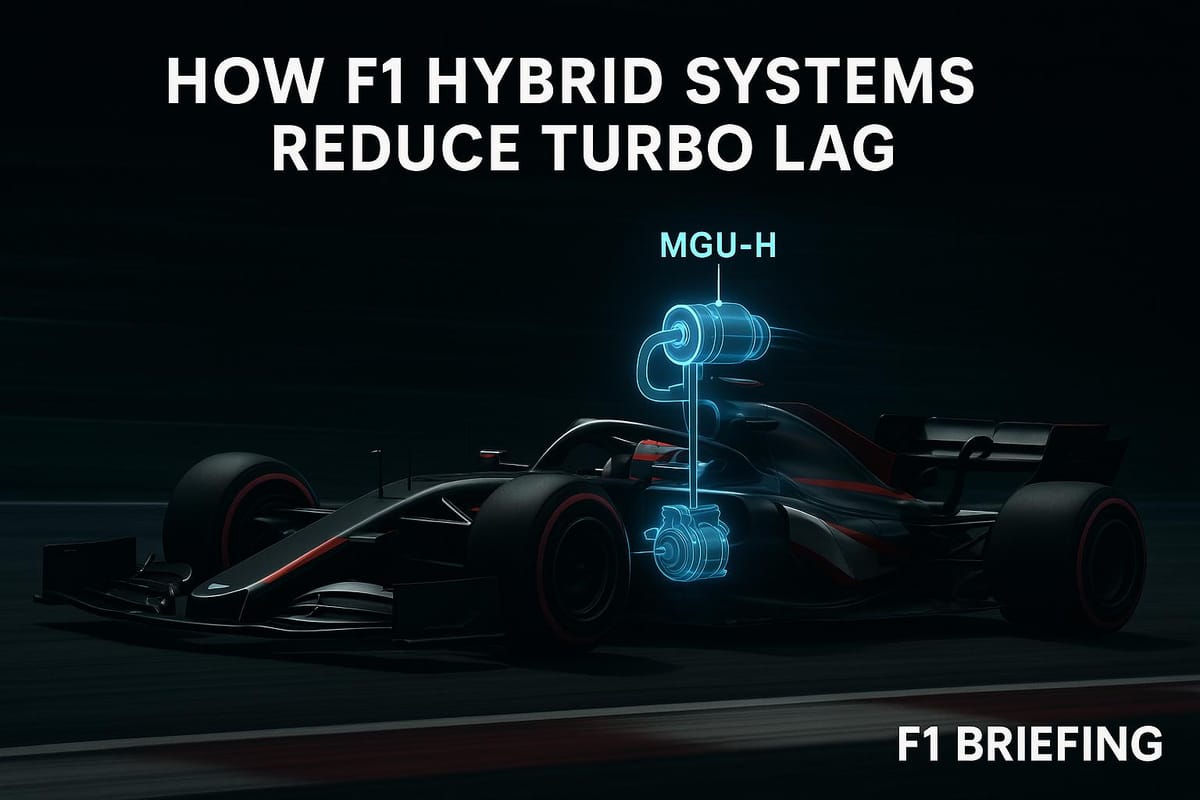

How F1 Hybrid Systems Reduce Turbo Lag

Explore how modern F1 hybrid systems like MGU-H eliminate turbo lag, enhancing performance, efficiency, and acceleration on the track.

Turbo lag, the delay between pressing the throttle and the turbocharger delivering power, used to be a major issue in Formula 1. Modern F1 hybrid systems, like the MGU-H, have nearly eliminated this problem. Here's how:

- MGU-H Technology: Spins the turbocharger using electrical energy, ensuring instant response.

- Energy Recovery Systems (ERS): Recycles exhaust energy to power the turbo and other components.

- Advanced Software: Predicts power needs and pre-spools the turbo for smooth acceleration.

- Efficient Turbo Design: Innovations like split turbos maintain performance even at low speeds.

Quick Comparison: Traditional vs. Hybrid Turbo Systems

| Feature | Traditional Turbo | F1 Hybrid System |

|---|---|---|

| Turbo Response Time | Over 1 second | Near-instantaneous |

| Thermal Efficiency | 20–30% | Over 50% |

| Power Delivery | Abrupt and inconsistent | Smooth and immediate |

These advancements ensure F1 cars deliver unmatched speed, efficiency, and reliability on the track.

F1 Hybrid Systems vs Turbo Lag

MGU-H Basics

The Motor Generator Unit - Heat (MGU-H) plays a crucial role in eliminating turbo lag in today’s F1 power units. This component is directly connected to the turbocharger shaft and transforms excess exhaust heat into electrical energy. Operating at incredible speeds - up to 180,000 rpm - it’s a key part of the hybrid energy system that ensures smooth power delivery.

