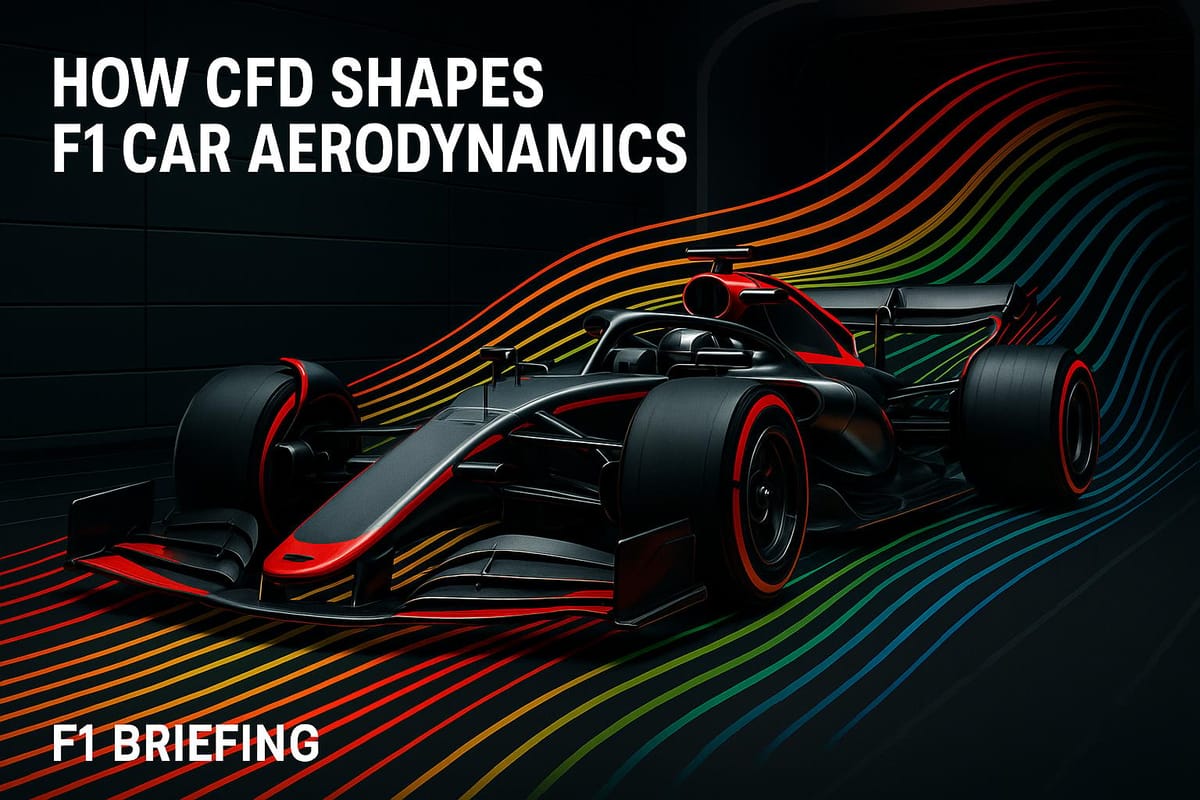

How CFD Shapes F1 Car Aerodynamics

Explore how CFD technology transforms Formula 1 car design, optimizing aerodynamics for improved performance and competitive advantage.

Computational Fluid Dynamics (CFD) has revolutionized how Formula 1 teams design cars, enabling them to optimize aerodynamics efficiently and stay competitive. By simulating airflow digitally, teams can analyze downforce, drag, and turbulence without relying solely on physical wind tunnel tests. This approach saves time, reduces costs, and allows for testing bold designs in a controlled virtual environment.

Key Takeaways:

- What is CFD? A digital tool that simulates airflow around cars to improve performance.

- Why it matters: Aerodynamics impacts downforce (grip), drag (speed), and cooling systems.

- How it helps: Speeds up design iterations, lowers costs, and allows risk-free testing.

- Challenges: FIA limits CFD usage, and simulations require validation through physical tests.

- Future trends: AI, real-time simulations, and cloud computing are enhancing CFD's role in F1.

CFD isn’t just a tool - it’s a core part of how F1 teams refine their cars for maximum on-track performance.

Formula 1 Race Car Aerodynamics: Simulation in CONVERGE

How CFD Works in F1 Car Aerodynamics

CFD, or Computational Fluid Dynamics, breaks down the complexities of airflow into detailed, manageable data points, offering engineers a precise understanding of aerodynamics.

