How FIA Tests Rear Wing Flexibility

How the FIA enforces rear wing rigidity: 75 kg static load tests, 4K on-track monitoring, tighter slot-gap limits and new 2025 technical directives.

The FIA ensures Formula 1 rear wings comply with strict regulations to prevent teams from gaining unfair aerodynamic advantages. Flexible wings can reduce drag on straights while maintaining downforce in corners, which violates Article 3.8 of the FIA Technical Regulations requiring all components to remain rigid. To enforce this, the FIA uses static load tests and dynamic on-track monitoring.

Key points:

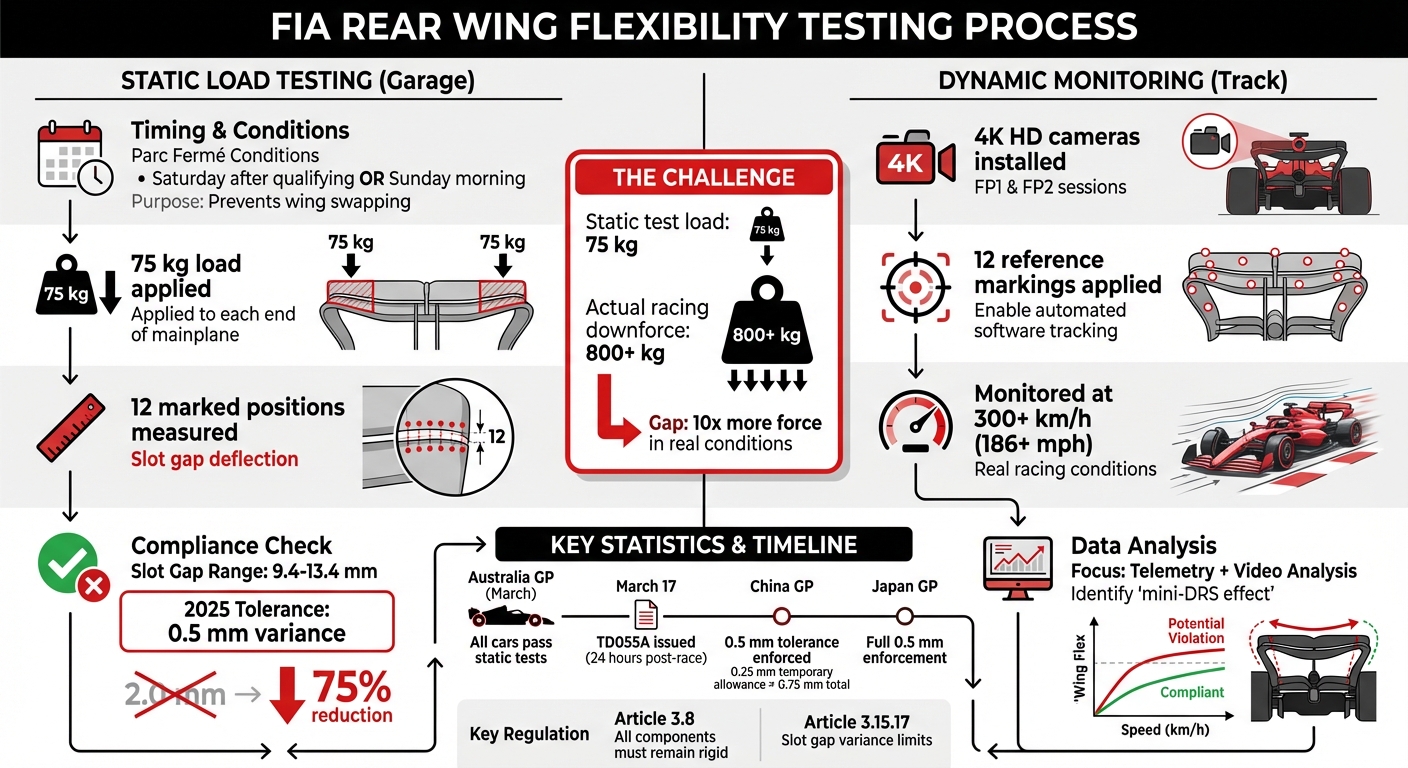

- Static Load Test: A 75 kg load is applied to the rear wing to measure deflection. Slot gaps must stay within the 9.4–13.4 mm range.

