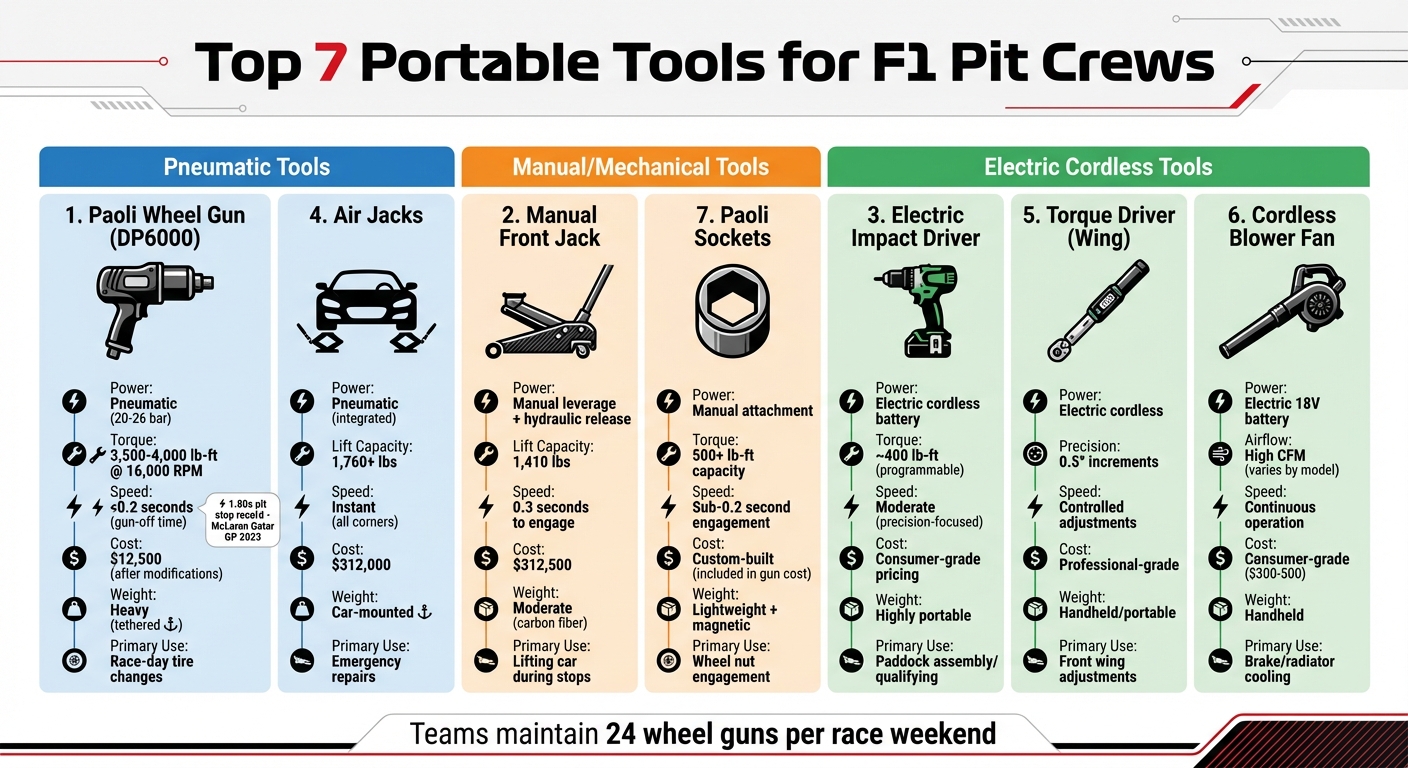

Top 7 Portable Tools for F1 Pit Crews

Overview of seven portable F1 pit tools — wheel guns, jacks, cordless drivers, blowers and custom sockets — focused on speed, precision, and reliability.

F1 pit stops are a blend of speed, precision, and teamwork, with specialized tools playing a critical role. From high-torque wheel guns to cordless blowers, these tools are designed to handle the intense demands of a race. Here’s a quick overview of the top portable tools used by F1 pit crews:

- Paoli Wheel Guns (DP6000 Series): Deliver 3,500 ft-lb of torque in under 0.2 seconds, ensuring rapid tire changes. Each unit costs up to $12,500 after modifications.

- Manual Jacks: Lightweight yet strong, these jacks lift a 1,410-pound car in seconds. Priced at $312,500, they’re engineered for speed and durability.

