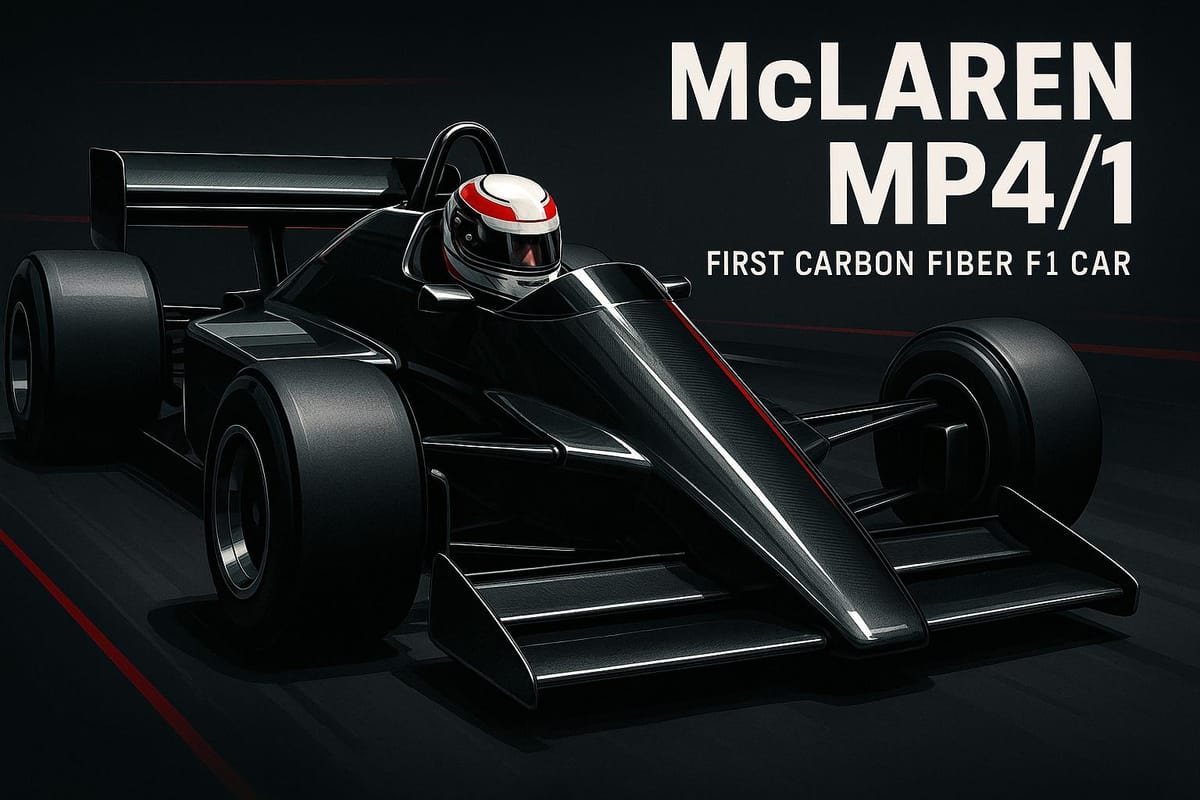

McLaren MP4/1: First Carbon Fiber F1 Car

The MP4/1 revolutionized Formula 1 with its carbon fiber chassis, enhancing performance and safety standards in the sport and beyond.

The McLaren MP4/1, introduced in 1981, was the first Formula 1 car to use a full carbon fiber monocoque chassis. This innovation replaced traditional aluminum structures, offering a lighter, stiffer, and safer design. Its success redefined F1 engineering, influencing car safety standards and performance. Key highlights:

- Material Shift: Transitioned from aluminum to carbon fiber, reducing weight and increasing rigidity.

- Safety Improvements: Enhanced crash protection, withstanding high-speed impacts better than aluminum.

- Industry Impact: Sparked widespread adoption of carbon fiber in F1 and high-performance road cars.

John Barnard, the car's designer, collaborated with Hercules Aerospace to overcome production challenges. The MP4/1's legacy continues to shape motorsport and automotive engineering today.

The Development of the McLaren MP4/1

John Barnard's Vision and Concept

John Barnard brought a fresh perspective to Formula One chassis design, drawing heavily from his background in aerospace engineering. At a time when most teams still relied on traditional aluminum, Barnard saw the untapped potential of carbon fiber composites. This material offered something aluminum couldn't: the ability to create a chassis that was not only lighter but also stiffer and safer. Carbon fiber's remarkable strength-to-weight ratio, a quality already valued in aerospace, became the cornerstone of his concept. Barnard's approach replaced 50 individual aluminum sections with just five composite moldings, showcasing the efficiency and strength of carbon fiber. His expertise in advanced techniques like layering, resin application, and autoclave curing was critical in shaping a single, cohesive structure. These innovations marked a turning point in Formula One design, though they also brought a host of technical and manufacturing challenges.

