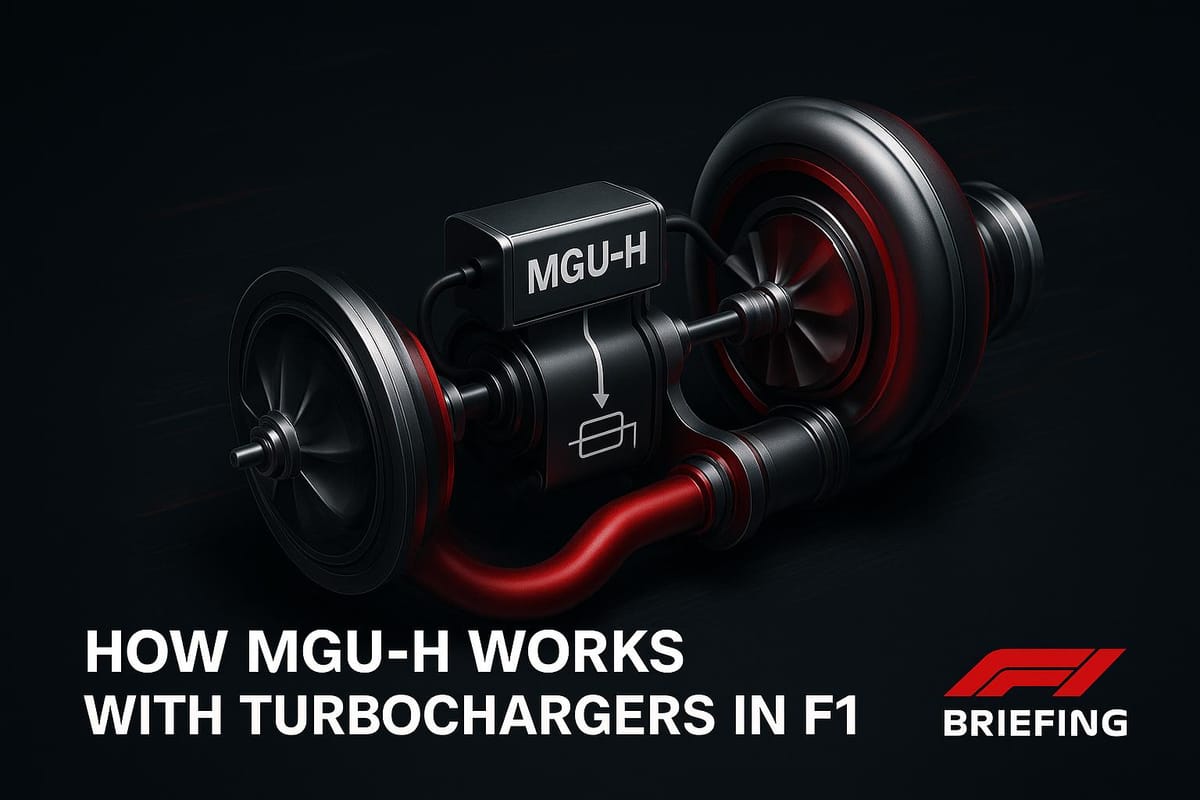

How MGU-H Works with Turbochargers in F1

Explore the role of MGU-H in F1 engines, its impact on performance, turbo lag reduction, and the future of hybrid technology in racing.

The MGU-H is a key component in Formula 1's hybrid engines, transforming exhaust heat into electrical energy while also reducing turbo lag. It works alongside the turbocharger to improve power delivery and efficiency. Here's how it operates:

- Energy Recovery: The MGU-H captures heat from exhaust gases and converts it into electricity.

- Turbocharger Support: It powers the turbocharger to prevent lag, ensuring smooth and instant throttle response.

- Energy Use: The energy can either be stored in the car's battery or sent directly to the MGU-K for immediate use.

- Efficiency Impact: Combined with turbochargers, F1 engines have achieved thermal efficiency exceeding 50%.

From 2026, the MGU-H will be removed from F1 regulations to reduce costs and simplify engines, but its legacy has shaped both the sport and advancements in automotive technology.

The Theory Behind Turbos and the MGU-H! | F1 TV Tech Talk

How the MGU-H Collects and Uses Energy

The MGU-H plays a crucial role in Formula 1 by turning waste heat from exhaust gases into electrical energy. This process involves advanced engineering and precise energy management, both of which directly influence race performance.

