Pit Stop Simulations: How Teams Prepare

How F1 teams use simulations, driver-in-loop rigs and intense pit-crew drills to plan pit windows, rehearse sub-2.5s stops and adapt strategy in real time.

In Formula 1, pit stops are more than just quick tire changes - they can define a race. Teams use advanced simulations and relentless practice to perfect every detail, from timing the ideal pit lap to executing sub-2-second stops. Simulations analyze tire wear, fuel loads, and race scenarios like safety cars, generating terabytes of data per weekend. This data is transformed into precise strategies and rehearsed tirelessly by pit crews to ensure flawless execution under pressure. Every millisecond saved can mean millions in prize money and championship points.

Key Takeaways:

- Teams simulate thousands of race scenarios using tools like Monte Carlo simulations and cloud computing.

- Driver-in-loop simulators refine pit entry precision and braking points.

- Pit crews practice hundreds of stops, targeting consistency and speed under 2.5 seconds.

- Strategies are pre-planned with contingencies for weather, tire wear, and safety cars.

- Post-race analysis feeds into future simulations, improving accuracy and execution.

Pit stops are a blend of data, precision, and practice, where split-second decisions can change the outcome of a race.

Race Weekend F1 Pit Stop Practice

Software Tools for Pit Stop Simulations

Formula One teams rely on advanced software to simulate and strategize key aspects of a race. These tools integrate factors like track layout, tire behavior, fuel usage, and unpredictable race events into a virtual environment. The goal? To answer critical questions such as: When is the best time to pit? What happens if a safety car comes out? Which tire compound will provide the best mix of speed and durability?

Building Digital Models of Tracks and Pit Lanes

To simulate pit stops accurately, teams recreate each circuit using high-resolution GPS and laser-scanned data. These models capture essential details - pit-lane length, curves, elevation changes, and even curb profiles - that directly influence pit stop performance.

Once the track’s geometry is mapped, teams overlay historical telemetry data. This includes speed traces, throttle and brake usage, tire temperatures, and sector times from previous races. Commercial providers like rFpro supply base track models, which teams then enhance with their own car data, tire characteristics, and strategy algorithms. They also factor in practical details like pit-lane speed limits (usually around 50 mph), traffic patterns near pit entry and exit, and safety-car line locations. All this data helps calculate realistic pit-lane time losses under various scenarios.

Simulating Race Strategies for Pit Window Optimization

After building detailed track models, teams use race strategy simulators to run thousands of virtual races. These tools evaluate key performance factors, such as lap times, fuel load effects (which can shave off tenths of a second per lap as fuel burns), tire degradation, and pit-lane time losses. The simulators also assess how competitive the car is relative to others on the track.

What makes these simulations even more powerful is their ability to factor in randomness - like safety cars, weather changes, and even driver mistakes. Techniques like Monte Carlo simulations and reinforcement learning help predict the best pit stop timing by weighing the trade-offs between worn tires and the time lost during a pit stop. They also evaluate strategies like undercuts and overcuts, where the timing of a pit stop can be used to gain track position.

For example, research using Bi‑LSTM models (a type of deep learning) has demonstrated a precision of 0.77, recall of 0.86, and an F1‑score of 0.81 when predicting optimal pit stop timing in real race scenarios.

Cloud computing also plays a big role. Oracle Red Bull Racing uses Ansys tools to simulate up to 1,000 design updates weekly, complementing limited wind-tunnel testing. AWS powers live race graphics like "pit stop advantage" and "pit strategy battle", using real-time cloud-based simulations that account for tire compounds, lap times, and car spacing. Before each race, engineers input updated track models, tire data, expected temperatures, and car performance estimates into the software. This allows them to run extensive simulations comparing one-stop, two-stop, or three-stop strategies. The results form a pre-race strategy guide, complete with contingency plans for unexpected conditions.

For those interested in basic pit stop simulations, a simpler approach involves building a discrete-event race model in Python. Open-source tools like FastF1 provide access to historical timing and telemetry data, enabling users to explore strategies like undercuts, overcuts, and optimal pit windows. While these models aren’t as advanced as those used by teams, they offer valuable insights into race strategy.