Material Sourcing and Construction Challenges

While the concept was groundbreaking, bringing it to life was no small feat. At the time, the UK lacked the infrastructure to produce large-scale carbon fiber components for something as complex as a Formula One chassis. Sourcing high-quality materials was a significant obstacle since British suppliers were not equipped to handle the demands of such a project. Before the MP4/1, carbon fiber had been used sparingly in F1, mostly for small parts like rear wing supports. Applying it to an entire chassis was entirely new territory. Unlike aluminum, which relied on well-understood techniques like mechanically fastening flat panels, carbon fiber required a completely different approach. It involved precise layering, resin application, and curing in specialized autoclaves - processes that few facilities in the UK could manage at the necessary scale and precision. To push forward, McLaren had to look beyond domestic suppliers, eventually finding the expertise they needed overseas.

The Role of Hercules Aerospace

To tackle these challenges, McLaren partnered with Hercules Aerospace, a company based in Utah with deep expertise in carbon fiber technology. Hercules had years of experience working with carbon fiber in aerospace applications and had the production capabilities to meet the demands of Formula One. Together, they refined the manufacturing process for the MP4/1's monocoque, perfecting the layering techniques, resin formulations, and autoclave curing methods to deliver a chassis that met the sport's rigorous performance and safety requirements.

Steve Foster, Senior Design Engineer – Composites, highlighted that the MP4/1's crashworthiness and stiffness-to-weight ratio set a new benchmark for safety in Formula One.

This collaboration between McLaren and Hercules not only solved the immediate challenges of constructing the MP4/1 but also proved that carbon fiber was the future of Formula One. Barnard's vision, backed by this innovative partnership, paved the way for carbon fiber to become the standard material in the sport.

First Light - The story behind the McLaren MP4/1

Technical Features and Performance Benefits

The MP4/1's carbon fiber monocoque redefined Formula 1 car design by doubling the stiffness-to-weight ratio compared to aluminum counterparts while significantly cutting down on weight. This groundbreaking approach not only boosted performance but also elevated safety standards, embodying John Barnard's vision for a race car that was both fast and secure. These advancements laid the groundwork for a deeper understanding of the car's technical brilliance.

Stiffness and Weight Reduction

The use of carbon fiber in the MP4/1 resulted in a chassis that was both lighter and incredibly rigid. This enhanced stiffness minimized chassis flex during high-speed cornering, giving drivers better precision and feedback. The reduced weight also translated directly into improved acceleration and braking, making the car more responsive on the track.

By replacing up to 50 aluminum sections with just five composite moldings, the design achieved a streamlined, lighter structure. The strength and stiffness were maximized by distributing loads along the carbon fibers. The benefits of this engineering were evident during the 1981 season, with John Watson securing multiple podium finishes, including a victory at the British Grand Prix at Silverstone. These advancements not only improved performance but also significantly enhanced driver safety.

Improved Driver Safety

The MP4/1's carbon fiber monocoque was a game-changer in terms of driver protection. Unlike aluminum, which could buckle or fail under extreme stress, carbon fiber was able to absorb and dissipate crash energy far more effectively. This meant the car could withstand impacts without compromising the safety of the driver. Andrea de Cesaris's multiple crashes served as proof of the material's reliability, silencing critics who doubted its durability.

Overcoming Early Concerns

When the MP4/1 was introduced, there were initial doubts about the practicality of using carbon fiber. Concerns ranged from its behavior in crashes to its repairability and the high production costs. However, the car's performance on the track quickly addressed these fears:

| Concern | Initial Fear | MP4/1 Reality |

|---|---|---|

| Crash Behavior | Material would shatter dangerously | Effectively absorbed and dissipated energy |

| Repairability | Difficult to fix after damage | Proved manageable with proper techniques |

| Production Cost | Too expensive to justify | Offset by significant performance and safety gains |

The MP4/1's success during the 1981 season demonstrated that the advantages of carbon fiber far outweighed the challenges. Despite its higher production costs, the improved safety and performance made it a worthwhile investment, paving the way for carbon fiber's widespread adoption in Formula 1.

Impact on Formula One and Beyond

The debut of the McLaren MP4/1 didn’t just shake up Formula 1 - it redefined what was possible in racing and engineering. Here’s how this groundbreaking car shaped competition, safety, and even the future of automotive design.

