MGU-K vs. MGU-H: Energy Recovery on Fast Tracks

How MGU-K and MGU-H recover and deploy energy on high-speed F1 tracks, and what the 2026 MGU-H removal means for hybrid power.

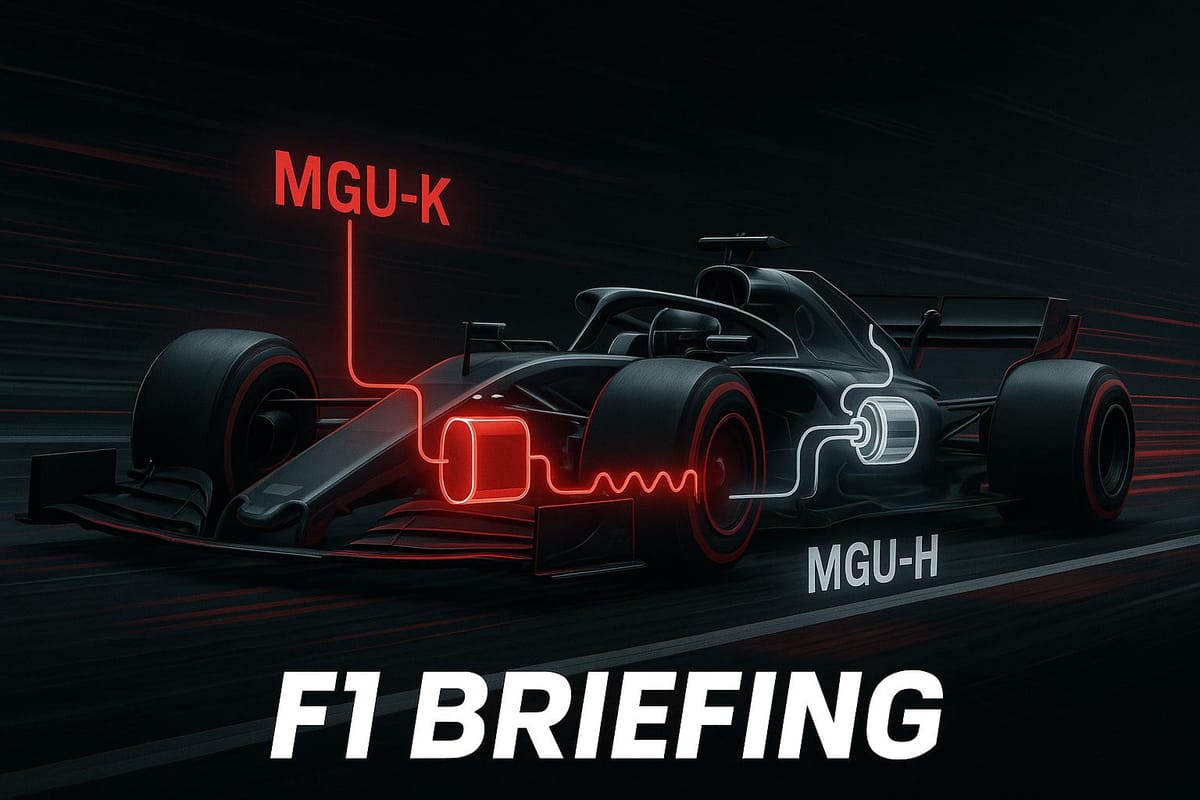

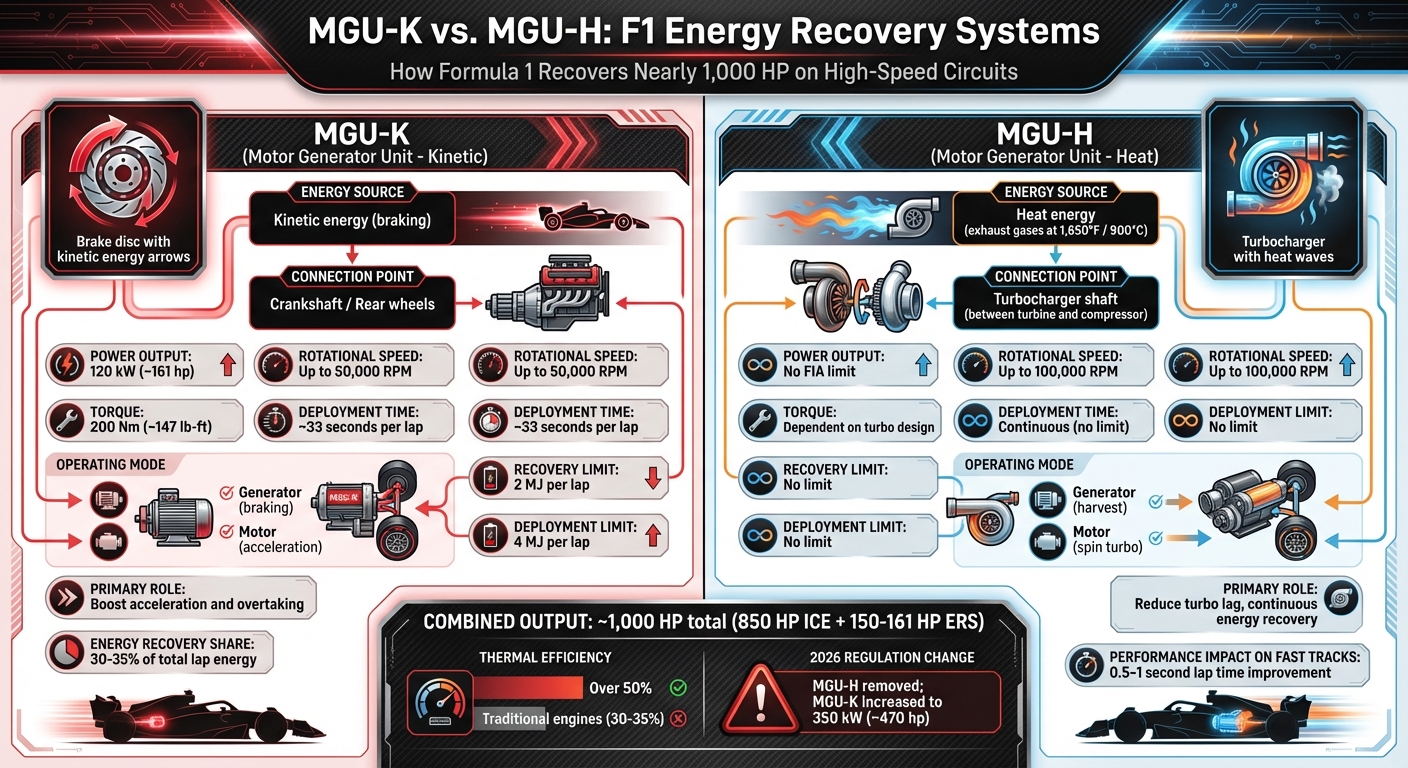

Formula 1 power units combine a 1.6-liter V6 turbo engine with an Energy Recovery System (ERS) to deliver nearly 1,000 horsepower. The ERS relies on two key components: the MGU-K and the MGU-H. These systems work together to recover and deploy energy, significantly boosting performance, especially on high-speed circuits like Monza or Silverstone.

- MGU-K: Recovers kinetic energy during braking and provides up to 161 horsepower for about 33 seconds per lap. It connects to the crankshaft and directly powers the rear wheels.

- MGU-H: Recovers heat energy from exhaust gases and operates continuously. It powers the turbocharger to reduce lag and can send energy directly to the MGU-K or the battery.

The MGU-H is particularly effective on tracks with long straights, where braking zones are limited. Its continuous energy recovery complements the MGU-K's short bursts, ensuring sustained power. However, due to its complexity, the MGU-H will be removed from F1 regulations starting in 2026, with the MGU-K's output set to increase to compensate.

Quick Comparison

| Feature | MGU-K | MGU-H |

|---|---|---|

| Energy Source | Kinetic energy (braking) | Heat energy (exhaust gases) |

| Connection Point | Crankshaft / Rear wheels | Turbocharger shaft |

| Power Limit | 120 kW (~161 hp) | No limit |

| Deployment | ~33 seconds per lap (capped) | Continuous |

| Primary Role | Boost acceleration | Reduce turbo lag, recover energy |

The MGU-K and MGU-H have reshaped F1 strategies, with their combined output pushing power units to nearly 1,000 horsepower. On high-speed tracks, managing their energy flows effectively is critical for achieving optimal lap times and overtaking opportunities.

MGU-K vs MGU-H: F1 Energy Recovery Systems Comparison

MGU-K: Recovering Energy from Braking

How the MGU-K Captures Energy

The MGU-K connects directly to the crankshaft, allowing it to harness kinetic energy during braking. When the driver applies the brakes, the MGU-K switches to generator mode. As the rear wheels rotate, they turn the crankshaft, which activates internal magnets. This process generates electrical resistance, slowing the car down while converting kinetic energy into electricity through electromagnetic induction.

