Sensor Data Transmission in F1: How It Works

How F1 cars collect, filter and transmit ~1.1M sensor data points/sec using on-car CAN networks, encrypted wireless telemetry, and factory links.

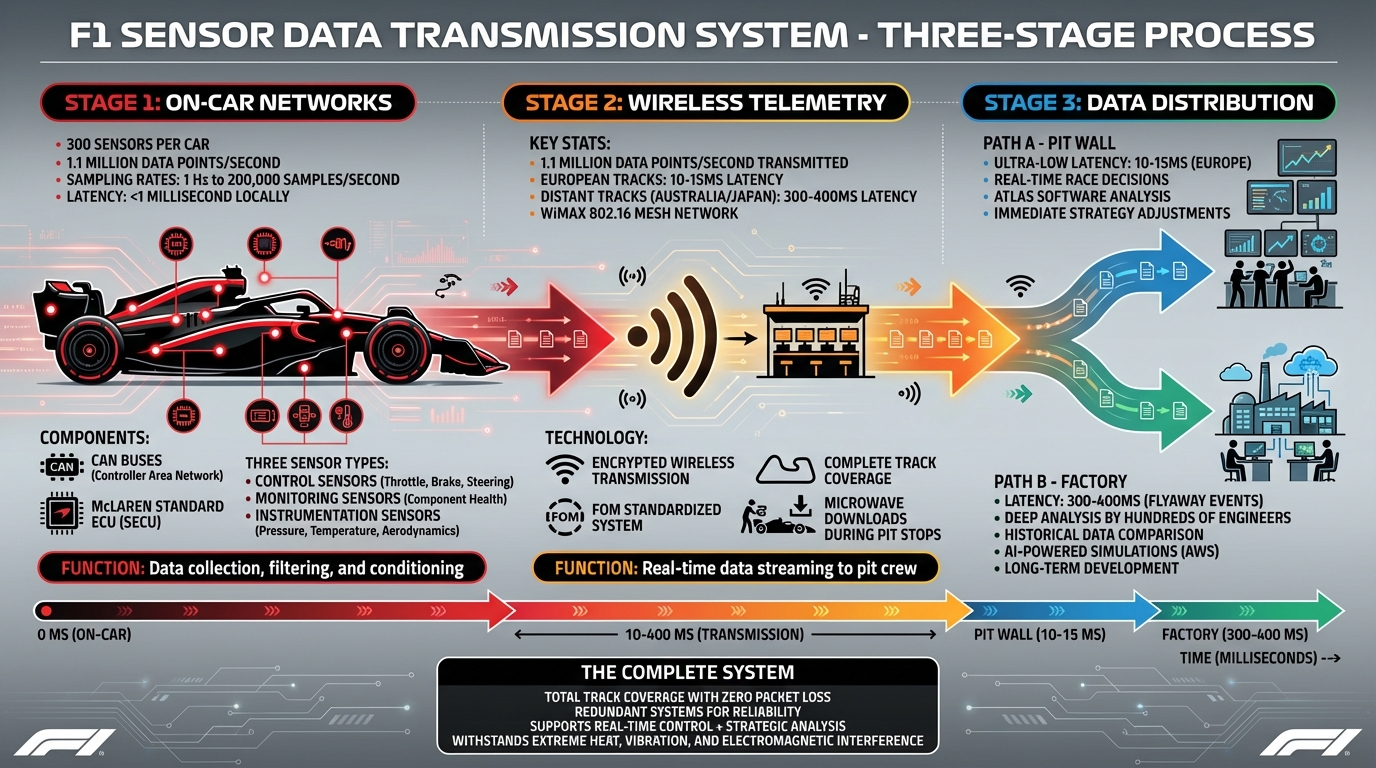

Formula One cars generate 1.1 million data points per second using around 300 sensors. This data enables teams to make real-time decisions on strategy, performance, and safety. The process involves three key systems:

- On-Car Networks: Sensors collect and process data through CAN buses and the ECU, ensuring minimal latency and reliability under extreme conditions.

- Wireless Telemetry: Encrypted data is transmitted to the pit crew via a WiMax mesh network, with delays as low as 10-15ms in Europe but up to 300-400ms for distant tracks.

- Data Distribution: Information is shared between the pit and factory teams for immediate analysis and long-term improvements.

Each system has challenges like data prioritization, interference, and latency but works together to optimize race outcomes.