- Electric Cordless Impact Drivers: Used for precise tasks like bodywork assembly, offering programmable torque settings for accuracy.

- Air Jacks: Backup systems for emergencies, allowing simultaneous repairs and tire changes.

- Torque Drivers for Front Wing Adjustments: Fine-tune wing angles in 0.5° increments, enhancing aerodynamics.

- Cordless Blower Fans: Repurposed leaf blowers cool brakes and radiators during pit stops, preventing overheating.

- Paoli Sockets: Custom-designed to handle extreme torque and ensure flawless wheel nut engagement.

Each tool is engineered for reliability under extreme conditions, balancing speed with precision. Whether it’s a $312,500 jack or a modified consumer-grade impact driver, every piece of equipment contributes to the efficiency of pit stops that can decide race outcomes.

F1 Pit Crew Portable Tools Comparison: Specs, Performance & Cost

The AMAZING Engineering of Pit Stop Tools! | How Impact Wrenches, Jacks, and Refueling Systems Work

1. Paoli Wheel Guns (DP6000 Series)

The Paoli DP6000 Series wheel gun has become the go-to tool for F1 pit stops, capable of delivering over 3,500 ft-lb of torque at an astonishing 16,000 RPM. This powerhouse can remove a wheel nut in under 0.2 seconds. Teams typically purchase these guns for around $6,250, but after modifications - like adding custom sockets with built-in magnets and reinforcing the internals - the price can climb to about $12,500 per unit.

Operating at 20–26 bar with high-pressure nitrogen or air, these guns achieve their incredible speed and efficiency. To ensure safety and reliability, the tools are color-coded for directional threads: right-hand threads for the car's right side and left-hand threads for the left. This prevents wheel nuts from loosening during a race. Modern versions also tie directly into the pit gantry's electronic systems. Once the gunner confirms approximately 500 ft-lb of torque with a button press, the system signals the car is ready to go.

"The guns automatically reverse direction, and 1.4s into the stop, the gunners get back onto the captive nut. Around 1.9s into the stop the guns come off, confirmation buttons are pressed, and the car is ready to go." - Matt Youson, Special Contributor, Formula 1

While many F1 components focus on reducing weight, wheel guns prioritize durability. Teams extensively modify their internals to ensure they can withstand the rigors of race day. Each team maintains a fleet of 24 wheel guns to guarantee redundancy and reliability.

"Everything is pushed to the limit, because the last thing you want is a gun to break during the race." - Dave Redding, Team Manager, Williams

This level of precision doesn't just demand reliable tools - it also requires skilled and physically strong operators. The guns' rapid operation exerts significant physical strain, particularly on the arms and wrists. Chris Stafford, Right Rear Gunner for Williams, puts it plainly:

"It is quite a lot of pressure bearing in mind the gun off time - that's the time taken for the bolt to be removed - is less than two-tenths. The force is acutely felt in the arms and wrists."

With the guns operating at 26 bar pressure, the resulting kickback is intense. Gunners must have exceptional upper body strength and stability to keep the socket securely engaged with the nut, ensuring flawless performance under extreme conditions.

2. Manual Jacks with Hydraulic Release

Manual jacks are a crucial tool in Formula 1 pit stops, designed to lift a 1,410-pound car about 2 inches off the ground. They rely on mechanical leverage and a sharp downward motion executed by a single crew member. Once the job is done, a quick-release latch drops the car back to the ground in an instant, saving those all-important fractions of a second.

Speed and Efficiency During Pit Stops

The front jack operator has one of the most physically demanding roles in the pit crew. Take McLaren's record-breaking 1.80-second pit stop at the Qatar Grand Prix in October 2023, for example. Within just 0.3 seconds of Lando Norris pulling into the pit box, the front jack was fully engaged. Using a swivel handle - designed to pivot and allow the operator to step aside for safety - the operator kept the car elevated while clearing the exit path. At around 1.7 seconds into the stop, the quick-release button was pressed, dropping the car back to the ground.

"The jack handle pivots to allow him to move to the side of the car... the mechanic pulls a lever to release the front jack, the lifting pad drops away... and the car drops quickly to the ground." - ScarbsF1, Technical Analyst

While the front jack focuses on immediate lift and release, the rear jack requires a slightly different approach. Its operator must wait until the car has passed before sprinting into position, making a lightweight design essential for quick maneuvering. Williams Racing showcased this precision at the 2019 German Grand Prix, setting a then-record 1.88-second stop for Max Verstappen after over 1,200 practice runs to perfect their timing.