The electricity generated is alternating current, which is then rectified and stored in the car’s high-voltage lithium-ion battery. Formula 1 regulations set a strict limit - teams can recover a maximum of 2 megajoules (MJ) of energy per lap. This ensures all teams stay within defined efficiency boundaries. Once the car accelerates past roughly 62 mph (100 kph), the MGU-K shifts roles and acts as a motor, delivering an extra burst of power.

Compared to the older KERS system it replaced in 2014, the MGU-K produces three times more heat. This makes cooling systems critical, especially on hot days when track temperatures surpass 104°F (40°C). Under these conditions, the risk of failure increases, highlighting the need for effective thermal management. The ability to efficiently convert energy is vital for maintaining peak performance on high-speed tracks.

MGU-K Performance on High-Speed Circuits

When accelerating, the MGU-K can provide up to 120 kW (about 161 horsepower) for approximately 33 seconds per lap. This added power plays a key role in overtaking or maintaining speed on long straights. The unit can spin at speeds of up to 50,000 RPM and generate a maximum torque of 200 Nm (around 147 lb-ft), giving the internal combustion engine a substantial boost.

On circuits like Monza or Spa, the MGU-K faces unique challenges. Long straights and fewer braking zones limit how much energy can be recovered, making it difficult to reach the 2 MJ per lap cap. Despite this limitation, teams must carefully plan when to deploy the stored energy. Drivers can select different deployment modes - using full power during qualifying laps for maximum performance or opting for race modes that emphasize straight-line speed to stay competitive during races.

MGU-H: Recovering Energy from Exhaust Heat

How the MGU-H Captures Energy

The MGU-H sits directly on the turbocharger shaft, nestled between the exhaust-driven turbine and the intake compressor. As exhaust gases, heated to over 1,650°F (900°C), spin the turbine at nearly 100,000 RPM, the MGU-H harnesses this rotational energy - energy that would otherwise go to waste - and converts it into electricity.

Functioning like an electrical brake, the MGU-H slows the turbo shaft's rapid rotation and transforms it into alternating current. This current is then immediately rectified into direct current by power electronics. The amount of energy the MGU-H can recover depends on the exhaust flow, as well as thermal and component constraints.

By reclaiming energy that would typically escape through the wastegate, the MGU-H turns excess exhaust heat into usable electrical power. This constant energy recovery has allowed F1's turbo-hybrid engines to reach thermal efficiencies exceeding 50% - a stark improvement compared to the 30–35% efficiency found in most traditional gasoline engines.

In addition to energy recovery, the MGU-H plays a vital role in reducing turbo lag. When in motor mode, it can spin the turbocharger to maintain boost pressure during gear changes or while cornering. The energy it collects can either be sent directly to the MGU-K for immediate use, stored in the battery, or used to keep the turbocharger spinning. This makes the MGU-H especially effective on circuits where high speeds and quick acceleration are critical.

MGU-H Performance on High-Speed Circuits

The MGU-H truly shines on high-speed circuits, thanks to its ability to continuously recover energy. Tracks with long straights, such as Monza, Baku, and Spa, provide the perfect environment for the system. During these extended full-throttle sections, the engine produces a steady and strong exhaust flow, giving the MGU-H a consistent energy source throughout the lap.

This continuous recovery means that teams can bypass battery storage and send power directly from the MGU-H to the MGU-K. This direct energy feed is especially advantageous on fast circuits with limited braking zones, where the MGU-K has fewer opportunities to recover energy from braking.

To maximize performance, teams often tweak their control software to prioritize this direct energy transfer during both qualifying and races. The result? Enhanced straight-line speed and more efficient power delivery. The MGU-H’s ability to maintain a steady flow of recovered energy not only improves immediate performance but also contributes to the overall efficiency of the power unit.

However, the complexity and high cost of the MGU-H have led to its removal from F1's power unit regulations starting in 2026. This decision by the FIA reflects the ongoing evolution of energy recovery strategies in the sport, as teams look for new ways to balance performance, efficiency, and cost.