- Dynamic Monitoring: High-definition 4K cameras and telemetry capture wing behavior during practice sessions to identify flexing under race conditions.

- Stricter Tolerances in 2025: Slot gap variance was reduced from 2.0 mm to 0.5 mm to eliminate the "mini-DRS effect."

- Technical Directives: Updates like TD055A revised rules on wing geometry and slot gap limits.

These measures balance performance and safety while ensuring compliance under both controlled and racing conditions. Teams must now design stiffer wings that meet these rigorous standards without exceeding cost caps.

FIA Rear Wing Testing Process: Static Load Tests and Dynamic Monitoring Methods

F1 2025 - New Flexi Wing Test EXPLAINED (CATIA)

Static Load-Deflection Testing

The FIA uses static load testing as its primary method to check rear wing compliance. This controlled procedure applies precise vertical loads to the wing to measure how much it deforms. These tests are typically conducted under parc fermé conditions, either on Saturday after qualifying or on Sunday morning. This timing ensures that teams can't install a stiffer wing for testing and then switch to a more flexible one for the race. As Nikolas Tombazis, FIA Single Seater Director, explained:

We frequently test in parc fermé conditions - either on Saturday after qualifying or Sunday morning... That ensures that they're not fitting a stiff wing for the test and running something else in the race.

This approach allows for accurate measurements, which are further detailed below.