Durability Under Race Conditions

Speed isn't the only factor; these jacks must also endure the extreme stresses of race day. Despite their simple mechanical design, each jack carries a hefty price tag of about $312,500. The frame is made of steel tubing for strength, while the lifting pads incorporate carbon fiber and foam padding to safeguard the car’s fragile front wing. The quick-release mechanism operates through a latch system, held in place by coil springs inside a cylindrical housing. A cable running through the handle connects to a lever that triggers the release. To adapt to varying pit lane gradients, nylon wheels can be swapped to adjust the jack’s height.

3. Electric Cordless Impact Drivers (e.g., Milwaukee or Einhell)

Pneumatic wheel guns might steal the show during those lightning-fast pit stops, but behind the scenes, electric cordless impact drivers are the real workhorses. These tools are essential during practice sessions, qualifying rounds, and paddock work. For example, Mercedes-AMG Petronas collaborates with Einhell, while McLaren opts for the DeWalt DC D703 installation driver for tasks like bodywork reassembly. These off-the-shelf tools are prized for their precision and reliability, ensuring delicate components stay intact. From reassembling bodywork to fine-tuning front wings, the programmable torque settings on these tools make all the difference.

Precision for Specific Tasks (e.g., Torque Accuracy)

What sets cordless electric drivers apart is their ability to precisely control torque. Unlike traditional pneumatic guns that can unleash up to 4,000 ft-lb of torque, electric models - like the Milwaukee 2867 - can be dialed down to around 400 ft-lb, which is perfect for tasks like wheel installation. Teams program these tools using mobile apps to set exact torque limits, preventing mishaps like the infamous 2021 Monaco Grand Prix, where Valtteri Bottas was forced to retire after a wheel nut became "machined" onto the axle.

"The electric impact can be dialed back to only hit with the roughly 400 pound-feet required... a margin of error with such critical components is certainly nice." - Kyle Smith, Maintenance and Tech Expert, Hagerty

For even finer tasks, such as front wing adjustments, specialized cordless drivers equipped with stepper motors allow mechanics to adjust flap angles in precise half-degree increments. This level of control is crucial for tweaking aerodynamics between sessions - something high-pressure pneumatic systems, built purely for speed, simply can't achieve.

Durability Under Race Conditions

F1 teams trust professional-grade tools from brands like Milwaukee, DeWalt, and Makita because these companies pour significant resources into research and development. Instead of gambling on custom-built equipment, teams stick to proven models - often older, reliable versions - and customize them with unique sockets and team branding. This approach ensures that replacement parts are readily available around the globe. With races spanning 22+ locations, mechanics can easily grab a replacement tool or battery from a local hardware store if needed.

When it comes to bodywork tasks, teams typically favor 12V systems paired with 2Ah cylindrical-cell batteries. These setups prioritize lightweight handling over brute force, making them ideal for precise work. While these modified impact drivers come with a slight cost premium compared to standard consumer models, the investment is worth it. They deliver consistent performance and provide peace of mind, sparing teams from the risks of unproven experimental gear.

4. Air Jacks

Air jacks aren't just an optional add-on; they’re a crucial backup when emergencies strike. While manual quick-lift jacks handle routine pit stops, air jacks step in during high-pressure situations, like fixing punctures or swapping out a damaged nosebox. Unlike manual systems, these air-powered side jacks allow mechanics to lift the car and perform repairs at the same time. This dual capability is invaluable during unexpected incidents, ensuring minimal downtime and keeping the car in the race.

Speed and Efficiency During Emergencies

In a typical pit stop, the front jack engages in just 0.3 seconds and releases at 2.1 seconds. During emergencies, air jacks work alongside the standard jacks, enabling multiple tasks to happen simultaneously. For example, while tire changers handle the wheels, other crew members can address bodywork or suspension repairs without waiting for the car to be repositioned.

Lightweight and Portable Design

Air jacks are built with portability in mind. They feature carbon-fiber pads and steel or aluminum tubing, making them light enough for crew members to sprint with ease. Quick-release mechanisms allow the car to be lowered instantly, and swivel handle designs improve maneuverability in the cramped pit lane environment.