MGU-K vs. MGU-H: Performance Comparison

Technical Specifications Comparison

The MGU-K and MGU-H differ significantly in their design, location, and how they are regulated. The MGU-K is directly connected to the crankshaft and rear wheels, positioned low at the back of the chassis. On the other hand, the MGU-H is mounted on the turbocharger shaft, situated between the turbine and compressor, and operates at speeds exceeding 100,000 rpm. Unlike the MGU-K, the MGU-H has no specific FIA power cap or per-lap deployment limit. Its ability to continuously harvest energy from exhaust gases - either storing it or sending it directly to the MGU-K - makes it particularly effective on high-speed circuits.

Here’s a quick breakdown of their differences:

| Specification | MGU-K | MGU-H |

|---|---|---|

| Energy Source | Kinetic energy during braking | Exhaust heat via turbocharger |

| Connection Point | Crankshaft / rear wheels | Turbocharger shaft |

| Power Limit | 120 kW (~160 hp) | No FIA cap |

| Rotational Speed | Up to 50,000 rpm | Up to ~100,000 rpm |

| Torque Limit | 200 Nm | Dependent on turbo design |

| Per-Lap Deployment | Capped at 4 MJ | No limit |

| Operating Modes | Generator (braking) / Motor (acceleration) | Generator (harvest) / Motor (spin turbo) |

Strengths and Weaknesses of Each System

The performance of these systems is directly tied to their specifications, which define their strengths and limitations, especially on high-speed circuits.

The MGU-K's main advantage is its direct mechanical link to the drivetrain. This connection provides an instant power boost to the rear wheels, enhancing acceleration out of slower corners and adding extra thrust during overtaking on long straights. By 2016, Renault's Rémi Taffin noted that the MGU-K could deliver its full 120 kW for nearly the entire lap in qualifying mode, with deployment tailored to track grip and driver inputs. This predictability makes it a key tool for race strategy, allowing teams to create deployment maps for qualifying, overtaking, defense, and even fuel-saving scenarios.

However, the MGU-K has its challenges, particularly on circuits with fewer heavy braking zones, like Monza or Baku. Without sufficient braking energy to recover, teams must limit deployment during the lap or race. Additionally, the system generates a lot of heat, which can lead to cooling issues in high-temperature conditions. A failure in the MGU-K can result in a significant loss of power, leaving the car uncompetitive.

The MGU-H shines in its ability to recover energy continuously. By harvesting exhaust gases even at full throttle, it generates electricity on long straights without depending on braking zones. Beyond energy recovery, it also serves as an advanced turbo control mechanism, spinning the turbo at low revs and generating power at high revs. In some cases, the MGU-H can send power directly to the MGU-K, extending its deployment without depleting the battery.

That said, the MGU-H has its downsides. Operating under harsh conditions - extreme heat and high rotational speeds - it is technically demanding and prone to reliability issues. Its sophisticated power electronics, which convert alternating current to direct current for the MGU-K and battery, add weight and complexity to the system. While its benefits are undeniable, its complexity played a role in its regulatory ban starting in 2026. To compensate, the FIA plans to increase the MGU-K's output to approximately 350 kW (around 470 hp) to maintain hybrid performance.

On fast circuits, managing energy between the two systems is critical. Teams often prioritize the MGU-H as the primary generator, using it to supply power to the MGU-K for sustained deployment. Heavy braking zones are optimized to maximize energy recovery for the MGU-K without upsetting the car's balance. During qualifying, the MGU-K can operate near full deployment across the lap. In race conditions, its deployment is focused on overtaking and long straights, while the MGU-H works continuously in the background to replenish the energy store. Together, these systems, when carefully managed, play a pivotal role in shaping team strategies and influencing race outcomes on high-speed tracks.

How MGU-K and MGU-H Work Together on Fast Tracks

Energy Efficiency on High-Speed Circuits

On high-speed circuits like Monza and Silverstone, the MGU-K and MGU-H operate as a unified system, not as separate entities. The MGU-K, which connects to the crankshaft, recovers kinetic energy during braking and delivers up to 120 kW (roughly 161 HP) directly to the rear wheels during acceleration. While the MGU-K provides a 33-second energy boost, the MGU-H plays a crucial role in extending this power by supplying energy continuously. This is where the MGU-H proves indispensable.

The MGU-H recovers heat energy from exhaust gases, accounting for 65-70% of the total energy recovered during a lap - far surpassing the MGU-K's capabilities, which are limited to braking phases. Instead of storing all the recovered energy in the battery, the MGU-H can send power directly to the MGU-K. This direct transfer ensures the 161 HP boost lasts longer across the lap.