Test Procedure and Equipment

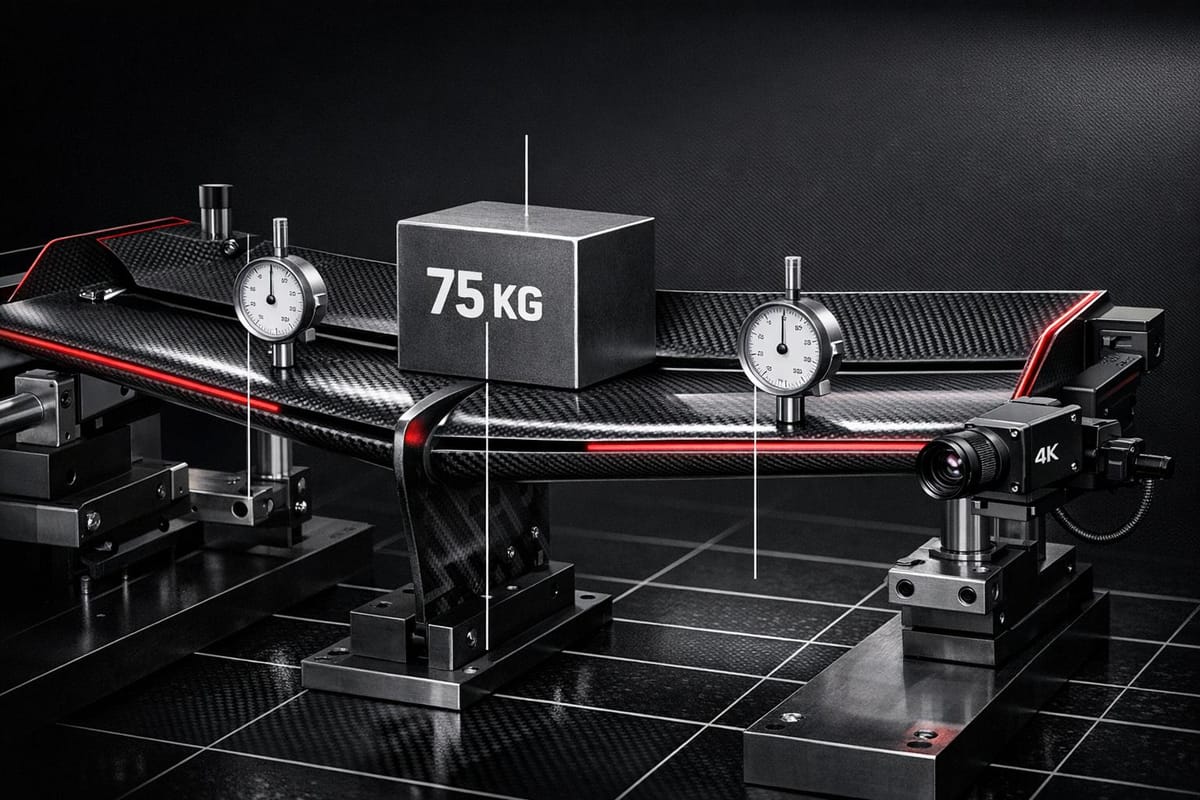

During the test, FIA scrutineers apply a 75 kg load to each end of the rear wing mainplane. Standardized weights and precision tools are used to measure the deflection, focusing specifically on the slot gap - a critical area for aerodynamic performance. Teams are required to mark 12 specific positions on their wing, enabling the FIA to match the test data with high-definition footage captured during Friday's sessions.

In March 2025, following the Australian Grand Prix in Melbourne, the FIA tested all the participating cars. While every car complied with the existing rules, the combination of static testing and video analysis revealed a problem: the current tolerances didn’t fully prevent teams from exploiting the "mini-DRS effect" at high speeds.

These precise measurements are vital, as they directly inform the slot gap variance rules that govern rear wing flexibility.

Slot Gap Variance Rules

Slot gap measurements are regulated under Article 3.15.17 of the Technical Regulations, which defines how much the gap can change when a load is applied. At the beginning of the 2025 season, the permitted variance was 2.0 mm under a 75 kg load. However, after analyzing data from Melbourne, the FIA determined this tolerance was too lenient and reduced it to 0.5 mm for the Chinese Grand Prix - a 75% reduction. To give teams time to adjust, an additional temporary tolerance of 0.25 mm was allowed for the Shanghai race, making the effective limit 0.75 mm for that event.

The FIA's decision to tighten these tolerances was aimed at eliminating the aerodynamic advantage teams were gaining through flex-induced slot gap changes. Nikolas Tombazis highlighted that the 2025 regulation updates were designed to close the loophole behind the "mini-DRS effect." By phasing in these stricter rules, the FIA balanced the need for fair competition with giving teams enough time to modify their designs without discarding existing wing components.

On-Track Testing and Monitoring

Static tests in the garage can provide a solid starting point for measuring rear wing performance, but they fall short of replicating the intense aerodynamic forces experienced at speeds over 186 mph (300 km/h). To address this, the FIA places significant emphasis on dynamic monitoring during practice sessions. This real-time analysis helps uncover flexibility issues that might not show up in controlled, lab-like conditions. By combining static tests with on-track monitoring, the FIA gains a deeper understanding of how wings behave under actual race conditions.

High-Definition Camera Systems

To monitor rear wing behavior, the FIA requires all teams to equip their cars with high-definition 4K cameras during Free Practice 1 and Free Practice 2. These cameras are aimed specifically at the rear wing elements, capturing their movements under high-speed loads. To enhance this process, teams must apply 12 reference markings to their rear wing components. These markings allow the FIA's automated software to measure even the smallest changes in the slot gap between the mainplane and the upper flap during high-stress moments on the track.

This dynamic footage has proven invaluable, often revealing flexing issues that static tests alone fail to detect.

Data Analysis for Compliance

By combining high-definition camera footage with telemetry data, the FIA can identify even the slightest inconsistencies between how the wings perform in static tests versus real-world conditions. This integrated approach is particularly effective in identifying what’s known as the "mini-DRS effect." In this scenario, rear wing elements flex at high speeds to reduce drag on straights, only to return to their original shape during braking or cornering.