Adoption by Rival Teams

John Watson’s victory at the 1981 British Grand Prix was a pivotal moment. His win wasn’t just a triumph for McLaren; it sent a clear message to rival teams: carbon fiber was the future of Formula 1 chassis design. Within a few years of the MP4/1's debut in March 1981, teams like Lotus, Williams, and Ferrari began working on their own carbon composite cars. They quickly recognized the benefits - carbon fiber's unmatched stiffness-to-weight ratio and improved safety were too compelling to ignore.

What’s remarkable is how quickly the industry shifted despite initial skepticism. Early critics worried that carbon fiber might shatter dangerously in crashes. But the MP4/1’s performance on the track - and its resilience in accidents - proved otherwise. By the mid-1980s, carbon fiber had become the gold standard in Formula 1, and the MP4/1’s sleek design set the blueprint for future engineering in the sport.

Changes to Driver Safety Standards

The MP4/1 wasn’t just about speed; it also set new benchmarks for safety. A defining moment came with John Watson’s crash at Monza. In an accident that could have been fatal with an aluminum chassis, Watson walked away unscathed, showcasing the remarkable crash protection of carbon fiber. This incident played a key role in convincing the Fédération Internationale de l'Automobile (FIA) to implement stricter crash test standards. These new regulations demanded higher energy absorption and greater structural integrity for chassis designs.

The success of the MP4/1 also encouraged teams to explore composite materials for other components, like suspension systems and gearbox casings, further boosting safety and performance. Many experts consider the MP4/1’s contribution to driver protection one of the most important milestones in Formula 1 history.

Impact on Automotive Engineering

The MP4/1 didn’t just transform Formula 1 - it also left a lasting mark on the wider automotive world. By proving that carbon fiber could create lightweight yet durable structures, the MP4/1 paved the way for its use in high-performance road cars. McLaren led this charge with the McLaren F1, the first fully composite production car. Later, the Mercedes-Benz SLR McLaren became the first series-production vehicle to feature extensive carbon composite construction, bridging the gap between racing technology and luxury road cars.

Today, carbon fiber is synonymous with high-performance vehicles, from supercars to luxury sports models. Techniques developed during the MP4/1 era continue to influence modern automotive manufacturing. The legacy of the MP4/1 isn’t just confined to Formula 1; it’s visible in cutting-edge vehicle design and engineering around the globe.

Lessons from the McLaren MP4/1 for Modern F1

The story of the McLaren MP4/1 demonstrates how bold ideas, strategic alliances, and calculated risks can redefine Formula One. Just as the MP4/1 pushed the boundaries of innovation during its debut, modern F1 teams continue to thrive by challenging conventional limits. The principles that drove the success of the MP4/1 still resonate in the strategies and technologies shaping the sport today.

Cross-Industry Collaboration

One of the MP4/1's standout achievements was McLaren's partnership with Hercules Aerospace, a company outside the traditional motorsport realm. Designer John Barnard leveraged his diverse racing background to connect with the Utah-based aerospace firm, which had unparalleled expertise in carbon fiber - a material that was new to Formula One at the time. This collaboration led to groundbreaking advancements that set industry benchmarks for decades.

Even now, partnerships between F1 teams and companies in aerospace, defense, and advanced materials continue to fuel technological progress. Time and again, the most transformative innovations arise from looking beyond the sport’s immediate ecosystem.

The Role of Risk-Taking in New Ideas

McLaren’s decision to embrace carbon fiber was a bold move, especially given the skepticism surrounding its use in motorsport. However, the gamble paid off when the MP4/1 quickly proved its worth with strong performances, including John Watson's victory at Silverstone and multiple podium finishes.

As competitors witnessed the MP4/1’s success and the safety advantages of its design, they were quick to adopt similar technologies. This underscores the importance of visionary leadership and innovation programs that are willing to take risks on unproven ideas, knowing they could yield significant competitive advantages.

Carbon Fiber Technology Evolution Since 1981

The MP4/1 laid the foundation for the evolution of carbon fiber technology in motorsport. Initially, the car was constructed by layering carbon fiber around a mold, bonding it with resin, and curing it in an autoclave. McLaren later refined this process by switching from a "male mold" to a "female mold" technique, resulting in smoother and more precise exterior surfaces.

Since then, manufacturing processes have advanced significantly. Automated systems now reduce material waste while enhancing strength-to-weight ratios. At McLaren's Carbon Technology Centre, cutting-edge carbon fiber components - ranging from rear wings to front floors - are developed to support next-generation F1 cars.

