F1 Fuel Costs: Sustainable vs. Current Fuels in 2026

F1's 2026 switch to 100% sustainable fuel could raise per-liter costs nearly tenfold, pushing team fuel bills higher and forcing budget and technical shifts.

Formula 1 is set for a major shift in 2026: all teams must use 100% sustainable fuel, eliminating fossil-derived carbon. This change aligns with F1's goal of achieving Net Zero Carbon by 2030, but it comes with steep costs. Sustainable fuel is projected to cost $170–$225 per liter, compared to the current $22–$33 per liter, with some estimates reaching $300 per liter. Annual team fuel expenses could jump from $3–$4 million to $10–$12 million.

Key points:

- Sustainable fuels will replace the current E10 blend (90% fossil fuel, 10% ethanol).

- Fuel costs are excluded from the 2026 budget cap, easing financial pressure.

- Smaller teams without fuel partnerships may face greater challenges.

- Long-term cost reductions depend on scaling production and refining processes.

F1's transition to these fuels is not just about racing - it could influence global energy practices by promoting alternatives compatible with existing engines. While initial costs are high, advancements in production and regulatory adjustments aim to make this shift more practical over time.

Current F1 Fuel Costs and Usage

Per-Liter Costs and Annual Team Spending

F1 teams currently rely on E10 fuel, a high-performance blend made up of 90% fossil-derived unleaded gasoline and 10% renewable ethanol. This specialized fuel is designed to meet the extreme demands of F1 engines. The price for this fuel varies, typically ranging between $22 and $33 per liter, depending on the supplier and technical agreements in place.

Teams with exclusive technical partnerships - like Ferrari with Shell, Mercedes with Petronas, and Aston Martin with Aramco - often benefit from better pricing due to their close collaboration with fuel suppliers. On the other hand, teams without such partnerships might face higher costs. Under F1's budget cap, fuel expenses are included, meaning that every dollar spent on fuel reduces the funds available for other aspects of the car or team operations. Currently, teams spend around $3 million to $4 million annually on fuel. While this is a significant expense, it remains a manageable part of their overall budgets - at least until the changes slated for 2026 come into play.

Fuel costs are also closely linked to the impressive fuel efficiency of modern F1 engines.

Fuel Consumption and Efficiency in F1 Cars

F1's hybrid power units are marvels of engineering, designed to maximize fuel efficiency while maintaining performance. These engines boast thermal efficiencies exceeding 50%, which is remarkable for internal combustion systems. The 1.6-liter V6 turbocharged engine is paired with an advanced Energy Recovery System (ERS), which includes the MGU-K (capturing energy from braking) and the MGU-H (recovering energy from exhaust gases).

Fuel consumption during races is strictly capped at 100 kg per race. While 80% of the car's power comes from the internal combustion engine, the ERS plays a crucial role in enhancing efficiency and reducing fuel usage. However, this balance will shift significantly under the 2026 regulations, which aim for a 50:50 power split between the internal combustion engine and electric systems. Additionally, the MGU-H will be removed entirely.

These advancements in efficiency and the upcoming regulatory changes highlight the evolving economic and technical challenges facing F1 teams.

