Teams must conserve battery energy for critical overtaking opportunities on the long straights rather than deploying it continuously. This circuit-specific energy management is essential for translating ERS efficiency into race-day advantages.

| Track Type | Strategy | Focus |

|---|---|---|

| High-Speed (e.g., Monza, Las Vegas) | Conservative deployment | Prioritize energy savings for overtaking; rely on MGU-H for recovery on long straights |

| Technical (e.g., Monaco, Montreal) | Frequent recharging | Maximize MGU-K recovery during braking; use ERS for quick acceleration out of tight corners |

| Mixed (e.g., Sochi) | Balanced approach | Limited braking zones test the MGU-H’s recovery efficiency |

To prepare for these challenges, teams use advanced simulation tools like "Driver in Loop" (DiL) simulators to model track-specific energy profiles ahead of race weekends. During qualifying, the battery is fully depleted to achieve the fastest possible lap time. In races, however, the system must strike a balance between recovery and deployment to maintain a consistent state of charge. A well-managed energy profile can make or break a team’s performance, even if they have the fastest car on the grid.

The Future of ERS in Formula One

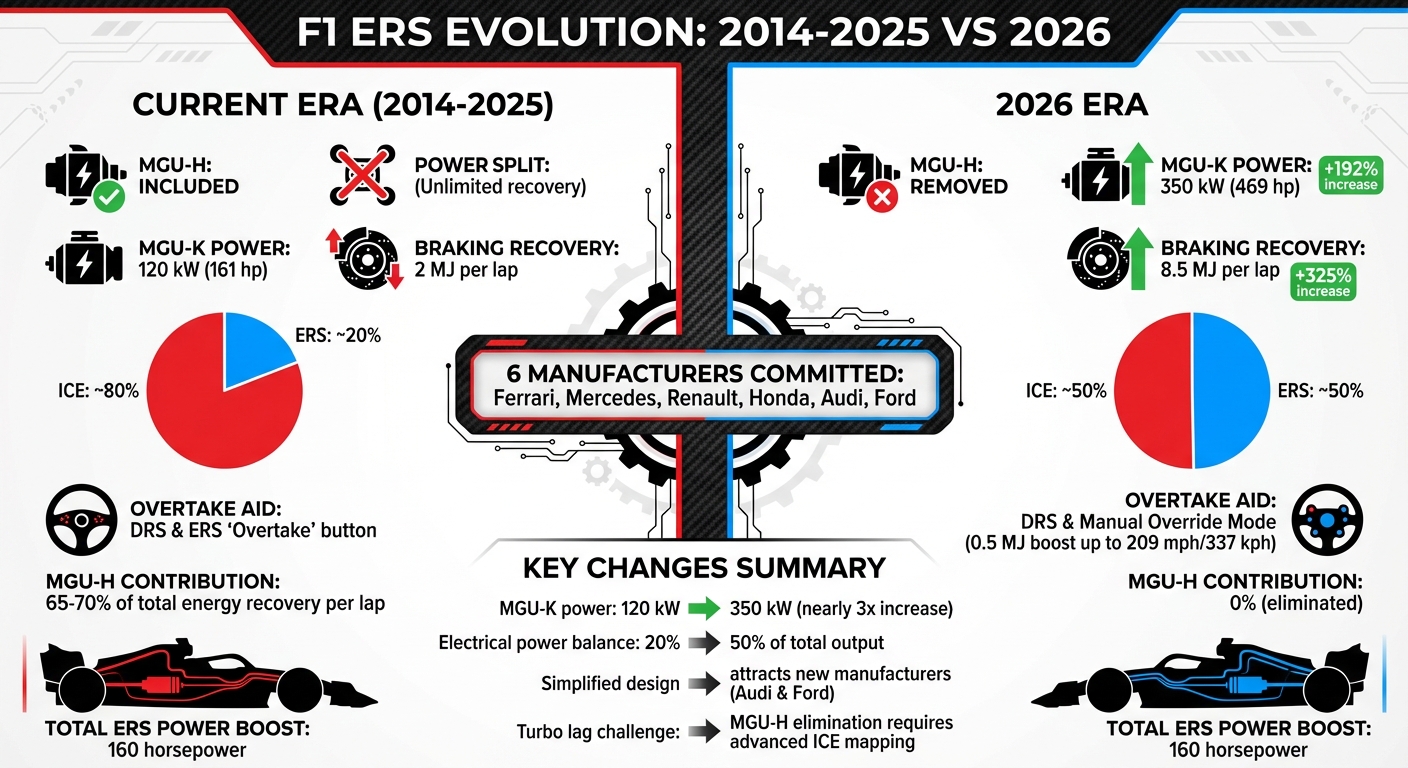

F1 ERS Evolution: 2014 vs 2026 Hybrid Power Unit Regulations Comparison

Formula One's 2026 regulations mark a massive shift for hybrid power units, the most significant since their debut in 2014. These changes are set to redefine how teams handle energy recovery, impacting both reliability and performance. With these updates, the challenges surrounding power unit durability and energy management are only becoming more complex.

2026 Regulation Changes and Development Limits

One of the most notable changes is the elimination of the MGU-H, a component responsible for recovering 65–70% of total energy. This move simplifies the power unit's design and has been a key factor in attracting new manufacturers. As Lawrence Barretto, F1 Correspondent, put it:

"The removal of the MGU-H, which has proved a tricky component to master, was a popular move, too".

Six manufacturers - Ferrari, Mercedes, Renault, Honda, Audi, and Ford (partnering with Red Bull Powertrains) - have already committed to the 2026 regulations. Audi and Ford, in particular, highlighted the removal of the MGU-H and the shift toward hybrid technology more aligned with road cars as key motivators for their involvement.