Using Driver-in-Loop Simulators

Once strategic models identify the best pit stop timings, driver-in-loop (DiL) simulators bring these plans to life. These simulators, essentially full-scale cockpit rigs, are connected to high-fidelity virtual track models. Drivers use them to practice pit entries, refine braking points, and perfect their stopping precision.

The digital track models provide critical details like pit-lane length, speed limits, and the curvature of pit entries. For instance, Mercedes-AMG PETRONAS uses rFpro models to enhance the realism of their simulators. During these sessions, telemetry data - such as braking points and steering inputs - is collected to refine the strategy software. If discrepancies arise, the software’s assumptions about pit-lane time losses are adjusted. At the same time, drivers' improvements feed back into the system, creating a continuous cycle of refinement.

This seamless integration between simulation and real-world practice ensures that strategy and execution align perfectly, transforming virtual insights into on-track success.

Converting Simulations into Pit Stop Plans

Once simulations are complete, teams transform the raw data into precise, actionable strategies for race day. After running thousands of virtual scenarios, the simulation outputs - like lap projections, tire performance curves, fuel adjustments, and safety car probabilities - are refined into clear plans that engineers, strategists, and pit crews can confidently execute under pressure.

To make these strategies practical, teams organize the data into tables and scenario trees. For each lap, these models outline key details: expected race positions, the pit window range (earliest and latest viable stops), tire life estimates, and the trade-offs between pitting versus staying out. Probabilities for events like safety cars or retirements are calculated, showing how often a strategy might be disrupted and what the potential time loss or gain could be. Strategists then condense this information into dashboards or printed sheets, highlighting ideal "green" laps for pitting, risk levels, and backup strategies if the race doesn't follow the expected pattern.

Creating Pre-Race Pit Stop Playbooks

All this simulation data gets distilled into structured pit stop playbooks. Plan A represents the fastest strategy under normal conditions. But since races rarely go as planned, teams create Plan B and Plan C to account for variables like unexpected tire wear, shifting track temperatures, higher fuel use, or frequent safety cars.

These plans differ in approach. For example, Plan A might involve a one-stop strategy starting on medium tires, while Plan B could pivot to a two-stop approach using soft tires. Plan C might focus on gaining track position with aggressive undercuts or overcuts rather than pure speed. Each plan includes triggers that indicate when to switch strategies. For instance, "Switch to Plan C if tire degradation exceeds 0.3 seconds per lap by lap 10" or "Move to Plan B if a safety car appears between laps 5 and 12."

These contingencies are organized into tables. For example: "If a safety car appears on laps 1–5: pit if starting on softs, stay out on mediums. For laps 6–12: always pit and switch to hard tires if within 3 seconds of the field." Red-flag scenarios have their own guidelines, covering tire choices for restarts, fuel targets, and whether to shift from a one-stop strategy to a sprint-style approach.

The pit wall keeps these plans handy - either laminated or in digital tools - with clear yes/no decision trees. This ensures decisions can be made quickly and accurately, avoiding reliance on ad-hoc calls during high-pressure moments.

Once the plans are finalized, teams break them down into specific operational requirements. For example, if a late-race push on soft tires is part of the strategy, a fresh set of softs must be preserved during qualifying. Fuel targets are converted into dashboard indicators (e.g., showing plus/minus fuel relative to the plan) so drivers can adjust their driving style accordingly. These detailed setups aim to save critical milliseconds during the race.

The garage also prepares for potential scenarios suggested by simulations, like front-wing changes or nose swaps. This involves staging equipment, assigning wheel-gun operators, and setting jack positions to ensure the team is ready for any early-race damage or adjustments.

Defining Pit Stop Choreography

Simulation data doesn’t just dictate when to pit - it also shapes how pit stops are executed. For instance, simulations predict how often both team cars might pit on the same lap, forcing double stops where both cars are serviced back-to-back. If this is likely, teams pre-plan specific choreography for these scenarios. They create one setup for single-car stops and another for stacked stops, ensuring each mechanic knows their exact position to avoid delays.

