Checklist for F1 Resource Allocation Under Budget Caps

Practical checklist for allocating F1 resources under the 2026 budget cap—prioritize aero upgrades, power-unit efficiency, spares, contingencies, and FIA compliance.

Formula 1's budget caps have reshaped the sport, pushing teams to make smarter financial decisions. Starting in 2026, the cap rises to $215 million, with $1.8 million added per race beyond 21 events. This increase, along with stricter regulations, forces teams to balance spending between aerodynamics, power units, and unforeseen costs like crash damage. Here's what you need to know:

- 2026 Cap Details: $215 million base, plus $1.8M per race over 21.

- Key Focus Areas: Aerodynamic upgrades, power unit efficiency, and reliability.

- Challenges: Balancing upgrades vs. spares under tight budgets.

- Smaller Teams' Advantage: Extra wind tunnel hours and higher infrastructure allowances.

- Compliance: Rigorous FIA audits; overspending risks penalties like fines and reduced testing.

Success in 2026 will depend on efficient resource allocation, prioritizing performance gains, and preparing for unexpected costs.

F1 2026 Budget Cap Breakdown and Resource Allocation Strategy

Checklist for Assessing Current Budget Position

Calculate Allocations by Team Standing

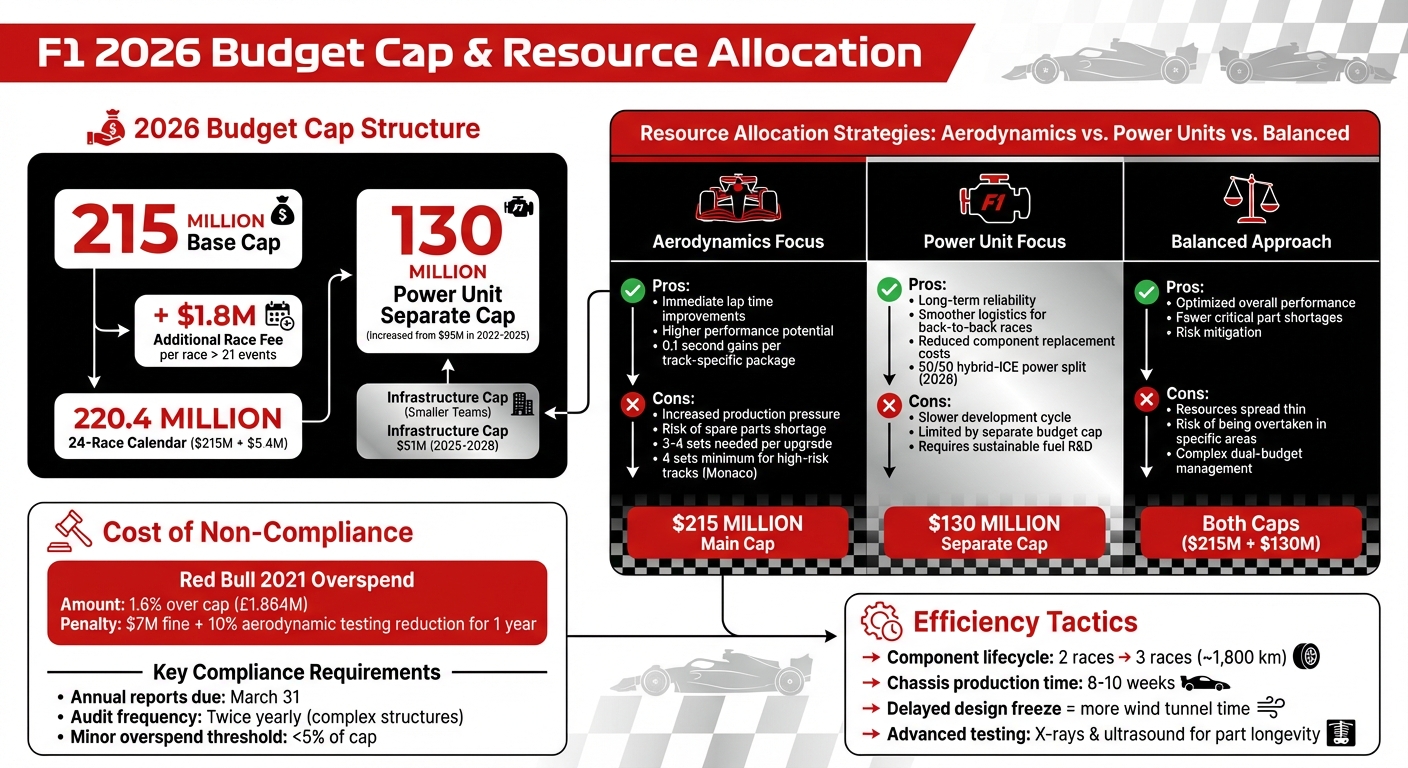

The 2026 Formula 1 budget cap is set at $215 million, a 30.3% increase, now encompassing capital investments and HR costs. Teams also need to account for additional expenses tied to the race calendar. For every Grand Prix beyond the 21st round, the base cap increases by $1.8 million. With a 24-race schedule, that adds $5.4 million to the overall budget.

Factory-backed teams face tighter regulations regarding intellectual property transfers from their road-car divisions. Any technology sourced from hypercar projects or commercial engineering subsidiaries must be fully documented and charged against the F1 budget. The FIA has also ramped up audits to twice per year for teams with intricate corporate structures. Even minor overspending - defined as less than 5% of the cap - can lead to severe penalties. For instance, Red Bull’s 1.6% overspend in 2021 resulted in a $7 million fine in 2022.

Additionally, geographical compensation mechanisms are in place for 2026. For example, Swiss-based teams like Sauber/Audi receive extra budget allowances to offset higher wage costs, where the average salary is $80,000 compared to $54,000 in other regions.

These calculations are critical for managing the technical and financial challenges that come with competing in F1. Teams must also assess how these allocations align with their competitive goals.

Reserve Unused Budget for Contingencies

Beyond planned spending, teams should identify unallocated funds to maintain flexibility for unforeseen challenges. A financial buffer can be the difference between weathering unexpected events and falling behind. Past situations have shown the importance of reallocating unused resources like spare components.