A notable example occurred in March 2025, during the Australian Grand Prix in Melbourne. While all cars initially passed static tests, on-track footage revealed unexpected flexing behavior. Using the combined data as evidence, the FIA swiftly acted by tightening the allowed slot gap variance from 0.08 inches (2.0 mm) to 0.02 inches (0.5 mm). This adjustment was implemented immediately for the following race in Shanghai.

Recent Updates to Testing Protocols

In 2025, the FIA made swift changes to its testing protocols, building on insights from static and on-track observations. Initially, the governing body expressed confidence in the existing regulations. However, after analyzing high-definition footage from the Australian Grand Prix, it became clear that some wings, despite passing static tests, were flexing excessively at racing speeds. This dynamic wing behavior led to immediate updates in the regulations.

Phased Reduction of Tolerances

One of the most notable changes was a dramatic 75% reduction in the allowed slot gap variance. At the start of the season in Australia, teams were permitted up to 0.08 inches (2.0 mm) of movement during the 165-pound (75 kg) vertical load test. By the Japanese Grand Prix, this tolerance was reduced to just 0.02 inches (0.5 mm). For the Chinese Grand Prix, a provisional tolerance of 0.01 inches (0.25 mm) was introduced before stricter enforcement began.

"The 2025 regulations were designed to counteract the so-called 'mini-drs effect'... That test was applied from the start of the season, but it soon became apparent it was insufficient." - Nikolas Tombazis, Single Seater Director, FIA

These stricter tolerances led to the issuance of updated technical directives to ensure compliance across all teams.

New Technical Directives

The FIA’s revised approach was anchored by Technical Directive TD055A, issued just 24 hours after the Australian Grand Prix on March 17, 2025. This directive addressed concerns raised by the high-definition camera analysis of on-track wing performance. It revised Article 3.15.17, mandating that rear wing profiles maintain a minimum gap of 0.37 inches to 0.51 inches (9.4 mm to 13 mm) along the entire span when DRS is not deployed. Additionally, Article 3.10.10 was updated to prevent teams from using electronic controls to manipulate wing geometry.

These updates reflect the FIA’s commitment to ensuring fair competition and maintaining the integrity of the sport.

Impact on Teams and Compliance

The introduction of stricter testing protocols has pushed Formula 1 teams to rethink their rear wing designs, all while staying within the constraints of the cost cap. After the 2025 Australian Grand Prix, the FIA issued Technical Directive TD055A, which required teams to redesign, manufacture, and deliver compliant rear wings in time for the next race in China - leaving them just one week to make these adjustments. With regulatory tolerances tightened, teams had to create stiffer carbon fiber structures, fundamentally altering their aerodynamic setups to meet both performance and compliance demands .

Changes to Rear Wing Design

The new regulations forced teams to abandon aero-elastic designs that used wing flexing to gain a competitive edge. McLaren, for instance, had to overhaul its rear wing designs after onboard footage from the Azerbaijan Grand Prix revealed Oscar Piastri's MCL38 exploiting a "mini-DRS" effect. The wing flexed under load, allowing Piastri to defend against Charles Leclerc without engaging the actual DRS system. Following this, the FIA required McLaren to revise its entire rear wing lineup .

Ferrari’s approach demonstrates the high-stakes nature of these design choices. Team Principal Fred Vasseur disclosed that Ferrari had deliberately avoided developing flexible wings, anticipating an FIA ban. However, when the ban didn’t come as quickly as expected, competitors who had embraced the design gained an advantage.

