F1 Freight: Crating High-Value Components

How F1 teams disassemble, crate and ship fragile car parts worldwide using climate-controlled containers, RFID tracking, and multimodal freight.

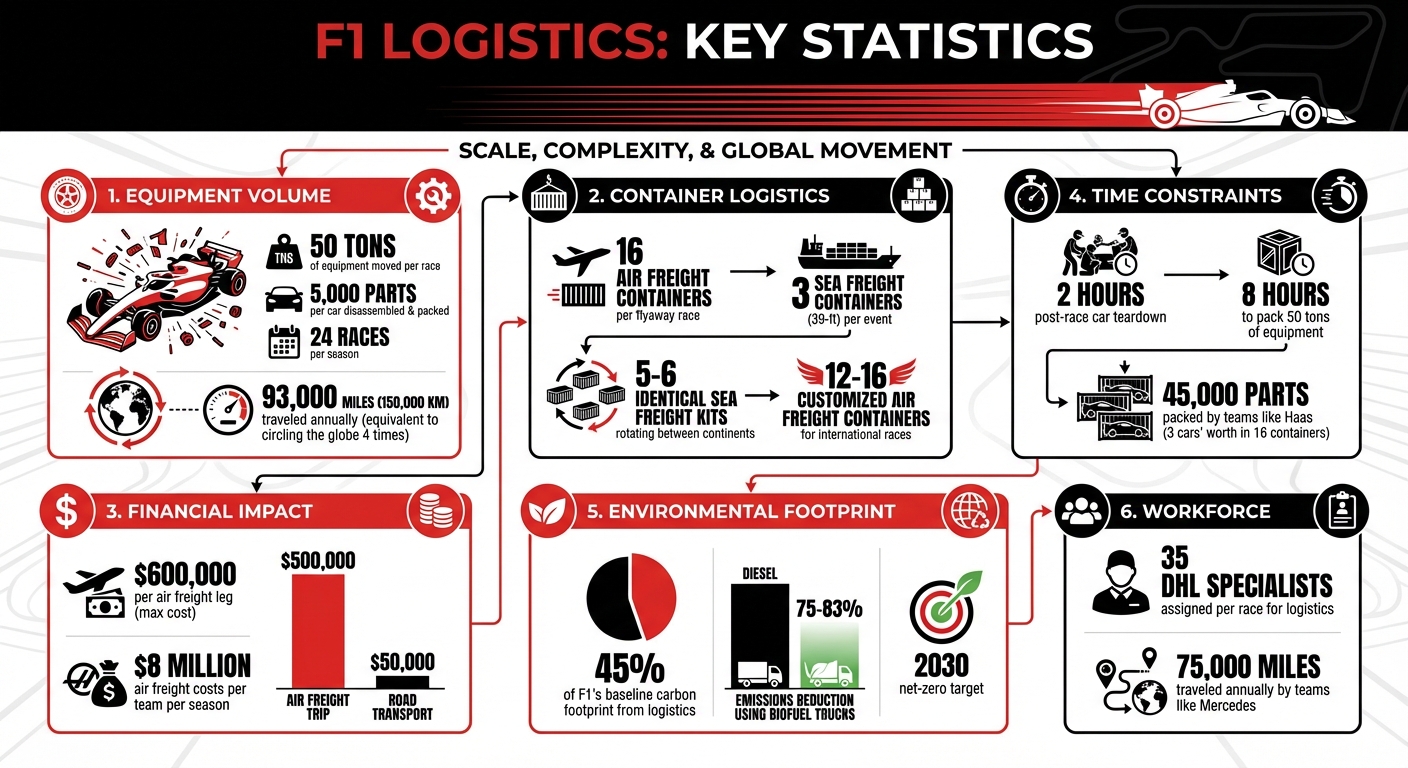

Formula 1 logistics is a massive operation, moving 50 tons of equipment across 24 races each season. Teams disassemble cars into 5,000 parts, pack them into specialized crates, and transport them via air, sea, and road. Air freight costs up to $600,000 per leg, while sea freight is slower but cheaper and used for non-critical items. Teams also rely on climate-controlled containers and advanced materials to protect sensitive components like carbon fiber chassis and electronics. Delays, like Haas's 2022 cargo issue, can disrupt schedules and impact performance. Sustainability efforts, such as biofuel trucks and rail transport, are reshaping F1 logistics to reduce emissions and costs.