To save costs and increase efficiency, teams are extending the lifecycle of components from two races to three, covering approximately 1,800 km. Advanced techniques like X-rays and ultrasound are being used to ensure parts last longer, reducing the need for frequent manufacturing. Unused spare parts, often considered "dead" capital, can be redirected toward performance improvements, maximizing lap-time gains.

Effectively managing unutilized funds is just as important as accurate spending when it comes to minimizing risks and staying competitive.

Aerodynamics Investment Priorities

Evaluate Wind Tunnel and CFD Usage

Aerodynamics plays a pivotal role in Formula 1 performance. To stay ahead, teams must make the most of their wind tunnel and CFD (Computational Fluid Dynamics) tools. One key tactic is to delay design freezes, giving teams more time to refine their designs before committing to production.

Jody Egginton, Technical Director at Racing Bulls, explained this approach:

The date we want to release the chassis into the drawing office and then into production is all driven to maximise aero, followed by design time

Timing is everything here. Producing a single Formula 1 chassis takes around eight to ten weeks once it’s released for manufacturing.

Streamlining production through automation can shrink this timeline and extend aerodynamic testing opportunities. Egginton emphasized the importance of efficiency:

The more technology and more efficiency you can get into the production side of things, the more time you can devote to aero development

By refining production workflows, teams can unlock extra time for aerodynamic development, which can be the difference between staying competitive or falling behind.

Once wind tunnel and CFD processes are optimized, the focus shifts to deciding the most effective aerodynamic upgrade strategy.

Focus on Key Aerodynamic Upgrades

Teams face a tough decision: should they develop track-specific aerodynamic packages or a single universal package that performs consistently across all circuits? Track-specific setups can yield performance gains of about 0.1 seconds. In a sport where qualifying times are often separated by fractions of a second, that advantage could determine whether a driver advances to the next qualifying round or gets eliminated.

However, this strategy comes with a trade-off: spares versus performance. When rolling out a new aerodynamic update, teams usually manufacture three to four sets of parts. High-risk tracks like Monaco demand at least four sets to account for potential crashes. On lower-risk circuits, teams can scale back to three sets, reallocating the saved budget toward future upgrades.

As Egginton noted:

With budget cap, you can't give yourself margin... Typically, we wouldn't come to an event without having enough spares – but everyone's interpretation of what 'enough' constitutes, will be different

Looking ahead to the 2026 regulation changes, many teams are choosing to stick with their 2024 mechanical architectures through 2025. This allows them to focus resources on aerodynamic advancements while preparing for the sweeping changes in 2026. It’s a strategic balancing act - staying competitive now while laying the groundwork for future success.

