MGU-H Optimization: Key Strategies

Explore the crucial role of MGU-H optimization in F1, focusing on energy recovery, turbo management, and future strategies amid regulatory changes.

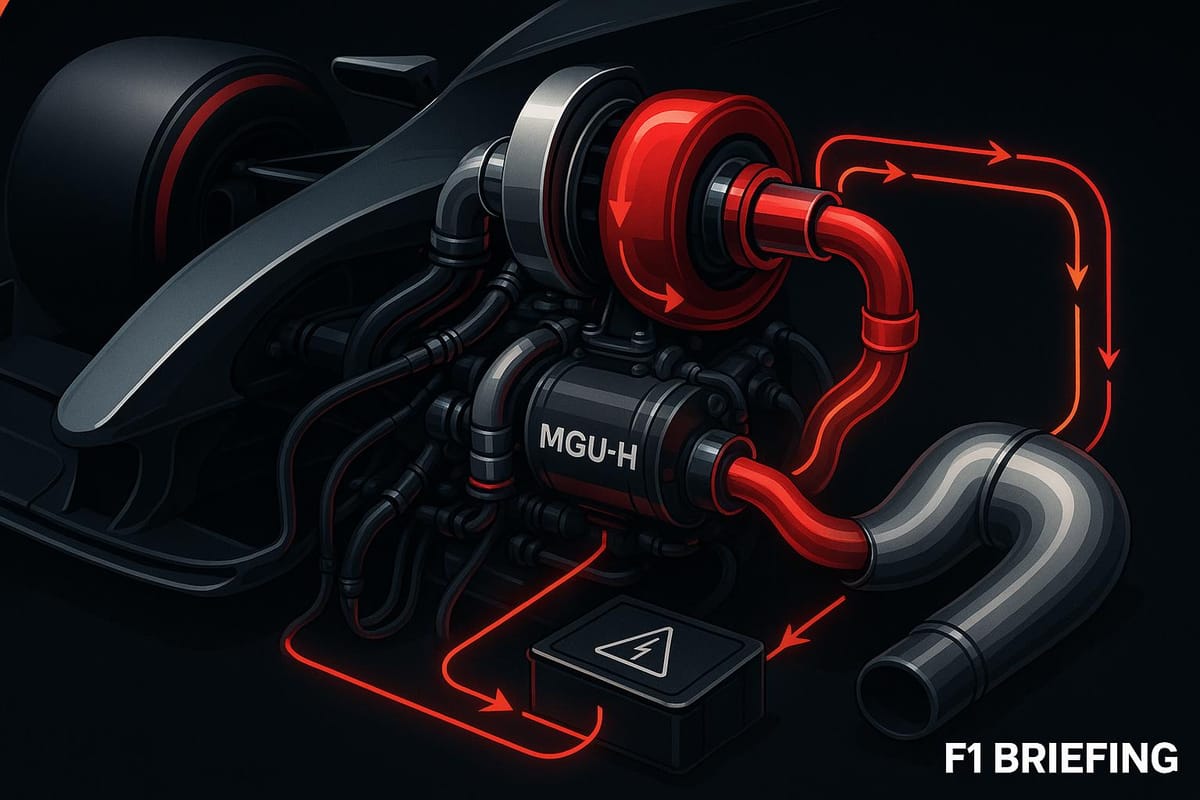

The MGU-H system in Formula One cars is a critical component of hybrid power units, recovering energy from exhaust gases and converting it into electrical power. This boosts engine efficiency and improves turbocharger performance. Here's what you need to know:

- How It Works: The MGU-H, mounted on the turbocharger shaft, spins up to 125,000 RPM to recover energy from exhaust gases (over 1,800°F) and convert it into electricity. It can send this energy directly to the MGU-K for immediate use or store it in the battery for later.

- Key Functions: It eliminates turbo lag by maintaining turbocharger speed during low exhaust flow and prevents overspeed by converting excess energy into usable power. It also integrates with the broader Energy Recovery System (ERS), working in tandem with the MGU-K and Energy Store.

- Optimization Approaches:

- Aggressive Energy Deployment: Prioritizes immediate power for overtaking or qualifying but increases thermal stress.