The expected tire changes - like frequent soft-to-medium swaps or mixed compounds in variable weather - determine how many tire carriers are assigned to each side of the car and how spare tires are staged in the pit box. Training sessions, analyzed with motion-capture and video, refine these movements. Whether it’s a standard stop or a double-stack triggered by a safety car, the pit crew’s actions are fine-tuned to match the probabilities outlined by the strategy models.

Simulations also estimate the total time lost in the pit lane, including entry, stationary time, and exit. This helps define how aggressively the driver should push on in-laps and out-laps or conserve tires before a stop. For the crew, these models set the limits on how long the car can remain stationary and how much margin exists before a stop becomes disadvantageous compared to rivals. This data guides decisions on whether to attempt ultra-fast sub-2-second stops or prioritize safer, slightly slower choreography.

The tools in the pit box, like stopwatches and light systems, are calibrated to align with these targets. Release decisions are made based on simulated risk thresholds, ensuring the car re-enters the track safely and competitively. This integration of strategy and execution turns data-driven insights into on-track performance, where every fraction of a second counts.

Pit Stop Practice: Achieving Consistency and Speed

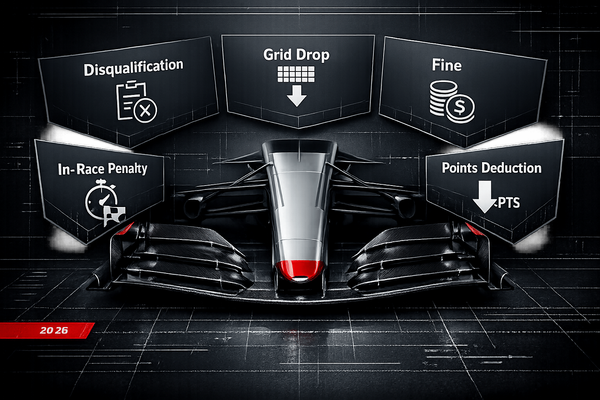

When simulation data shapes the blueprint for pit stop choreography, Formula 1 teams take it to the next level with relentless practice. For pit crews, every stop is a high-stakes performance, rehearsed hundreds or even thousands of times throughout a season. The aim isn’t just to be fast - it’s about delivering consistent, error-free stops under intense pressure, where sub-2.5 second performances become the standard.

The goals are straightforward: shave down average pit stop times, reduce variability between stops, and eliminate mistakes like misaligned wheel nuts, unsafe releases, or incorrect tire fittings. Teams rely on high-speed timers to track every task, gathering data on average times, variations, and error rates. They also benchmark themselves against competitors, targeting consistent sub-2.5 second "race-ready" stops while occasionally hitting sub-2.0 second peaks.

Structured Drills for Pit Crews

Once the digital playbooks are set, teams translate those insights into precise training routines. Practice is divided into two stages: micro-drills and full-sequence drills. Micro-drills focus on perfecting individual tasks - like jack placement, operating the wheel gun, or handling tires. As individual skills improve, the crew moves on to full-sequence drills, where every role is integrated into a complete stop. These drills start at a controlled pace, often around 3.0 seconds, and gradually ramp up in speed. Sensors and video tracking reveal bottlenecks, helping teams pinpoint where to focus coaching efforts.

During peak training periods, crews may perform over 60 practice pit stops a day at the factory. To keep things efficient, some teams use static cars mounted on skates or dollies that simulate rolling into the pit box. This setup reduces costs and noise while maintaining realism. The repetition builds muscle memory and sharpens reaction times, ensuring the crew is ready for race-day intensity.