Energy Collection from Exhaust Gases

The process starts when hot exhaust gases pass through the turbocharger's turbine. As explained by Racecar Engineering:

"The MGU-H uses exhaust gas entropy (the heat energy remaining in the exhaust gas as a function of its temperature, expansion, and mass flow rate) to spin the turbine during the energy recovery phase, turning the energy from the exhaust gases into electrical energy."

The turbine spins at an incredible speed of up to 120,000 rpm, driven by the hot exhaust gases. This rotation generates a magnetic field, causing electricity to flow through coils wrapped around magnets. Teams must carefully manage this process to stay within regulatory speed limits while extracting as much energy as possible.

Key factors influence how efficiently energy is collected: the exhaust gas temperature, the rate at which the gases expand, and the mass flow rate through the system. Higher temperatures and greater mass flow rates provide more energy for recovery, making engine mapping and throttle control critical for maximizing MGU-H performance.

Direct Energy Use vs. Storage

Once the MGU-H captures energy, teams face a strategic decision: use it immediately or store it for later. The energy can be sent directly to the MGU-K, delivering a power boost to the wheels, or stored in the Energy Store battery for future use. This flexibility allows teams to adapt their energy deployment to suit different race scenarios.

Unlike the MGU-K, which operates under strict regulations, the MGU-H has no limits on how much energy it can generate or exchange with the Energy Store. For reference, the MGU-K is capped at a maximum output of 120 kW, can only send 2 MJ of energy per lap to the Energy Store, and can receive a maximum of 4 MJ per lap from it.

The choice between immediate energy use and storage often depends on the situation. During qualifying, teams typically prioritize direct deployment for maximum power. In races, however, energy storage becomes crucial for strategic moves like overtaking or defending positions.

Efficiency and Performance Factors

Modern F1 power units, including the MGU-H, have achieved remarkable thermal efficiency levels - exceeding 50%. The MGU-H alone can produce around 90–100 kW from its motor, which spins at 120,000 rpm. With a minimum weight of 4 kg, this results in an impressive power-to-weight ratio of approximately 22.5 kW/kg.

Honda’s development between 2017 and 2021 illustrates how improving efficiency can boost performance. By transitioning from a longer shaft design to high-flux magnets and better cooling systems, Honda enhanced the MGU-H’s output and torque. They collaborated with their HondaJet team to address vibration issues by improving bearing rigidity, lubrication, and cooling systems, along with redesigning shaft structures.

The overall efficiency of the MGU-H also depends on the integration of the turbocharger assembly. Teams work to optimize the turbine, MGU-H, and compressor components together to recover as much energy as possible. For example, refining compressor blade designs with complex three-dimensional shapes can improve performance - though engineers must carefully account for blade resonance and durability. These advancements are critical for maximizing energy recovery, refining race strategies, and improving overall car performance.

How the MGU-H Reduces Turbo Lag

One standout feature of the MGU-H system in Formula 1 is its ability to eliminate turbo lag - a common issue in turbocharged engines. By seamlessly switching between generating energy and functioning as an electric motor, the MGU-H ensures near-instant throttle response.

What Is Turbo Lag in F1?

Turbo lag happens when the exhaust gas flow isn't strong enough to spin the turbocharger's turbine at the speed needed for optimal boost pressure. This delay is especially noticeable at lower engine speeds or when a driver quickly reapplies the throttle after lifting off. In racing, even a slight hesitation during throttle adjustments - like mid-corner acceleration - can mean losing precious positions.

The MGU-H operates under extreme conditions, spinning at speeds over 120,000 rpm while enduring exhaust gas temperatures that exceed 1,832°F (1,000°C). Despite these harsh conditions, the system must react instantly to deliver smooth and uninterrupted power. This dual role of energy recovery and performance enhancement is what makes the MGU-H so critical.

How the MGU-H Works as an Electric Motor

The MGU-H tackles turbo lag by shifting from energy recovery mode to acting as an electric motor. When the exhaust gas flow drops and isn’t enough to keep the turbocharger spinning at its optimal speed, the MGU-H steps in. It uses stored electrical energy to directly drive the turbocharger's shaft, maintaining the ideal speed even during moments of reduced exhaust flow.

