F1 Hybrid Engines: Timeline of Key Innovations

Explore the evolution of F1 hybrid engines, their impact on efficiency, and the future of sustainable racing technology.

F1 hybrid engines have revolutionized racing and efficiency. Here’s what you need to know:

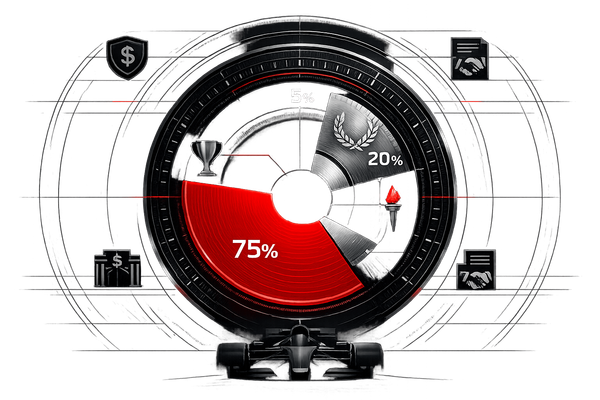

- Fuel Efficiency: Fuel consumption dropped from 160 kg in 2013 to 100 kg by 2020, with a target of 70 kg by 2026.

- Thermal Efficiency: Hybrid engines achieve over 50% thermal efficiency, compared to 30% in 2013 road cars.

- Environmental Goals: F1 aims for net zero emissions by 2030 and will use 100% renewable fuels by 2026.

- Hybrid Evolution: From 2009’s KERS to 2014’s turbocharged V6 units, F1 has continuously improved energy recovery and power delivery.

- Impact Beyond Racing: Hybrid technology innovations influence road cars, with systems like KERS inspiring energy-efficient vehicles.

F1’s hybrid engines are shaping the future of motorsport and driving advancements in global automotive technology.

The Evolution of Hybrid Technology in Formula One

Early Steps: Building Toward Hybrid Technology

Formula 1 took its first step toward hybrid technology in 2009 with the introduction of KERS (Kinetic Energy Recovery System). The FIA implemented KERS not only to modernize the sport but also to highlight Formula 1's effort to address global concerns about environmental responsibility. While the system showed promise, it also revealed a host of challenges that would need to be tackled.

KERS (Kinetic Energy Recovery System) in 2009

In theory, KERS was a straightforward concept: it captured kinetic energy during braking, stored it - either in a flywheel or high-voltage batteries - and released it later to boost acceleration. Under FIA regulations, teams could use up to 60 kW of power (around 80 horsepower) from their KERS setups.

For example, the Flybrid system weighed 24 kg, stored 400 kJ of energy, and could deliver 60 kW for 6.67 seconds. Its flywheel, which was 240 mm in diameter and weighed just 5 kg, spun at an incredible 64,500 rpm.

The system made an immediate impact. In 2009, drivers like Lewis Hamilton and Kimi Räikkönen secured race wins and pole positions using KERS. Giancarlo Fisichella even highlighted its competitive edge, saying:

"Actually, I was quicker than Kimi. He only took me because of KERS at the beginning."

However, despite its early successes, KERS presented a steep learning curve for teams.

Problems and Lessons from Early Hybrid Systems

KERS wasn't without its flaws. Teams quickly encountered obstacles such as weight penalties (up to 30 kg), reliability issues, increased tire wear, cooling difficulties, and high costs. These problems led some teams to question whether the benefits of KERS outweighed its drawbacks. In fact, several teams chose to remove the system after initial trials.

Safety was another major concern. In July 2008, a BMW mechanic received a severe electrical shock when touching the steering wheel and side pod of a KERS-equipped car. The issue stemmed from high-frequency AC voltage caused by capacitive coupling between the high-voltage and 12-volt systems. Red Bull also experienced a fire at their factory, further underscoring the risks. Ferrari faced its own setback at the 2009 Malaysian Grand Prix, where a system failure forced them to temporarily abandon KERS.