- Conservative Management: Focuses on reliability and steady performance over long races.

- Thermal-Focused Optimization: Balances performance and reliability using advanced temperature monitoring.

- Track-Specific Tuning: Leverages historical data to fine-tune strategies for specific circuits.

Teams refine these strategies to maximize performance while managing thermal loads and energy flow. With the MGU-H set to be phased out in 2026, the current focus is on squeezing its full potential while preparing for upcoming regulations.

How Do F1 Engineers Optimize The MGU-H? - Pole Position Experts

How MGU-H Systems Work

To truly grasp the benefits of MGU-H optimization, it's essential to first understand how these systems operate. The MGU-H is mounted on the turbocharger shaft, spinning at speeds of up to 125,000 RPM to harness energy that would otherwise escape as heat. This placement allows it to recover energy from exhaust gases, which typically dissipate as waste heat. Acting as both a motor and generator, the MGU-H adjusts its role based on the car's performance needs in real time.

MGU-H Operation Basics

The MGU-H captures energy from the exhaust by converting the rotational energy of the turbocharger's turbine - driven by exhaust gases that can exceed 1,800°F (980°C) - into electrical energy. Positioned directly on the turbocharger shaft, the MGU-H efficiently harvests this rotational motion.

The recovered energy can either be sent directly to the MGU-K for immediate power delivery or stored in the Energy Store (ES) battery for later use. Impressively, the system can reclaim up to 120 kW of power, with no restrictions on how much energy it can recover per lap.

High-voltage systems, operating between 400-800 volts, facilitate the transfer of this electricity. These voltages ensure efficient energy flow while minimizing heat-related losses. Additionally, the MGU-H can reverse its function, acting as a motor to spin the turbocharger when extra boost is required. This clever design eliminates turbo lag altogether, ensuring seamless performance.

These foundational principles enable the MGU-H to perform advanced turbocharger management tasks.

Turbo Management Functions

One of the standout features of the MGU-H is its ability to manage turbocharger speed, completely eliminating turbo lag. In traditional turbocharged engines, turbo lag refers to the delay between pressing the throttle and achieving full boost pressure. The MGU-H solves this by actively controlling the turbocharger's speed.

For instance, when a driver lifts off the throttle, exhaust gas flow decreases, causing the turbocharger to slow down. Without intervention, this would lead to a delay when the driver re-applies the throttle. The MGU-H addresses this by keeping the turbocharger spinning at optimal speeds, even during low exhaust flow. It draws energy either from the battery or directly from the MGU-K to maintain the compressor wheel's rotation.

This active management ensures instant throttle response, a level of precision unattainable with traditional systems. The MGU-H keeps turbocharger speeds within a tight range - between 95,000 and 125,000 RPM - regardless of changes in exhaust flow. This consistency delivers steady boost pressure, crucial for maintaining power through corners and during rapid throttle adjustments.

Additionally, the MGU-H prevents turbocharger overspeed by acting as a generator when exhaust energy exceeds optimal levels. Instead of dumping excess exhaust pressure through a wastegate, the MGU-H converts it into usable electrical power, maximizing efficiency.

ERS Component Integration

The MGU-H plays a critical role within the broader Energy Recovery System (ERS), working seamlessly with other components to manage energy. Its primary partner is the MGU-K (Motor Generator Unit – Kinetic), which recovers energy during braking and provides extra power during acceleration.

Energy transfer between the MGU-H and MGU-K happens directly, bypassing the battery entirely. This direct connection allows for unlimited energy flow between the two units, enabling the MGU-H to send power to the MGU-K instantly, delivering up to 160 additional horsepower.

The Energy Store (ES) battery acts as a buffer, capable of holding up to 4 MJ of electrical energy. While MGU-K energy storage is capped at 2 MJ per lap, the MGU-H can continuously charge the battery throughout the lap, making it the primary energy source for the entire ERS.

A sophisticated network of control electronics oversees the energy distribution across all ERS components. These systems perform thousands of calculations every second, optimizing energy flow based on factors like track position, battery charge, and driver inputs. This automation ensures drivers always have the right amount of power when they need it.