F1 Logistics by the Numbers: Equipment, Costs, and Carbon Footprint

Custom Crating Techniques for F1 Components

Disassembly and Packaging of Fragile Parts

As soon as a race wraps up, the mechanics dive into a meticulously planned, two-hour teardown of the car. Components like the front and rear wings, suspension arms, and the power unit are carefully removed in a precise sequence. This ensures every part is handled according to its specific needs for protection.

"Post-race, cars strip fast - Sainz's FW47 sheds wings, suspension, engine in two hours. Mechanics crate 5,000 parts in foam-lined boxes - chassis in custom covers, engines bubble-wrapped."

- Jack Rennon

The carbon fiber chassis is locked into specially designed shock-absorbing frames, which shield it from stress during loading and unloading. Meanwhile, power units are wrapped in layers of bubble wrap and secured in engine trolleys to safeguard critical seals. Smaller, more delicate parts - like electronics and suspension components - are placed in foam inserts custom-cut to hold each piece securely in place, preventing movement during transit.

Geoff Simmonds from the Haas F1 Team highlights the sheer scale of this logistical effort:

"It's a game we're always playing... we pack 45,000 parts - three cars' worth - in 16 containers".

Teams also employ RFID tags and GPS tracking on high-value items, such as engines and gearboxes, to monitor their location and condition throughout the journey. This intricate packaging process integrates seamlessly with advanced container systems, ensuring the components remain safe and intact during transit.

Climate-Controlled and Custom Containers

After the components are meticulously packed, maintaining the right environmental conditions becomes a top priority. To prevent damage to sensitive materials like carbon fiber composites and electronics, teams use climate-controlled trucks for European races and sealed, hurricane-resistant containers for international events.

"Our compact but powerful HPE (Hewlett Packard Enterprise) Simplivity racks... are built into allegedly hurricane‑proof sealed housings – just in case we're hit by a pack‑down monsoon as they're tucked into their air freight containers."

- Red Bull Racing

Air freight containers, known as Unit Load Devices (ULDs), are carefully engineered to fit the cargo holds of Boeing 747 and 777 aircraft. Sergio Bondi, Ferrari's Head of Logistics, explains the precision involved:

"We use special packing structures called Unit Load Devices, designed to fit Boeing 777s, which allow us to load the freight as efficiently as possible, as if we are playing a giant‑sized game of Tetris".

For international races, a typical kit includes 12 to 16 customized air freight containers. These containers are designed not only to maximize space but also to ensure that nothing shifts during the flight.

Materials and Protective Features in F1 Crating

Lightweight and Durable Crate Materials

When it comes to transporting high-value equipment, F1 teams rely on specially designed reusable crates crafted from advanced composite materials. These materials strike a balance between strength and weight, ensuring durability while keeping the overall weight low. This lighter design not only cuts down on fuel costs during transport but also reduces the likelihood of damage, ensuring critical components arrive safely.

Inside these crates, foam-lined drawers and custom-fitted slots provide added security for delicate parts like suspension arms and electronics. This setup minimizes movement and vibration during transit, safeguarding against potential damage. While the initial investment for these high-tech composites is steep, the long-term benefits - like reduced breakage and reliable performance under challenging conditions - make them a worthwhile choice.

Each team takes these basic principles and tailors their crate designs to meet their specific needs.