Simulation Workflow

The CFD process begins with a systematic approach to transform a digital car model into a detailed aerodynamic analysis. It starts with mesh generation, where the virtual space is divided into millions of tiny cells. Each cell represents a small volume of air, and the finer the mesh, the more accurate the simulation. In Formula 1, simulations often involve 50–200 million cells, depending on the level of detail required.

After creating the mesh, engineers set boundary conditions that mimic real-world racing scenarios. These conditions include variables like car speed, air temperature, track surface characteristics, and crosswinds. For instance, a simulation might replicate Monza's high-speed straights at 230 mph with air temperatures of 86°F, or model the unpredictable crosswinds at Silverstone.

The core of CFD lies in solving the Navier-Stokes equations, which describe how fluids move. High-performance computers tackle these equations for each cell to calculate changes in pressure, velocity, and density. Depending on the complexity of the simulation and computational resources, this process can take hours or even days.

Once the data is processed, visualization tools convert raw numbers into digestible formats like pressure maps, velocity streamlines, and 3D airflow patterns. These visual outputs help engineers identify areas of turbulence, airflow separation, and other aerodynamic challenges, paving the way for targeted improvements.

The insights gained from these simulations guide engineers in refining the car's aerodynamics.

Data Collected Through CFD

CFD simulations generate an immense amount of data, providing insights that go far beyond what traditional wind tunnel tests can offer. This data shapes nearly every aspect of aerodynamic development.

- Pressure data reveals how air interacts with various surfaces of the car. Engineers assess pressure differences across the wings to calculate downforce and study pressure gradients along the body to find areas where drag can be minimized without losing downforce.

- Velocity fields show how air moves around the car. These fields highlight areas where airflow speeds up or slows down, which directly affects pressure distribution. High-speed airflow often corresponds to low-pressure zones, while stagnant air indicates high-pressure regions.

- Turbulence metrics identify areas where airflow becomes chaotic. Excessive turbulence can increase drag and hurt performance. Engineers use this data to smooth airflow where possible or strategically exploit turbulence to gain an advantage.

Additionally, CFD provides data on wake behavior and heat transfer. Wake analysis focuses on the disturbed air left behind the car, which is crucial for understanding how one car impacts another during close racing. Heat transfer data helps optimize cooling systems by showing how effectively air removes heat from components like brake ducts and radiators.

Integration with Physical Testing

While CFD offers detailed virtual insights, physical testing remains essential for validation. By combining CFD with wind tunnel experiments, teams create a development cycle that balances precision and efficiency.

Correlation studies are a key part of this integration. Engineers compare CFD predictions with wind tunnel results to identify any discrepancies. When the two align, it builds confidence in the virtual models. If they don’t, it signals the need for adjustments or further investigation.

The FIA imposes strict limits on wind tunnel time and CFD resources, with allocations depending on championship standings. Top-performing teams get fewer testing resources, while lower-ranked teams receive more to help level the playing field. This makes efficient validation even more critical.

Validation protocols ensure that designs optimized in CFD perform as expected in real life. Teams often use CFD for broad design exploration before testing the most promising concepts in the wind tunnel. This approach maximizes the value of limited wind tunnel time while using CFD’s flexibility to explore a wide range of ideas.

Finally, track correlation is the ultimate test. Teams compare CFD and wind tunnel predictions with data collected during actual races and practice sessions. Sensors on the car measure real-world downforce, drag, and pressure distributions, providing feedback that helps refine both virtual and physical testing processes.

This iterative approach ensures that the aerodynamic insights from CFD and wind tunnel testing translate into measurable on-track performance.

Applications of CFD in F1 Aerodynamics

In Formula 1, Computational Fluid Dynamics (CFD) is indispensable for shaping race performance. Teams use it to fine-tune aerodynamic balance, perfect component designs, and simulate race conditions - all of which give them a competitive edge on the track.

Balancing Downforce and Drag

CFD helps engineers strike the perfect balance between downforce and drag. By virtually testing various setups - like adjusting the angles of the front and rear wings - teams can pinpoint configurations that meet their performance goals. It’s not just about tweaking individual parts; CFD uncovers how changes in one component affect the entire aerodynamic system. For example, a small adjustment to a wing might enhance downforce but could also increase drag. With CFD, these trade-offs are analyzed with precision, ensuring the car achieves maximum efficiency.

Designing Aerodynamic Components

CFD provides a detailed look at how air flows around the car, offering engineers a 3D view of airflow patterns. This data drives the design of highly specialized components, such as multi-element front wings and intricate floor designs. These simulations allow engineers to refine every detail of a component before it’s even built, saving time and resources compared to relying solely on wind tunnel testing. CFD also collects a wealth of data - like air velocity, pressure, and temperature - at every point on the car, giving teams a complete picture of how each part performs. This virtual testing speeds up design iterations and ensures that when components are manufactured, they’re already optimized for peak performance.