High-speed cameras and precise timing sensors are standard tools in these practice areas. Footage is analyzed frame-by-frame to identify inefficiencies, like misaligned wheel guns or late tire handoffs. Timing data for each station - front-left, front-right, rear-left, rear-right, and the jacks - helps pinpoint roles that are consistently off pace. Overlaying multiple stops allows analysts to tweak choreography, adjusting details like when tire carriers step in or the positioning of gun operators. Even micro-delays of 0.05–0.10 seconds can add up, and on tracks like Silverstone, where pit lane time losses range from 20–25 seconds, shaving off just 0.2–0.3 seconds can mean the difference between overtaking a rival or falling behind.

The payoff is clear. Red Bull Racing holds the world record for the fastest F1 pit stop: 1.82 seconds, achieved on Max Verstappen’s car during the 2019 Brazilian Grand Prix. This record-breaking stop shaved 0.34 seconds off the previous record of 2.16 seconds, also set by Red Bull in 2013. Williams, another standout in pit stop performance, dominated the rankings between 2016 and 2018, logging the fastest stops in nine out of ten races during the 2016 season, with several stops under 2.2 seconds.

While these drills perfect routine stops, teams also prepare for the unexpected.

Scenario-Based Training for Unpredictable Situations

Pit stops rarely go as planned, so teams rehearse for scenarios flagged by simulation models as likely or high-risk. This scenario-based training tackles challenges like double-stacking cars, front-wing changes, nose replacements, mixed tire sets, and rapid tire changes in unpredictable weather.

For double-stacking, crews choreograph the timing for servicing the first car, clearing it, and bringing in the second car. Practice includes contingencies for delays, with simulations using radio or light signals to mimic safety car calls. Data from these drills captures key metrics like total lane occupancy time and the gap between cars, helping teams decide whether stacking is viable or if the second car should be delayed.

Front-wing and nose changes are another focus. Crews rehearse removing damaged components, aligning replacements, and securing them quickly. For scenarios like minor endplate changes or full nose replacements, the goal is to cut stop times from 15–18 seconds to 8–10 seconds without compromising safety. Low-visibility drills and confirmation checks ensure precision under pressure.

Weather-related drills prepare crews for last-minute tire changes prompted by sudden rain or drying tracks. Teams practice switching to intermediates or wets with minimal notice, coordinating tasks like locating, pre-heating, and delivering the correct tires. Strategy teams tie these drills to simulation outputs, predicting the best lap for tire changes, while the pit crew adapts in real time if conditions differ from expectations.

To replicate race-day stress, teams introduce random elements into practice, such as late calls, slow jacks, or cross-threaded wheel nuts. This progression from controlled to chaotic drills builds resilience, ensuring crews can handle the unexpected. The continuous improvement process - plan, practice, measure, adjust - is a cornerstone of every team’s strategy. Crews analyze performance across races and seasons, refining their tools, techniques, and training focus.

For those interested in diving deeper into pit stop strategies and trends, platforms like F1 Briefing offer detailed breakdowns and expert commentary, providing valuable insights for fans and professionals alike.

Monitoring and Refining Pit Stop Performance

After pit crew practice, teams don’t just stop there - they continuously improve through three key phases: pre-race validation, mid-race adjustments, and post-race analysis. These phases create a feedback loop, feeding data back into simulations to sharpen strategies and execution throughout the racing season.

Pre-Race Validation and Adjustments

On race day, teams take simulation outputs and validate them with real-world data. Strategy groups use a mix of historical race data, overnight simulations, and fresh findings from practice sessions to tweak pit stop models before the race begins. Key factors include tire wear rates from practice runs, changes in track grip, ambient and track temperatures, fuel usage patterns, expected pit lane time losses, and safety car probabilities.

Updated simulations are run on race morning to evaluate possible scenarios - like early safety cars or traffic congestion - and finalize base and backup plans (Plan A, B, and C). These plans outline target pit windows and tire strategies for each car. Sometimes, this process shifts pit windows by several laps or even changes the number of stops if tire degradation surprises the team.