Crate Design Comparison Across Teams

The way teams design their crates reflects their unique priorities, from cost management to sustainability and protection against extreme conditions. Here’s how some of the top teams approach their crating strategies:

| Team | Primary Crate Material | Key Protective Feature | Weight Efficiency | Cost Consideration |

|---|---|---|---|---|

| Red Bull Racing | Advanced composites with hurricane-proof sealed housings | Hurricane-proof sealed housings for critical IT equipment | High - optimized for air freight | Premium investment for maximum protection |

| Mercedes | Lightweight composite crates with standardized dimensions | Foam-lined drawers; RFID tracking for high-value items | High - designed to fit Boeing 777F holds | Balanced cost with a focus on reusability |

| McLaren | Modular composite containers | Component-specific foam slots; integrated climate control | Moderate - prioritizes handling ease | Cost-conscious with sustainability goals |

Red Bull Racing, for instance, goes all out with hurricane-proof sealed housings to protect their critical IT equipment, ensuring sensitive electronics remain safe even in extreme weather conditions. On the other hand, McLaren focuses on modular designs that make handling easier and cut down on storage costs, aligning with their broader sustainability efforts. Across the board, RFID tagging has become a standard feature for tracking high-value items like engines and gearboxes. This technology allows logistics teams to identify crate contents without needing to open them, streamlining the entire process.

Case Studies: Crating Methods by Leading F1 Teams

Red Bull Racing's Custom Chassis Containers

Red Bull Racing has developed one of the most advanced crating systems in Formula 1, designed to safeguard their most critical assets. For each event, the team moves approximately 35 tons of equipment using 16 airfreight containers and three 39‑ft sea freight containers.

Their carbon tubs are secured within shock-absorbing frames, while other components are stored in foam-lined drawers to minimize movement during transit. To protect their trackside IT infrastructure, they use hurricane-proof housings for HPE Simplivity data center racks. Additionally, they assign entire container loads to specific crews, enabling them to complete packing in just eight hours.

"It's a well‑oiled machine and a real team effort"

- Red Bull's Race Team Logistics Manager.

Mercedes' Reusable Crate Designs

Mercedes, on the other hand, takes a standardized and reusable approach to their crating system. They rely on lightweight composite crates specifically designed to fit into Boeing 777F cargo holds. These crates are equipped with RFID tracking, making it easier to monitor high-value items as the team travels roughly 75,000 miles annually.

Transportation and Crating Integration

Multi-Modal Freight Strategies

Formula 1 teams rely on a mix of air, sea, and road transportation to manage their logistics effectively. Each mode serves a specific purpose: air freight takes care of time-critical items like chassis and engines, sea freight handles larger, less urgent equipment such as hospitality furniture and garage panels, and road transport is used for European races. This approach strikes a balance between speed and efficiency, which is especially important since logistics contribute to around 45% of Formula 1's baseline carbon footprint.

In recent years, the use of sea freight has grown significantly. Teams now employ five to six identical sea freight kits that rotate between continents during the season. This system minimizes the need to air-freight bulky items. Sergio Bondi, Ferrari's Head of Logistics, explains:

"We favour sea freight to air wherever possible because, although it's slower, it results in considerable savings".

Ferrari has also taken steps to diversify its logistics. In early 2025, the team partnered with Ceva Logistics to transport one of its American race kits via rail between Miami and other U.S. venues, further cutting back on air transport.

McLaren showcased a similar commitment to sustainable logistics at the November 2023 Las Vegas Grand Prix. Partnering with DP World, the team moved freight from Austin to Las Vegas using a combination of rail, biofuel-powered trucks, and electric trucks. The biofuel trucks reduced greenhouse gas emissions by 75% compared to standard diesel, while the electric trucks ensured zero tailpipe emissions for the final leg of the journey. Mark Baker, McLaren's Head of Sea Freight & Infrastructure, highlighted the broader strategy:

"We are actually trying to slow things down. One, to save emissions, and two to reduce our storage costs".

These multi-modal logistics strategies work hand-in-hand with the precise loading protocols outlined below.

Loading and Handling Procedures

To complement these transportation methods, careful loading and handling practices are essential to protect the high-value equipment teams rely on. Specialized equipment and experienced personnel are a must to ensure every component is safe during transit. For instance, DHL assigns a dedicated team of 35 specialists at each race to manage setup, breakdown, and packing operations.

At flyaway races, strict regulations ensure fairness among teams. No team is allowed to unpack or set up their garages until all freight has arrived at the circuit. This rule creates intense pressure for logistics coordinators to deliver on time. As Steve Nielson, Formula 1's Sporting Director, explains:

"You're working right on the edge of what's possible logistically, and any hiccup has a knock-on effect on the teams".

How F1 Cars Travel the World: uncovering the Secrets!