Simulating Race Scenarios

CFD isn’t just for design - it’s also a powerful tool for simulating real-world race conditions. Teams can replicate how the car will behave under specific circumstances, such as varying temperatures or crosswinds, and use that data to refine their designs. These simulations are especially valuable given the FIA’s strict limits on physical testing. With CFD, teams can run countless virtual tests quickly and cost-effectively, helping them prepare for the unpredictable nature of race day.

Challenges and Limitations of CFD in F1

CFD has undoubtedly transformed the way Formula 1 teams approach aerodynamic design, but it’s not without its hurdles. Teams encounter a mix of regulatory and technical challenges that limit just how far they can push this technology.

FIA-Imposed Restrictions

To maintain fair competition and control costs, the FIA enforces strict limits on CFD usage. These regulations cap the amount of computational analysis teams can perform during a season, ensuring no one gains an outsized advantage by pouring unlimited resources into simulations. While this levels the playing field, it also means teams must prioritize how and where they use CFD, often leaving certain areas unexplored.

Technical Limitations

Even with cutting-edge tools, CFD simulations face inherent technical challenges. High computational demands force teams to make compromises in mesh resolution - the level of detail in the simulation grid. This affects how accurately they can model complex airflow patterns.

Turbulence modeling is especially tricky. The chaotic motion of air around an F1 car, including swirling vortices and flow separation, is incredibly difficult to replicate with precision. When airflow detaches from surfaces or when multiple streams of air interact, the resulting effects on performance can be unpredictable and are not always fully captured by simulations.

To improve accuracy, teams often use dense grids with millions of data points. But there’s a trade-off: higher resolution means longer computation times and greater resource consumption. Even the most advanced systems can’t escape this balancing act between detail and efficiency.

The Need for Validation

Because of these limitations, validation plays a critical role. CFD predictions aren’t taken at face value - they’re cross-checked against wind tunnel tests and real-world track data. Wind tunnels provide a controlled environment to verify simulation results, while data from the track helps refine the models further. Any discrepancies between simulation and reality often lead to adjustments, but this process can delay development timelines.

Modern F1 cars add another layer of complexity. With hundreds of aerodynamic elements interacting simultaneously, it’s tough to pinpoint whether performance issues stem from simulation inaccuracies, manufacturing tolerances, or unexpected aerodynamic behavior. This iterative process of refining models and designs is essential to achieving the precision required in today’s hyper-competitive F1 landscape.

The Future of CFD in Formula One

The role of Computational Fluid Dynamics (CFD) in Formula 1 continues to grow, driven by advancements in technology and changes in regulations. What started as basic simulations has transformed into an essential tool for optimizing aerodynamic performance and design.

Historical Development of CFD in F1

CFD first made its way into Formula 1 in the late 1980s and early 1990s. Back then, teams like McLaren and Ferrari began experimenting with simple airflow simulations. These early efforts were limited by the hardware of the time, with simulations taking days or even weeks to complete. The models were basic, focusing on airflow around simplified car shapes.

The early 2000s marked a turning point. With the rise of parallel processing and more powerful computing systems, simulation times dropped dramatically - what once took weeks could now be done in hours. This leap allowed teams to test and refine designs much faster, paving the way for modern CFD techniques.

Today, Formula 1 teams operate with highly advanced computational systems. These setups allow for the simulation of complex aerodynamic interactions with far greater precision and efficiency than ever before. This evolution has laid the groundwork for the cutting-edge CFD tools used today.

New Trends and Developments

Several exciting trends are shaping the future of CFD in Formula 1:

- AI and Machine Learning: Teams are beginning to use AI and machine learning to identify optimal aerodynamic configurations automatically. These tools can analyze vast datasets and suggest improvements faster than traditional methods.

- Real-Time CFD: Some teams are experimenting with real-time CFD simulations during practice sessions. By feeding live track data into their models, engineers can make on-the-spot aerodynamic adjustments to improve performance.

- Cloud Computing: Moving CFD workloads to the cloud allows teams to scale resources flexibly. This approach reduces costs while maintaining high performance, freeing teams from relying solely on expensive, on-site computing infrastructure.

- Virtual and Augmented Reality: Advanced visualization tools are changing how engineers interact with simulation data. Virtual and augmented reality allow designers to "walk through" airflow simulations, offering insights that traditional graphs and charts might miss.

- Quantum Computing: Although still in its infancy, quantum computing holds promise for revolutionizing CFD by solving complex simulations at speeds currently unimaginable.