"When used as a motor, the MGU-H solves the problem of turbo lag. It spins the turbocharger when there isn't enough entropy in the exhaust gas at the right time to ensure that the power unit delivers available peak performance in the given condition." - Hywel Thomas, Mercedes AMG HPP's managing director

Energy Recovery System Operation

Here’s how the Energy Recovery System (ERS) works in tandem with the MGU-H to optimize performance:

| ERS Component | Power Output | Energy Recovery/Deployment |

|---|---|---|

| MGU-H | Unrestricted | Transfers up to 4 MJ to MGU-K |

| MGU-K | 120 kW (~160 hp) | Recovers 2 MJ/Deploys 4 MJ per lap for instant acceleration |

The MGU-H can either recharge the battery or send power directly to the MGU-K, ensuring immediate energy availability during acceleration. This setup bypasses typical MGU-K limitations, maximizing performance when it’s most needed.

Electric Turbo Support

F1 teams have further refined turbocharger designs to minimize lag. For instance, Mercedes’ "split" turbo design positions the compressor at the engine’s front and the turbine at the rear, with the MGU-H strategically placed between them in the engine’s V-configuration. This layout helps maintain turbocharger speed even when exhaust pressure drops.

While F1 regulations cap turbocharger speeds at 125,000 rpm, the MGU-H provides precise control, ensuring optimal performance. These advancements have pushed modern F1 power units to achieve over 50% thermal efficiency - far exceeding the 20-30% efficiency levels seen in the 1980s.

The Theory Behind Turbos and the MGU-H! | F1 TV Tech Talk

Turbo Lag Reduction Methods

These techniques work hand-in-hand with the MGU-H and ERS systems to ensure the consistent performance demanded in F1 racing.

Turbo Pre-Spooling Software

Today's F1 power units rely on advanced ECU programming to predict power needs and reduce turbo lag. The ECU controls turbo speeds of up to 150,000 RPM, adjusting boost levels dynamically based on several key parameters:

| Parameter | Control Method | Benefit |

|---|---|---|

| Throttle Position | Electronic Mapping | Prepares for power demands |

| Engine Load | Real-time Monitoring | Regulates boost pressure |

| Vehicle Speed | Continuous Analysis | Keeps speeds optimal |

By pre-spooling the turbocharger, these algorithms ensure torque is ready when needed. This process works seamlessly with hybrid power systems, giving drivers a smooth and responsive throttle experience.

MGU-H and MGU-K Power Balance

The MGU-H and MGU-K systems are key players in maintaining precise power delivery. At higher speeds, the turbocharger contributes over 10% of additional crankshaft power, while at lower speeds, this figure drops to under 5%. This balance ensures quick acceleration without any noticeable lag.

Team Design Solutions

Beyond software and hardware integration, teams employ clever design strategies to fine-tune energy management. These include:

- Strategic placement of components to maximize energy recovery and usage

- Direct power transfers between the MGU-H and MGU-K for instant response

- ECU-controlled boost pressure for precise power delivery

"The MGU-H is more of an F1 thing... It's called an e-turbo, and it is designed to spin the turbocharger at lower revs... when the car accelerates, the electricity is used to spin the compressor, providing immediate power. There's no turbo lag. Power application is immediate, like with any normally aspirated engine." – Taffin

These systems allow F1 cars to deliver consistent power across all speeds, effectively solving the traditional problems associated with turbo lag.

Hybrid Turbo System Results

Speed and Response Data

Modern Formula 1 hybrid systems have revolutionized performance with the use of advanced MGU-H technology. These systems ensure lightning-fast response times while maintaining turbocharger speeds of up to an impressive 125,000 RPM. This level of precision guarantees consistent power delivery, no matter the racing conditions.

| Performance Metric | Traditional Turbo | Modern Hybrid System |

|---|---|---|

| Turbo Response Time | Over 1 second | Near instantaneous |

| Thermal Efficiency | 20–30% | Over 50% |

| Power Boost | Variable | Up to 10% boost from electrical energy |

Fuel Usage Reduction

The efficiency of hybrid systems doesn’t just enhance performance - it also slashes fuel consumption. In fact, hybrid technology has played a pivotal role in reducing the fuel usage of F1 cars. Back in 2013, cars required around 160 kg (353 lb) of fuel per race. By 2026, the target is to cut this down to just 70 kg (154 lb). A key contributor to this efficiency is the MGU-H, which captures surplus exhaust energy and converts it into additional power, reducing the car's reliance on fuel.