Race-day conditions often differ from what simulators predict, so strategy engineers adjust tire life and performance curves using updated track temperatures, grip levels, wind patterns, and tire behavior observed in earlier sessions. For instance, cooler track temperatures might allow longer stints on softer tires, while hotter or rougher conditions could push teams toward harder compounds or more frequent stops. Advanced weather models guide decisions, helping teams time pit stops to match rain or drying conditions and optimize tire changes between slicks, intermediates, and wets.

The Mercedes-AMG PETRONAS F1 Team works with G42, a leader in AI and cloud computing, to analyze vast amounts of telemetry data in real time. G42’s AI tools help fine-tune car setups - like aerodynamics, tire pressure, and fuel loads - which directly influence pit stop strategies.

These efforts set the foundation for dynamic, in-race decision-making.

Mid-Race Feedback Loops

During the race, strategy teams rely on live telemetry - tire temperatures, fuel levels, engine modes - as well as lap times, GPS data, and gaps to rivals. This information feeds into strategy software that runs constant simulations, updating the projected race time for different pit stop options every lap.

For example, if tire degradation is higher than expected and lap times drop off quickly, the tools might suggest pitting 2–3 laps earlier, even if it means rejoining in traffic. Engineers weigh these recommendations against risks like undercut opportunities or safety car probabilities before issuing clear instructions, such as "box this lap" or "extend three laps", to the driver and race engineer.

Drivers also provide feedback on grip and tire balance, which helps refine the models. If a driver reports solid traction and stable lap times, the stint might be extended. But if they experience overheating or sliding, and the data confirms rising tire temperatures, an earlier stop is prepared. This continuous loop ensures the strategy evolves as the race unfolds.

Teams also monitor rival strategies by analyzing lap times, tire choices, stint lengths, and pit stop durations. If a competitor pits early, a team may respond immediately to avoid being undercut or delay their stop to gain clear air and fresher tires later. Observing which tire compounds are performing well across the field can also lead to mid-race strategy changes, like switching to a harder compound for better longevity.

Scuderia Ferrari F1 Team uses AI and machine learning tools like Amazon SageMaker to develop virtual sensors and analyze race strategy variables, including pit timing and execution. These tools allow quicker adjustments during races.

Consider a scenario where pre-race plans predict a one-stop strategy, but rising track temperatures increase tire wear. If rivals start pitting earlier for a second stop, live data might show that switching to a two-stop strategy is now faster. The team reruns simulations, adjusts the plan, and makes the extra stop, staying competitive with quicker-reacting rivals.

After these real-time adjustments, teams dive into post-race analysis to refine their models for future races.

Post-Race Analysis for Long-Term Improvement

Post-race, teams review every detail of pit stop performance to improve their simulations and strategies. Engineers analyze execution errors, timing gaps, and strategic choices by comparing model predictions with what actually happened.

Deep learning models, trained on historical data, play a big role in improving accuracy. For instance, these models can achieve precision rates of 77% and recall rates of 86%, with an F1-score of 0.81.

Teams refine track-specific degradation models and update training scenarios to make pit stops faster and more reliable. Red Bull Racing, for example, manages up to 1,000 design changes weekly, supported by advanced data systems to monitor and refine performance.

Interactive data visualization tools are invaluable during this phase. Platforms like TracingInsights.com offer detailed analytics with features like clickable lap comparisons, fuel-adjusted lap times, and intuitive color coding. These tools help engineers and analysts quickly identify patterns and areas for improvement, ensuring that strategies evolve effectively.

Feedback loops between pit crews, engineers, and data analysts are crucial. Tools like FastF1, an open-source API for accessing high-frequency race data, support post-race evaluations and simulation updates. This cycle of planning, practicing, measuring, and adjusting ensures that models become more precise and pit crews better prepared for unpredictable race-day scenarios.

For fans curious about the intricacies of pit stop strategies, F1 Briefing offers accessible case studies. It breaks down timing data, tire choices, and race context to explain why teams make certain decisions. The platform also sheds light on behind-the-scenes factors - like strategy software, driver-pit wall communication, and the ripple effects of small delays - giving fans a deeper understanding of how pit stop performance shapes race outcomes over a season.