The MGU-H's role extends to the Internal Combustion Engine (ICE) as well. By maintaining consistent turbocharger boost pressure, the MGU-H allows engineers to fine-tune the engine for maximum efficiency. This synergy has pushed the thermal efficiency of F1 power units beyond 50%, a significant leap compared to the 35% efficiency typical of high-performance road car engines.

MGU-H Optimization Methods

The MGU-H plays a crucial role in energy recovery, and teams continuously refine how they manage the turbocharger and energy flow to get the best performance out of the system.

Turbocharger Speed Management

One of the standout features of the MGU-H is its ability to use stored electrical energy to instantly spin the turbocharger's compressor. This eliminates turbo lag and delivers boost almost immediately. The system is smart enough to adapt on the go: it uses stored energy when exhaust flow is low and captures excess energy when exhaust flow is high. Advanced control algorithms handle these real-time adjustments, ensuring the turbocharger operates in sync with the engine's needs and the demands of the track. This tight control over turbocharger speed is key to efficiently routing energy through the hybrid system.

Energy Distribution Planning

The energy recovered by the MGU-H has two options: it can either power the MGU-K immediately or be saved for future use. Sophisticated energy management algorithms decide the perfect timing for energy release, ensuring it’s used during moments when performance peaks matter most.

Optimization Method Comparison

Building on energy distribution planning, let’s dive into how different MGU-H optimization methods perform and what they bring to the table. Choosing the right strategy can make all the difference, as each method has its own strengths and trade-offs.

Method Performance Analysis

When it comes to optimizing MGU-H systems, the results often depend on the circuit layout, race conditions, and what the team prioritizes - whether it’s speed, reliability, or a mix of both.

Aggressive energy deployment is all about using recovered energy immediately for a speed boost. This approach shines during qualifying laps or overtaking battles, where every ounce of power counts. However, it comes with a downside: higher thermal stress and reduced energy reserves for later stages of the race.

Conservative energy management takes a different route, focusing on preserving components and maintaining a steady energy reserve. It may not deliver those dramatic power surges, but it ensures consistent performance over long races. Plus, it helps reduce wear and tear on components, keeping them cooler and more reliable.

Thermal-focused optimization strikes a middle ground. Using advanced temperature monitoring, this method adjusts energy recovery and deployment rates on the fly. While it requires sophisticated controls, it balances performance and reliability, making it a strong choice for unpredictable track conditions.

| Method | Performance Impact | Reliability Rating | Best Use Cases | Thermal Management |

|---|---|---|---|---|

| Aggressive Energy Deployment | High peak boost | Moderate | Qualifying sessions and overtaking maneuvers | High thermal stress; frequent cooling needed |

| Conservative Energy Management | Consistent, steady output | High | Long races and high-temperature conditions | Lower thermal load; minimal cooling required |

| Thermal-Focused Optimization | Adaptive performance | High | Mixed conditions with real-time adjustments | Actively managed with temperature monitoring |

| Track-Specific Tuning | Circuit-dependent boost | Moderate to High | Familiar tracks with detailed historical data | Varies by track characteristics |

Track-specific tuning adds another layer to the mix by leveraging historical data to fine-tune strategies for circuits the team knows well. This method can deliver impressive results on tracks where past data provides a clear roadmap.

Ultimately, the choice of method comes down to team philosophy and the demands of the race. Teams with a strong record of reliability might lean toward aggressive strategies to push their limits, while others may play it safe to ensure consistent results.

Race Data and Performance Examples

When it comes to understanding how optimization strategies translate into on-track success, analyzing race data provides invaluable insights. By connecting optimization techniques to actual performance, race data highlights the tangible benefits of MGU-H strategies. These examples demonstrate how technical advancements directly influence results on race day.

Notable MGU-H Performance Cases

Some teams have excelled in managing their MGU-H systems by ensuring seamless coordination between hybrid components. This smooth integration results in steady power delivery throughout a race stint, which is particularly advantageous on tracks that favor high straight-line speeds. In other scenarios, rapid energy recovery has proven to be a game-changer, offering critical power boosts during overtaking maneuvers.

Additionally, advanced cooling systems have enabled teams to push their performance boundaries without compromising reliability. This balance between performance and durability has been key in maintaining a competitive edge under demanding conditions.