F1 Fuel - The Hidden Development Race - And why E-Fuels are so EXPENSIVE

Sustainable Fuel Costs in 2026

F1 Fuel Costs Comparison: Current E10 vs 2026 Sustainable Fuels

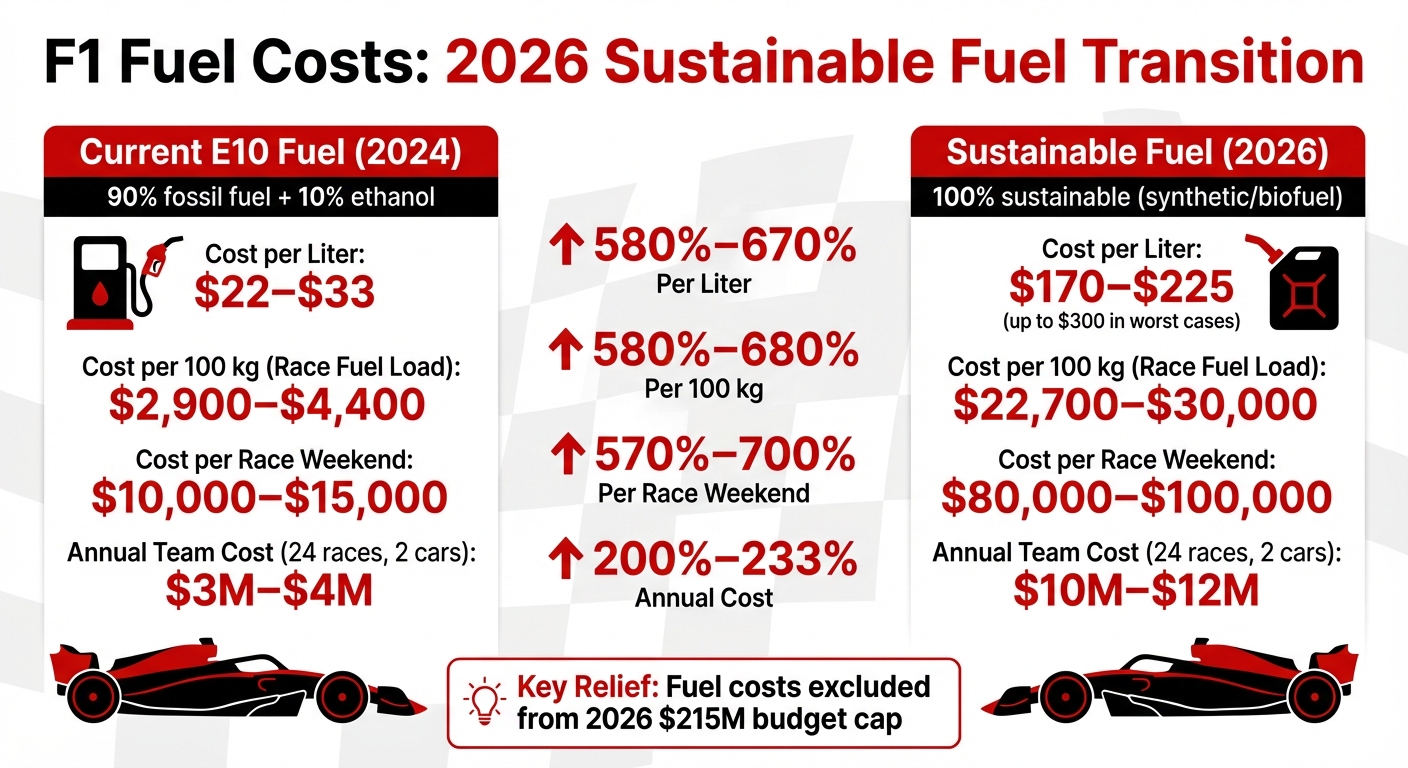

Cost Comparison: Sustainable vs. Current Fuels

Switching entirely to sustainable fuels brings a massive price hike. While E10 fuel is priced at $22–$33 per liter, sustainable fuels are projected to soar to $170–$225 per liter - a staggering 580% to 670% increase. In worst-case scenarios, prices could even surpass $300 per liter.

| Metric | Current E10 Fuel | Sustainable Fuel (2026) | Increase |

|---|---|---|---|

| Cost per Liter | $22–$33 | $170–$225 | ~580%–~670% |

| Cost per 100 kg (Race Fuel Load) | ~$2,900–$4,400 | ~$22,700–$30,000 | ~580%–~680% |

| Cost per Race Weekend | ~$10,000–$15,000 | $80,000–$100,000 | ~570%–~700% |

| Annual Team Cost (24 races, 2 cars) | $3M–$4M | $10M–$12M | ~200%–~233% |

For racing teams, this translates to annual fuel expenses skyrocketing from $3 million–$4 million to $10 million–$12 million by 2026. However, the FIA has excluded fuel purchase and transport costs from the budget cap, offering teams some financial relief. The sharp price difference highlights the hurdles in producing sustainable fuels at scale.