The weight distribution challenges were evident as well. BMW, for instance, adopted different strategies for their drivers - Nick Heidfeld used KERS in four races, while Robert Kubica used it only once due to concerns about its impact on car balance. Christian Horner of Red Bull summarized the system's role as:

"more of a strategic tool than a performance tool"

Cooling added another layer of complexity. KERS required additional heat exchangers to handle thermal loads, which made car design more complicated. Drivers also had to manually activate KERS while braking, adding to the challenge of operating the system during high-pressure races.

To address these issues, the FIA and teams implemented strict safety measures. These included insulated gloves for mechanics and specialized training for track marshals to handle the unique risks associated with KERS. As Renault's Tad Czapski explained:

"KERS brings new challenges and new dangers and we shall all have to share them"

Despite its shortcomings, KERS provided valuable insights and paved the way for the advanced hybrid systems that define modern Formula 1. These early trials were essential in shaping the technology we see on the track today.

The 2014 Hybrid Era: Turbocharged V6 Power Units

In 2014, Formula 1 underwent a transformative shift with the introduction of 1.6-liter turbocharged V6 power units paired with advanced hybrid systems. This marked a new chapter in how F1 managed power and efficiency.

Rule and Technical Changes

The new regulations introduced by the FIA in 2014 placed strict limits on fuel consumption and energy usage, pushing teams to innovate. A fuel flow cap of 100 kg per hour above 10,500 rpm was implemented, along with a total race fuel limit of 100 kg. These restrictions forced engineers to maximize energy output from a limited fuel supply .

The power units combined two advanced energy recovery systems. The MGU-K (Motor Generator Unit-Kinetic), an upgrade to the previous KERS system, provided 161 horsepower for up to 33 seconds each lap. Meanwhile, the MGU-H (Motor Generator Unit-Heat) harvested energy from exhaust gases and helped minimize turbo lag by managing the turbocharger. Although the engines could reach 15,000 rpm, they were electronically capped at around 12,000 rpm for reliability. Additionally, each power unit was required to last at least 4,000 km before being replaced.

These changes not only reshaped engine design but also had a profound impact on race strategies.

V6 vs Inline-4: Engineering Decisions

The decision to adopt a V6 layout instead of an inline-4 was driven by both performance and structural considerations. The V6 design allowed the engine to act as a stressed member of the chassis, improving the car's overall rigidity and reducing the need for additional structural components. Its compact size also gave engineers more freedom to optimize the placement of energy storage systems and cooling equipment, which were crucial under the new regulations.

Race Strategy and Performance Effects

The fuel and energy limitations of 2014 forced teams to reevaluate their approach to both engine design and race-day tactics. The internal combustion engine produced around 600 horsepower, supplemented by 160 horsepower from the energy recovery systems for up to 33 seconds per lap. Compared to 2013, when V8 engines delivered roughly 750 horsepower with just 80 horsepower from KERS, this represented a major shift. Teams also used about 60% less fuel than under the previous V8 rules, achieving thermal efficiency levels of over 50% - a significant improvement over the efficiency of standard road cars.

Drivers had to juggle energy management with tire strategy, carefully timing their use of the 33-second hybrid boost. Initially, the slower lap times of the 2014 cars sparked debate, but by 2016, advancements in technology had brought lap times at circuits like Silverstone back to V8-era speeds.

Mercedes quickly established dominance in this new era. Their highly efficient power unit gave them a significant edge, with Mercedes-powered cars scoring the lion’s share of points in 2014. Since the hybrid era began, Mercedes has achieved an impressive 139 pole positions and 131 race wins out of 237 races as of 2025.

"The philosophy behind the rules – to create more road-relevant power units with greater potential for technology transfer to road cars and dramatically improve efficiency, a benefit to INFINITI – is a logical one for F1." - Edd Straw, F1 Editor, Autosport Magazine

Major Developments in F1 Hybrid Technology

Building on the advancements of KERS and the 2014 V6 era, Formula 1 hybrid technology has continued to evolve, pushing the boundaries of efficiency and performance. These innovations have not only redefined how power units operate but also how teams manage energy throughout a race.