Power Unit Development Priorities

Invest in Hybrid Efficiency and Sustainable Fuels

With tighter budget caps in place, teams face the challenge of balancing power unit development with aerodynamic advancements. This balancing act becomes even more critical as the 2026 regulations demand a complete overhaul of power unit strategies.

The upcoming rules call for the use of fully sustainable fuels and a 50/50 power split between the internal combustion engine and the electric hybrid system. Meeting these requirements will require substantial R&D efforts. To support this transition, the budget for power unit manufacturers will increase from $95 million (2022–2025) to $130 million in 2026. This separate allocation allows teams to push their power unit suppliers to innovate on sustainable fuel efficiency without impacting their main $215 million team budget.

Formula 1's pledge to achieve net-zero carbon emissions by 2030 makes advancements in sustainable fuel technology a top priority. As Calum Ross from Deloitte Sports Business Group explains:

Technology innovation will be crucial in allowing teams to reach environmental sustainability objectives, so it was key that the caps didn't stand in the way of this.

Close collaboration between teams and power unit suppliers - whether Audi, Honda, or Red Bull Ford - is essential. Teams need to ensure their chassis designs are optimized for the new hybrid systems. A seamless integration of chassis and power unit development will lead to better performance on the track.

Investing in hybrid and sustainable technologies now will also pave the way for improved power unit reliability in the long term.

Budget for Reliability and Durability

While innovation is critical, ensuring reliability and durability is just as important to protect budget flexibility under the cost cap.

Every failed component or repair chips away at the $141.2 million team cost cap. Beyond lost track time, poor durability can divert funds away from aerodynamic upgrades and spare parts. This makes reliability a strategic priority.

Power unit development operates under its own distinct financial limits, separate from the main team budget. Teams that effectively allocate R&D within this power unit-specific budget can extend component life and free up resources for performance enhancements.

The consequences of budget breaches are a stark reminder of the stakes. In October 2022, Red Bull Racing exceeded the 2021 cost cap by £1.864 million (1.6%), partly due to administrative costs and payments to Red Bull Powertrains. The penalty? A $7 million fine and a 10% reduction in aerodynamic testing for one year. Similarly, Alpine faced a procedural breach in 2024 related to power unit reporting, which was resolved through an Accepted Breach Agreement.

Starting in 2025, power unit suppliers will also need to adhere to a mandatory winter shutdown period, similar to the existing summer break. This measure is designed to manage operational costs and staff workloads. Teams must plan their development timelines carefully to ensure that key reliability improvements are completed before this downtime begins.

Balancing Resource Allocation with Risk Assessment

Aerodynamics vs. Power Units: A Comparison

Investing in aerodynamics often means cutting back on power unit reliability, and vice versa. Understanding how these two priorities interact is key to smarter resource allocation.

| Aspect | Aerodynamics Focus | Power Unit Focus | Balanced Approach |

|---|---|---|---|

| Pros | Immediate lap time improvements; potential for higher performance | Long-term reliability; smoother logistics for back-to-back races | Optimized overall performance; fewer shortages of critical parts |

| Cons | Increased production pressure; risk of running out of spares | Slower development; limited by separate budget caps | Resources spread thin; risk of being overtaken in specific areas |

| 2026 Cap Impact | Falls under the main chassis cap (~$215 million) | Managed under a separate power unit cap | Requires balancing two distinct financial limits |

Aerodynamic development often delivers immediate performance gains, which is why many teams prioritize it. Jody Egginton, the Technical Director at Racing Bulls, explains:

We're geared-up to make sure there's minimum compromise on the aerodynamics side, because that's where a lot of the performance lives.

However, focusing heavily on aerodynamics comes with its own challenges. Late design freezes may maximize aero performance but can also lead to production delays, creating bottlenecks and increasing the risk of running out of parts during the season.

On the other hand, power unit investments operate within a separate financial framework, which helps ensure engine costs don’t drain the chassis budget. While this separation allows more focused development, it can also slow progress if suppliers face resource limitations. The upside? Improved reliability reduces the need for frequent component replacements, freeing up funds for performance upgrades later in the season.