Why Sustainable Fuels Cost More

The steep costs are largely tied to the intricate processes involved in production. Creating synthetic fuels, for example, requires five times more renewable electricity than what’s needed for battery electric vehicles. A key component of this process, Direct Air Capture (DAC) - used to extract concentrated CO₂ - costs between $500 and $1,200 per tonne of CO₂. Adding to this, green hydrogen, which is essential for synthetic fuel production, is far costlier than hydrogen made from fossil fuels. Currently, 96% of hydrogen in the EU is still derived from natural gas.

Mercedes Team Principal Toto Wolff shed light on these challenges:

"What makes it so expensive is that the whole supply chain and energy contribution needs to be green. To achieve all of that, you need a certain specification of ingredients that is very expensive - and it's coming in much more expensive than anyone thought."

Unlike fossil fuels, sustainable fuels are still in the prototype stage and lack the economies of scale that could lower costs. Processing raw materials like municipal waste, non-food biomass, or algae involves far more complex supply chains than refining crude oil.

Despite these high costs, FIA Single Seater Director Nikolas Tombazis remains optimistic about the future:

"Initially, everything is new, everything is innovative, and everything is a prototype. And gradually, as people learn, they will gradually move them [the costs] down."

As production methods improve and scale increases, prices are expected to decrease, making sustainable fuels more accessible in the long run.

How Rising Fuel Costs Affect F1 Teams

Impact on Small Teams vs. Large Teams

Fuel expenses for Formula 1 teams are expected to soar from the current $3–$4 million range to as much as $10–$12 million by 2026, creating a significant financial challenge. While the FIA has excluded fuel costs from the $215 million budget cap for 2026, teams will still need to find an extra $7–$9 million within their overall budgets to cover the difference.

Larger teams with strong financial backing have an advantage here. Take Mercedes, for instance - its partnership with Petronas not only provides financial support but also offers technical collaboration on fuel development, which helps reduce costs. Red Bull’s Christian Horner has pointed out that sustainable fuel could become a key area of competitive disparity between teams in 2026.

Smaller teams, however, are in a tougher spot. Without official fuel partnerships, they face higher prices and fewer resources to manage the nearly 10-fold increase in fuel costs. One team principal, who chose to remain anonymous, described this financial strain as unsustainable. For these teams, the challenge lies in finding ways to keep up while staying within their already stretched budgets.

Budget Reallocation Options

To handle these rising costs, teams are rethinking how they allocate their budgets. The additional $7–$9 million needed for fuel will likely come from cuts in areas like marketing, hospitality, or even executive compensation. These adjustments are becoming unavoidable as the price of sustainable fuel continues to climb.

Sponsorship revenue is also taking on greater importance. Teams are actively pursuing new sponsorship deals, not just to manage rising costs but also to align with sustainability efforts, which can be a selling point for potential sponsors.

Another strategy involves improving energy recovery and thermal efficiency. By maximizing these technologies, teams can reduce their dependence on costly fuels, offering some relief from the financial burden.

Managing Higher Fuel Costs

Working with Fuel Suppliers

Teaming up with fuel suppliers is proving to be a key strategy as teams prepare for the fuel price surge expected in 2026. Research shows that teams with official technical partnerships - like those with Shell or Petronas - tend to secure better pricing deals compared to customer teams that pay standard market rates. These partnerships often go beyond simple transactions, paving the way for joint efforts in fuel development and cost-saving initiatives.

Honda, on the other hand, is charting its own course by investing in internal R&D. Their approach focuses on creating specialized fuel compositions, which are then shared with suppliers for blending and optimization. Teams have also been meeting with suppliers and the FIA to address the looming 10-fold price increase. One idea gaining traction for 2027 is to standardize costly "exotic" fuel ingredients while allowing innovation in less expensive areas.

But partnerships alone aren’t enough - technical improvements are also playing a big role in tackling these rising costs.