While dropping the MGU-H eliminates a significant source of heat-related failures, it introduces new hurdles. The MGU-K's power output will jump from 120 kW to 350 kW (≈469 hp), and its energy recovery capacity will increase from 2 MJ to 8.5 MJ per lap. Additionally, the power balance will shift to roughly 50:50 between the internal combustion engine (ICE) and electrical systems, with the ICE's output reduced to around 400 kW.

A new feature, the "MGU-K Override", will allow trailing drivers to deploy the full 350 kW of electrical power up to speeds of 209 mph (337 kph). This provides an additional 0.5 MJ for overtaking, adding a tactical layer to race strategy. Here's a breakdown of the key changes:

| Feature | Current Regulations | 2026 Regulations |

|---|---|---|

| MGU-H | Included (Unlimited recovery) | Removed |

| MGU-K Power | 120 kW (161 hp) | 350 kW (469 hp) |

| Braking Recovery | 2 MJ per lap | 8.5 MJ per lap |

| Power Split (ICE:ERS) | ~80:20 | ~50:50 |

| Overtake Aid | DRS & ERS "Overtake" button | DRS & Manual Override Mode |

These changes demand a fresh approach to power unit management, forcing teams to rethink strategies for balancing performance and efficiency.

Managing Reliability and Performance Trade-offs

With the MGU-H gone, teams lose its ability to spin the turbocharger, making turbo lag a potential issue. To address this, they'll rely on advanced internal combustion engine mapping and software solutions.

The increased electrical output - nearly tripling - places additional stress on the battery and MGU-K systems. Mercedes-AMG Petronas has already been testing ERS battery voltages near 1,000 volts to prepare for these demands. These advancements could even shape the future of consumer vehicles.

Toyoharu Tanabe, Honda F1's Technical Director, highlighted the delicate balance teams must strike:

"With only three power units per car per year, it is crucial to strike a balance between performance and reliability".

This balancing act becomes even more critical under the new rules, as the MGU-K will bear the full responsibility for energy recovery, a task previously shared with the now-absent MGU-H.

Energy management strategies will also need to evolve. Since the MGU-K can only recover energy during braking, drivers must carefully manage this resource across a lap. Unlike the current system, where the MGU-H replenishes the battery during acceleration, the 2026 setup will require a more strategic approach, tailored to the nuances of each track.

Conclusion: ERS as a Foundation of F1 Development

ERS has reshaped the landscape of Formula 1 by merging the engine and electric systems into a seamless power unit. As Red Bull Racing aptly described, today’s hybrid systems are not just traditional engines with added features - they are fully integrated units where electrical and mechanical elements function in unison.