A balanced approach aims to spread resources across both areas, minimizing the risk of critical failures. However, this strategy can leave teams vulnerable to rivals who focus exclusively on one domain. In a sport where even a 0.1-second advantage can mean the difference between a top-10 start and an early elimination, every decision counts.

This balancing act is especially crucial for smaller teams that face tighter resource constraints.

Strategies for Smaller Teams

For smaller teams like Williams and Haas, managing limited resources under strict budget caps requires creativity and precision. These teams have less room for error but benefit from additional testing opportunities. Thanks to the FIA's Aerodynamic Testing Restrictions (ATR), teams lower in the standings receive more wind tunnel and CFD hours than championship leaders. This system is designed to level the playing field, but its effectiveness depends on how well smaller teams use these extra resources.

Recent examples highlight the challenges smaller teams face. At the Australian Grand Prix, Williams struggled with a chassis shortage due to an overloaded production schedule. After Logan Sargeant’s crash, his car had to be reassigned to Alexander Albon because the team couldn’t produce a third chassis in time. Reflecting on this, Team Principal James Vowles stated:

We're going to have to be creative to stay competitive in 2026. It's not about willpower, it's about available resources.

Haas, on the other hand, took a more conservative approach in 2022. Following Mick Schumacher’s heavy crash during Saudi Arabian Grand Prix qualifying, the team chose to withdraw his car from the race to preserve parts for the next event in Melbourne. While this decision sacrificed short-term results, it ensured the team’s long-term competitiveness by avoiding a parts shortage.

Smaller teams also benefit from higher caps on infrastructure investment. Between 2025 and 2028, backmarker teams can allocate up to $65 million for upgrades to facilities like wind tunnels and simulators, compared to just $51 million for top teams. Modernizing production capabilities not only shortens manufacturing cycles but also leaves more time for aerodynamic development. As Egginton notes:

The more technology and more efficiency you can get into the production side of things, the more time you can devote to aero development.

The key for smaller teams lies in focusing on high-impact upgrades rather than pursuing frequent, minor updates. By targeting packages that yield the greatest lap-time improvements relative to their cost, they can maximize their limited budgets. Additionally, designing components to last for three-race intervals instead of two can reduce manufacturing demands, freeing up resources for research and development.

These strategies tie directly into the broader challenge of balancing resource allocation, allowing smaller teams to make the most of every dollar under the cap.

Where Do F1 Teams Spend Their Budget?

Monitoring and Adjusting Resource Allocation

Managing resources effectively within strict budget limits requires more than just careful planning - it demands constant oversight and the flexibility to make adjustments when necessary.

Track FIA Reporting and Costs

Keeping meticulous records of every expense - whether it's related to car design or race operations - is critical for meeting FIA audit requirements. Teams are required to submit their annual financial reports by March 31, with more complex corporate structures facing biannual audits starting in 2025. These audits dive deep into various expenses, including personnel costs and intellectual property transfers, to ensure compliance with the spending cap. They also guard against attempts to funnel extra spending through external programs like hypercar projects.

The consequences of non-compliance are significant. For example, Red Bull Racing exceeded the cap by just 1.6% in 2021, which led to a $7 million fine and a 10% reduction in aerodynamic testing time. Even minor procedural mistakes can have repercussions. In 2025, Aston Martin faced a procedural breach related to its 2024 financial submissions, which was resolved through an Accepted Breach Agreement, though no overspending was found. These examples highlight the importance of ongoing collaboration with the FIA’s Cost Cap Administration to ensure accurate interpretation of accounting rules, especially when dealing with shared resources across different business units. To stay compliant, teams must conduct regular financial reviews to catch and address issues early.

Conduct Regular Budget Reviews

Accurate reporting is just the first step - regular budget reviews are equally essential. Quarterly evaluations allow teams to react quickly and ensure they remain under the cap, which is set at approximately $141.2 million for 2025, with an additional $1.8 million allowed for each Grand Prix beyond the standard 21-race calendar. During these reviews, it's important to track exempt expenses - like driver salaries, executive pay, marketing, hospitality, and power unit development - separately to avoid confusion.

Looking ahead to 2026, the budget cap is expected to increase to around $215 million, as previously exempt categories like human resources and capital investments will be included. By monitoring these costs now, teams can prepare for the upcoming changes and avoid being caught off guard when the new rules take effect.