"When used as a motor, the MGU-H solves the problem of turbo lag. It spins the turbocharger when there isn't enough entropy in the exhaust gas at the right time to ensure that the power unit delivers available peak performance in the given condition."

– Hywel Thomas, Managing Director, Mercedes AMG HPP

By directly controlling the turbocharger speed, the MGU-H minimizes its dependence on exhaust gas pressure, giving teams more control over power delivery.

Mercedes took a groundbreaking approach in the early 2010s by separating the key components of the turbocharger. They placed the exhaust-driven turbine and the intake compressor on opposite ends of the engine's V-configuration, with the MGU-H positioned in between. This clever design not only reduced turbo lag but also boosted overall engine performance.

The impact of this technology extends beyond Formula 1. Craig Balis, Senior VP and Chief Technology Officer at Garrett Motion, highlights its potential for road cars:

"On the same engine, compared to a conventional turbo, an e-turbo can move you from 110 to 160-170 kW/L (2.417 to 3.516 hp/ci). This is the effect of right-sizing the turbo and using the electrification for transient response."

How It Impacts Driver Strategy and Race Performance

By eliminating turbo lag, the MGU-H changes how drivers approach races. With instant throttle response, drivers can make precise mid-corner adjustments or modulate the throttle in technical sections without worrying about delays. This immediate reaction helps both offensive moves, like overtaking, and defensive strategies, such as rapid acceleration out of tight corners.

The dual-purpose design of the MGU-H - balancing turbo lag elimination with energy storage for deployment via the MGU-K - adds a layer of complexity to race strategy. Teams must decide when to prioritize instant throttle response versus conserving energy for maximum power output.

Beyond its performance benefits, this technology also supports environmental goals. Garrett Motion reports that e-turbo systems can cut carbon dioxide emissions by up to 15 percent, showcasing how Formula 1 innovation can lead to advancements that benefit everyday vehicles.

Engineering Challenges and Advances in MGU-H Technology

The development of the MGU-H has pushed Formula 1 engineering to its limits, tackling some of the sport's most complex technical challenges. This system must function flawlessly while spinning at speeds exceeding 120,000 rpm, enduring exhaust gases hotter than 1,832°F (1,000°C), all while consistently generating and transferring electrical energy without failure. These extreme demands have led to groundbreaking solutions, setting the stage for current and future advancements in MGU-H performance.

Heat Management and Material Strength

The punishing environment in which the MGU-H operates demands materials that can handle extreme heat, provide insulation, and maintain mechanical integrity. Engineers have had to carefully select and adapt materials to meet these requirements.

For instance, advanced polymers play a key role in ensuring the system's durability. PEEK (Polyether Ether Ketone) is commonly used for components like bearing housings, seals, and mounting parts near the turbocharger, as it can withstand temperatures above 482°F (250°C). PTFE (Polytetrafluoroethylene) is another essential material, providing reliable sealing and insulation at continuous operating temperatures of up to 500°F (260°C). Additionally, polyimide films such as Kapton are used for electrical insulation in wiring and connectors, ensuring safe energy transmission even under intense heat.

Balancing Reliability and Performance

While materials address one side of the challenge, the other lies in achieving the perfect balance between energy recovery and durability. Teams must push the limits of performance while ensuring the system can endure the grueling conditions of a race weekend. Although there are no power output limits for the MGU-H itself, its maximum rotational speed is regulated, forcing teams to innovate within these constraints.

Honda’s approach offers a prime example of this balancing act. When Honda rejoined Formula 1 as a power unit supplier in 2015, they initially prioritized reliability over peak performance. Over time, however, their focus shifted toward improving energy recovery rates through efficiency upgrades. A Honda engineer reflected on this evolution:

"Although Honda originally focused on improving reliability when it started participating in the F1 as a power unit supplier in 2015, development has continued with a focus on increasing the rate of energy recovery through a variety of efficiency improvements."

Lessons from Team Development

Collaboration and cross-industry expertise have been critical in overcoming MGU-H challenges. Honda’s partnership with its HondaJet gas-turbine engine development team is a standout example. When Honda redesigned the RA617H to move the compressor outside the V-bank to improve performance at high-altitude circuits, they encountered vibration issues due to the longer shaft. The HondaJet team’s experience with gas turbines provided the solutions: enhancing bearing rigidity, improving lubrication and cooling, strengthening vibration damping structures, and refining the shaft design to minimize imbalances.