Built to Withstand Tough Conditions

Speed and portability are only part of the story - air jacks also need to endure extreme race conditions. They’re designed to handle the impact of cars entering the pit lane at 50 mph and can lift vehicles weighing over 1,760 lbs. Teams put these jacks through rigorous testing to ensure reliability. For instance, McLaren tested redesigned units in over 800 simulated pit stops.

These high-performance tools come with a hefty price tag - each air jack costs approximately $312,000, and teams typically carry at least two backups per race. As Williams Team Manager Dave Redding puts it:

"Everything is pushed to the limit, because the last thing you want is a gun [or jack] to break during the race."

5. Torque Drivers for Front Wing Adjustments

When it comes to pit stop tools, torque drivers for front wing adjustments are all about precision. Unlike wheel guns, which are built for sheer power, these tools are designed to fine-tune front wing angles with incredible accuracy, helping teams maintain the aerodynamics essential for top performance. Cordless torque drivers combine precision with portability, showcasing the pit crew's reliance on tools tailored for specific tasks.

Precision for Specific Tasks

Fine-tuning the front wing is no small task - it requires absolute accuracy. Torque drivers equipped with stepper motors can adjust wing angles in precise 0.5° increments, offering a level of control that's impossible with traditional manual tools. While wheel guns deliver over 3,500 ft-lb of torque, these drivers focus on low-torque adjustments, ensuring accuracy and reducing the chance of errors during lightning-fast pit stops. As Matt Youson from Formula1.com puts it:

"The wing-winders on either side pre-set torque drivers to move the flap-angle up or down".

Portability and Weight

Beyond precision, portability is crucial. These drivers are compact and easy to handle, making them perfect for quick adjustments in the tight quarters of a pit lane. Teams often opt for 12V or 18V cordless models from trusted brands like Bosch, DeWalt, or Milwaukee. Equipped with lightweight 2Ah cylindrical-cell batteries, these tools are designed to be both efficient and easy to maneuver.

Durability Under Race Conditions

Pit stops happen in intense environments, and torque drivers must hold up under pressure. Positioned near hot brakes and radiators, these tools are built to handle high temperatures and constant vibrations. Reinforcements ensure they remain reliable, even in the most demanding race conditions, where every fraction of a second matters.

6. Cordless Blower Fans (Repurposed Leaf Blowers)

When it comes to pit stop efficiency, every tool in the garage needs to be portable and deliver top-tier performance. Among the essentials are repurposed leaf blowers, which play a critical role in keeping F1 cars cool during pit stops. These cars rely on high-speed airflow for cooling while racing, but when stationary, they’re at risk of overheating. Cordless blower fans step in to provide much-needed air circulation for brakes, radiators, and side pods, preventing heat-related damage.

Speed and Efficiency During Pit Stops

To maximize airflow, teams modify these blowers with custom fairings and nozzles tailored to their car’s cooling intakes. Ferrari, for instance, uses a six-blower setup during extended stops to manage temperatures, while McLaren opts for DeWalt DCBl772x1 FlexVolt blowers paired with 15Ah batteries for longer runtime. Beyond cooling, these blowers are also used to clear debris - like rubber marbles or stray paper - from radiator inlets and sidepods, ensuring both aerodynamic performance and effective cooling. This dual functionality makes them indispensable during the high-pressure moments of a pit stop.

Portability and Weight

The cordless design is a game-changer in the tight, chaotic environment of the pit lane. It allows mechanics to move freely around the car, even when surrounded by over 20 team members. Many teams lean towards lightweight 2Ah cylindrical-cell batteries for easier handling, though McLaren’s use of 15Ah batteries prioritizes extended runtime.

Durability Under Race Conditions

These blowers aren’t just portable - they’re built to withstand the intense conditions of the paddock. Brands like Makita are widely used by teams such as Red Bull, Ferrari, and Mercedes, while AlphaTauri has chosen Ego blowers for their superior airflow capabilities, particularly for brake cooling. These tools are trusted for their reliability and the extensive research and development behind them. Plus, they can be replaced quickly at any of the 22 global race locations if needed. Kyle Smith, a tech and maintenance expert, highlights their dependability:

"The tools available for purchase are just as good as what a one-off tool the team might design and construct, yet come with the dependability of a major brand and likely millions of dollars of R&D behind it".