But the impact of ERS goes beyond the racetrack. Technologies like regenerative braking, now a staple in electric and hybrid consumer vehicles, trace their roots back to F1 innovation. This makes Formula 1 not just a spectacle of speed but also a testing ground for advancements that shape the future of everyday driving.

The decision to remove the intricate MGU-H and increase the MGU-K's output to 350 kW (around 469 hp) simplifies the technology while preserving competitiveness. This move has already drawn interest from major players like Audi and Ford, who pointed to these changes as pivotal in their choice to enter the sport.

These updates don’t just streamline the technology - they also improve the driving experience. ERS enhances vehicle handling by delivering instant torque, eliminating turbo lag, and offering smoother, more predictable control. As Honda F1’s Technical Director, Toyoharu Tanabe, explained:

"Compared to the pure ICE car, the modern hybrid PU is very complicated... it demands precise control logic calibration".

As Formula 1 continues to evolve, ERS remains central to its technical progress, showing that speed and sustainability can thrive together.

FAQs

How will removing the MGU-H impact Formula 1 strategies and racing dynamics?

The removal of the MGU-H (Motor-Generator Unit-Heat) in the 2026 Formula 1 regulations is set to shake up race strategies in a big way. Right now, the MGU-H captures waste heat from the turbocharger, converting it into extra energy that helps eliminate turbo lag and boosts power delivery. Once it’s gone, teams will lose this "free" energy source, which means turbo response could become more sluggish, and the total recoverable energy will drop.

This shift will push engineers to find new ways to balance turbo performance with fuel efficiency, a tricky equation to solve. Drivers, on the other hand, will need to pay closer attention to their battery's state of charge. Strategies will likely revolve around precise use of the MGU-K, particularly for overtaking and managing fuel flow - especially on circuits that demand a lot of power. In this new landscape, driver skill and smart energy management will take center stage. Overtaking will rely more on timing and raw engine performance than the near-infinite boost the MGU-H used to provide.

What challenges will teams face under the 2026 hybrid power unit regulations?

The 2026 hybrid power unit regulations bring a host of challenges for Formula One teams. With the maximum electrical output rising to 350 kW, components such as the MGU-K, wiring, and power electronics will face increased stress. To cope with the extra heat generated by this higher energy flow, teams will need to rethink their cooling systems and refine thermal management techniques.

On top of that, stricter rules on energy harvesting and deployment per lap, paired with larger battery storage capacity, will push teams to develop more sophisticated control algorithms and energy management strategies. Any missteps in managing these systems could result in penalties or a drop in performance, making reliability more critical than ever.

The integration of a more powerful Energy Recovery System (ERS) with the internal combustion engine (ICE) adds another layer of complexity. The higher electrical demands will test the limits of batteries, turbochargers, and power electronics, requiring the use of advanced materials and rigorous durability testing to ensure these components can withstand the grind of an entire race weekend. While these regulations aim to deliver more power and promote sustainability, they also demand smarter engineering and rock-solid designs.

How is ERS technology from Formula 1 influencing advancements in consumer hybrid and electric vehicles?

Formula 1’s Energy Recovery System (ERS) is making waves in the world of hybrid and electric vehicle technology. Introduced during the 2014 hybrid-turbo era, this system has proven its ability to recover both kinetic and thermal energy, which translates into a significant boost in power and improved fuel efficiency. To put it into perspective, F1’s ERS can add up to 160 horsepower while cutting fuel consumption by roughly 35%. Looking ahead to the 2026 season, increased electrical output limits are driving manufacturers to innovate with lighter batteries, more efficient power electronics, and advanced thermal management systems - advancements already finding their way into everyday vehicles.

These breakthroughs are paving the way for smaller, lighter battery packs, extended electric-only ranges, and smoother performance in plug-in hybrid cars. On top of that, the software algorithms developed for energy optimization in F1 are being adapted for consumer vehicles, offering features like predictive regenerative braking and real-time efficiency coaching. These advancements not only improve fuel economy but also enhance durability and reduce charging times, delivering practical benefits for today’s drivers. Simply put, F1’s ERS technology is setting the stage for a future of more efficient and high-performing hybrid and electric cars.