System Longevity

Hybrid systems also excel in extending the lifespan of engine components. By offering precise control over power delivery and heat management, these systems tackle one of the biggest challenges in high-performance engines - thermal stress. Key benefits include:

- Maintaining optimal turbocharger speeds to prevent overloading

- Minimizing thermal stress on critical components

- Ensuring balanced and efficient power distribution across the power unit

"Hybrid power-unit turbo lag is minimal, as the MGU–H (Motor Generator Unit–Heat) element of the ERS can be used to control the speed of the turbocharger (currently restricted to 125,000 rpm), reducing its speed in a similar manner to a conventional wastegate, or increasing the speed to reduce turbo lag. Efficient use of the MGU–H can provide significant extra performance." – Steve Rendle

The combination of efficiency, durability, and cutting-edge technology makes modern hybrid systems a game-changer in F1 engineering. These systems prove that high performance doesn’t have to come at the cost of reliability, paving the way for a new era of motorsport innovation.

Conclusion: Next Steps for F1 Turbo Technology

Main Points Review

The journey of F1 hybrid systems has turned turbo lag from a major performance obstacle into a challenge that engineers can now effectively handle. With efficiency surpassing 50%, the advancements since the high-lag days are undeniable. The combination of the MGU-H and cutting-edge energy recovery systems has significantly improved power delivery under all conditions, setting the stage for the next wave of regulatory changes.

Future Developments

Looking ahead, the 2026 power unit regulations promise to redefine hybrid turbo technology. Here's a quick comparison of current and upcoming features:

| Feature | Current (2025) | Future (2026) |

|---|---|---|

| Battery Power Output | 120 kW | 350 kW |

| Energy Recovery per Lap | 4 MJ | 8.5 MJ |

| Fuel Usage per Race | 100 kg (220 lb) | 70 kg (154 lb) |

| Power Split | ICE-dominant | 50/50 ICE-electric |

One of the most notable changes is the removal of the MGU-H component in 2026, which presents fresh challenges in managing turbo lag. To address this, teams will rely on improved electrical systems, with the MGU-K's output nearly tripling to 350 kW. This increase in electrical power, paired with the introduction of 100% sustainable synthetic fuels, reflects F1's commitment to both peak performance and environmental consciousness.

"All parties are committed to the 2026 regulations and look forward to the prospect of exciting racing. A level of electrification will always be part of any future considerations. The use of sustainable fuel will be an imperative." - FIA statement

These changes have already caught the attention of new players like Audi. Meanwhile, teams are exploring AI and machine learning to fine-tune hybrid energy strategies, ensuring Formula One continues to lead the way in automotive innovation.

FAQs

How does the MGU-H help reduce turbo lag in Formula 1 cars?

The MGU-H (Motor Generator Unit - Heat) is a key component in reducing turbo lag by using electrical energy to manage the turbocharger's speed. When exhaust gas flow isn’t sufficient to spin the turbo effectively, the MGU-H steps in as an electric motor, keeping the turbo running at its ideal speed. This allows for a faster throttle response, delivering power almost immediately when the driver accelerates.

On the flip side, when the turbo spins faster than necessary, the MGU-H captures the surplus energy and stores it in the car’s energy recovery system. This stored energy can then be used to sustain turbo performance or power other systems, improving both efficiency and responsiveness during a race.

How does the Energy Recovery System (ERS) improve F1 hybrid performance and reduce turbo lag?

The Energy Recovery System (ERS) in Formula One is a game-changer for performance, turning wasted energy into additional power. It has two key components: the MGU-K (Motor Generator Unit - Kinetic) and the MGU-H (Motor Generator Unit - Heat).

The MGU-K captures energy generated during braking, while the MGU-H harnesses heat from the turbocharger. One standout feature of the MGU-H is its ability to combat turbo lag by keeping the turbocharger spinning at optimal speed. This ensures a seamless and immediate power boost during acceleration.

Together, these systems add about 160 extra horsepower, significantly improving engine response and giving drivers a competitive edge on the track.

How will removing the MGU-H in 2026 impact turbo lag in F1 cars?

The elimination of the MGU-H in 2026 is likely to reintroduce some level of turbo lag to Formula 1 cars. Right now, the MGU-H plays a key role in minimizing lag by using recovered energy to keep the turbocharger spinning, ensuring a steady power output even at lower engine speeds.

Without it, drivers might experience a noticeable delay between pressing the throttle and the engine responding, particularly when accelerating out of corners. This change could make cars trickier to handle during crucial race moments, pushing teams and drivers to adjust their strategies and driving techniques to navigate this new challenge effectively.