Progress in Energy Recovery Systems

The MGU-H and MGU-K systems have seen remarkable refinements over the years. The MGU-K, which converts braking energy into electricity, can now produce up to 120 kW (around 160 horsepower) at 50,000 rpm, with a torque cap of 200 Nm. Meanwhile, the MGU-H, responsible for harvesting energy from exhaust gases, operates at speeds of up to 125,000 rpm.

Honda's development journey highlights these advancements. In 2017, Honda redesigned the RA617H engine by relocating the compressor outside the V-bank and increasing its size. This adjustment allowed the engine to maintain optimal boost pressure and airflow, even at high-altitude circuits like Austria and Mexico. By 2018, Honda teamed up with its HondaJet gas-turbine team to improve the MGU-H's shaft support structure, transitioning from greased bearings to oil lubrication for enhanced reliability. Further improvements came in 2019, with an increased compressor pressure ratio inspired by HondaJet technology. In 2020, Honda introduced turbine blades with more intricate three-dimensional shapes, maximizing energy capture from exhaust gases.

Battery and Power Control Unit (PCU) Improvements

The evolution of F1's Energy Store (ES) systems has been dramatic. Early battery systems from around 2007 weighed a hefty 107 kilograms (236 pounds) and operated at just 39% efficiency. Today, modern systems weigh only 20 kilograms (44 pounds) and achieve an impressive 96% efficiency. Current regulations permit the MGU-K to send up to 2 MJ of energy per lap to the battery, with up to 4 MJ flowing back to the MGU-K. Importantly, there are no restrictions on energy transfers between the MGU-H and the battery, giving teams greater flexibility in energy management.

Honda's RA619H power unit in 2019 demonstrated this progress with an increased MGU-H output, ensuring sustained motor performance. By 2021, the RA621H took things further, incorporating high magnetic flux density magnets and advanced thermal conductivity insulators. These upgrades boosted cooling efficiency, increased MGU-H output and torque, and expanded the operational range for energy recovery, even at lower engine speeds.

Thermal Efficiency and Power Delivery

One of the most striking achievements in F1 hybrid technology is the leap in thermal efficiency. Today's hybrid power units achieve a remarkable 52% thermal efficiency, compared to the roughly 29% seen in the V8 engines that preceded them.

"If you asked someone in 2013 about the possibility that an engine could be that efficient, most people, myself included, would just smile at you because we would not have thought it possible." – Luca Marmorini, former head of Ferrari's engine operation

This efficiency boost has direct performance benefits. Modern power units deliver over 1,000 horsepower while consuming about one-third less fuel over a race distance compared to the older 2.4-liter V8 engines, which produced around 850 horsepower with KERS. At Spa-Francorchamps in 2019, an F1 car set a fastest lap of 1:46.409 using 100 kg of fuel, compared to a 1:50.756 lap in 2013 that required 135 kg of fuel.

The entire ERS system weighs at least 150 kilograms (330 pounds), with 20 to 25 kilograms (44–55 pounds) allocated for energy storage. Modern F1 engines also generate less heat and noise than their 2014 counterparts. Formula 1 proudly describes its current power units as "the most efficient engine on the planet achieving 52% thermal efficiency", a level far beyond the 40% efficiency typical of other automotive engines.

Environmental Benefits and Impact

Formula 1 has made impressive strides in energy recovery and thermal efficiency with its hybrid engines, leading to meaningful environmental progress. These advancements not only reduce the sport's carbon footprint but also influence the broader automotive landscape.

Lower Fuel Use and Emissions

The numbers tell a compelling story of F1's environmental progress. By 2026, fuel consumption per race is expected to drop to just 70 kg (154 pounds). Current turbo-hybrid engines generate 20% more power while emitting 26% less carbon compared to the V8 engines from earlier eras. This is largely due to the hybrid systems that recover energy through braking (via the MGU-K) and exhaust heat (via the MGU-H), making energy usage far more efficient.

Interestingly, the cars themselves account for only about 0.7% of Formula 1's total emissions. The sport's annual carbon footprint, estimated at 256,000 tons of CO2, primarily stems from logistics and travel. This highlights the efficiency of the racing technology, especially when viewed against its power output.