F1 Sensor Data Transmission: From Car to Factory in Milliseconds

Former F1 Data Engineer Explains Race Telemetry | MoTeC [#TECHTALK]

1. On-Car Networks and Data Conditioning

Before any data leaves the car, it must be gathered, organized, and prepared in real time. Formula 1 cars are equipped with around 300 sensors, all connected through multiple CAN (Controller Area Network) buses and analog lines. These sensors feed data into the centralized McLaren Standard Electronic Control Unit (SECU), a system that has been mandatory since 2008. The SECU handles several key tasks: powering the sensors, time-stamping signals, filtering out noise, and logging data before it’s transmitted or downloaded. This initial step ensures the data remains clean and reliable as it moves into more advanced telemetry systems.

The CAN bus setup is critical for managing the complexity of these systems. Instead of requiring individual wires for each sensor - an approach that would add significant weight and clutter - CAN buses allow multiple sensors and control units (engine, brakes, gearbox, hybrid system) to share information over lightweight twisted-pair wiring. This design keeps the car’s wiring to a total length of roughly one mile while ensuring the system remains both reliable and predictable. Sensors are grouped into three categories: control sensors (for throttle, brake, and steering), monitoring sensors (to track component health), and instrumentation sensors (measuring pressures, temperatures, and aerodynamic forces).

Data Bandwidth

The on-car network handles an immense amount of data. Every second, the system generates 1.1 million telemetry data points, forcing the SECU to decide what gets sampled, logged, and transmitted. Most data channels operate at sampling rates between 1 Hz and 1 kHz, but some - like suspension vibration sensors - can reach up to 200,000 samples per second. To make this data manageable, the SECU uses digital signal processing to extract important metrics, such as RMS levels, peak values, and frequency bands, before reducing the data to more practical logging rates. Without this preprocessing step, the sheer volume of raw data would overwhelm both the telemetry systems and on-car storage.

Latency

The on-car network is designed to deliver ultra-low latency with a deterministic response. Control systems - like fuel injection, ignition timing, brake-by-wire, and hybrid torque - must react within milliseconds to maintain stability and performance. For example, during hard braking or traction control events, even a slight delay could destabilize the car. Data flows from sensors to the SECU, where it is processed and used to drive actuators in real time. Engineers in the garage can view this "live" data with only a 10–15 millisecond delay during European races, ensuring it closely mirrors what the car is experiencing on track.

Reliability

Reliability is non-negotiable in motorsport. Any failure in the on-car network could jeopardize performance or safety. These systems must withstand extreme heat, constant vibrations, and electromagnetic interference from power electronics. To achieve this, teams use automotive-grade CAN networks, shielded wiring, and redundant power supplies for critical components. Sensors are prioritized by importance: control sensors are the most critical, followed by monitoring, and then instrumentation. If non-critical instrumentation fails, the car can still continue racing, but teams carefully weigh the benefits of adding more sensors against the risks of increased complexity, weight, and potential failure points.

Use Cases

On-car networks support three essential functions during a race:

- Control systems: These rely on precise, real-time data from sensors monitoring throttle position, torque, wheel speed, and pressure. This information drives systems like the engine, hybrid ERS, brake-by-wire, and traction control.

- Monitoring and reliability: Continuous tracking of critical metrics like power unit temperatures, tire pressures (via FIA-mandated TPMS), brake temperatures, and gearbox health allows the ECU and team to activate protective modes or adjust strategies to prevent failures.

- Performance and strategy: Conditioned data on tire temperature profiles, fuel usage, energy deployment, and aerodynamic loads feeds into models that help engineers determine optimal stint lengths, undercut opportunities, and engine modes. This data supports strategic decisions both in the garage and at the factory.

Once the on-car data is conditioned and prioritized, the next step is to transmit it wirelessly for further analysis and decision-making off the vehicle.

2. Wireless Telemetry Links

Once data is processed on the car, it's transmitted in real time to the pit wall and garage. This wireless connection serves as the backbone for communication between the finely tuned on-car data and the teams working off-track to refine race strategies. Formula One uses a standardized telemetry system, overseen by Formula One Management (FOM). Each car operates on a secure, encrypted wireless mesh network that guarantees complete track coverage, even on circuits packed with activity.

Data Bandwidth

The telemetry system handles an astonishing amount of data - about 1.1 million data points every second. Sensors on the car record data at varying speeds, from 1 Hz up to 1 kHz, while processed vibration data can hit rates as high as 200 kilosamples per second. To manage this overwhelming volume without losing any packets, the network continuously streams updates on critical parameters like tire pressures, aerodynamic forces, engine performance, and driver inputs. During pit stops, larger data sets are downloaded quickly via brief microwave transmissions, and when the car is stationary, a wired umbilical cord connection allows for even faster data extraction.