These blowers face extreme conditions, operating near components heated to 158°F (70°C) in high heat and humidity. Yet, they must perform flawlessly to protect race cars worth $15 million.

7. Paoli Sockets and Optionals

Paoli provides the wheel guns, but when it comes to the sockets, teams take matters into their own hands. Each team designs and manufactures custom sockets tailored to the specific geometry of their wheel nuts. This precise match prevents issues like rounding or stripping during the high-stakes frenzy of a pit stop. These specialized sockets feature interlocking designs that ensure reliability under pressure, keeping operations smooth and efficient. The result? Faster pit stops and components tough enough to endure the brutal demands of racing.

Speed and Efficiency During Pit Stops

With wheel guns spinning at 16,000 RPM and gun-off times under 0.2 seconds, there’s no room for error. To keep the steel wheel nut securely in place - even if the gun is pulled away too quickly - sockets are equipped with high-strength magnets. Chris Stafford, the Right Rear Gunner for Williams, captures the intensity of the job:

"It is quite a lot of pressure bearing in mind the gun off time – that's the time taken for the bolt to be removed - is less than two-tenths. You definitely feel it in your arms and wrists".

Durability Under Race Conditions

These sockets are engineered to handle extreme torque - over 3,500 lb-ft - and operate at air pressures between 20 and 26 bar (290 to 377 PSI). Unlike other lightweight components in F1, these sockets are intentionally built heavy to withstand the immense forces involved. Dave Redding, Team Manager at Williams, underscores the importance of reliability:

"Everything is pushed to the limit, because the last thing you want is a gun to break during the race".

To ensure teams are always prepared, they bring 24 wheel guns to every race weekend, providing spares for each position. Off-the-shelf guns cost around $6,250, but F1 teams often spend twice that amount on custom modifications.

Precision for Specific Tasks

While durability ensures the sockets can handle extreme forces, precision engineering guarantees they perform flawlessly. These sockets are designed to deliver exactly 500 lb-ft of torque to secure the wheel without cross-threading, even in the chaos of a pit stop. Adding to this precision, modern setups include electronic sensors connected to overhead gantries. These sensors provide instant feedback to the crew chief, confirming the correct torque has been applied and eliminating any guesswork.

Tool Comparison Table

In an F1 pit crew, every tool is designed to strike a balance between speed, precision, and reliability. Each piece of equipment serves a specific purpose, contributing to the seamless choreography of a pit stop.

Here’s a breakdown of the key specifications and performance details for seven essential portable tools:

| Tool | Power Source | Torque/Spec | Weight/Portability | Primary Use | Pros | Cons |

|---|---|---|---|---|---|---|

| Paoli Wheel Gun (DP6000) | Pneumatic (20–26 bar) | 3,500–4,000 lb‑ft at 16,000 RPM | Heavy; tethered to air lines | Race-day tire changes | Blazing speed (sub‑2‑second stops); built for durability | Risk of over‑tightening; requires significant arm strength |

| Manual Front Jack | Manual leverage with hydraulic release | N/A | Moderate (carbon fiber construction) | Lifting car front during stops | Quick-release mechanism; adaptable to track conditions | Expensive (~$312,500); potential for mechanical failure |

| Milwaukee Impact Driver | Electric (cordless battery) | ~400 lb‑ft (programmable) | Highly portable | Paddock/qualifying wheel installation | Prevents cross-threading; precise torque control | Slower than pneumatic tools; unsuitable for live race stops |

| Air Jacks | Pneumatic (integrated system) | N/A | Fixed to the car | Rapid car lifting during stops | Instant lift for all four corners | Limited to car-mounted use; not operable manually |

| Torque Driver (Wing Adjustment) | Electric (cordless) | 0.5-degree increments | Highly portable (handheld) | Front wing angle adjustments | Precise aerodynamic tuning with stepper motor accuracy | Single-purpose tool; highly specialized |

| Cordless Blower Fan | Electric (18V battery) | High airflow (CFM varies) | Handheld | Brake and engine cooling | Essential for managing heat; easy battery swaps | Limited durability; custom nozzles often required |

| Paoli Sockets | Manual attachment | 500+ lb‑ft | Lightweight with magnetic design | Wheel nut engagement | Magnetic retention; custom-fit to team specs | Nut may fall if pulled too quickly |

This table showcases how teams prioritize speed, power, and portability to ensure pit stops are as efficient as possible.