These advancements highlight how the MP4/1’s pioneering use of composite materials continues to influence not just Formula One but also industries beyond the racetrack. Its legacy is a testament to the enduring impact of innovation and the pursuit of engineering excellence.

Conclusion: The McLaren MP4/1's Lasting Impact

The McLaren MP4/1 didn’t just change Formula One - it redefined the possibilities of automotive engineering. When John Barnard's groundbreaking design made its debut at Silverstone on March 6, 1981, it signaled the dawn of a new era, one where carbon fiber would become a cornerstone of performance and safety, both on and off the track.

By replacing roughly 50 aluminum components with just five composite moldings, the MP4/1 showcased the unmatched stiffness-to-weight ratio of carbon fiber. This innovation didn’t just improve performance; it laid the groundwork for a new standard in driver safety.

The car’s carbon fiber monocoque was a game-changer for crash protection. McLaren engineer Steve Oatley foresaw how this advancement would reshape Formula One safety. By absorbing and dispersing impact forces more effectively than aluminum, it fundamentally altered the way teams approached driver protection, making the sport significantly safer.

But the MP4/1’s influence didn’t stop at the racetrack. McLaren’s pioneering work with carbon fiber set the stage for iconic road cars like the McLaren F1, the first fully composite production car, and the Mercedes-Benz SLR McLaren, which featured an all-carbon-composite body. This approach remains central to McLaren’s modern supercars, demonstrating how lessons from the track continue to shape commercial automotive design.

The MP4/1 also changed the way Formula One teams approached engineering. It proved the value of challenging traditional methods, collaborating across industries, and embracing bold ideas. McLaren’s partnership with Hercules Aerospace was instrumental in unlocking these advancements - a reminder of how innovation often thrives at the intersection of different fields.

Since 1981, every McLaren has been built with a carbon chassis, a legacy that underscores four decades of progress. The MP4/1 didn’t just mark a technical milestone; it sparked a shift in the industry’s priorities, balancing performance, safety, and engineering ingenuity in ways that continue to inspire today.

FAQs

How did the McLaren MP4/1 revolutionize Formula 1 safety with its carbon fiber design?

The McLaren MP4/1, unveiled in 1981, was a game-changer in Formula 1 history as the first car to feature a carbon fiber monocoque chassis. This innovation completely reshaped safety standards in the sport. Compared to the traditional aluminum designs of the time, carbon fiber brought a combination of incredible strength and lightweight construction, offering drivers significantly better protection in high-impact crashes.

The material's resilience was put to the test later that same year during John Watson's dramatic crash at Monza. Despite the severity of the incident, Watson emerged unscathed, proving how effectively carbon fiber could absorb and dissipate crash energy. This milestone not only highlighted the safety benefits of carbon fiber but also encouraged its widespread use in Formula 1, cementing its role as a fundamental element in modern race car engineering.

What challenges did McLaren face in developing and manufacturing the carbon fiber components for the MP4/1?

McLaren encountered a host of challenges when introducing carbon fiber for the MP4/1's monocoque chassis in the early 1980s. Back then, carbon fiber was still a relatively unfamiliar material in motorsport, and sourcing it posed its own difficulties. To tackle this, McLaren teamed up with Hercules Aerospace, a U.S.-based company known for its expertise in producing high-quality carbon fiber components.

The manufacturing process presented another significant obstacle. Unlike the more conventional aluminum chassis, working with carbon fiber demanded advanced molding techniques and precise layering to achieve the right balance of strength and lightness. This process wasn’t just costly - it also required rigorous testing to ensure the material met Formula One's demanding safety and performance standards.

Despite these challenges, McLaren's bold approach transformed F1 car design. Their pioneering work established carbon fiber as the go-to material for modern Formula One cars, setting a new standard that continues to define the sport today.

How did the McLaren MP4/1's carbon fiber chassis influence the design of modern high-performance road cars?

The McLaren MP4/1 changed the game in Formula One by being the first car to feature a carbon fiber monocoque chassis. This breakthrough set new benchmarks for strength, lighter weight, and improved safety. Beyond reshaping F1 engineering, it introduced carbon fiber as a material that would eventually become indispensable in the world of high-performance road cars.

Fast forward to today, and carbon fiber is a cornerstone of supercar and luxury vehicle design. Its unmatched strength-to-weight ratio makes it ideal for enhancing performance - reducing weight means better acceleration, sharper handling, and greater fuel efficiency. Plus, it provides top-tier crash protection. The influence of the MP4/1 lives on, demonstrating how F1 innovations continue to leave their mark on the cars we see on the road today.