Latency

With such a massive data flow, keeping latency to a minimum is crucial. The delay in wireless telemetry depends heavily on the race location. For European tracks, live data reaches the garage with a delay of just 10–15 milliseconds, enabling engineers to analyze it almost instantly. However, for faraway events like those in Australia or Japan, the delay can stretch to 300–400 milliseconds due to the increased distance between the circuit and the factory.

Reliability

To handle the challenges of high data volumes and varying latency, the system is built with multiple layers of redundancy. The FOM network ensures complete track coverage, with no single points of failure. Encrypted data packets keep team communications secure, while fiber backups and multiple access points add extra layers of reliability. Additionally, all teams rely on the McLaren-designed Standard Electronic Control Unit (SECU), which buffers data before transmission, further reducing the risk of losing critical information during high-stakes moments on the track.

Use Cases

Wireless telemetry plays a central role in many race-day decisions. Engineers tap into this real-time data to fine-tune pit stop timing, monitor tire wear, and adjust performance strategies - often benchmarking against competitors during practice and races. They analyze sensor data, such as throttle, braking, and steering inputs, across multiple laps to pinpoint areas where time can be shaved off. During practice sessions, extra sensors gather detailed airflow and downforce data, which teams use to refine car setups for qualifying and race day.

Next, we’ll dive into how this data is shared with remote factory teams for further analysis.

3. Data Distribution Systems (Garage vs. Factory)

Building on the foundation of on-car and wireless telemetry systems, data distribution plays a key role in Formula 1 operations by splitting responsibilities between the immediate needs of the pit wall and the long-term analysis conducted at the factory. Once telemetry data arrives in the garage, it takes two distinct routes: one supports real-time decision-making during the race, and the other feeds into deeper, strategic evaluations back at the factory. This setup ensures a balance between quick reactions and comprehensive post-race insights.

Data Bandwidth

In the garage, live telemetry is divided into two streams: one for immediate use and another for strategic purposes. Engineers at the track need instant access to critical data like tire pressures, aerodynamic loads, and engine temperatures to make split-second decisions. This real-time information is transmitted using FOM's fiber links and a WiMax mesh network. On the other hand, factory systems receive larger, aggregated datasets through dedicated connections. These connections allow hundreds of engineers to dive into historical data, analyze competitor performance, and focus on long-term car development - without interfering with the real-time data flow needed at the track.

Latency

The garage enjoys ultra-low latency, typically around 10–15 milliseconds at European circuits. This near-instantaneous response time is crucial for pit wall teams to adapt swiftly to changing track conditions and driver inputs. However, latency increases for flyaway events, reaching approximately 300–400 milliseconds. While this delay makes factory data unsuitable for immediate race-day decisions, it is still fast enough for live monitoring and strategic analysis during the event.

Reliability

Both systems are built on highly reliable and redundant infrastructures. Factory connections leverage secure, team-specific networks directly linked to FIA systems, minimizing the risk of data loss during transmission and ensuring a continuous flow of information.

Use Cases

This dual-path approach allows teams to meet both the immediate demands of race day and the broader goals of vehicle development. At the garage, engineers rely on tools like ATLAS software to overlay sensor data in real time. This enables them to monitor critical metrics - such as throttle usage, braking points, and cornering speeds - and identify opportunities to shave off fractions of a second. Additional inputs, such as tire pressure monitoring and thermal imaging, further enhance decision-making. Meanwhile, the factory focuses on long-term objectives. Engineers combine car telemetry with competitor data to identify trends over the season, analyze driver performance, and use AI-powered tools hosted on platforms like AWS to refine aerodynamic setups for future races. By splitting responsibilities - tactical decisions at the garage and strategic planning at the factory - teams ensure they extract the full potential from their extensive sensor networks.

Advantages and Disadvantages

When it comes to Formula One, understanding the strengths and limitations of various data systems is essential for optimizing race performance. Let's break down the pros and cons of on-car networks, wireless telemetry, and data distribution systems - three key technologies that teams rely on.

On-Car Networks

On-car networks are built for speed and reliability. These systems process massive amounts of data directly onboard at incredibly high sampling rates. Their wired setup ensures minimal latency, making them perfect for critical functions like brake-by-wire systems and power unit management. Plus, they’re immune to radio interference, which adds an extra layer of security for safety-critical operations.