Prepare for Contingencies

Unexpected events like crashes or reliability issues can wreak havoc on a budget since these costs aren't exempt from the cap. As Jody Egginton, Technical Director, pointed out:

With budget cap, you can't give yourself margin

Past challenges, such as chassis shortages caused by accidents, underline the importance of maintaining a contingency fund. A well-thought-out fund provides breathing room for unforeseen expenses, whether it's unexpected races, mid-season technical directives, or regulation changes requiring unplanned modifications. Teams should also run scenario simulations - ranging from single-car accidents to double retirements - to understand how these situations could affect their remaining budget. This proactive approach ensures they can adjust their spending priorities without jeopardizing their overall financial strategy.

Conclusion and Key Takeaways

Success Factors for 2026 and Beyond

With the evolving F1 budget regulations, teams face the challenge of balancing technical progress with strict financial discipline. The budget cap demands a data-driven strategy, ensuring every dollar spent delivers measurable performance gains. Success under these constraints hinges on prioritizing aerodynamic upgrades that offer the most immediate lap-time improvements, optimizing production processes to maximize wind tunnel usage, and maintaining rigorous financial management.

As the 2026 regulations approach, with the budget cap increasing to roughly $215 million to account for new technical and power unit requirements, teams must focus on preparation. This involves balancing investments in aerodynamics and power units while strategically planning for long-term success. For example, extending component lifecycles from two races to three can free up resources for research and development aimed at performance gains. Pre-auditing capital and HR expenditures will also play a crucial role in navigating this transition effectively.

Another critical factor is managing unexpected costs. Budget overruns and parts shortages can lead to severe consequences, including financial penalties and reduced testing time, both of which directly impact a team's competitiveness. Flexibility and sound risk management are what set leading teams apart in this high-stakes environment.

Ultimately, thriving in this era requires more than just technical expertise - it demands smart financial strategies. Regular budget reviews, open communication with the FIA Cost Cap Administration, and setting aside contingency funds for unforeseen challenges are all essential practices. Even a small performance improvement, like a tenth-of-a-second gain, can justify a well-targeted upgrade. In this new chapter of F1, success isn't about outspending rivals - it's about outthinking them.

FAQs

How will the 2026 budget cap changes affect smaller F1 teams?

The 2026 budget cap adjustments are set to shake things up for smaller F1 teams, introducing stricter financial limits in areas like aerodynamic testing, wind tunnel usage, and power unit development. The goal? To narrow the spending gap between teams and create a more balanced competition.

However, for smaller teams, these tighter restrictions could make it harder to bridge the performance gap with wealthier rivals. With less flexibility in how they allocate resources, catching up might become a tougher challenge. On top of that, stricter transparency and reporting rules could curb any room for creative financial maneuvering. Navigating these changes will be essential for smaller teams aiming to stay competitive under the revamped budget rules.

How can F1 teams manage aerodynamics and power unit development within budget caps?

F1 teams navigate the challenges of budget caps by carefully balancing aerodynamics and power unit development, focusing on areas that deliver the biggest performance gains. For instance, refining aerodynamics within the boundaries of wind tunnel and CFD testing regulations allows for efficient use of limited testing resources. At the same time, teams strategically allocate funds to power unit upgrades, ensuring they remain competitive while adhering to financial restrictions.

To manage costs effectively, many teams rely on advanced simulation tools like computational fluid dynamics (CFD), which help cut down on expensive physical testing. They also implement phased development strategies, focusing on smaller, incremental upgrades instead of massive overhauls. This methodical, data-driven approach ensures teams can innovate and improve their cars without breaking financial limits.

Why is it important for F1 teams to maintain a financial buffer under budget caps?

Maintaining a financial cushion is crucial for F1 teams operating under budget caps. It provides the flexibility to handle unexpected costs while staying within the strict financial limits. Whether it's unplanned technical upgrades, delays in manufacturing, or sudden operational changes, having this buffer ensures teams can address these challenges without breaching their spending cap.

It also helps teams navigate cost fluctuations caused by factors like supply chain disruptions, inflation, or regulatory shifts. With thoughtful planning and resource allocation, teams can stay competitive and focus on critical areas like aerodynamics and power units. In a sport as fast-moving and technically demanding as F1, this financial safeguard plays a key role in balancing top-notch performance with strict compliance.