Engine and Aerodynamic Improvements

The 2026 regulations bring in efficiency upgrades that could help counterbalance higher fuel expenses. For starters, the new power units will feature a 50:50 balance between the internal combustion engine (ICE) and battery power, cutting overall fuel consumption. The MGU-K’s power output will jump from 120 kW to 350 kW - nearly tripling its current capacity - while energy recovery during braking will double to about 8.5 megajoules per lap.

Active aerodynamics will also be introduced, reducing drag and improving vehicle efficiency. Plus, eliminating the MGU-H simplifies the power unit, lowering both technical complexity and development costs. By fine-tuning the interaction between the ICE and the upgraded MGU-K, teams aim to maximize electric power usage and cut down on fuel consumption.

In addition to these technical shifts, teams are also exploring new ways to procure fuel more efficiently.

Alternative Procurement Methods

Beyond supplier deals and technical upgrades, teams are turning to innovative procurement techniques to keep fuel costs under control. One promising approach is the development of "drop-in" fuels - chemically identical to traditional fuels - which avoids the need for costly engine modifications.

The FIA also predicts that fuel costs will decrease over time, following the typical technology learning curve as production scales up and suppliers refine their expertise. Long-term agreements with suppliers are another way teams are protecting themselves from sudden price hikes while ensuring a steady supply of custom fuel blends. Additionally, the FIA’s decision to exclude fuel costs from the F1 budget cap gives teams some financial flexibility as these new strategies take shape.

Long-Term Economic Effects and Industry Impact

Sustainability and F1's Public Image

As Formula 1 embraces 100% sustainable fuels, the long-term economic effects are already taking shape. This shift is not just a technical milestone - it’s transforming how the sport is viewed by fans, sponsors, and manufacturers. The adoption of "drop-in" fuels, which can power existing internal combustion engines without modifications, sends a clear message: achieving carbon neutrality doesn’t mean sidelining the world’s 1.4 billion cars. Moves like these are reshaping F1’s reputation, making it more appealing to a broader audience while sparking interest across industries.

This commitment also gives fuel companies the confidence to invest in large-scale production. Liam Parker, F1's Chief Communications and Corporate Relations Officer, highlighted the importance of this clarity:

"If you're a fuel manufacturer and you want to invest in something on a large scale, you need some policy direction and freedom... this creates certainty for the fuel manufacturers to invest in scale from a customer point of view as well".

F1’s ambitious Net Zero by 2030 target positions the sport as a proving ground for technologies that could eventually reshape global fueling practices. By showcasing these advancements, F1 not only appeals to environmentally conscious sponsors but also captures the attention of younger, eco-aware audiences. This evolving public image could pave the way for a larger market transition, where initial high costs give way to competitive pricing as the technology matures.

Future Cost Trends and Production Scale

The path to affordability lies in scaling production. While the early stages of sustainable fuel development come with steep costs, F1 and its partners are banking on economies of scale and technological advancements to bring those costs down over time.

One of the priciest components in this process is Direct Air Capture technology, which currently costs between $500 and $1,200 per ton of CO₂. However, as production ramps up, these costs are expected to decrease significantly. To manage expenses further, the FIA and F1 teams are already planning for 2027 rule updates that aim to standardize certain costly "exotic" fuel ingredients. This approach allows for innovation in less expensive areas while keeping overall costs in check.

Conclusion: Balancing Costs and Sustainability in F1

F1's shift to 100% sustainable fuel in 2026 comes with a hefty price tag. The per-liter cost of this fuel is expected to rise almost tenfold, leading to a significant increase in annual team expenses. To ease this financial burden, the FIA has decided to exclude fuel costs from the budget cap, ensuring teams can still allocate resources toward car development and performance improvements. However, this transition demands careful planning and collaboration across the industry, with upcoming rule changes aiming to address these challenges.

Plans for 2027 include efforts to standardize expensive fuel components and improve production methods. These steps are designed to reduce costs while encouraging technological progress. Mercedes Team Principal Toto Wolff highlighted the complexity of the situation, stating:

"What makes it so expensive is that the whole supply chain and energy contribution needs to be green... we need to look at whether there's anything we can tweak to bring the per-liter price down".