Conclusion

Transporting and managing high-value Formula 1 components is one of the sport's toughest behind-the-scenes challenges. Each team must dismantle and move around 5,000 parts per car over a staggering 93,000 miles (150,000 kilometers) per season - essentially circling the globe four times. The stakes couldn’t be higher: a single delayed or damaged part, like a chassis or power unit, can ruin an entire race weekend. These logistical demands bring significant financial and operational pressures.

Air freight costs a hefty $500,000 per trip compared to $50,000 for road transport, forcing teams to carefully manage their expenses within the budget cap. Air freight alone racks up about $8 million per team each season. To manage these costs, teams have embraced multi-modal strategies, using five to six identical sea freight kits that leapfrog between continents while flying critical components directly to race venues.

Time is another relentless challenge. Teams must pack 50 tons of equipment in just eight hours after a race, often working through the night to meet the tight schedules of triple-header events. As Ferrari’s Logistics Manager, Sergio Bondi, explains:

"Everything has to be ready according to strict deadlines, and there are virtually no margins of error".

A missed shipment or customs delay can trigger a domino effect of problems, which is why teams develop detailed contingency plans, like rerouting sea freight mid-journey if necessary. This level of preparation underscores the precision and risk management required in F1 logistics.

Sustainability is also reshaping operations. Logistics accounts for roughly 45% of Formula 1's carbon footprint, pushing teams to adopt greener practices. Biofuel-powered trucks, which cut emissions by 83%, and rail transport are key steps toward the sport’s 2030 net-zero target. From the careful crating of parts to the strategic use of multi-modal freight and innovative protective materials, logistics in Formula 1 is more than just a necessity - it’s a competitive edge. As the sport evolves, these logistical advancements will play an even bigger role in shaping team success.

FAQs

How do F1 teams protect critical components during transportation?

F1 teams go to incredible lengths to make sure that every crucial component - like power units, gearboxes, and electronic systems - reaches the next race in flawless condition. Each part is carefully removed from the chassis, thoroughly inspected, and packed in custom-built containers designed to prevent movement, absorb shocks, and maintain exact temperature and humidity levels. For especially delicate components, such as hybrid batteries, climate-controlled cases are used to ensure they remain undamaged during transit.

To add another layer of protection, crates are equipped with vibration-dampening mounts, while critical parts like chassis and suspension systems are secured in specially designed cradles. Real-time GPS tracking and constant inventory checks keep the shipments on their intended paths, allowing teams to respond immediately to any issues. These detailed logistics ensure that the advanced technology driving an F1 car is fully prepared to perform when it arrives at the track.

How is Formula 1 making its logistics more sustainable?

Formula 1 is taking steps toward greener logistics by adopting smarter practices to minimize its environmental impact. One key change is reducing reliance on air freight. Instead, teams are shipping non-essential items - like garage panels and hospitality furniture - via sea freight, which emits far less carbon. For races within Europe, they’re streamlining road transport by using advanced route-planning software and modern, fuel-efficient trucks.

Collaborations are also playing a role. For instance, McLaren has teamed up with DP World to explore lower-emission shipping options and improve how cargo is packed and transported. Together, these efforts are helping F1 shrink its carbon footprint while still managing the intricate logistics required for a global racing schedule.

Why do F1 teams use different methods to transport their equipment?

Formula 1 teams juggle various transportation methods to keep up with the fast-paced demands of their global race schedule. For nearby races, trucks are the go-to option. They’re efficient for moving cars, spare parts, and equipment, making loading and unloading quick and hassle-free.

When it comes to international events, speed takes priority. Teams rely on chartered cargo planes to transport disassembled cars and critical components in climate-controlled crates. These planes ensure everything arrives on time, often within a tight 48-hour window.

For larger, less time-sensitive items like hospitality furniture or garage panels, sea freight is a cost-effective solution. Though slower, it allows teams to move bulkier items in larger quantities, requiring careful planning to meet strict deadlines.

Ultimately, teams must balance speed, cost, and cargo requirements while navigating logistical hurdles like airport or port access at specific venues. This combination of transport methods keeps the teams on schedule, protects their gear, and helps manage expenses.