One of the key trade-offs lies between pneumatic and electric tools. Pneumatic tools excel in delivering the raw speed needed for record-breaking pit stops, but they come with limitations. As Kyle Smith, a Technical Contributor, explains:

"The pit stop wheel guns can hammer with a force up to 4,000 pound‑feet... The electric impact can be dialed back to only hit with the roughly 400 pound‑feet required".

This level of precision makes electric tools indispensable in scenarios where over-tightening could cause damage. Weight is another critical factor; for example, front jacks use carbon fiber to stay lightweight and deploy quickly, even with their hefty price tag of about $312,500. Meanwhile, cordless tools like blowers and impact drivers eliminate the need for air lines, reducing trip hazards and improving mobility. These trade-offs highlight the careful engineering that goes into every tool used in the pit lane.

Conclusion

The seven portable tools discussed in this article highlight the cutting-edge technology behind Formula 1 pit stops, where every fraction of a second counts. Tools like high-torque wheel guns and programmable drivers make lightning-fast tire changes possible.

But it’s not just about speed - timing and strategy play a pivotal role in on-track performance. Precision tools allow teams to calculate pit-stop losses with incredible accuracy, enabling bold undercut strategies or defensive overcuts that can change the outcome of a race. These tools are more than just equipment; they’re a cornerstone of race strategy.

Teams are continuously refining their approach, investing millions in custom innovations. From magnetic socket retention systems to carbon-fiber jacks priced at around $312,500, every detail is designed to save precious time. The growing adoption of programmable cordless tools, spurred by incidents like Valtteri Bottas’ Monaco mishap in 2021, underscores the importance of balancing speed with reliability.

Looking ahead, smarter systems are on the horizon. Imagine wheel guns that automatically signal task completion to pit gantries - technology like this could further minimize human error. With teams practicing pit stops roughly 100,000 times before a season even begins, the combination of human expertise and advanced tools remains the driving force behind F1’s relentless pursuit of perfection.

For a deeper dive into the world of F1 technology and strategy, check out F1 Briefing.

FAQs

Why are Paoli Wheel Guns so important and expensive in F1 pit stops?

Paoli Wheel Guns are a must-have for Formula 1 pit crews, allowing them to complete lightning-fast tire changes - sometimes in less than three seconds. These pneumatic tools are built for speed and precision, ensuring wheel nuts are tightened or loosened with pinpoint accuracy, even under the intense pressure of a pit stop.

The hefty price tag of these tools is no accident. It reflects their cutting-edge technology, ability to withstand extreme conditions, and the pivotal role they play in a team's race-day success. In Formula 1, where every millisecond counts, a quicker pit stop can be the deciding factor between victory and defeat. That’s why investing in Paoli Wheel Guns isn’t just smart - it’s essential.

How do F1 teams ensure manual jacks stay reliable during a race?

F1 teams rely on manual jacks as indispensable tools, engineered for peak performance while keeping the design simple and dependable. Made from high-strength steel, these jacks use a basic lever-and-pivot system with very few moving parts. This design minimizes the chance of mechanical failure, even when lifting a car that weighs 1,631 pounds. The use of standardized components and lift points throughout the garage ensures that replacements can be made swiftly if necessary.

The reliability of these jacks is no accident - it’s the result of meticulous preparation. Before every race, teams thoroughly inspect, lubricate, and test the jacks to ensure they’re in perfect working order. Pit crews also spend countless hours practicing their jack techniques throughout the season, striving for absolute precision. On race day, the jack operator’s role is critical: they maintain a steady grip and only release the car once every wheel nut is securely fastened, delivering consistent performance under the intense pressure of competition.

Why are cordless blower fans crucial for cooling F1 cars during pit stops?

Cordless blower fans play a crucial role during pit stops, delivering fast and accurate airflow to cool down a car’s hottest components - all without being tied to a power source. These lightweight, battery-operated tools let crew members quickly direct air to key areas like brake discs, calipers, and radiators the moment the car comes to a stop. This helps keep brake temperatures in check, prevents engine overheating, and supports consistent lap performance.

What makes them so essential is their portability and simplicity. Equipped with powerful lithium-ion batteries and customizable nozzles, they provide focused cooling exactly where it’s needed. And because they’re widely available, teams can replace them quickly and cost-effectively, even under the high-pressure demands of F1 operations. These features make cordless blower fans an irreplaceable asset for ensuring peak performance during every race.