Further advancements came with the RA621H in 2021. Honda incorporated high magnetic flux density magnets and high thermal conductivity insulators to improve cooling, output, and torque. These changes expanded the system’s energy recovery capabilities, even at lower RPMs. By switching from greased bearings to oil lubrication and optimizing the shaft support structure, Honda raised the MGU-H's rated output, enabling it to sustain high performance over longer periods.

Meanwhile, Mercedes adopted a different strategy. They developed a specialized chamber within the intake plenum to "super-cool" air, increasing oxygen content for more powerful combustion. Additionally, they introduced a new alloy for the engine block to enhance reliability and reexamined how to better utilize the heat rejected by the turbocharger.

As Yasuaki Asaki, Honda Racing’s Head of Power Development, explained:

"MGU-H is a system that regenerates energy from exhaust gas. The amount of power recovered [allowed by regulation] of this MGU-H is unlimited. For this reason, that is the heart of the game. The turbo boost pressure is raised by the electric motor, and when the waste gate opens, the exhaust pressure drops and power comes out. It is called e-boost, but the usage is to aim for control that maximizes competitiveness with complicated electrical management."

These innovations have transformed the MGU-H from a complex, experimental component into a highly refined system. By optimizing energy recovery and performance, it has redefined how power is delivered and managed in modern Formula 1.

F1's Future Without the MGU-H

Big changes are coming to Formula 1 in 2026. The MGU-H, one of the most advanced energy recovery systems in motorsport, is being removed from the power unit regulations. This shift will reshape how teams design engines and strategize for races, pushing them to rethink their approach to power and efficiency.

Why the MGU-H is Being Removed

The main reason for eliminating the MGU-H is to cut costs. Developing and maintaining this system has proven to be both expensive and complex. Its intricate design has also been a barrier for new manufacturers looking to join the sport. On top of that, the MGU-H doesn't have much relevance to road car technology, making it harder for manufacturers to justify the hefty investment. By simplifying the power unit, Formula 1 aims to reduce costs and attract new players. With cost caps increasing from $95 million to $130 million, the move is expected to open doors for more competition.

FIA President Mohammed Ben Sulayem highlighted the importance of this shift, saying:

"The confirmation that there will be six Power Unit manufacturers competing in Formula 1 from 2026 is testament to the strength of the championship and the robust technical regulations that have been diligently created by the FIA in close collaboration with Formula 1 and the Power Unit manufacturers."

This change will require significant adjustments to power unit design.

Effects on Power Unit Design and Performance

The removal of the MGU-H will drastically alter how F1 cars manage power. The MGU-K will take center stage as the sole energy recovery system, with its power output set to skyrocket. Currently capped at 120 kW, it will jump to about 350 kW in 2026, translating to roughly 476 horsepower of electric power. By then, electric power will make up 50% of an F1 car's total output, making the MGU-K a critical factor in performance.

However, the absence of the MGU-H will bring challenges. Cars are expected to face more turbo lag, making them harder to drive and less efficient. Teams will need to find creative ways to address this. Andy Cowell, Mercedes' director of High Performance Powertrains, explained the impact:

"We will all now start developing anti-lag systems. The MGU-H is the most marvellous anti-lag system on a turbocharged engine because it gives you speed control. That's been removed so we'll now have to come up with various devices and systems and that will probably involve burning fuel in the exhaust - a less desirable engineering trade-off."

To counteract turbo lag, teams are likely to develop advanced anti-lag systems, which may include controlled fuel burning in the exhaust. These changes will require innovative engineering and could lead to new strategies both on and off the track.

Maintaining Performance and Environmental Goals

Even with these technical challenges, Formula 1 remains committed to its environmental and performance goals. The sport continues to aim for net-zero carbon emissions by 2030. The new power unit regulations align with this mission, focusing on sustainable fuels and efficiency. Starting in 2026, F1 cars will run on 100% sustainable fuels, which are projected to reduce greenhouse gas emissions by at least 65% compared to traditional fossil fuels. Additionally, fuel usage per race will be capped at 70 kg, emphasizing efficiency.

Chase Carey, former Chairman and CEO of F1, underscored the sport's dedication to sustainability:

"In launching F1's first-ever sustainability strategy, we recognise the critical role that all organisations must play in tackling this global issue. By leveraging the immense talent, passion and drive for innovation held by all members of the F1 community, we hope to make a significant positive impact on the environment and communities in which we operate. The actions we are putting in place from today will reduce our carbon footprint and ensure we are net zero carbon by 2030."