"We were convinced that [the FIA] would go for the 'no go'. And it went for the 'go'! So probably we lost one or two months. It's difficult because with the cost cap you have to make your choices." - Fred Vasseur, Team Principal, Ferrari

Balancing Performance and Flexibility

The FIA's updated regulations aim to strike a balance between performance and safety, but achieving this balance has become a significant challenge for teams. One major hurdle lies in reconciling the static tests performed in the garage with the extreme forces experienced on the track. While the FIA’s static tests apply 165 pounds (75 kg) of vertical load, Formula 1 wings generate over 1,760 pounds (800 kg) of downforce at high speeds - far more than the combined weight of the car and driver.

Traditionally, teams designed wings to pass these controlled tests while allowing some flex under real-world racing conditions. This approach reduced drag on straights without compromising cornering downforce. However, with the new, stricter rules, this performance window has been drastically reduced. Teams now face the dual challenge of creating wings that remain rigid under racing loads while still delivering the aerodynamic balance needed for both low-speed and high-speed corners. Additionally, these designs must now pass more rigorous dynamic evaluations to ensure compliance .

Conclusion

The FIA has stepped up its game by combining static and on-track tests to ensure rear wing compliance. This approach addresses loopholes that previously allowed teams to exploit aero-elasticity. By tightening slot gap tolerances and using high-definition 4K cameras during practice sessions, the FIA can now verify compliance under both controlled conditions and real-world racing scenarios .

These updated protocols aim to achieve two key goals: keeping the competition fair and prioritizing driver safety. Excessive wing flex not only provides an unintended aerodynamic edge but also increases the risk of structural failures - both of which are unacceptable in the high-stakes world of Formula One .

For teams, these changes mean rethinking their designs while staying within strict cost caps. As Nikolas Tombazis, the FIA's Single Seater Director, pointed out:

If we need to react to maintain fairness, then we will do so.

The FIA has phased in these tests gradually - rear wings in March and front wings in June - giving teams time to adapt without having to scrap costly components immediately. This underscores the fact that meeting the new rigidity standards is now non-negotiable .

Looking forward, the FIA's hybrid testing model sets a new standard for enforcing technical regulations in Formula One. Teams must now design wings that hold up under both static tests and the intense aerodynamic forces of a race. Striking this balance between innovation and compliance will remain a challenge, ensuring fair play and safeguarding drivers on the track.

FAQs

How does the FIA test rear wing flexibility in F1 cars?

The FIA enforces strict rules on rear wing flexibility in F1 cars by performing precise load and deflection tests. These tests involve applying specific forces to the rear wing and measuring how much it bends, ensuring it stays within the allowed limits. Teams are also required to mark certain areas on the wing for detailed inspection, often monitored through onboard cameras.

Beyond these tests, the FIA relies on static load assessments and video footage during race weekends to spot any unusual wing movement. These steps are crucial to prevent teams from using flexible wings to gain an unfair aerodynamic edge, ensuring that all cars comply with the regulation requiring aerodynamic parts to remain firmly secured throughout the race.

Why did the FIA tighten slot gap variance rules for 2025?

The FIA has announced stricter regulations on slot gap variances for 2025, targeting the use of flexible rear wings that could offer teams an unfair aerodynamic edge. The goal is to maintain fair competition by ensuring all teams adhere to consistent aerodynamic standards.

By closing potential gaps in the rules regarding wing flexibility, the FIA is emphasizing its dedication to maintaining fairness in Formula One. This approach ensures innovation continues to flourish, but within well-defined and transparent limits.

How do F1 teams ensure their rear wings meet updated FIA regulations?

F1 teams are constantly tweaking their rear wing designs to meet the FIA's stricter flexibility rules. To stay within the regulations, they reinforce the wing structures and rely on cutting-edge materials to maintain rigidity. The FIA has stepped up its game with tougher inspections, including static load tests and on-board camera monitoring, to ensure the wings hold steady under high-speed conditions.

To comply, teams use stronger materials, improve the structural framework, and even add sensors that track wing performance in real-time. These adjustments help them strike a balance between maintaining rigidity and maximizing aerodynamic efficiency. With further updates to testing likely on the horizon, teams are always working to stay ahead of the curve.