Another key function of the MGU-H is pre-spinning the turbocharger's compressor during low-load phases. On long straights, such as Silverstone’s Hangar Straight or Monza’s stretch from Lesmo 2 to Parabolica, this ensures smooth and uninterrupted power delivery, avoiding the lag often associated with traditional turbochargers. The combined output - approximately 850 HP from the combustion engine, plus an additional 150-161 HP from the Energy Recovery System (ERS) - delivers sustained acceleration critical for overtaking and defending positions. This seamless integration of the two systems is a cornerstone of effective ERS management during races.

Team Strategies for ERS Management

Teams rely on this integrated system to fine-tune their ERS strategies through advanced software controls. As mentioned earlier, the synchronized use of the MGU-K and MGU-H is essential, and teams now optimize ERS deployment to maximize lap performance. Sophisticated software modes determine when and how the systems operate, prioritizing exhaust energy recovery to ensure ample energy for the MGU-K during straights and corner exits. In qualifying "Hot Lap" mode, for instance, teams focus on harvesting maximum exhaust energy early in the lap, enabling the MGU-K to deliver extended boosts during critical segments.

At Monza, Red Bull has capitalized on the MGU-H’s high recovery rate to sustain MGU-K boosts along the Parabolica straight, shaving 0.2-0.3 seconds per lap. Similarly, Mercedes has used the MGU-H to eliminate turbo lag in Silverstone’s high-speed corners, ensuring full ERS deployment for overtaking maneuvers. This strategy played a pivotal role in the 2022 season, where hybrid power was critical for securing pole positions. By carefully managing battery charge and timing ERS boosts for overtakes and defensive moves, teams can achieve lap time improvements of 0.5-1 second on circuits where power is a deciding factor.

How Do F1 MGU-K And MGU-H Optimize ERS Energy Flow? - Pole Position Experts

Conclusion

The MGU-K and MGU-H work together as a seamless energy recovery system, forming the backbone of modern F1 performance on high-speed tracks. The MGU-K, linked to the crankshaft, captures kinetic energy during braking and delivers up to 120 kW (roughly 161 hp) directly to the rear wheels for about 33 seconds per lap. Meanwhile, the MGU-H, located on the turbocharger shaft, continuously collects thermal energy from exhaust gases, contributing approximately 65–70% of the total energy recovered during a lap. Together, they shape the energy recovery strategies that define race-day performance.

The MGU-H complements the MGU-K by channeling recovered exhaust energy directly into the system, enabling a near-continuous hybrid boost on long straights. It also helps eliminate turbo lag by pre-spinning the compressor, ensuring smoother and more immediate power delivery when acceleration is critical.

When combined, these systems push total output to nearly 1,000 hp on high-speed circuits. By turning what would otherwise be wasted energy into additional performance, they extend power availability throughout the lap - an essential advantage on tracks with fewer but more intense braking zones.

This partnership between the MGU-K and MGU-H is why leading F1 teams dedicate significant resources to ERS management software and energy mapping. On fast circuits, where efficient energy recovery is vital, the MGU-H ensures the battery stays charged, allowing the MGU-K to provide maximum boost precisely where it can shave off crucial lap time.

FAQs

Why will the MGU-H be eliminated from F1 regulations starting in 2026?

In 2026, Formula 1 will bid farewell to the MGU-H as part of its effort to streamline hybrid engine systems. This move aims to make the engines less complicated, more affordable, and more dependable. By removing this intricate element, teams can shift their attention to refining the MGU-K, which is pivotal for energy recovery and power deployment during races.

This decision ties into F1's larger objectives of cutting development expenses and opening the door for new engine manufacturers, all while keeping the competition fierce on the track.

What role does the MGU-K play in boosting performance on high-speed tracks?

The MGU-K (Motor Generator Unit - Kinetic) is a key component in Formula 1 cars, designed to recover kinetic energy during braking. This energy, instead of being wasted, is stored and later used to boost acceleration and increase top speed. It gives drivers that extra push when they need it most, especially on high-speed tracks.

By turning braking energy into usable power, the MGU-K doesn’t just enhance performance - it also improves energy efficiency. This makes it an indispensable part of the cutting-edge technology powering today’s Formula 1 cars.

How does the MGU-H help reduce turbo lag in F1 cars?

The MGU-H (Motor Generator Unit-Heat) plays a key role in minimizing turbo lag by capturing heat energy from the turbocharger and converting it into electrical energy. This process allows the turbocharger to spin faster, delivering power more smoothly and with less delay. On top of that, the energy stored during this process can be reused later, boosting both efficiency and performance during a race.