F1's commitment to sustainable fuels goes beyond managing immediate financial pressures. By adopting drop-in fuels that work with existing engines, the sport positions itself as a testing ground for new technologies that could drive decarbonization on a larger scale.

The economics of sustainable fuel are expected to improve over time. As FIA Single-Seater Director Nikolas Tombazis explained:

"Initially, everything is new, everything is innovative, and everything is a prototype in some ways. And gradually, as people learn, they will gradually move them [the costs] down".

As production processes evolve and wider adoption increases, costs should become more manageable, making this technology more accessible.

F1's approach is a balancing act - leading the charge in environmental responsibility while maintaining financial and competitive stability. By excluding fuel from budget caps, standardizing high-cost elements, and fostering partnerships, the sport stays on track to achieve its Net Zero by 2030 goal. While the initial costs are steep, the potential long-term rewards for F1 and the broader energy landscape could make this investment worthwhile.

FAQs

Why will sustainable fuels cost more than current fuels in F1 by 2026?

Sustainable fuels come with a hefty price tag compared to traditional gasoline-based race fuels, largely due to their intricate production process and the limited scale at which they’re manufactured. These fuels are produced by combining captured carbon dioxide with green hydrogen through an energy-intensive process that depends on renewable electricity and specialized catalysts. This complexity drives the cost up significantly. To put it into perspective, sustainable fuels are estimated to cost about $300 per liter (roughly $1,130 per gallon), while current race fuels are priced at just $1–$2 per gallon.

Adding to the expense is the underdeveloped supply chain. The production of renewable electricity and captured carbon dioxide hasn’t yet reached the scale required to sustain a full Formula 1 season. This forces manufacturers to rely on small-scale facilities, which come with high capital and operating costs. On top of that, meeting the FIA’s stringent performance standards and the absence of well-established distribution networks add even more to the overall expense. However, as production scales up and renewable energy becomes more accessible, these costs are expected to gradually decline.

How will smaller F1 teams handle the rising cost of sustainable fuels in 2026?

Smaller Formula 1 teams are bracing for a sharp rise in fuel expenses as the sport shifts to 100% sustainable fuels starting in 2026. Early estimates put the cost of this new fuel at about $300 per liter - a staggering figure that's nearly ten times the price of current gasoline. For teams already operating on tight budgets, this change presents a serious financial challenge, especially since the FIA’s cost cap won’t completely cover these additional costs.

To adapt, teams are expected to prioritize fuel efficiency under the updated regulations, which emphasize energy use rather than fuel flow. This means refining engine performance and enhancing aerodynamics to minimize fuel consumption. Smaller teams might also explore partnerships with larger manufacturers for bulk fuel purchasing agreements or seek financial assistance from governing bodies. On top of that, reallocating budgets and attracting sponsors with a focus on sustainability could help offset the increased expenses.

Through a mix of efficiency upgrades, strategic alliances, and creative financial planning, smaller teams are determined to remain competitive despite the financial hurdles posed by sustainable fuels.

How will switching to sustainable fuels in 2026 impact F1's competition and team strategies?

The introduction of 100% sustainable fuels in 2026 is set to align with Formula 1's environmental goals while keeping the sport as thrilling and competitive as ever. These fuels are designed to work effortlessly with the current power units, meaning teams won’t need to make major changes to their car designs. This ensures that on-track performance remains steady, preserving the excitement for fans and the challenge for engineers.

That said, the cost of these fuels could have a big impact on the sport’s financial landscape. Estimates suggest fuel prices could jump from the current $22–$33 per gallon to an eye-watering $170–$225. For smaller teams, this might create serious financial pressure, while larger teams with deeper pockets could gain an edge by investing in advanced engine-fuel optimizations. Without measures to manage costs, this could widen the performance gap across the grid.

Adapting to these new fuels will also require closer collaboration between teams and manufacturers. Success will hinge on improvements in areas like engine mapping, cooling systems, and the materials used in power units. Teams that can adapt quickly to these changes may climb the competitive ladder, potentially shaking up the current team hierarchy and reshaping race strategies.