But there’s a catch. The wired architecture increases the car's weight and complexity, and if a single ECU fails, it could result in total data loss.

Wireless Telemetry

Wireless telemetry is what allows teams to monitor real-time data during races. Each car streams about 1.1 million data points per second to the pit crew. The standardized WiMAX 802.16 mesh infrastructure guarantees full track coverage and secure transmissions.

However, there are limitations. RF bandwidth is finite, so teams have to prioritize which data streams live and at what rates. City circuits can cause interference, and during overseas races, latency can rise significantly.

Data Distribution Systems

Data distribution systems link the garage to the factory, enabling large teams of engineers to simultaneously analyze live telemetry, historical data, and even competitor information. At European events, fiber connections keep latency extremely low, allowing engineers to collaborate in near real-time.

That said, these systems depend on wide-area networks and cloud platforms, which introduces security risks for highly sensitive car data. Long-distance transmissions during overseas events also suffer from increased delays.

How Teams Combine These Systems

No team relies on just one method. Instead, they use all three in tandem. For example, detailed suspension data is captured on-car, critical metrics are streamed live via telemetry, and larger datasets are sent to the factory for overnight analysis. This combination helps refine strategies and setups for the next session.

| System | Bandwidth | Latency | Reliability | Applications |

|---|---|---|---|---|

| On-Car Networks | Very high (up to 200 kS/s) | <1 ms locally | High (wired), but ECU failure risk | Real-time control, high-rate sensors |

| Wireless Telemetry | ~1.1M points/sec per car | Near real-time at track; 300–400 ms remotely | High (mesh network), but vulnerable to interference | Live pit strategy, driver coaching |

| Data Distribution | Massive (300 sensors/car) | 10–15 ms in Europe; 300–400 ms remotely | Network/cloud-dependent | Factory analysis, AI simulations |

Conclusion

Formula One's data transmission system combines on-car networks, wireless telemetry, and data distribution into a powerful pipeline that fuels race-winning decisions. Each component plays a distinct role, contributing to the seamless operation of this intricate system.

On-car networks gather high-resolution data directly from the vehicle, but that data remains onboard until it’s either streamed in real time or downloaded later. Wireless telemetry acts as the bridge, transmitting vast streams of data from the car to the pit wall. However, due to bandwidth limitations, teams must carefully decide which data channels are prioritized for live transmission and which can wait for post-session analysis. From there, data distribution systems send this information to factory operations centers, where engineers use simulations and historical comparisons to further refine strategies, achieving latencies as low as 10–15 milliseconds during European races.

The real magic of this system lies in how these elements work together. On-car networks capture detailed, granular data; wireless telemetry ensures critical information reaches decision-makers in real time; and factory systems provide deeper insights through comprehensive analysis. For instance, a pit-wall strategist might use telemetry to call for an early pit stop when tire temperatures rise, while factory engineers review logged data to fine-tune gearbox performance. This synergy has turned Formula One into a sport where data-driven decisions are made lap-by-lap, often within seconds of spotting a trend.

FAQs

How do F1 teams decide which sensor data to transmit during a race?

F1 teams focus on transmitting the sensor data that has the biggest impact on race performance and safety. The most important metrics include engine performance, tire conditions, and aerodynamic behavior, as these are crucial for making strategic decisions during the race.

Given the immense volume of data generated, teams rely on sophisticated filtering systems and bandwidth management to prioritize the most critical information. This ensures engineers can respond instantly to dynamic situations, such as unexpected weather shifts or high-stakes moments like pit stops.

How is sensor data kept reliable during extreme race conditions?

To perform reliably under extreme conditions, F1 sensors are designed with tough, protective casings that can endure intense heat, constant vibrations, and high g-forces. To avoid losing crucial information, teams rely on redundant data transmission systems. Additionally, real-time error detection and adaptive filtering algorithms work together to preserve both accuracy and data integrity. These features make sure that essential information reaches the teams seamlessly, even in the harshest racing environments.

How does data transmission latency impact decision-making during F1 races?

In Formula 1, even a slight delay in data transmission can disrupt how quickly teams access vital information from their cars. This lag can impact their ability to make immediate, game-changing decisions. Whether it's tweaking race strategies, adjusting car settings, or responding to safety concerns, every second counts - especially in high-pressure situations.

To maintain their competitive edge, F1 teams focus intensely on reducing latency. By ensuring they can process and act on data in real time, they’re able to respond to evolving conditions, fine-tune performance, and stay ahead of the competition during the race.