Conclusion

By blending cutting-edge simulations, meticulous practice, and real-time feedback, teams are turning raw data into precise race strategies. Intuition and basic calculations have taken a backseat to advanced algorithms and analytics that simulate thousands of race scenarios before the cars even touch the track. This shift allows teams to replace uncertainty with calculated decisions, equipping them to adapt quickly when races take unexpected turns.

Take the Mercedes-AMG PETRONAS F1 Team, for example. They've joined forces with G42, a prominent AI and cloud computing company based in the UAE, to supercharge their data analysis and machine learning capabilities. G42's AI algorithms process telemetry data to fine-tune car setups for specific tracks, adjusting key factors like aerodynamics, tire pressure, and fuel load. This ensures every decision during race weekends is backed by data. Similarly, Scuderia Ferrari has leveraged AI and machine learning through Amazon Web Services (AWS) and Amazon SageMaker to create a virtual ground speed sensor. This innovation not only delivers faster and more reliable data to engineers but also helps reduce vehicle weight - a critical factor in a sport where every gram counts. On top of that, Ferrari uses machine learning models inspired by game theory to navigate the countless variables in race strategy.

The level of precision in Formula 1 is staggering. Red Bull Racing relies on Siemens Digital Industries Software's PLM solutions to manage their infrastructure, handling numerous design updates between races. They also use Ansys CFD for aerodynamics, Ansys Granta MI for materials data management, and Ansys LS Dyna for virtual impact testing. Oracle plays a key role in supporting their data-heavy simulations. Even something as quick as a 2.5-second pit stop is prepped and perfected using digital models and hands-on practice.

These technological advancements directly shape real-time decisions and ongoing performance improvements. Teams close the loop by feeding data from every session back into their models, refining accuracy with each race. Advanced deep learning models now validate strategies, showcasing just how far simulation technology has come.

For fans eager to dive deeper into the technical side of the sport, F1 Briefing is a fantastic resource. It simplifies the complex systems behind Formula 1, breaking down how simulation outputs, driver feedback, and pit crew precision come together to create race-winning strategies. It’s a great way to see how data transforms into the split-second decisions that define championships.

FAQs

How do Formula 1 teams use simulations to plan the best pit stop strategy during a race?

Formula 1 teams depend heavily on cutting-edge simulations to fine-tune their pit stop strategies. These tools process real-time race data, weather predictions, and tire performance stats to pinpoint the ideal moments for a stop. By evaluating factors like track conditions, fuel levels, and the positions of rival cars, teams can make lightning-fast decisions that enhance their overall performance.

Before race day, teams run countless simulations to prepare for various scenarios, including safety car deployments or unexpected weather shifts. These simulations ensure that every pit stop decision is grounded in solid data, giving teams a crucial advantage during the race.

How do driver-in-loop simulators help teams improve pit stop strategies in Formula 1?

Driver-in-loop simulators are essential for perfecting pit stop strategies, offering teams a controlled setting to test and adjust various scenarios. These simulators merge real driver input with cutting-edge software to mimic race conditions, enabling teams to study how elements like tire wear, track surface changes, and timing impact pit stop efficiency.

By replicating these real-world variables, teams can fine-tune their timing, communication, and overall execution to achieve quicker, more seamless pit stops during races. Additionally, they provide drivers with a chance to practice smooth pit lane entries and exits, shaving off crucial seconds when it matters most.

How do F1 teams prepare for unexpected situations like weather changes or safety car deployments during pit stops?

Formula 1 teams use a blend of cutting-edge simulations, real-time data analysis, and detailed planning to navigate the unpredictable nature of racing. Simulations help teams anticipate different race scenarios - like sudden rain showers or the deployment of a safety car - so they can craft strategies that allow for quick adjustments.

Once the race begins, teams keep a close eye on live telemetry, weather updates, and the actions of competitors. This constant stream of information helps pit crews and strategists make split-second decisions, ensuring they minimize time losses and maintain peak performance, no matter how the conditions evolve.