Adapting to Regulation Changes

Evolving regulations are playing a significant role in shaping MGU-H strategies. With changes to power unit architecture on the horizon, teams are shifting their focus to extract maximum performance from the current systems in the short term. This transitional period has also influenced how resources are allocated within power unit development departments, as manufacturers prioritize next-generation technology.

In response, teams are intensifying their efforts to gather detailed performance data during practice sessions. They're experimenting with different optimization settings to better understand the limits of their current systems while also preparing for future advancements. This dual approach helps teams stay competitive now while laying the groundwork for long-term success.

Striking the right balance between immediate performance gains and the reliability of components has become a critical factor. Effective energy management and precise thermal control are now essential for securing race-day advantages in a highly competitive environment.

Conclusion: Getting the Most from MGU-H Systems

Optimizing MGU-H systems is no small feat, but it’s a challenge that has reshaped Formula One engineering in the hybrid era. The strategies discussed - ranging from precise thermal control to fine-tuned energy recovery - are the backbone of competitive power units today.

At the heart of MGU-H optimization is the understanding that every component is interconnected. For instance, temperature management plays a pivotal role in turbocharger efficiency, while timing energy recovery must align seamlessly with track demands and race strategies. Teams that excel in balancing these factors often find themselves ahead, both in qualifying sessions and on race day.

As Formula One prepares for the 2026 regulatory changes, where the MGU-H will be phased out, teams are in a race against time to extract every ounce of performance from the current systems. This transitional period demands a dual focus: squeezing the most out of existing technology while gearing up for the next generation of power units.

Cutting-edge tools like real-time thermal monitoring and predictive energy models are pushing these systems to their limits. Engineers now approach everything from practice setups to mid-race strategy tweaks with unprecedented precision. These innovations not only enhance race-day performance but also pave the way for broader advancements in hybrid technology.

The lessons learned from MGU-H optimization extend far beyond Formula One. Advanced cooling methods, energy management techniques, and seamless component integration are influencing hybrid systems across motorsport and beyond.

As the MGU-H era nears its end, the opportunity to excel still exists. Teams that master track-specific energy recovery and adaptive thermal management will continue to set themselves apart, proving that expertise in this final phase is as crucial as ever.

FAQs

How does the MGU-H reduce turbo lag in Formula 1 cars?

The MGU-H plays a crucial role in reducing turbo lag by using its motor function to spin the turbocharger's shaft when exhaust gases aren't sufficient to do the job. This allows the turbo to hit its ideal speed almost immediately, resulting in better throttle response during acceleration.

In addition, it captures heat energy from the exhaust and converts it into electricity. This electricity can either power the turbo directly or be stored for future use. The result? A more efficient and responsive engine - essential for staying ahead in the fiercely competitive world of Formula 1 racing.

What are the pros and cons of using an aggressive energy deployment strategy for MGU-H optimization in F1?

An assertive approach to energy deployment focused on MGU-H optimization can significantly enhance energy recovery and improve throttle response. This strategy is particularly effective in cutting down turbo lag, delivering a noticeable boost in performance during crucial race moments. It can provide teams with a distinct advantage, especially when overtaking or navigating high-pressure situations.

That said, this tactic isn't without its downsides. Rapid energy consumption can drain stored reserves, potentially leaving less power for the latter stages of the race. On top of that, the added mechanical strain on the system might raise reliability issues, which could impact the car's overall performance and long-term durability.

How will removing the MGU-H in 2026 change F1 power unit strategies?

The removal of the MGU-H in 2026 is set to shake up F1 power unit strategies in a big way. Without the MGU-H, teams will lose about 60% of the electrical energy recovery that used to come from exhaust gases. This system played a crucial role in maintaining turbo boost and cutting down turbo lag. Now, teams will have to rely entirely on the MGU-K for energy recovery. To meet the new demands, the MGU-K's output will jump from 120 kW to 350 kW, and braking energy recovery will double, reaching roughly 8.5 megajoules per lap.

These changes mean teams will need to rethink their approach to the internal combustion engine (ICE). They'll have to focus on improving mechanical braking systems and fine-tuning energy deployment strategies. Finding ways to make up for the efficiency and turbo boost once provided by the MGU-H will push teams to explore new and creative solutions.