"Innovation and community drove Formula 1's work in 2024. We are thrilled to outline our progress and continued work in this space." – Ellen Jones, Head of ESG at Formula 1

Looking ahead, F1 is developing 100% sustainable fuels derived from renewable bio-waste. These fuels are projected to reduce greenhouse gas emissions by at least 65% compared to traditional fossil fuels. If successful, this initiative could have far-reaching implications for global transportation.

These advancements not only cut emissions but also set the stage for broader adoption of hybrid technology across industries.

Impact on Car Industry Trends

Formula 1's hybrid breakthroughs are reshaping the automotive industry. Automakers closely follow F1's progress, using it as a blueprint for developing hybrid and electric vehicles that meet growing consumer demand.

Take the Kinetic Energy Recovery System (KERS) introduced in 2009. This system stored braking energy in a battery, giving drivers a 10% power boost for 6.7 seconds per lap. Similar energy recovery systems have since been adopted in hybrid-electric vehicles, helping convert kinetic energy into electricity, reduce fuel consumption, and enhance electric motor performance.

F1 engineers have achieved a 10% increase in thermal efficiency in just six years, setting a rapid pace of innovation. Beyond engines, the sport's focus on efficiency has improved manufacturing techniques, simulation tools, tire modeling, and lubricant formulations - advances that eventually benefit everyday vehicles.

"Formula 1 created the most efficient hybrid system ever built, but now they are intensifying their efforts to develop a 100% sustainable drop-in fuel from renewable bio-waste – a fuel that could be used in cars and trucks round the world." – Arjan Sissing, Head of Global Brand Management at Deutsche Post DHL Group

F1’s influence extends to system-wide approaches, with its regulations prioritizing environmental considerations. These rules often surpass the standards required for consumer vehicles, pushing automakers to prepare for future demands and shifting customer expectations.

"Formula 1 has a long history of providing technological development that has much wider implications than simply making fast racing cars... the sport has taken a conscious decision to structure its regulations to ensure that the technology it delivers is of immediate and direct relevance to the future improvement of road car efficiency." – Eric Bouiller, Team Principal Lotus F1 Team

Perhaps the most transformative development lies in F1's push for 100% sustainable fuels. These renewable bio-waste-based fuels could be used globally in cars and trucks, offering a practical solution for reducing emissions from existing internal combustion engines while complementing the rise of hybrid and electric vehicles.

"We believe Formula 1 can set an example of how a sustainable fuel can be created and used." – Ross Brawn, Managing Director Motor Sports at Formula 1

Conclusion: The Future of Hybrid Power in Formula One

Formula 1 has come a long way since the early days of KERS in 2009. Over the years, the sport has pushed the boundaries of hybrid technology, culminating in today’s turbo-hybrid power units. Now, F1 is gearing up for another leap forward as it prepares for the 2026 regulations, which promise to redefine hybrid power in motorsport.

The changes ahead are nothing short of groundbreaking. The electric power output will jump from 120 kW to 350 kW - a staggering 300% increase. This adjustment brings F1 closer to a balanced 50/50 split between internal combustion and electric energy, a significant shift from the current 80:20 ratio. Energy recovery during braking will also double, reaching 8.5 MJ per lap, while fuel consumption will drop to just 70 kg (154 lbs) per race.

Nikolas Tombazis, FIA Single Seater Technical Director, highlighted the vision behind these changes:

"Lighter, more powerful and more focused on driver skill, the 2026 FIA Formula One Technical Regulations have been designed to provide closer racing among drivers, increase the competition between teams and to improve the spectacle. In addition, we have opted for a higher electrical component of the power unit, a more efficient car overall, and fully sustainable fuels, as part of our drive towards a more sustainable future for our sport."