The removal of the MGU-H signals a shift toward technologies that have more practical applications beyond the racetrack. While the sport is parting with one of its most advanced systems, the focus on an upgraded MGU-K and sustainable fuels ensures that Formula 1 continues to lead in pushing the limits of performance and efficiency.

Conclusion

The MGU-H has been a game-changer in Formula 1, transforming exhaust heat into electrical energy, cutting turbo lag, and improving power deployment. By either storing energy in the battery or sending it directly to the MGU-K, it has given teams a powerful tool to fine-tune their energy strategies and enhance performance on the track.

This technology has also fueled progress beyond F1. As Garrett Motion stated, "F1 has served as a real-world laboratory for our e-turbo development". The innovations tested in the high-pressure environment of F1 are now influencing advancements in road car technology, bridging the gap between motorsport and everyday driving.

Looking ahead to 2026, Formula 1 is preparing for a major overhaul. The removal of the MGU-H aims to cut costs and attract new engine manufacturers, but it also introduces fresh engineering hurdles. Without the MGU-H to manage turbocharger performance, teams will need to develop new solutions to address turbo lag. At the same time, the MGU-K will see its power output triple to 350 kW, and new regulations will aim for a 50-50 power balance between electric systems and the internal combustion engine. These changes reflect F1's ongoing effort to combine cutting-edge technology with cost efficiency.

The lessons learned during the MGU-H era will undoubtedly shape the next chapter of F1's hybrid evolution. The sport is not just focused on speed and performance - it’s also driving toward sustainability. With a commitment to 100% sustainable fuels and net-zero carbon emissions by 2030, F1 is leading the charge in environmentally conscious innovation. Current power units are already nearly 20% more efficient than the average road car, and fuel consumption per race will drop significantly under the new regulations, down to just 70 kilograms compared to 160 kilograms in 2013.

As Formula 1 bids farewell to the MGU-H, it continues to push the boundaries of automotive technology. The focus is shifting toward solutions that not only enhance racing but also pave the way for sustainable mobility in everyday life. F1 remains the ultimate testing ground, delivering thrilling competition while driving advancements that shape the future of transportation.

FAQs

Why is the MGU-H being removed from Formula 1 in 2026, and what does this mean for the sport?

The MGU-H (Motor Generator Unit-Heat) is set to be removed from Formula 1 regulations starting in 2026. This component, which recovers energy from exhaust gases, is known for its complexity and limited connection to everyday road car technology. Its removal aims to simplify engine designs and lower the barrier for new manufacturers, such as Audi and Porsche, to enter the sport. By taking this step, Formula 1 hopes to cut costs and make the competition more accessible.

With the MGU-H out of the picture, the spotlight will turn to the MGU-K, which will take on a much larger role. This unit will produce up to 350 kW of electrical power - a huge leap from the current 120 kW. The updated engines will be designed to use less fuel while still delivering over 1,000 horsepower. These changes promise a future for Formula 1 that’s not only more efficient but also more thrilling and environmentally friendly.

How does the MGU-H help reduce turbo lag in F1 cars, and why is it important for drivers?

The MGU-H (Motor Generator Unit-Heat) plays a pivotal role in Formula 1 cars by tackling the issue of turbo lag. It uses electrical energy to directly spin the turbocharger, stepping in when exhaust gases alone can't do the job. This ensures the turbocharger remains active, delivering power without any delays.

For drivers, this translates to smoother acceleration and sharper responsiveness, especially when accelerating out of corners where maintaining speed is essential. The result? Enhanced control, faster reactions, and improved lap times - key factors in staying ahead on the track.

How has the MGU-H in Formula 1 influenced modern road car technology?

The MGU-H, an essential part of Formula 1's hybrid power units, has played a major role in shaping energy recovery technology. By capturing waste heat from turbochargers and converting it into usable energy, it helps improve fuel efficiency and cut down emissions.

This innovation hasn’t stayed confined to the racetrack. Automakers are now applying similar principles to hybrid and electric vehicles, aiming to boost performance and optimize energy management. Additionally, these advancements have driven improvements in thermal efficiency, paving the way for cleaner and more efficient consumer vehicles.