Impact of Regulatory Changes

CFD innovation in Formula 1 is closely tied to regulatory decisions. The FIA has implemented rules to limit computational time and wind tunnel usage, ensuring a level playing field. There are also ongoing discussions about standardizing CFD software and methodologies to ensure that success stems from engineering expertise rather than proprietary tools.

The introduction of cost caps has forced teams to rethink how they allocate resources. Investments in high-performance computing must now be balanced with hiring skilled aerodynamicists. This has led to a greater focus on efficiency and automation in CFD processes.

Environmental concerns are also influencing the future of CFD. As Formula 1 aims for carbon neutrality, the energy demands of high-performance computing have come under scrutiny. Future regulations may encourage the development of energy-efficient algorithms and hardware.

The potential introduction of active aerodynamics could further expand CFD's role. Simulating adjustable aerodynamic elements, such as wings that change angles during a race, would require teams to model not just steady airflow but also the dynamic effects of rapid changes. Standardized validation procedures may also become necessary to ensure CFD predictions align with real-world performance.

As regulations evolve, the balance between innovation and cost control will remain a central challenge. These changes will continue to shape how teams use CFD to refine their aerodynamic strategies and gain a competitive edge on the track.

Conclusion

Computational Fluid Dynamics (CFD) has transformed how Formula 1 teams approach aerodynamics, replacing much of the physical testing with a faster, more efficient virtual process. This shift allows teams to test an incredible number of design adjustments and significantly speed up development cycles.

Today’s simulations push the limits of computing power. Modern F1 CFD setups can utilize over 550 million computational cells. As Pat Symonds, F1’s CTO, highlighted, systems running on 1,152 cores - and potentially scaling to 2,300 cores - provide computing power that’s exponentially greater than before.

But it’s not just about raw computing strength. Teams like Mercedes-AMG Petronas have optimized their CFD workflows, achieving a 20% efficiency gain by integrating AMD EPYC processors into their systems. This has made CFD a cornerstone for aerodynamic development, with entire teams of engineers dedicated to advancing this technology.

While CFD excels at rapid prototyping and design iteration, it works hand-in-hand with wind tunnel testing to validate the accuracy of these simulations. This combination ensures that the designs tested virtually translate effectively into real-world performance.

Looking ahead, emerging technologies like artificial intelligence and machine learning are poised to take CFD to the next level. With evolving regulations and cost caps, teams that can maximize the potential of CFD will maintain a competitive edge. In the high-stakes world of Formula 1, CFD isn’t just another tool - it’s the driving force behind aerodynamic breakthroughs and championship victories. It stands as the backbone of innovation and success on the track.

FAQs

How do F1 teams ensure CFD simulations match real-world performance?

Formula 1 teams maintain the accuracy of their CFD simulations by cross-checking them against data collected from wind tunnel experiments and actual on-track measurements. This data includes details like pressure distributions, airflow patterns, and aerodynamic forces, all of which are used to fine-tune the virtual models.

To achieve even greater precision, teams employ advanced methods such as hybrid validation techniques that integrate key principles of fluid dynamics. This detailed calibration process ensures that CFD models align closely with how the car behaves aerodynamically in real-world conditions, offering dependable insights for refining car design and improving performance.

What limits does the FIA place on CFD usage, and how do F1 teams manage their resources?

The FIA has set strict rules governing the use of CFD (Computational Fluid Dynamics) in Formula One to ensure a level playing field and keep costs under control. For instance, teams are not allowed to perform any CFD or wind tunnel testing for new car designs until January 1, 2025. These measures are part of a broader effort to maintain competitive balance across the grid.

To stay within these regulations, teams must carefully manage their computational resources. This means prioritizing the development of their current cars and adhering to designated testing windows. They also have to account for mandatory shutdown periods, ensuring they make the most of their allotted time to optimize aerodynamic performance. This strategic planning is essential for maintaining competitiveness within the FIA's framework.

How will AI and machine learning shape the future of CFD in Formula 1 car design?

AI and machine learning are transforming computational fluid dynamics (CFD) in Formula 1, making aerodynamic simulations faster, more precise, and incredibly efficient. These cutting-edge tools let teams evaluate thousands of aerodynamic setups virtually, drastically reducing their reliance on physical prototypes and wind tunnel experiments.

By optimizing CFD workflows, AI can slash simulation times by as much as 80%. This allows for more iterations and data-driven design adjustments, giving teams a competitive edge. As technologies like quantum computing and direct numerical simulation (DNS) become practical, AI will take aerodynamic analysis to new levels of accuracy, enabling teams to redefine performance limits in F1 car design.