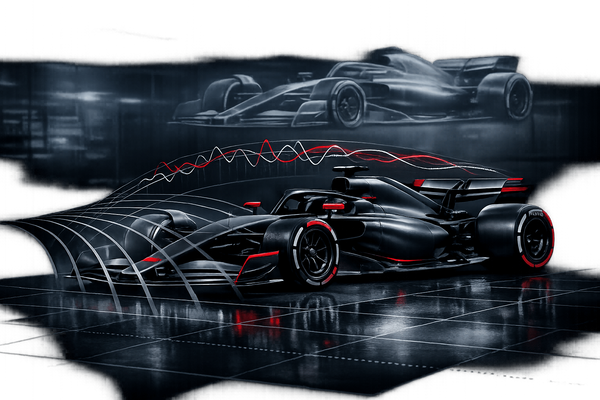

– Nikolas Tombazis

The cars themselves will undergo significant transformations. They’ll be 30 kg lighter, with a minimum weight of 768 kg (1,693 lbs). Downforce will be reduced by 30%, drag by 55%, and active aerodynamics - like adjustable front and rear wings - will enhance efficiency. A manual override mode for extra electric power will add another layer of strategy and excitement.

Perhaps the most impactful change is the introduction of 100% sustainable, renewable bio-waste fuels. This innovation is expected to cut greenhouse gas emissions by at least 65%. Stefano Domenicali, Formula 1 CEO, emphasized the broader implications:

"The new sustainably fueled hybrid power unit presents a huge opportunity for the global automotive industry, the drop in fuel has the potential to be used by cars around the world and dramatically cut emissions. Its potential is one of the key reasons why we will have a record number of engine suppliers in Formula 1 in 2026."

– Stefano Domenicali

This shift has already drawn new manufacturers to the sport, leading to a record number of engine suppliers for 2026. By combining increased competition with cost-conscious, sustainable solutions, F1 is cementing its role as a trailblazer in hybrid technology.

Over the years, F1 has proven how motorsport can drive real-world advancements. Thermal efficiency, for instance, has skyrocketed from 29% in 2013 to over 50% today. Energy recovery systems pioneered in F1 are now commonplace in road cars. The 2026 regulations not only promise more sustainable and thrilling racing but also lay the groundwork for innovations that could transform transportation for years to come. Formula 1 remains a powerful testing ground for ideas that shape both the racetrack and the road.

FAQs

How have F1 hybrid engines shaped the future of everyday car technology?

F1 hybrid engines have reshaped the way road car technology is developed, bringing features like Kinetic Energy Recovery Systems (KERS) and sophisticated turbo-hybrid systems into the spotlight. These advancements enhance both fuel efficiency and overall performance. Core components such as MGU-K (Motor Generator Unit - Kinetic) and MGU-H (Motor Generator Unit - Heat) have found their way into hybrid and electric vehicles, making them more efficient and powerful.

F1's expertise in energy management and lightweight materials has also left its mark on modern road car design. These innovations not only boost performance but also contribute to energy savings, underscoring how F1's engineering excellence translates into tangible benefits for everyday vehicles.

What were the main challenges with early F1 KERS systems, and how did teams overcome them?

Early F1 KERS (Kinetic Energy Recovery Systems) faced a rough start, grappling with reliability problems due to technical glitches and uneven performance. On top of that, packaging challenges made it tricky to fit the system into the car without messing up aerodynamics or weight balance.

To tackle these hurdles, teams experimented with different energy storage options like flywheels and batteries, tweaking designs to make them tougher and more efficient. They also worked on improving control systems to ensure smoother operation and better integration with the car's overall setup. These efforts laid the groundwork for the advanced hybrid systems we see in F1 today.

What environmental benefits will Formula 1's 100% sustainable fuels bring by 2026?

Formula 1 is set to make a bold leap by introducing 100% sustainable fuels by 2026, a move that will make F1 cars carbon-neutral and sharply cut down greenhouse gas emissions. This shift represents a major step toward reducing dependence on fossil fuels and aligns with the sport's ambitious goal of reaching net zero carbon emissions by 2030.

With this initiative, F1 isn’t just transforming its own operations - it’s sending a powerful message about the potential of sustainable energy. The hope is to inspire similar progress across the automotive sector and beyond.